Page 1

ST-10M SERIES

10 PAN CONVECTION STEAMERS

PARTS AND SERVICE MANUAL

EFFECTIVE AUGUST 12, 2014

The Company reserves the right to make substitution in the event that items specied are not available.

ERRORS: Descriptive and/or typographic errors are subject to correction.

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone: (802) 658-6600 Fax: (802) 860-3732

Superseding All Previous Parts Lists.

MARKET FORGE INDUSTRIES

www.mi.com

P/N 14-0288 Rev A (8/14)

Page 2

TABLE OF CONTENTS

PRINCIPLES OF OPERATION ..........................................................3

TROUBLESHOOTING ..................................................................5

WIRING DIAGRAMS & SCHEMATICS ...................................................9

REPAIR AND REPLACEMENT ........................................................ 13

ILLUSTRATED PART LIST

DOOR ASSEMBLY ................................................................... 15

CABINET ASSEMBLY ................................................................ 16

CONTROL PANEL ASSEMBLY ........................................................ 18

CONDENSER ASSEMBLY ............................................................ 19

COMPLETE CONDENSER ASSEMBLY ................................................ 20

POWER PLUS ....................................................................... 21

AUGUST 12, 2014 2 ST-10M SERIES CONVECTION STEAMERS

Page 3

PRINCIPLES OF OPERATION

GENERAL

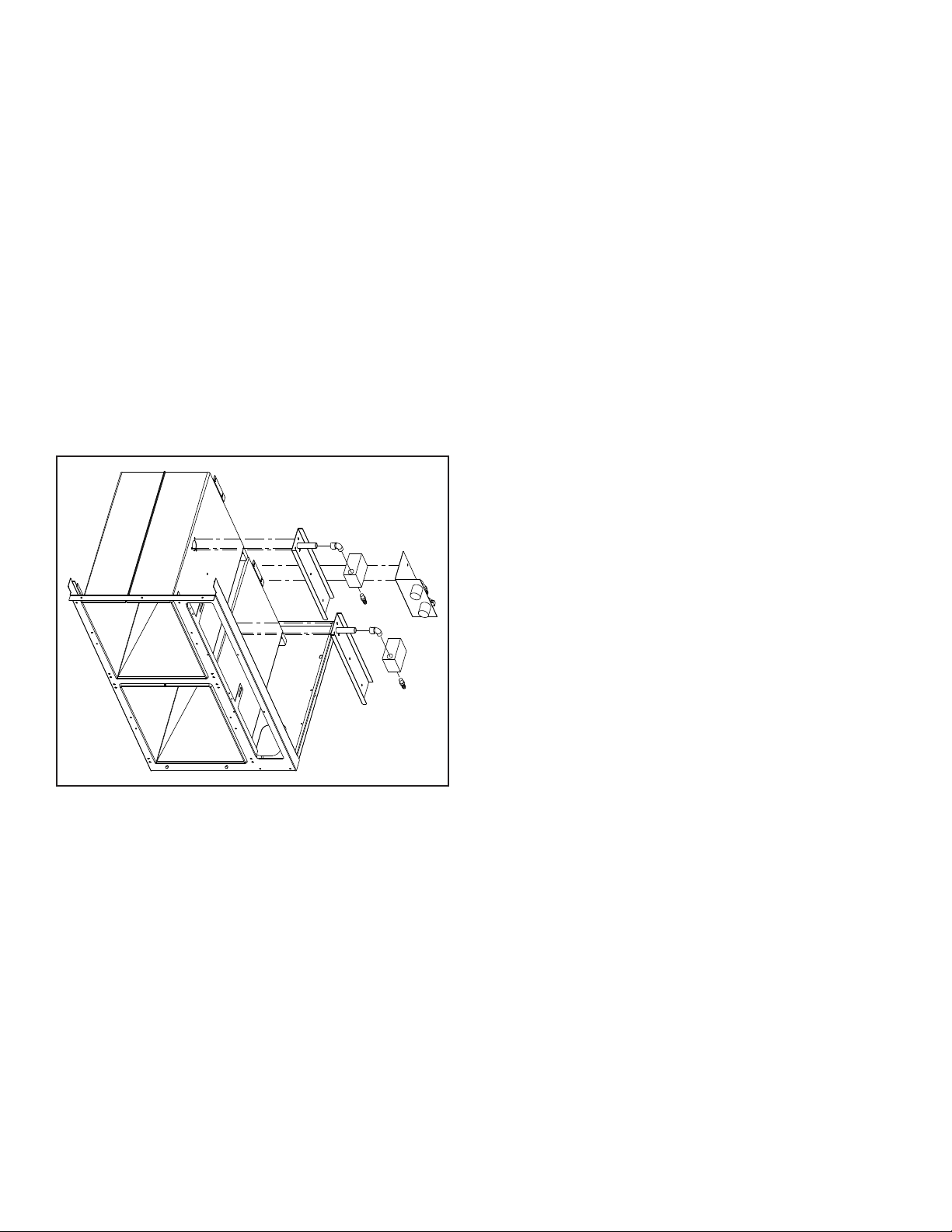

The ST-10 Pressureless Steam Cooker consists of two

identical cooking compartments, one above the other, in

a single cabinet assembly. Each compartment is tted

with independent electrically controlled steam circuits and

spring-loaded, self-sealing doors with slam action latches.

Compartments can be used separately or simultaneously

for either constant steam or 60-minute timing. The principles of operation in this section include an explanation

of steam, steam condensing, and electrical circuits and

their functioning.

PLUMBING CIRCUITS

The plumbing circuits consist of the piping, steam solenoid valves, orice, drain, and cold water condenser required to provide controlled steam application to the cook-

ing compartments. A simplied diagram of these circuits

is shown below.

Steam inlet lines for compartments are equipped with

normally closed solenoid valves operated by the electrical control circuits. The inlet valves are opened whenever

the compartment control circuit is activated by use of the

60-minute timers.

STEAM INLET LINE

A steam supply line is plumbed from the boiler output (or

direct-connected steam control) to a 1/2-inch barb tting

connected to the input sides of both steam inlet solenoid

valves. When a cooking compartment is not in use, the

valve for the compartment remains closed to prevent

steam from entering. During operation, the appropriate

inlet solenoid valve is opened by activation of the control circuit. Steam is projected onto the surface of pans

of food loaded into the compartment by an orice located

inside the compartment. Steam continues to ow through

the compartment in this manner until the control circuit

closes the solenoid valve.

STEAM EXHAUST AND DRAIN LINES

Perforated strainers at the drain line openings inside each

compartment allow only steam, condensation, and liquid

cooking drainage to enter. Prior to discharge into the boiler drain system, steam is converted to water by the cold

water condensing systems for each compartment.

Figure 1

NOTE: This is strictly a pictorial schematic diagram and

is not intended to show the actual conguration of

the plumbing. All components are shown in correct relationship with each other. However, the

diagram does not show their actual locations or

position within the cooker.

As shown in the diagram, steam inlet and exhaust connections are connected at the factory directly into a steam

boiler or direct-connected steam plumbing enclosed

within the base cabinet on which the cooker is mounted.

The boiler (or direct-connected steam control system) is

equipped to supply constant, regulated steam at 14–15

PSI. Steam exhaust, having been reduced to water by the

cold water condenser, is directed into the boiler (or direct-

connected steam control) drain system.

STEAM EXHAUST CONDENSING SYSTEM

The steam condensing system consists of the identical,

two-position, normally closed cold water solenoid valves,

with outlet sides connected into the exhaust plumbing for

each cooking compartment. A spray nozzle directs cold

water about the inside of the drain lines to increase cold

water contact with exhausted steam. Valve inlet sides

are connected remote from the supply line of the steam

boiler (or direct-connected steam plumbing). The valves

respond to a thermostatic switch located inside the compartment. When the timer starts the cold water solenoids

will energize.

ELECTRICAL CIRCUITS

The electrical circuits of the cooker control the power to

activate timer motors and energize solenoid-operated

valves and circuits, which in turn control application of

steam to the cooking compartment and condensation

of steam from the exhaust line. The cooker operates on

120V, 2 amp, 60Hz electrical service connected to all circuits from the circuits of the steam boiler (or direct-con-

nected steam controls) contained within the cabinet on

which the cooker is mounted. Power is supplied to the

control circuit at all times when the shut-off device for the

unit (supplied by the user) is in the ON position.

Page 4

PRINCIPLES OF OPERATION

CONTROL CIRCUIT COMPONENTS

A brief description of the electrical circuit elements follows.

60 Minute Timer/Constant Steam

The timer contains a 120-volt AC synchronous motor that

drives a timing dial through a gear reduction and clutch

mechanism. The timer dial is manually set for any interval

of operation from 0 to 60 minutes or constant steam as

read on the calibrated dial face. The manual rotation of

the dial moves the common element (1) of the timer switch

from the neutral (OFF) position to contact (3), which connects with the steam inlet solenoid valve operating circuit.

The cooker is placed into automatic operation with the

setting of the timer dial. Its timing cycle, however, is automatically delayed by a thermostatic switch, which assures

operating temperature is achieved before the timer motor

begins to “time out.” When the timer motor has operated

for the preset duration, the common element is transferred to contact (4), returning the inlet solenoid valve to

the closed position and energizing the buzzer. Contact to

the buzzer circuit remains closed until the dial is manually turned to the OFF position, returning the common element (1) of the timer switch to the neutral position.

DOOR INTERLOCK SWITCH

The interlock switch is a single-pole proximity switch with

normally open contacts. The switch is operated by the

proximity of a magnet within the door. When the door is

open, the switch contacts remain in the open position.

When the door is closed and securely latched in place,

the magnet is near the switch to close the contacts. Connected between the operating contact (3) of the timers

and the steam inlet solenoid valve, the door switch acts

as a protective device to interrupt valve operation unless

the door is closed.

THERMOSTATIC SWITCH

The thermostatically operated switch is a two-position,

normally open switch mounted on the cooking compartment. The switch functions to activate the cold water solenoid valves of the steam condensing system and to delay

timer motor operation until the compartment temperature

reaches 195°F, thus assuring that cooking temperature

exists throughout the timed duration.

INDICATOR LIGHTS

An indicator light is included for both compartments. The

light remains on (red) at all times when the coinciding timer dial is set and the door interlock switch is closed. The

light turns off at the end of the timed cooking duration.

BUZZER

The buzzer is an alarm device that operates by oscillation

of a striker against the core of an electromagnet. When

the 60-minute timer dials reach the “0-Minute” position,

the buzzer coil is energized to sound the buzzer. Movement of the timer dial to the OFF position opens the contact to the buzzer coil to shut it off.

Page 5

TROUBLESHOOTING

ELECTRICAL FAULT ISOLATION

Correction of an electrical failure rst requires isolation of

the fault to a single circuit or component. In most cases,

the nature of the failure and its effect upon the operation

of the cooker will be sufcient to narrow it down to one or

more circuit elements.

ELECTRICAL TROUBLE-SHOOTING PROCEDURES

Before performing the trouble-shooting procedures in this

section, the serviceman must be familiar with the function

of all controls as well as with the Principles of Operation

described the Operation Section.

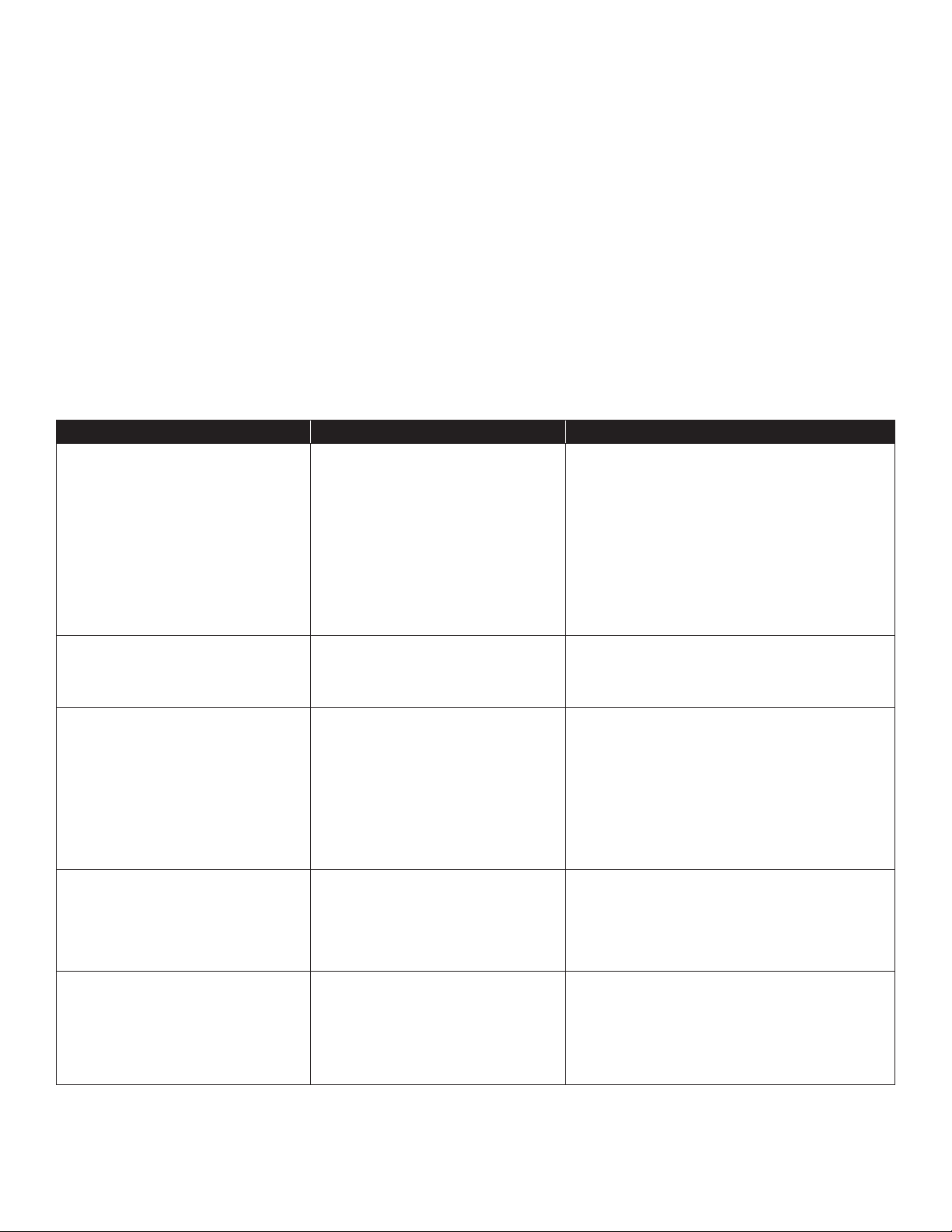

GENERAL TROUBLE-SHOOTING GUIDE

PROBLEM PROBABLE CAUSE REMEDY

Indicator light fails to light with timer

set.

1. Power to cooker off.

2. Door interlock switch contacts

not closed.

3. Door interlock switch faulty.

4. Indicator light burned out.

5. Faulty timer contacts.

The electrical trouble-shooting procedures that follow require access to components and terminals of the electrical control panel. Electrical controls are reached by removing screws that fasten the control panel to the frame.

The panel may be pulled forward for testing while interconnected to the cooker circuits or disconnected at the

pin connection for complete removal and repair.

1. Locate external circuit breaker for incoming power and place in ON position.

2. Shut cooker door to close switch contacts.

Check alignment of door with switch.

3. Replace switch.

4. Replace light.

Steam fails to enter cooking compartment with indicator light on.

Steam enters compartment continuously. Timer dial not turning.

Steam continues to ow into compartment and/or buzzer fails to

sound at end of timer cycle.

Steam ows continuously from

boiler (or direct connected steam

control) drain line with cooker in operation.

6. Faulty wiring.

1. Faulty steam solenoid valve.

2. Faulty wiring.

1. Constant steam position.

2. Faulty thermostatic switch.

3. Faulty timer motor.

4. Faulty steam solenoid valve.

5. Faulty wiring.

1. Timer contacts faulty.

2. Buzzer faulty.

3. Faulty wiring.

1. Cold water not connected.

2. Faulty thermostat.

3. Faulty cold water solenoid.

4. Faulty wiring.

1. Replace valve.

2. Inspect condition of wire and tightness of

all connections. Correct as needed.

1. Move knob to timing location.

2. Replace switch.

3. Replace Timer.

4. Replace valve.

5. Inspect condition of wire and tightness of

all connections. Correct as needed.

1. Replace timer.

2. Replace buzzer.

3. Inspect condition of wire and tightness of

all connections. Correct as needed.

1. Turn on external shut-off valve.

2. Replace thermostat. Replace valve.

3. Inspect condition of wire and tightness of

all connections. Correct as needed.

Page 6

TROUBLESHOOTING

Incoming Power

Before trouble-shooting any of the electrical parts or assemblies, verify that power is being supplied to the cooker. Incoming power is connected at the boiler (or direct-

connected steam) control box located in the base cabinet.

With power connected to the cooker, an AC volt-meter is

used to measure 120 volts across L1 and L2. If 120 volts

is present, and the cooker will not operate, the fault lies

within the electrical circuits of the cooker.

Electrical Inspection

The rst step in any electrical trouble-shooting procedure

is a thorough physical inspection of all wiring connections.

To access electrical components, remove the control panel.

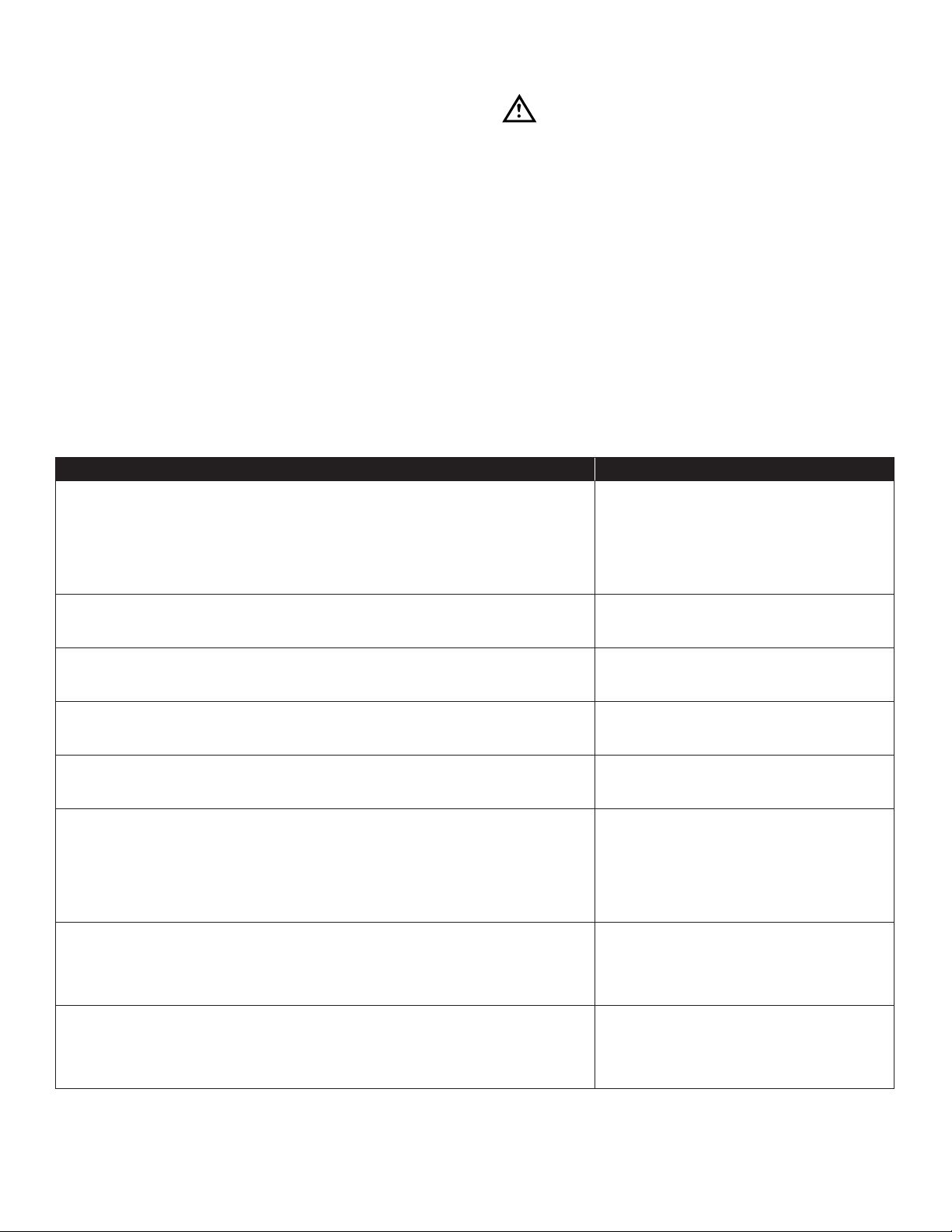

ELECTRICAL FAULT ISOLATION GUIDE

FAILURE FAULT LOCATION

Will not operate in either CONSTANT STEAM or 60-MINUTE TIMER position. 1. Incoming power.

WARNING

Before removing control panel or checking

connections and wiring, be sure that the circuit breaker for incoming power is OFF. When

power is supplied, all exposed terminals of the

control panel carry 120 volts.

Check all wiring connections by hand to assure that both

ends of all connection points are tightly secured. Use a

screwdriver to tighten connection points. If necessary, visually inspect all quick-disconnect terminals for evidence

of corrosion. Terminals in this condition should be separated, cleaned with emery cloth until shiny, and tightly reconnected.

2. Timer.

3. Door interlock switch.

4. Wiring.

Operating in CONSTANT STEAM position but not in 60-MINUTE TIMER position.

Operating in 60-MINUTE TIMER position but not in CONSTANT STEAM position.

Steam solenoid valve fails to open with indicator light on. 1. Solenoid valve coil.

Indicator light OFF with steam solenoid open. 1. Indicator light.

With indicator light ON and steam solenoid valve OPEN, timer dial fails to

turn.

Buzzer fails to SOUND at end of 60-MINUTE TIMER mode. 1. 60-Minute timer.

Steam ows continuously from boiler drain line. 1. Thermostatic switch.

1. 60-Minute timer.

2. Wiring.

1. 60-Minute timer.

2. Wiring.

2. Wiring.

2. Wiring.

1. Compartment thermostatic switch.

2. Constant steam position.

3. Timer motor.

4. Wiring.

2. Buzzer.

3. Wiring.

2. Cold water solenoid valve.

3. Wiring.

Page 7

TROUBLESHOOTING

60 MINUTE TIMER

Timer Contacts

Defective timer contacts will result in failure of either cooker compartment to operate. When this occurs, remove the

control panel, and proceed as follows:

4. Turn off power to the cooker at external circuit breaker.

5. Disconnect all ve wires from timer terminals.

6. Connect an ohmmeter between terminals 1 and 3.

7. Rotate timer dial beyond the “0-Minute” point (any

setting) to obtain a reading of zero ohms on the

ohmmeter. If zero ohm reading cannot be obtained,

timer contacts are defective and the timer must be

replaced.

8. Move ohmmeter leads to terminals 1 and 4.

9. Rotate timer dial to “0-Minute” position (an audible

click indicates correct position). If zero ohm reading

cannot be obtained, the timer is defective and must

be replaced.

10. Remove ohmmeter and replace all ve leads on timer

terminals.

Timer Motor

A defective timer motor will cause continuous operation in

the TIME mode, with the timer dial failing to return to the

“0-Minute” position. Since thermostatic switch failure can

cause the same symptom, fault must rst be isolated to

the timer by testing the thermostat.

To conrm timer motor condition, proceed as follows:

1. Carefully check motor wire leads and tighten loose

connections.

WARNING

Use care while working with control panel.

Terminals carry 120 volts.

2. Turn on power to the cooker.

3. Set timer dial (any setting beyond “0-Minute”). If operation is correct, the motor will turn the dial toward

“0-Minute.” If the motor fails to operate, it is defective

and the entire timer must be replaced.

DOOR INTERLOCK SWITCH

Malfunction of the cooker door interlock switch prevents

timer indicator lights from turning on and steam solenoid

from opening when the timer dial is set. If steam does not

enter the compartment and the indicator light fails to turn

on with the door latch securely engaged, the fault may be

in the door interlock switch.

Proceed as follows:

1. Turn off power to the cooker.

2. Disconnect wires to the door switch terminals

3. Connect an ohmmeter between the terminals of the

switch.

4. Actuate the switch by closing the cooking compartment door. If a zero reading cannot be obtained, the

switch is defective and must be replaced.

5. Remove the ohmmeter and replace the leads on

switch terminals.

STEAM SOLENOID VALVES

When either inlet solenoid valve fails to operate, the fault

may be a defective coil. A defective coil is found using an

AC volt-meter to check the voltage at the coil wire terminals, with the cooker compartment operating in either

CONSTANT STEAM or 60-MINUTE TIMER mode. If voltage of 120 volts is present and the coil fails to open the

valves, the fault is in the valve coil. Defective valve coils

are not separately replaceable, requiring complete valve

replacement.

INDICATOR LIGHTS

If the cooker compartment functions correctly, with the

single exception that the indicator light fails to light during

operation, the fault is a defective indicator light. A “burned

out” or defective light is veried by using an AC volt-meter

at the leads, with input power on the selector switch in the

correct position for that timer, the timer set, and the door

latches closed. If 120 volts is present, the fault is in the

indicator light and requires replacement. If 120 volts is not

present, the fault is in the wiring or control components

(selector switch, timer, or door switch).

4. Shut off power to the cooker.

Page 8

TROUBLESHOOTING

COOKING COMPARTMENT THERMOSTATIC SWITCH

A thermostatic switch included in the circuit for the timer

motor delays timer operation until steam owing into the

compartment satises the temperature-actuated switch

device. If a timer motor fails to operate within about one

minute after the indicator light comes on (with cooker

compartment empty), the cause may be a defective thermostatic switch. To test the switch, proceed as follows:

1. Disconnect the two wires connected to the thermostatic switch terminals.

2. Connect an ohmmeter between the two terminals of

the switch.

3. Place the cooker into operation and observe ohmmeter dial. Within one minute of operation, the switch

contacts close automatically to register a zero ohm

reading on the dial. If a zero ohm reading is not obtained, the switch is defective.

4. Shut off cooker, disconnect ohmmeter leads, and replace wires on switch terminals.

BUZZER

If the buzzer does not sound at the termination of the operator-selected timer setting (timer dial returned to “0-Minute” position), the fault may be a defective buzzer. Buzzer

operation is veried using an AC volt-meter at buzzer coil

connections with input power on and selector switch and

coinciding timer dial set at the “0-Minute” position. If voltage is 120 volts, the fault is in the buzzer,

which must be replaced. If 120 volts is not present, the

fault is in the wiring or control components (timer or selector switch).

WIRING

All of the electrical components of the cooker (timers, indicator lights, etc.) are connected to each other by wiring

shown in wiring diagram. If all of the electrical components are operating correctly (and the incoming power

has been checked), but the cooker fails to operate, the

fault lies in the wiring.

The wiring diagram shows all terminals and interconnections within the electrical circuits. All numbered terminals

are identied and all leads number coded as shown. Connections can be easily removed. Wiring Schematic shows

the same information schematically and is an aid in isolating circuits for testing.

Using an ohmmeter, wiring continuity between the con-

nections shown on the wiring diagram is readily veried.

This is best done in stages, removing only those wires

required for each continuity check. As each lead is replaced, it should be checked for evidence of corrosion,

and cleaned if necessary. All leads must be tightly attached so as to provide a good electrical connection.

COLD WATER CONDENSER CIRCUIT

If during cooker operation steam exits from the drain

line opening (located in lower boiler compartment) and

the condensing system fails to operate, as evidenced

by repeated discharge of water from the drain line, the

condensing circuit is malfunctioning. The failure can be

caused by a defective condenser thermostat or cold water

solenoid coil, or by wiring failure.

If the condenser thermostat functions correctly, but either of the cold water solenoid valves fails to operate, the

cause might be a faulty valve coil. A defective coil is found

using an AC volt-meter to check the voltage at the coil

wire terminals with the cooker compartment in operation.

If voltage of 120 volts is present and the valve fails to

open, the fault is in the valve coil. Defective valve coils are

separately replaceable.

Page 9

WIRING DIAGRAMS & SCHEMATICS

Page 10

WIRING DIAGRAMS & SCHEMATICS

Page 11

WIRING DIAGRAMS & SCHEMATICS

Page 12

WIRING DIAGRAMS & SCHEMATICS

WIRING SCHEMATIC FOR STEAMER

WIRING SCHEMATIC FOR POWER PLUS

Page 13

REPAIR AND REPLACEMENT

WARNING

Under no circumstances should hardware

(or parts) be replaced with a different length,

size, or type other than as specied in the

parts list. The hardware used in the cooker

has been selected or designed specically for

its application, and the use of other hardware

may damage the equipment and will void any

warranty.

Door Gasket Replacement

The cooking compartment door gaskets are made of a

silicone-type rubber material that is very durable but subject to wear during normal operation. Should the gasket

leak, readjust the door gasket to the unit or replace it.

Procedure—Replace Gasket:

1. Open the cooking compartment door.

2. Remove the six screws on the outside of the door,

and remove the inner door assembly.

3. Remove the eight nuts from the door gasket mounting plate on the inside of the inner door assembly.

4. Remove the door gasket mounting plate and the door

gasket.

Exterior Panel Removal

WARNING

To prevent hazard in servicing the cooker, be

certain that the steam supply boiler is shut

down, the cold water shut-off valve is closed,

and the electrical disconnect circuit breaker

for the cooker/boiler unit is off before removing side panels.

Access to all internal plumbing and electrical assemblies

is from the right side and right front. The left-side panel is

removed by removing the bottom screw and pushing up

on the panel until the lower lip disengages the frame.

The electric control panel may also be removed as a unit

by removing screws and pulling the panel forward. Removal of the control panel is completed by unplugging

interconnecting wiring at the pin housing.

Steam and Water Solenoid Valve Replacement

Replacements for the 1/2-inch steam solenoid valves and

the 1/4-inch water valves are available as complete units

from Market Forge Authorized Service Agencies. It is necessary to replace an entire steam valve when the coil is

faulty or the diaphragm ruptures. Replacement coils are

available for the water valves.

5. Install the new door gasket to the mounting plate.

6. Reassemble the mounting plate with gasket to the inside of the inner door assembly using the eight nuts.

7. Reassemble the inner door assembly using the six

screws on the outside of the door.

NOTE: Remember that the lip on the door gasket mount-

ing plate must t into the channel on the inside

edge of the gasket to insure a proper seal.

Procedure—To Adjust Gasket to Unit:

To prevent steam leaks around the door, adjust the gasket

tension to cavity. Adjust the gasket by loosening the six

screws on top and bottom of door, move inner door plate

in or out, left side or right side, and tighten the six screws.

Page 14

REPAIR AND REPLACEMENT

DOOR LATCH TENSION ADJUSTMENT

CAUTION

SHUT OFF MAIN ELECTRICAL POWER TO

UNIT.

Procedure:

1. Open the cooking compartment door.

2. Remove the control panel by removing the eight

mounting screws and disconnecting the wire plug and

restraining wire.

3. Tighten both nuts down until the springs are fully

compressed.

4. Back each nut off 1/2 turn.

5. Remount the control panel, reconnecting wire plug

and restraining wire.

Door Handle Tension Adjustment

Procedure:

1. Open the cooking compartment door.

2. Remove the six screws and washers from the top

edge and bottom edge of the door.

3. Remove the inner door gasket mounting plate assembly from the outer door. Do not disassemble these

three components—remove them as an assembly.

4. Tighten both nuts down until the springs on the outer

door are fully compressed.

5. Back each nut off 1/2 turn.

6. Remount the inner door gasket mounting plate assembly by assembling the six screws and washers.

Page 15

DOOR ASSEMBLY

ITEM PART NO. DESCRIPTION QTY.

1 91-7692 OUTER DOOR 1

2 91-7694 INNER DOOR 1

3 91-7696 GASKET RETAINING PLATE 1

4 91-7783 DOOR GASKET 1

5 91-5745 DOOR HANDLE 1

6 09-1608 STRIKER 1

7 08-5027 MAGNET 1

8 91-5901 MAGNET BRACKET 1

9 08-4600 COMPRESSION SPRING 2

AUGUST 12, 2014 15 ST-10M SERIES CONVECTION STEAMERS

Page 16

CABINET ASSEMBLY

AUGUST 12, 2014 16 ST-10M SERIES CONVECTION STEAMERS

Page 17

CABINET ASSEMBLY

ITEM PART NO. DESCRIPTION QTY.

1 91-7616 POST, REAR 2

2 REF CONDENSER ASSEMBLY 1

3 10-5859 INLET SOLENOID 2

4 08-4892 BARB, 1/2” IPS x 3/8” ID TUBE 2

5 10-8823 ELBOW, STREET, 1/2” IPS 2

6 91-7595 INLET ADAPTER ASSEMBLY 2

7 91-6474 INLET GASKET 2

8 10-9174 RELAY TUBE 2

9 91-6477 BRACKET, LINER HOLD DOWN 2

10 08-4978 BARB, 1/4” IPS FEMALE x 1/4” ID TUBE 2

11 08-4866 SPRAYER NOZZLE (MODEL ST-10 ONLY) 2

12 08-4833 REDUCING TEE, 1” x 1” x 1/4” IPS 2

13 08-1207 BARB, 1” IPS 2

14 91-7638 STIFFENER, BACK 1

15 91-7639 BRACKET, LINER TIE 1

16 91-7493 PANEL, BACK 1

17 91-7619 PANEL, TOP 1

18 91-7569 PANEL, SIDE 2

19 91-7690 BRACKET, REED SWITCH 2

20 08-6308 REED SWITCH 2

21 10-8105 THERMOSTAT, CONDENSER (MODEL ST-10 ONLY) 2

22 10-3739 REDUCER, 1/2” IPS x 3/8” IPS 2

23 10-4586 NUT, SEALER, 1/2” IPS 4

24 10-9175 RELAY, SOCKET 2

25 91-6470 CONTROL PANEL ASSEMBLY 1

26 91-7698 BAFFLE, RACK SLIDE 2

27 98-1599 RACK, WIRE 4

28 91-6486 DOOR ASSEMBLY 2

29 91-7684 STRAINER 2

30 08-4600 COMPRESSION SPRING 4

31 91-6475 HINGE, TOP 2

32 91-6476 HINGE, BOTTOM 2

33 91-6492 LATCH, RECEIVER 2

34 91-6491 GROMMET 2

35 08-6538 VACUUM BREAKER 2

36 91-6940 RELAY BRACKET 2

AUGUST 12, 2014 17 ST-10M SERIES CONVECTION STEAMERS

Page 18

CONTROL PANEL ASSEMBLY

ITEM PART NO. DESCRIPTION QTY.

1 91-6489 CONTROL PANEL 1

2 91-7612 ARTWORK, CONTROL PANEL 1

3 08-6464 60 MINUTE TIMER 2

4 08-6541 TERMINAL STRIP 2

5 91-6471 BRACKET, TERMINAL STRIP 2

6 10-7395 BUZZER 2

7 08-3826 KNOB, TIMER 2

8 10-5052 LIGHT, RED 2

AUGUST 12, 2014 18 ST-10M SERIES CONVECTION STEAMERS

Page 19

CONDENSER ASSEMBLY

ITEM PART NO. DESCRIPTION QTY.

1 08-6538 3/8” CHECK VALVE 1

2 08-7970 NEOPRENE HOSE 21” 2

3 08-7975 CLAMP 2

4 08-4978 HOSE BABS 1

5 10-3539 BUSHING 1/2 x 1/4 HEX 1

6 08-5438 TEE, BRASS 1” x 1/2” x 1” 1

7 08-1207 HOSE FITTING 1” NPT 1

8 15-7208 BRAIDED STAINLESS STEEL HOSE 2-1/2” 1

9 08-4864 HOSE BARB, 90o, 1/8” IPS 2

10 08-1206 HOSE CLAMP 2

11 08-7923 TEE 1/8” NPT 1

12 08-4890 HOSE COUPLER, 1/8 IPS x 1/4 ID 2

13 91-6491 GROMMET 1

14 08-4866 SPRAY NOZZLE (MODEL ST-10 ONLY) 1

15 08-4821 CONDENSER SOLENOID (MODEL ST-10 ONLY) 2

16 91-7640 CONDENSER BRACKET 1

AUGUST 12, 2014 19 ST-10M SERIES CONVECTION STEAMERS

Page 20

COMPLETE CONDENSER ASSEMBLY

ITEM PART NO. DESCRIPTION QTY.

1 08-6538 3/8” CHECK VALVE 1

2 08-7970 NEOPRENE HOSE 21” 2

3 08-7975 CLAMP 2

4 08-4978 HOSE BABS 1

5 10-3539 BUSHING 1/2 x 1/4 HEX 1

6 08-5438 TEE, BRASS 1” x 1/2” x 1” 1

7 08-1207 HOSE FITTING 1” NPT 1

8 15-7208 BRAIDED STAINLESS STEEL HOSE 2-1/2” 1

9 08-4864 HOSE BARB, 90o, 1/8” IPS 2

10 08-1206 HOSE CLAMP 2

11 08-7923 TEE 1/8” NPT 1

12 08-4890 HOSE COUPLER, 1/8 IPS x 1/4 ID 2

13 91-6491 GROMMET 1

14 08-4866 SPRAY NOZZLE (MODEL ST-10 ONLY) 1

15 08-4821 CONDENSER SOLENOID (MODEL ST-10 ONLY) 2

16 91-7640 CONDENSER BRACKET 1

AUGUST 12, 2014 20 ST-10M SERIES CONVECTION STEAMERS

Page 21

POWER PLUS

ITEM PART NO. DESCRIPTION QTY.

1 10-9175 RELAY SOCKET, (ONE PER COMPARTMENT) 2

2 10-9174 CUBE RELAY, (ONE PER COMPARTMENT) 2

3 08-6502 PRESSURE SWITCH 2

4 98-4206 POWER SUPPLY, 5 VDC 1

5 97-6455 TIME DELAY RELAY 2

AUGUST 12, 2014 21 ST-10M SERIES CONVECTION STEAMERS

Loading...

Loading...