Page 1

ST-10 SERIES

10 PAN CONVECTION STEAMERS

INSTALLATION - OPERATION - MAINTENANCE

MODELS

ST-10M24E

ST-10M36E

ST-10M24G

ST-10M36G

ST-10M24D

ST-10M36D

44 Lakeside Avenue, Burlington, Vermont 05401 USA

Telephone: (802) 658-6600 Fax: (802) 864-0183

www.mi.com PN 14-0272 Rev D (4/16)

© 2016 - Market Forge Industries Inc.

Page 2

Your Service Agency’s Address:

Model

Serial number

Steamer installed by

Installation checked by

Page 3

IMPORTANT

TABLE OF CONTENTS

WARNING: Improper installation, adjustment, alternation,

service or maintenance can

cause property damage, injury or death. Read the installation, operation and maintenance instructions thoroughly

before installing or servicing

this equipment.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE

USER SMELLS GAS MUST BE

POSTED IN A PROMINENT LOCATION. This information may

be obtained by contacting your

local gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or

other ammable vapors or liquids in the vicinity of this or any

other appliance.

The information contained in this

manual is important for the proper installation, use, and maintenance of this steamer. Adherence to these procedures and

instructions will result in satisfactory baking results and long,

trouble free service. Please

read this manual carefully and

retain it for future reference.

INSTALLATION

Introduction .............................................................. 2

Service Connections ..................................................... 3

Installation............................................................... 9

Assembly ............................................................ 9

Setting in Place ...................................................... 9

Mechanical Connections .............................................. 9

Water Connections ................................................... 9

Installation Checkout ................................................. 9

Initial Control Settings ................................................ 9

Cooker Checkout .................................................... 10

Shut Down Procedure ............................................... 10

Reversing the Doors ................................................. 10

PRV – Pressure Reducing Valve Maintenance and Adjustments ............. 12

OPERATION

Operating Procedures ................................................... 13

Manual Control Panel ................................................... 14

Digital Control Panel .................................................... 15

Test Kitchen Bulletin ..................................................... 16

Suggested Steam Times ................................................. 17

MAINTENANCE

Cleaning & Preventative Maintenance..................................... 19

ERRORS: Descriptive, typographic or pictorial errors are

subject to correction. Specications are subject to change

without notice.

Page 4

Introduction

DESCRIPTION

The ST-10 is a pressureless steam cooker consisting of

two independently controlled compartments enclosed in

a single cabinet. Each compartment is equipped with a

separate three-piece door with inner gasket plate isolated from the exterior surface. Door latches operate by

slam action for positive sealing of inner door. Steam and

steam-condensing circuits are electrically controlled. Operating controls are displayed on a single front-mounted

panel and include separate timers with indicator lights for

selection of constant steam or 60-minute-long duration

cooking.

A separate steam source required for operation of the

Pressureless Cooker is normally purchased with it, please

refer to the respective manual for guidance.

BASIC FUNCTIONING

The Model ST-10 may be operated with only one compartment in use; or both may be used simultaneously. Each

compartment is equipped with identical controls, allowing

selection of constant steam or 60-minute timer operation.

The cooker becomes operational when it is set to constant steam, or the timer is set at the desired cooking time

and the compartment door is closed. The indicator light

comes on and the steam solenoid valve opens, allowing

steam to ow into the compartment.

When steam owing inside the compartment has raised

the interior temperature to 195°F, the contacts of a thermostatic switch automatically close, completing the circuit

to the timer motor and starting the cooking time period. At

the end of the set interval, timer contacts switch to shut

off the cooking operation and sound a signal buzzer. The

buzzer is silenced by returning the timer dial to the OFF

position. In the constant steam mode, operation will be

continuous.

Steam emitted from the compartment along with liquid

cooking drainage is directed through a drain screen inside

the compartment into the cooker drain line. A cold water

solenoid valve connected into the cooker drain line is automatically actuated by a thermostatic switch in the boiler

drain to condense the steam to water prior to discharge

into the boiler drain.

SERVICE

Required service, both preventive and corrective, is explained in Section 6. Should repairs be required, a net-

work of authorized agencies is available to assist with

prompt service. A current Directory of Authorized

Service Agencies may be obtained by contacting:

Market Forge

44 Lakeside Avenue, Burlington, VT 05401

802-658-6600

www.mi.com

The model and serial numbers must be referenced when

corresponding with Market Forge. The data plate containing the serial number pertaining to the equipment is located on the lower front trim of the cabinet.

INSTALLATION

2

Page 5

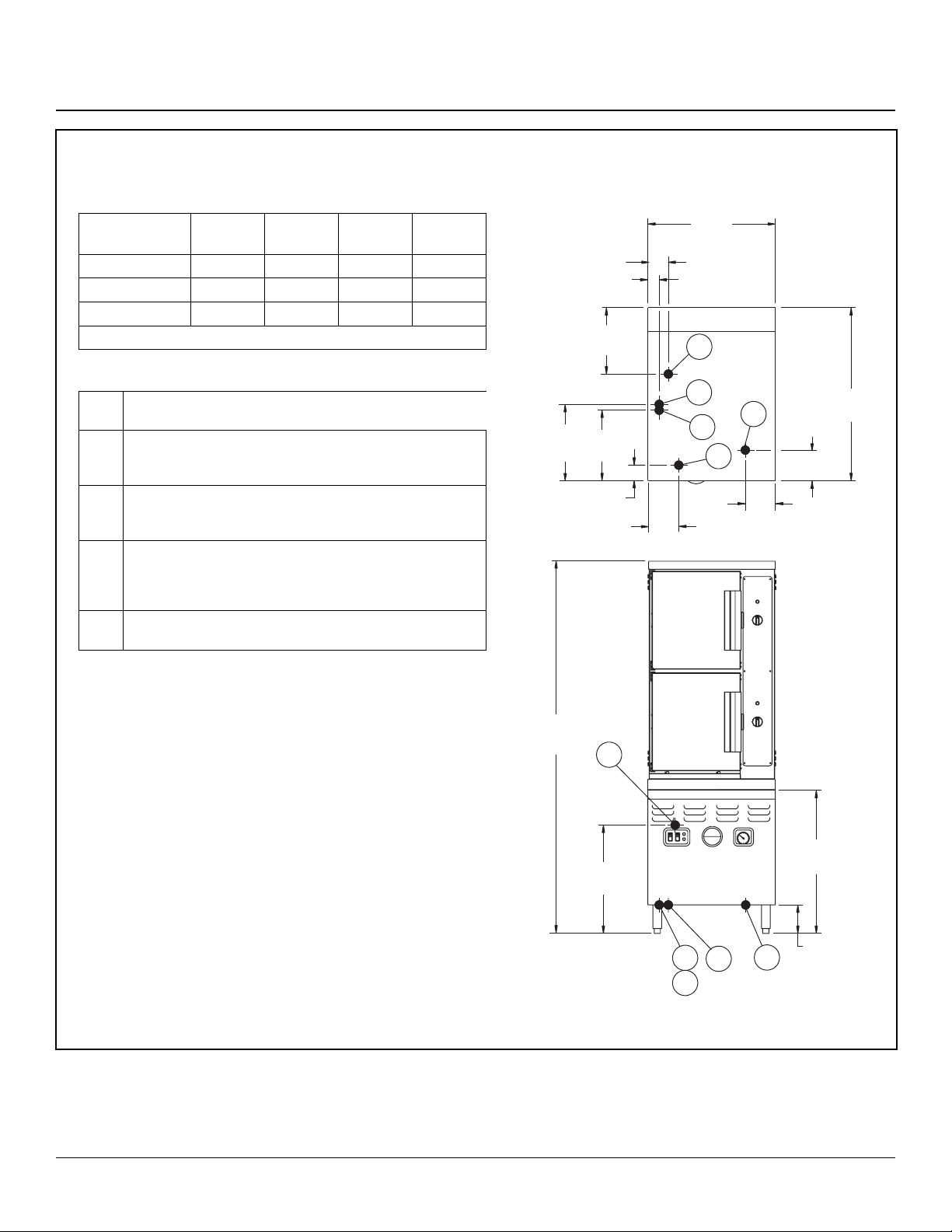

ST-10M24E

Service Connections

ELECTRICAL REQUIREMENTS

24kW

3pH

208 (197-219) 66 100 117 --

240 (220-240) 58 87 -- 116

480 (360-500) 29 44 -- 58

Details of other electrical systems available upon request.

36kW

3pH

42kW

3pH

48kW

3pH

SERVICE CONNECTIONS

EP Electrical Connection - Use wire suitable for at least 90°C.

Nominal amp per line wire.

CW1 Cold Water - 3/8” (10mm) NPT for cold water to boiler. Cold

water lines will have a maximum of 50 PSI (3.5kg/cw2) and a

minimum of 25 PSI (1.8 kg/cw2) water pressure

CW2 Cold Water - 3/8” (10mm) NPT for cold water to condenser.

Cold water lines will have a maximum of 50 PSI (3.5kg/cw2)

and a minimum of 25 PSI (1.8 kg/cw2) water pressure.

D Drain - Pipe full 2” (50mm) NPT to flush floor drain capable

of receiving water flowing at a maximum rate of 5 gallons (19

liters) per minute. DO NOT MAKE SOLID CONNECTION TO

FLOOR DRAIN.

ST Steam Take-off - Connection for operation of adjacent steam

powered equipment.

DIMENSIONS ARE IN INCHES [MM]

4 [102]

2.5 [64]

10.5

[267]

CW1

12.5

10.5

[318]

[267]

3 [76]

5 [127]

24 [610]

D

CW2

6 [152]

33

EP

ST

[838]

6 [152]

OPERATION WILL BE BY:

Electrically powered, A.S.M.E. constructed and National Board

Registered, 15 PSI (1 kg/cm2) steam boiler rated at 24kW, additional

ratings available as an option

NOTE: The only available space to supply utilities to the boiler is the 6”

(152mm) space between the floor and the cabinet base. PVC & CPVC

Pipe are not acceptable materials for drains.

CAUTION: REMOTE KETTLE OPERATION If this boiler is feeding a

remote kettle that will be more than 5 feet (1.5 meters) away, consult

factory before ordering.

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water quality

must be within the following general guidelines.

TDS: 40-125 ppm Hardness: 35-100 ppm Chlorine: <0.2 ppm

Silica: <13 ppm Chlorides: <25 ppm

Chloramine: <0.2 ppm pH: 7.0 - 8.5

The best defense against poor water quality is a water treatment system

designed to meet your water quality conditions.

Figure 1

69.25

[1759]

22

[559]

ST

28

[711]

6 [152]

CW1

CW2

EP

D

3

INSTALLATION

Page 6

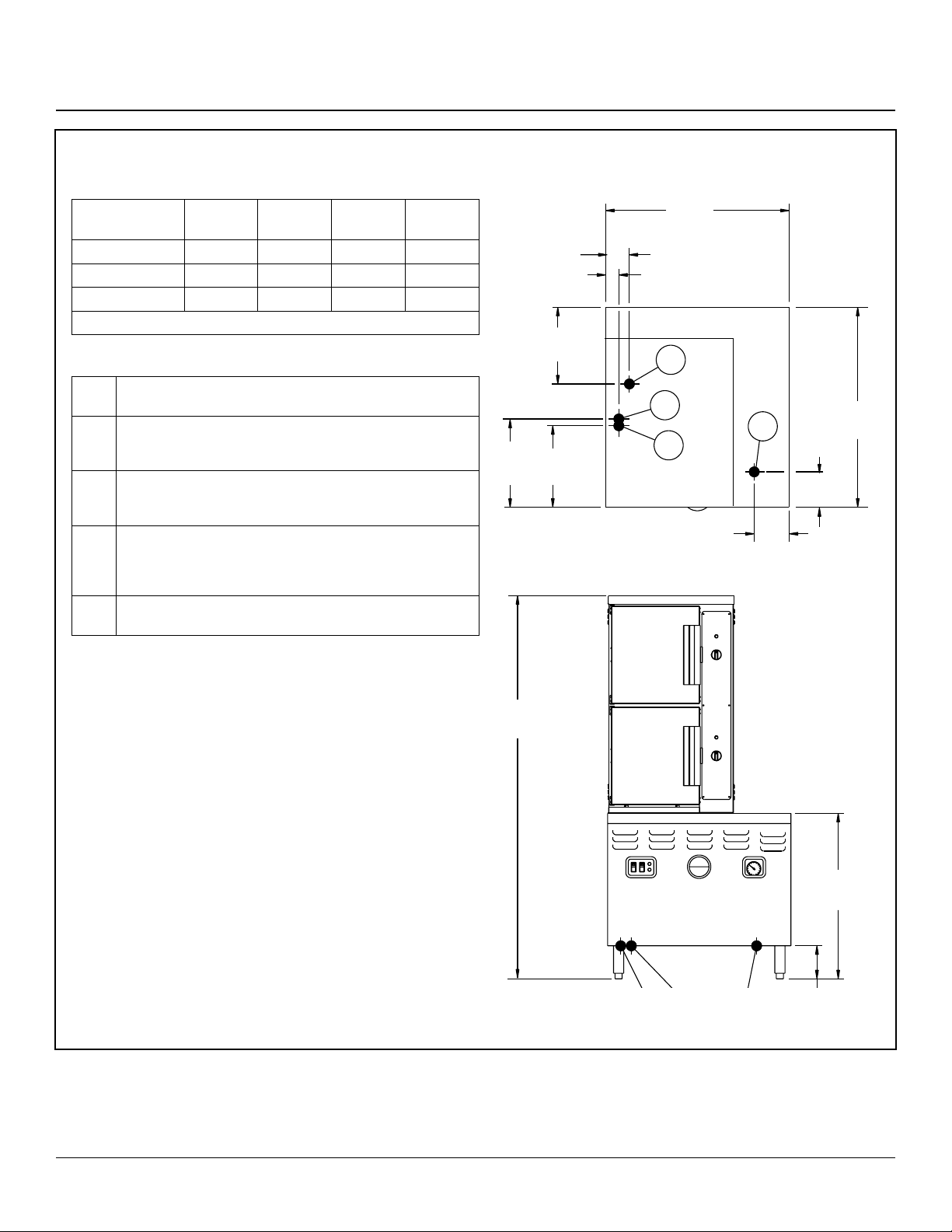

Service Connections

ST-10M36E

ELECTRICAL REQUIREMENTS

24kW

3pH

208 (197-219) 66 100 117 --

240 (220-240) 58 87 -- 116

480 (360-500) 29 44 -- 58

Details of other electrical systems available upon request.

36kW

3pH

42kW

3pH

48kW

3pH

SERVICE CONNECTIONS

EP Power Supply - Use wire suitable for at least 90°C. Nominal

amp per line wire:

CW1 Cold Water - 3/8” (10mm) NPT for cold water to boiler. Cold

water lines will have a maximum of 50 PSI (3.5kg/cw2) and a

minimum of 25 PSI (1.8 kg/cw2) water pressure

CW2 Cold Water - 3/8” (10mm) NPT for cold water to condenser.

Cold water lines will have a maximum of 50 PSI (3.5kg/cw2)

and a minimum of 25 PSI (1.8 kg/cw2) water pressure.

D Drain - Pipe full 2” (50mm) NPT to flush floor drain capable

of receiving water flowing at a maximum rate of 5 gallons (19

liters) per minute. DO NOT MAKE SOLID CONNECTION TO

FLOOR DRAIN.

ST Steam Take-off - Connection for operation of adjacent steam

powered equipment.

DIMENSIONS ARE IN INCHES [MM]

4 [102]

2.5 [64]

10.5

12.5

[318]

[267]

10.5

[267]

D

CW1

CW2

36 [914]

6 [152]

EP

33

[838]

6 [152]

OPERATION WILL BE BY:

Electrically powered, A.S.M.E. constructed and National Board Registered,

15 PSI (1 kg/cm2) steam boiler rated at

24kW

NOTE: The only available space to supply utilities to the boiler is the 6”

(152mm) space between the floor and the cabinet base. PVC & CPVC

Pipe are not acceptable materials for drains.

CAUTION: REMOTE KETTLE OPERATION If this boiler is feeding a

remote kettle that will be more than 5 feet (1.5 meters) away, consult

factory before ordering.

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water quality

must be within the following general guidelines.

TDS: 40-125 ppm Hardness: 35-100 ppm Chlorine: <0.2 ppm

Silica: <13 ppm Chlorides: <25 ppm

Chloramine: <0.2 ppm pH: 7.0 - 8.5

The best defense against poor water quality is a water treatment system

designed to meet your water quality conditions.

Figure 2

69.25

[1759]

28

[711]

INSTALLATION

4

Page 7

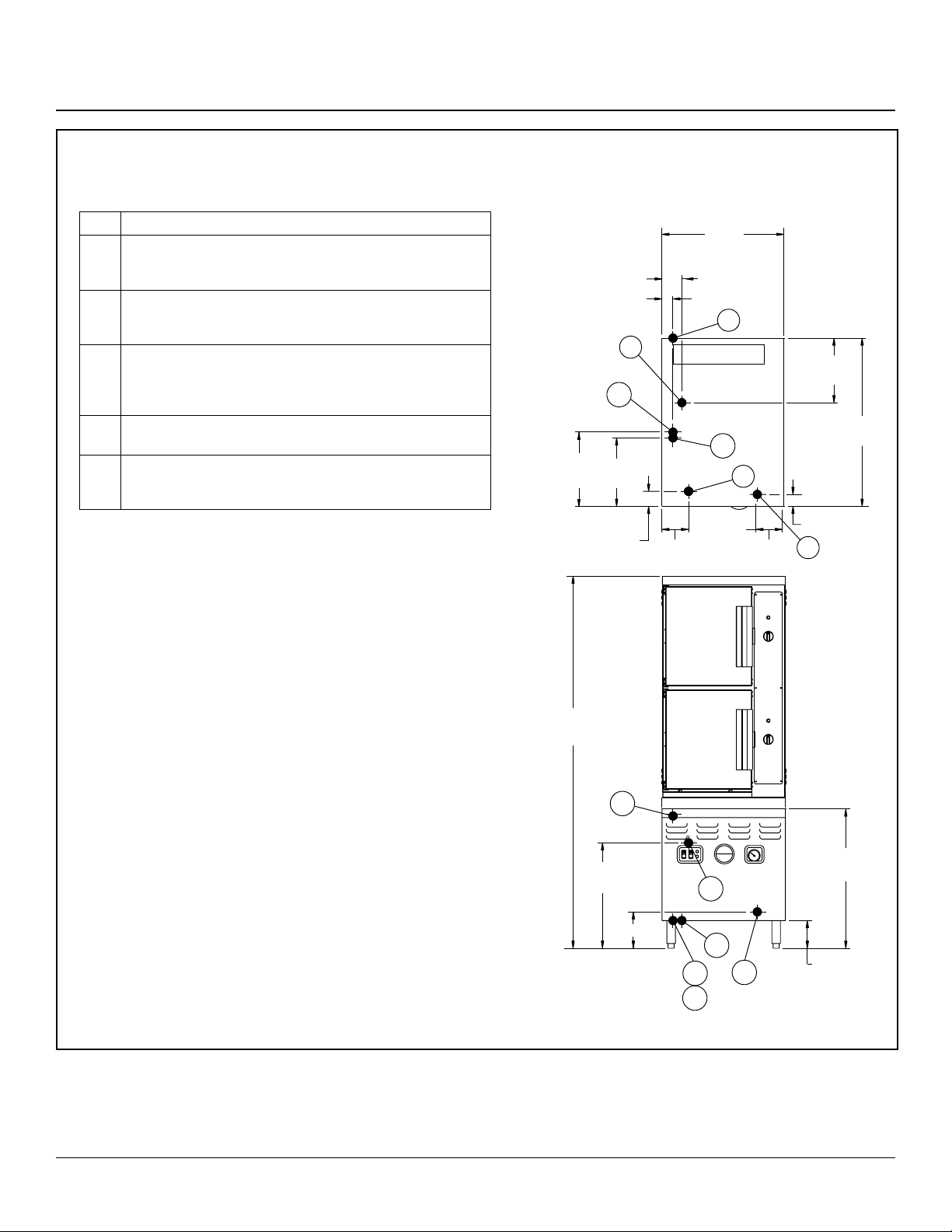

ST-10M24G

Service Connections

SERVICE CONNECTIONS

G Gas Connection - 3/4” (19mm) NPT, 200,000 BTU

CW1 Cold Water - 3/8” (10mm) NPT for cold water to boiler. Cold

water lines will have a maximum of 50 PSI (3.5kg/cw2) and a

minimum of 25 PSI (1.8 kg/cw2) water pressure.

CW2 Cold Water - 3/8” (10mm) NPT for cold water to condenser.

Cold water lines will have a maximum of 50 PSI (3.5kg/cw2) and

a minimum of 25 PSI (1.8 kg/cw2) water pressure.

D Drain - Pipe full 2” (50mm) NPT to flush floor drain capable

of receiving water flowing at a maximum rate of 5 gallons (19

liters) per minute. DO NOT MAKE SOLID CONNECTION TO

FLOOR DRAIN.

EC Electrical Connection - 120 Volts AC, 60 Hz, single phase,

and a 9 foot Power Cord/NEMA 5-15.

ST Steam Take-off - Connection for operations of adjacent steam

powered equipment. Requires steam take-off kit (optional at

extra cost).

OPERATION WILL BE BY

Gas fired, A.S.M.E. constructed and National Board Registered, 15PSI (1

kg/cm2) steam boiler rated at 200,000 BTU

Notes: If equipment is installed where elevation exceeds 2,000 feet

(609.6 meters) above sea level, specify installation altitude so that proper

gas orifices can be provided.

The only available space to supply utilities to the gas boiler is the 6”

(152mm) space between the floor and the cabinet.

Allow 3” (76mm) space from side wall and 6” (152mm) from rear wall if

adjoining walls are combustible.

PVC & CPVC PIPE ARE NOT ACCEPTABLE MATERIALS FOR

DRAINS.

CAUTION: REMOTE KETTLE OPERATION If this boiler is feeding a

remote kettle that will be more than 5 feet (1.5 meters) away, consult

factory before ordering.

DIMENSIONS ARE IN INCHES [MM]

4[102]

2.5 [64]

D

CW1

12.5

10.5

[318

[267]

3 [76]

69.25

[1759]

5 [127]

EC

24 [610]

EC

FLUE

CW2

ST

5 [127]

10.5

[267]

33

[838]

2.75 [70]

G

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water quality

must be within the following general guidelines.

TDS: 40-125 ppm Hardness: 35-100 ppm Chlorine: <0.2 ppm

Silica: <13 ppm Chlorides: <25 ppm

Chloramine: <0.2 ppm pH: 7.0 - 8.5

The best defense against poor water quality is a water treatment system

designed to meet your water quality conditions.

Figure 3

5

22

[559]

8 [203]

CW1

CW2

28

[711]

ST

D

G

6 [152]

INSTALLATION

Page 8

Service Connections

SERVICE CONNECTIONS

ST-10M36G

G Gas Connection - 3/4” (19mm) N.P.T. female for 200,000 BTU

boiler.

G1 Gas Connection - 1” (25mm) N.P.T. female for 300,000 BTU boiler.

CW1 Cold Water - 3/8” (10mm) NPT for cold water to boiler. Cold water

lines will have a maximum of 50 PSI (3.5kg/cw2) and a minimum

of 25 PSI (1.8 kg/cw2) water pressure.

CW2 Cold Water - 3/8” (10mm) NPT for cold water to condenser. Cold

water lines will have a maximum of 50 PSI (3.5kg/cw2) and a minimum of 25 PSI (1.8 kg/cw2) water pressure.

D Drain - Pipe full 2” (50mm) NPT to flush floor drain capable of

receiving water flowing at a maximum rate of 5 gallons (19 liters)

per minute. DO NOT MAKE SOLID CONNECTION TO FLOOR

DRAIN.

EC Electrical Connection - 120 Volts AC, 60 Hz, single phase, and

a 9 foot Power Cord/NEMA 5-15.

ST Steam Take-off - Connection for operations of adjacent steam

powered equipment. Requires steam take-off kit (optional at extra

cost).

OPERATION WILL BE BY

Gas fired, A.S.M.E. constructed and National Board Registered, 15 PSI (1

kg/cm2) steam boiler rated at 200,000 BTU

Notes: If equipment is installed where elevation exceeds 2,000 feet (609.6

meters) above sea level, specify installation altitude so that proper gas orifices can be provided.

The only available space to supply utilities to the gas boiler is the 6” (152mm)

space between the floor and the cabinet.

Allow 3” (76mm) space from side wall and 6” (152mm) from rear wall if adjoining walls are combustible.

PVC & CPVC PIPE ARE NOT ACCEPTABLE MATERIALS FOR DRAINS.

CAUTION: REMOTE KETTLE OPERATION If this boiler is feeding a remote

kettle that will be more than 5 feet (1.5 meters) away, consult factory before

ordering.

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water quality must

be within the following general guidelines.

TDS: 40-125 ppm Hardness: 35-100 ppm Chlorine: <0.2 ppm

Silica: <13 ppm Chlorides: <25 ppm

Chloramine: <0.2 ppm pH: 7.0 - 8.5

The best defense against poor water quality is a water treatment system

designed to meet your water quality conditions.

DIMENSIONS ARE IN INCHES [MM]

4[102]

2.5 [64]

D

CW1

12.5

10.5

[318

[267]

5 [127]

CW1

CW2

69.25

[1759]

3 [76]

EC

ST

22

[559]

8 [203]

CW2

36 [914]

EC

FLUE

ST

D

5 [127]

G

G1

10.5

[267]

2.75 [70]

G

6 [152]

33

[838]

G1

27

[686]

28

[711]

INSTALLATION

Figure 4

6

Page 9

ST-10M24D

Service Connections

SERVICE CONNECTIONS

EC Electrical Connection - 120 Volts AC, 60 Hz, single

phase, and a 9 foot Power Cord/NEMA 5-15.

CR Condensate Return - 1/2” (13mm) N.P.T. female from

ball float trap may be connected to condensate return

line (optional at extra cost).

CW Cold Water - 3/8” (10mm) NPT for cold water to con-

denser. Cold water line will have a maximum of 50 PSI

(3.5kg/cw2) and a minimum of 25 PSI (1.8 kg/cw2)

water pressure.

D Drain - Pipe full 2” (50mm) NPT to flush floor drain

capable of receiving water flowing at a maximum rate of

5 gallons (19 liters) per minute. DO NOT MAKE SOLID

CONNECTION TO FLOOR DRAIN.

S Steam Supply - Minimum BHP required: 3.0 BHP at a

minimum pressure of 15 PSI (1.0 kg/cm2). 3/4” (19mm)

NPT pressure reducing valve will reduce incoming

pressure of 20 to 50 PSI (1.3 to 3.5 kg/cm2) to required

15 PSI (1.0 kg/cm2).

NOTES: The only available space to supply utilities is the 6”

(152mm) height between the floor and the cabinet.

PVC & CPVC are not acceptable materials for drain lines.

DIMENSIONS ARE IN INCHES [MM]

24 [610]

4.3 [109]

4 [102]

2.5 [64]

2 [51]

D

10.5

[267]

EC

CR

CW

7 [177]

10.5

[267]

33

[838]

S

3 [76]

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water

quality must be within the following general guidelines.

TDS: 40-125 ppm Chlorides: <25 ppm

Silica: <13 ppm pH: 7.0 - 8.5

Chloramine: <0.2 ppm Chlorine: <0.2 ppm

Hardness: 35-100 ppm

The best defense against poor water quality is a water treatment

system designed to meet your water quality conditions.

Appliance to be installed with backflow protection according to

federal, state or local codes.

Figure 5

69.25

[1759]

EC

CW

28

[711]

S

D

17

[432]

6 [152]

7

INSTALLATION

Page 10

Service Connections

ST-10M36D

SERVICE CONNECTIONS

EC Electrical Connection - 120 Volts AC, 60 Hz, single

phase, and a 9 foot Power Cord/NEMA 5-15.

CW Cold Water - 3/8” (10mm) NPT for cold water to con-

denser. Cold water lines will have a maximum of 50

PSI (3.5kg/cw2) and a minimum of 25 PSI (1.8 kg/cw2)

water pressure.

CR Condensate Return - 1/2” (13mm) N.P.T. female from

ball float trap may be connected to condensate return

line (optional at extra cost).

D Drain - Pipe full 2” (50mm) NPT to flush floor drain

capable of receiving water flowing at a maximum rate of

5 gallons (19 liters) per minute. DO NOT MAKE SOLID

CONNECTION TO FLOOR DRAIN.

S Steam Supply - Minimum BHP required: 3.0 BHP at a

minimum pressure of 15 PSI (1.0 kg/cm2). 3/4” (19mm)

NPT pressure reducing valve will reduce incoming

pressure of 20 to 50 PSI (1.3 to 3.5 kg/cm2) to required

15 PSI (1.0 kg/cm2).

NOTES: The only available space to supply utilities is the 6”

(152mm) height between the floor and the cabinet.

PVC & CPVC are not acceptable materials for drain lines.

DIMENSIONS ARE IN INCHES [MM]

36 [914]

4.3 [109]

4 [102]

2.5 [64]

2 [51]

D

10.5

[267]

EC

CR

CW

S

17 [432]

10.5

[267]

33

[838]

3 [76]

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water

quality must be within the following general guidelines.

TDS: 40-125 ppm Chlorides: <25 ppm

Silica: <13 ppm pH: 7.0 - 8.5

Chloramine: <0.2 ppm Chlorine: <0.2 ppm

Hardness: 35-100 ppm

The best defense against poor water quality is a water treatment

system designed to meet your water quality conditions.

Appliance to be installed with backflow protection according to

federal, state or local codes.

Figure 6

69.25

[1759]

EC

CW

28

[711]

S

D

17

[432]

6 [152]

INSTALLATION

8

Page 11

Installation

ASSEMBLY

The Pressureless Cooker is factory-mounted on a cabinet base containing either a steam boiler or direct steam

connection controls for the cooker. The assembled unit is

shipped bolted to a skid, with cabinet feet in a separate

container. Steps required for assembly are as follows:

1. Remove the four bolts that fasten the equipment

frame to the skid.

2. Install feet in threaded mounting locations of the cabinet frame.

3. Mount the two bafes on studs located on the rightinside of the cooking compartments.

4. Mount the four pan support racks in brackets inside

control compartments.

5. Attach panels to lower cabinet. Detailed instructions

are enclosed with the panels.

SETTING IN PLACE

Installation must be under an exhaust hood, which will

remove small amounts of water vapor emitted when the

cooker doors are opened, and exhaust fumes from the

air. Level the unit in nal location by turning the adjustable

feet. Using the cabinet top as a reference, obtain level

adjustment left-to-right and front-to-back.

MECHANICAL CONNECTIONS

Since the Pressureless Cooker is interconnected at the

factory to the steam boiler or direct steam plumbing, no

eld connections to the cooker are required. All electrical

and plumbing connections are routed to the steam boiler

cabinet through the 6-inch-high space between the oor

and the bottom edge of the cabinet frame.

WATER CONNECTIONS

Before connecting water to this unit, have water supply

analyzed to make sure that hardness is no grater than

2.0 grains per gallon and pH level is within the range of

7.0–8.5. Water that fails to meet these standards should

be treated by the installation of a water conditioner.

WARNING

EQUIPMENT FAILURE CAUSED BY INADEQUATE WATER QUALITY IS NOT COVERED

UNDER WARRANTY.

CAUTION

PVC or CPVC are not acceptable materials for

drains.

INSTALLATION CHECKOUT

If the cooker fails to perform as described, consult the

Trouble-Shooting Guide for corrective action. If difculty

arises with the boiler, reference the separate service and

parts manual for that equipment.

Before making this check-out, the operator must be thoroughly familiar with the operating procedures in this manual and with the function of each control described.

INITIAL CONTROL SETTINGS

Before beginning the start-up procedures for the cooker,

the instruction plate and service manual for the steam

boiler must be consulted and all start-up procedures completed to supply 15 PSI steam to the steam inlet line for

the cooker.

1. All steam boiler controls are in the operating mode

and 15 PSI steam is applied to the cooker inlet plumbing.

2. Cooker timers for both compartments are in the OFF

position.

3. Cooker compartments are empty of all information

materials, pan supports are mounted in place, and

doors are open.

9

INSTALLATION

Page 12

Installation

COOKER CHECKOUT

The cooker check-out procedures are as follows:

1. With the doors open set timers to about the “4-minute” position. Observe that indicator lights are off and

steam does not enter compartments.

2. Close cooker compartment doors. Observe that indicator lights turn on, and steam can be heard rushing

into the compartment simultaneously with the door

closing.

3. Observe the boiler drain line for passage of steam

into the open oor drain. Correct steam condenser

operation is evidenced by presence of water owing

from the drain line.

4. Observe cooker operation for several minutes. Operation is correct if timer dials begin to rotate after a

short delay period required for preheating. After the

delay period plus the “4-minute” initial setting, the timer dials will return to the “0-Minute” position, at which

a buzzer sounds. The buzzer is silenced by turning

the dial to the OFF position.

SHUT DOWN PROCEDURE

No shut-down procedure is required for the Pressureless

Cooker except to check that all timer dials (2) are in the

OFF position and the compartment doors are open. Consult the steam boiler instruction plate and complete the

shut-down procedures for the boiler.

REVERSING THE DOORS

The Pressureless Steam Cooker has a reversible cooking

compartment door. This section contains instructions for

reversing this door.

1. Turn off power to the unit.

2. Open the cooking compartment door

3. Remove the two screws that attach the top hinge to

the front of the unit.

4. Slide the door upwards, off the bottom hinge.

5. Remove the two screws that attach the bottom hinge

to the front of the units.

6. Remove the right and left side panels by unscrewing the 1 screw on each panel and sliding the panel

down.

7. Remove the door interlock assembly by unscrewing

the two nuts that hold it in place (assembly is attached

to the screws in the top right hinge mounting holes).

8. Remove the four screws in the right side hinge mounting holes and install them in the left side hinge mounting holes (where the hinges were originally mounted).

9. Using the nuts removed in step #6, reinstall the door

interlock assembly onto the 2 screws in the lower left

hinge mounting holes with by moving the assembly

over the cooking cavity to the other side of the unit.

Rotate the door interlock assembly 180° for installation, so that the switch is now facing up.

10. Reinstall the top hinge and screws into the right lower

hinge mounting holes. Rotate the hinge 180° for installation, so that the pin which the door rides on is

now facing up. The hinge must be rotated because

it will now function as the bottom hinge. DO NOT

COMPLETELY TIGHTEN THE HINGE MOUNTING

SCREWS YET. These will be used later for adjusting

the door.

11. Remove the door latch assembly from the face of the

unit. The 2 nuts mounting the door latch are located

behind the face of the unit and must be accessed

where the right side panel was removed.

12. Remove the two white hole plugs from the left door

latch mounting holes, and insert them into the right

door latch mounting holes (where the door latch assembly was originally mounted).

13. Rotate the door latch assembly 180°, and install into

the left door latch mounting holes.NOTE: Each stud

on the latch assembly should have a plastic washer, a

spring, a plastic washer and a Nyloc type nut.

14. To adjust the tension of the door latch, tighten both

nuts down until the springs are fully compressed,

then back each nut off -1/2 turn.

15. Rotate the door 180° for mounting.

16. Slide the remaining hinge into the top door bearing.

17. Slide the door and hinge assembly down onto the

hinge which you have already mounted to the front of

the unit. Use the two screws to mount the top hinge

into the right upper hinge mounting holes. DO NOT

COMPLETELY TIGHTEN THE HINGE MOUNTING

SCREWS YET.

18. Slowly push the cooking compartment door closed

until it is latched.

19. The cooking compartment door can now be raised,

lowered, and/or rotated into position by bumping it

with the palm of your hand or by using a small rubber

mallet.

INSTALLATION

10

Page 13

Installation

20. First, check the alignment at the front of the door by

making sure that the striker in the door is centered

with the latch mechanism on the front of the unit.

21. Square the door to the unit by raising or lowering the

hinge side of the door, keeping the latch centered

with the striker.

22. Visually inspect the door. Be sure that the door is

square to the unit, the striker is centered with the

latch, and the gasket is in contact with the entire lip of

the cooking compartment.

23. Gently open the cooking compartment door, taking

care not to move it out of position.

24. Tighten all 4 door hinge bracket mounting screws.

25. Close and visually inspect the door again, as described in step 22.

26. Reinstall the left and right side panels, using the

screws for each panel.

Figure 7

11

INSTALLATION

Page 14

PRV – Pressure Reducing Valve Maintenance and Adjustments

WATTS PRESSURE REDUCING VALVE –

MARKET FORGE PART NUMBER 10 - 1033

To provide adequate steam pressure regulation, your

cooker / steamer may be equipped with a Watts Pressure

Reducing Valve ( PRV ). The ¾” PRV is designed to regulate an incoming Maximum pressure of 200 PSI down to

Operating pressures between 5 – 20 PSI. The PRV will

safely regulate the incoming steam to your type of unit.

The chart below indicates the required Incoming Pressure

for the following Market Forge Models.

Model Max. Operation

Pressure

ST-10 - All

models

5 PSI 200 PSI

Max. Incoming

Pressure

ADJUSTING WATTS ¾” PRESSURE REDUCING

VALVE

1. Release the locking wing nut (Item 1) and loosen the

adjusting screw spring (Item 2)

2. Turn the inlet steam supply to full open. Then turn

adjusting screw (Item 2) clockwise just enough to allow the valve to open slightly. Allow cooker / steamer

to operate in this manner for several minutes by pulling out the steam operating handle or turning on the

timer.

3. Turn adjusting screw (Item 2) down slowly at intervals

until reduced pressure reaches the desired set-point

per the chart below.

4. Tighten locking wing nut (Item 1)

5. If a chattering noise should occur, move adjusting lever or screw (Item 3 as shown) located in bottom half

of the valve body, clockwise or counter-clockwise, until chattering stops.

2

1

3

Figure 8

INSTALLATION

12

Page 15

Operating Procedures

The ST-10 Pressureless Steam Cooker defrosts frozen

foods and cooks fresh and defrosted foods. Each cooking

compartment permits selection of continuous (constant

steam) cooking or timed (0–60 minutes) cooking. Instructions for operation are included in this section. Consult

Test Kitchen Bulletin for detailed cooking information.

STEAM SOURCE OPERATION

The Pressureless Cooker is supplied mounted on a

cabinet containing either a steam boiler or controls for

direct-connected steam. Manual controls are accessed

by opening the cabinet door. The start-up procedure for

the steam source is completed once before each daily

operating period of the cooker. (For steam boilers, see

instruction plate.)

PREHEATING

Before each initial operation of the cooker, and at any other time when the cooking compartment is cold, a 1-minute

preheating period is required. To preheat the cooker, put

steam source into operation and proceed as follows:

1. Close cooking compartment door.

2. Set 60-Minute Timer Dial (1) to “1-minute” setting.

NOTE Total elapsed preheating time equals the timer

setting plus a short delay period needed to active a

thermostatic switch included in the controls.

SHUTDOWN PROCEDURE

No shut-down procedure is required for the cooker except

to check that both timer dials (1) are in the OFF position and that both compartment doors are open. When

all cooking has been completed for the day, the steam

source must be shut off. (For steam boilers, see instruction plate.)

CAUTION

When the unit is not in use, leave the cooking

compartment door slightly ajar to prolong the

life of the door gasket.

3. Turn off buzzer, which sounds to indicate cooking is

complete, by setting the Timer Dial (1) to OFF position.

COOKING

Before loading the cooker, be sure compartment is hot.

See preheating for instructions.

1. Slide pans of food into cooking compartment pan

supports.

2. Close cooking compartment door.

3. Set timer cooking time:

4. CONSTANT STEAM—for continuous cooking.

5. 60-MINUTE TIMER—for timed cooking.

6. Set appropriate timer to the required cooking time.

7. Turn off buzzer, which sounds to indicate cooking is

complete, by setting timer dial (1) to the OFF position.

8. Open door sightly at rst letting most of the steam out

of the compartment and then fully open the door.

9. Unload by sliding pans of food from pan supports,

taking care to avoid hitting compartment opening.

13

OPERATION

Page 16

Manual Control Panel

Control Description

1. Timer/Constant Steam - Controls cooking up to 60

minutes or uses constant operation.

2. Indicator Light (Red) - Indicates when lit that cooker

is in operation.

READY

C

O

N

S

F

T

F

O

A

N

S

T

T

E

A

M

0

60

2

5

10

15

20

55

50

45

40

25

35

30

3. Buzzer - Signals end of cooking period (not shown).

1

ST-10

2

1

OPERATION

READY

C

O

N

S

F

T

F

O

A

N

S

T

T

E

A

M

0

60

5

10

15

20

55

50

45

40

25

35

30

CONVECTION

STEAM

COOKER

Figure 9

14

Page 17

Digital Control Panel

NOTE: USER PROGRAMING OF THE TIMER CYCLE

IS EASILY ACCOMPLISHED VIA A (12) BUTTON

NUMERIC KEYPAD AND A (4) DIGIT NUMERIC

LED DISPLA

START PROGRAMING

FIRST - Make sure doors are shut on both compartments.

SECOND - Flip on POWER SWITCH, located in the

middle of control panel to the ON position.

THIRD - Press the CLEAR button and HOLD for two

(2) seconds. This should clear the timer display to

00:00.

THE TIMER IS NOW READY FOR PROGRAMING. The

timers are programmable from one second to 99 minutes

and 99 seconds.

PLEASE NOTE - TIMER WILL NOT START COUNTING

DOWN UNLESS:

1. DOOR IS SHUT.

2. THE THERMOSTAT REACHES 193oF INSIDE THE

COMPARTMENT.

When the timer reaches “0” the word “END” will ash on

the display. The AUTO-ALARM will sound and continue

until the START/STOP button is pressed.

When you press STOP, the existing program remains in

the system. It is necessary to press CLEAR, then REPROGRAM the new time as needed.

NOTE: To STOP the TIMER in MID-COUNT DOWN,

PRESS and HOLD the STOP button for a few

seconds.

The word “PAUSE” will appear on the screen every time

the door is opened. When the door is closed, the timer will

resume the count down.

FEATURES

1. FOUR DIGIT DISPLAY – Example 00:00

NOTE: To save energy, remember to always re-

turn the TIMER to the OFF position after it

has been used in the CONSTANT STEAM

MODE.

2. AUTO ALERT = End of cycle sound.

3. “END” = Displayed at the end of cycle.

4. “PAUSE” = Displayed when doors are opened.

Figure 10

5. START/STOP = Control Button for start and stopping.

6. POWER SWITCH = Turn power ON and OFF.

NOTE: Unit is equipped with MANUAL OVERRIDE in

the event of a TIMER FAILURE (CONSTANT

STEAM).

15

OPERATION

Page 18

Test Kitchen Bulletin

1. Frozen vegetables should always be cooked in perforated 12” x 20” x 2-1/2” pans 7-1/2 lbs (34kg) maximum per pan.

2. Frozen entrees should be underlined with a perforat-

ed pan for best results. If they are defrosted rst, the

heating time will be decreased.

3. Fresh foods may also be cooked in this unit. Vegetables and other foods where the stock is not to be

retained should be cooked in perforated 12” x 20” x

2-1/2” pans for the most nutritious results.

4. There is a thermostatic time delay built into this unit

which adapts the unit to the proper cooking time. This

means that the total time will usually be longer than

the time setting.

5. There is a safety microswitch on the door which shuts

off the steam each time the door is opened if the unit

is in the cooking cycle.

6. Both compartments may be lled and timers set simultaneously.

7. Total cooking time will vary depending on the load,

even though the timer setting is the same.

8. All foods, except cakes and pastry, can be cooked in

a steam cooking unit.

9. Steam cooked meals have greater nutritional value

since they retain most of their vitamins and minerals.

10. Because foods are cooked faster by the higher temperatures of steam cooking, they can be prepared

closer to serving time, insuring maximum freshness.

11. Steam cooked foods have a higher percent yield

more portions per dollar spent.

13. Some important advantages of steam cooking are labor saving, reduced operating costs, space saving,

and the lifting of heavy stock pots is eliminated.

14. Rice and spaghetti products, if thoroughly wet at the

start of the cooking process, are very easily prepared.

15. Food such as potatoes, poultry, seafood, and some

meats may be blanched in the steam cooker, thus reducing the total cooking time and grease absorption.

16. Energy is used only when the steam cooking unit is

in operation.

NOTE: To save energy, remember to always re-

turn the TIMER to the OFF position after it

has been used in the CONSTANT STEAM

MODE.

17. The steam cooker will loosen foods burned on pans

making washing easier.

18. Solid pans are recommended when liquid is to be re-

tained and perforated pans when the liquid is not to

be retained.

19. Eggs may be cooked out of the shell if they are to be

chopped which eliminates peeling after steaming.

20. The steam cooker can be opened during the cooking

period to add or remove items. If any time is lost while

the door is open, an adjustment may be made on the

timer.

21. Steam cooking information, including recommended

pan size and type, weight per pan, cooking times and

pan yields are given on the following pages of this

bulletin.

12. Food may be served from the same pan in which it

is steam cooked, thus reducing food breakage since

there is no extra handling or transferring of food from

cooking pans to serving pans. It also reduces pot

washing tasks.

OPERATION

16

Page 19

Suggested Steam Times

The ST-10 Pressureless Cooker is a two compartment unit. Each compartment holds ve 12” x 20” x 2-1/2” or three 12” x 20” x 4” pans.

This unit enables the cook to prepare foods close to the time of service. The cooking ntimes given are timer settings and should be set

on a preheated compartment. There is a thermostatic time delay in each compartment that adjusts the total time depending on the temperature and amount of the food. Therefore the total time will be greater than the timer setting. At the end of the timer cooking cycle the

bell will ring, steam will stop owing and the food can be removed.

ITEM

FROZEN VEGETABLES

FROZEN

WEIGHT PER

PAN

RECOMMENDED

12” x 20” (1/1)

PERF. PAN

NO. OF

PANS

TIMER

SETTINGS

IN MINUTES

APPROX. NO. COOKED

SERVINGS PER PAN

Asparagus, Spears 7.5 lbs (3.4 kg) 2.5” (65mm) 1-5 12-15 30 - 3 oz (85g)

Beans, Green Regular 6 lbs (2.7kg) 2.5” (65mm) 1-5 10-15 25 - 3 oz (85g)

Beans, Green French

Cut

6 lbs (2.7kg) 2.5” (65mm) 1-5 5-7 25 - 3 oz (85g)

Beans, Lima 7.5 lbs (3.4 kg) 2.5” (65mm) 1-5 12-15 30 - 3 oz (85g)

Broccoli 6 lbs (2.7kg) 2.5” (65mm) 1-5 4-6 25

Brussel Sprouts 7.5 lbs (3.4 kg) 2.5” (65mm) 1-5 10-15 30 - 3 oz (85g)

Carrots 6 lbs (2.7kg) 2.5” (65mm) 1-5 10-15 25 - 3 oz (85g)

Cauliower 6 lbs (2.7kg) 2.5” (65mm) 1-5 7-12 25 - 3 oz (85g)

Corn, Cut 7.5 lbs (3.4 kg) 2.5” (65mm) 1-5 8-12 30 - 3 oz (85g)

Mixed, Vegetables 7.5 lbs (3.4 kg) 2.5” (65mm) 1-5 8-12 30 - 3 oz (85g)

Peas, Loose 7.5 lbs (3.4 kg) 2.5” (65mm) 1-5 3-5 30 - 3 oz (85g)

Spinach 9 lbs (4 kg) 2.5” (65mm) 1-5

Squash 12 lbs (5.5 kg) 2.5” (65mm) 1-5

FROZEN PREPARED ENTREES

Lobster Tails,

6-8oz. (170-255g)

7-8 lbs (3.2-3.6

kg)

2.5” (65mm) 1-5 15-25 15

Must be

Defrosted

Must be

Defrosted

30 - 4 oz (115g)

50 - 3 oz (85g)

Shrimp, C.D.P. 16-20 lbs (7-9 kg) 2.5” (65mm) 1-5 8-11 75

Shrimp, Green 16-20 lbs (7-9 kg) 2.5” (65mm) 1-5 11-15 50

Bulk Pack, Frozen

3.5-4 lbs

(1.6-1.8 kg)

2.5” (65mm) 1-5 35-45 10

Bulk Pack, Defrosted 3.5-4 2.5” (65mm) 1-5 25-35 10

MISCELLANEOUS

Eggs, in Shell 3 dozen 2.5” (65mm) 1-5 9-11 36 - 1 Egg each

Eggs, out of Shell 4 dozen 2.5” (65mm) 1-5 6-8 48 - 1 Egg each

Rice 4 lbs (1.8 kg) 2.5” (65mm) 1-5 18-22 60-65 - 3 oz (85g)

Spaghetti 3 lbs (1.4 kg) 2.5” (65mm) 1-5 18-22 40-45 - 4 oz (115g)

17

OPERATION

Page 20

Suggested Steam Times

ITEM

VEGETABLES

FROZEN

WEIGHT PER

PAN

RECOMMENDED

12” x 20” (1/1)

PERF. PAN

NO. OF

PANS

TIMER

SETTINGS

IN MINUTES

APPROX. NO.

COOKED

SERVINGS PER PAN

Beans, Snap Green or Wax 6 lbs (2.7 kg) 2.5” (65mm) 1-5 18-22 25-30 - 3 oz (85 g)

Beets, 2” (50mm)

Diameter

Broccoli, 1/2-3/4”

(12-20mm) Stalks

7.5 lbs (3.4 kg) 2.5” (65mm) 1-5 40-50 30-35 - 3 oz (85 g)

6 lbs (2.7 kg) 2.5” (65mm) 1-5 14-18 25-30 - 3 oz (85 g)

Carrots, Sliced 9 lbs (4 kg) 2.5” (65mm) 1-5 18-21 35-40 - 3 oz (85 g)

Cauliower, 1.5-2”

(38-50mm) Trimmed

6 lbs (2.7 kg) 2.5” (65mm) 1-5 12-16 30-35 - 3 oz (85 g)

Corn on the Cob, Husked 1 dozen 2.5” (65mm) 1-5 10-15 12

Cabbage, 1/4-1/6 of Head,

Cored

Onions, 2” (50mm)

Diameter

5 lbs (2.25 kg) 2.5” (65mm) 1-5 14-18 15-20 - 4 oz (115 g)

6 lbs (2.7 kg) 2.5” (65mm) 1-5 20-25 25-30 - 4 oz (115 g)

Peas, Shelled 5 lbs (2.25 kg) 2.5” (65mm) 1-5 5-6 25-30 - 3 oz (85 g)

Potatoes, French Fry Cut 10 lbs (4.5 kg) 2.5” (65mm) 1-5 18-21 50 - 3 oz (85 g)

Potatoes, 3” (75mm)

Regular Cut

10 lbs (4.5 kg) 2.5” (65mm) 1-5 35-40 50 - 3 oz (85 g)

Spinach, Cleaned & Cut 3 lbs (1.4 kg) 2.5” (65mm) 1-5 3-5 10-12 - 3.75 oz (105 g)

Summer Squash,

1” (25mm) Sliced

7 lbs (3.2 kg) 2.5” (65mm) 1-5

Winter Squash, Peeled 9 lbs (4 kg) 2.5” (65mm) 1-5

Turnip, Diced 5 lbs (2.25 kg) 2.5” (65mm) 1-5

MEAT - POULTRY - FISH

Chicken, Cut up

Chicken, 4 lbs. Whole

Fowl, 5 lbs.+ Whole

Fish, Fillets

Frankforts

Hamburgers, 3 oz. (85g)

Meatballs, 1 oz. (30g) size*

Meatloaf *

Pork Chops, Loin Bone,

4 oz. (115g)

Sausage, 1.5 oz. (45g)

Turkey, on Carcass

Turkey, off Carcass

8 lbs (3.6 kg) 2.5” (65mm) 1-5

3 each 2.5” (65mm) 1-5

2 each 2.5” (65mm) 1-5

3 lbs (1.4 kg) 2.5” (65mm) 1-5

5 lbs (2.3 kg) 2.5” (65mm) 1-5

5 lbs (2.3 kg) 2.5” (65mm) 1-5

6 lbs (2.7 kg) 2.5” (65mm) 1-5

15 lbs (6.8 kg) 2.5” (65mm) 1-5

6 lbs (2.7 kg) 2.5” (65mm) 1-5

6 lbs (2.7 kg) 2.5” (65mm) 1-5

20-22 lbs

(9-10 kg)

10-12 lbs

(4.5-5 kg)

2.5” (65mm) 1-5

2.5” (65mm) 1-5

7-10

10-15

28-32

20-30

45-50

50-60

10-15

3-5

18-22

20-25

40-50

25-30

18-21

2-2.5 Hours

1-1.25 Hours

30-35 - 3 oz (85 g)

25-30 - 3 oz (85 g)

20-25 - 4 oz (115 g)

15-20 - 2 oz (55 g)

25-30 - 2 oz (55 g)

20-25 - 2 oz (55 g)

12-15 - 2 oz (55 g)

35-40 - 2 oz (55 g)

20-25 - 2 oz (55 g)

20-25 - 2 oz (55 g)

50-60 - 2 oz (55 g)

24 - 2 oz (55 g)

18-20 - 2 oz (55 g)

50-60 - 2 oz (55 g)

55-65 - 2 oz (55 g)

* Raw weight for Meatballs and Meatloaf includes hamburg and extenders and yields 2 oz. (55g) protein plus extenders or

3 oz. (85g) total portion.

OPERATION

18

Page 21

Cleaning & Preventative Maintenance

PREVENTATIVE MAINTENANCE

A good preventive maintenance program begins with the

daily cleaning procedure. The following paragraphs set

forth minimum preventive maintenance procedures that

must be completed periodically.

CLEANING

After each period of daily operation (more frequently as

required to maintain cleanliness), the cooker should be

thoroughly cleaned by completing the following steps:

1. Remove left- and right-side pan supports, bafes, and

drain screens by lifting up and off mounting studs.

Wash with a mild detergent. Rinse and set aside for

reassembly.

2. Wash cooking compartment interior using a mild detergent and water. Rinse and dry thoroughly.

3. Replace pan supports, bafes, and drain screens in

compartment and leave door open.

DRAINAGE

Cooking Compartment Drainage

The bottom of the cooking compartment is angled slightly

toward the rear of the unit. This assures that any condensate build-up or spills will be directed toward the drain

hole, which is located at the rear bottom center of the

cooking compartment. Any liquid exiting the cooking compartment runs down the cooking compartment drain tube

and into the drain line.

Drip/Spill Trough Drainage

The ST-10 Pressureless Steam Cooker has a drip/ spill

trough below the cooking compartment door. It will catch

any condensate gathering on the front of the unit when

the door is opened.

19

MAINTENANCE

Loading...

Loading...