Page 1

ST-10 CONVECTION STEAMER

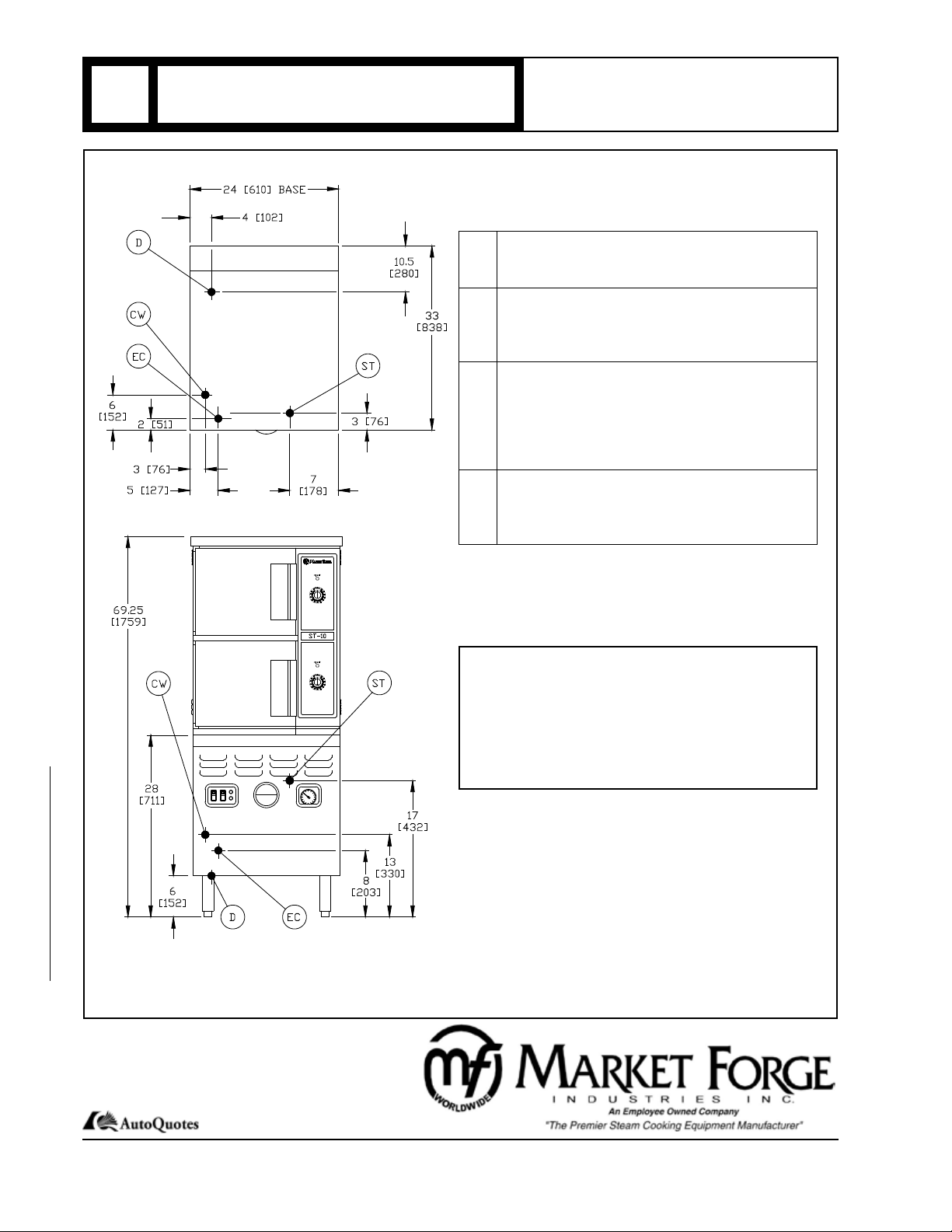

D

MODEL: □ ST-10D

SIZE: 24” x Wide x 69.25” High x 33” Front-to-Bac

DESCRIPTION:

Market Forge Model ST-10D direct connect convection

steam cooer. Will be integrally mounted on a cabinet

base containing direct steam connections.

The ST-10 will be of double-wall construction with 1”

(25mm) thic insulation between cooing compartments

and exterior walls, and will have two 18 gauge stainless

steel welded cooing compartments with coved internal

corners, and a 16 gauge stainless steel front panel.

Each cooking compartment on the ST-10 has a positive

slam action, eld-reversible door constructed of Type 304

stainless steel. Door latches are spring loaded. The inner

door gaset is a one-piece NSF-approved silicone rub

ber gaset. The cooing compartment is equipped with a

door interloc (switch) that shuts off steam to the cooing

compartment when the door is opened.

COOKER DIRECT CONNECT

(610mm Wide x 1759mm High x 838mm Front-to-Back)

JOB NAME: ________________________

ITEM NO.: _________________________

NO. REQUIRED: ____________________

SPEC SHEET: S-2478B

04/11

-

Each compartment will be equipped with a perforated

steam inlet bafe positioned for precise application of

high velocity steam across the surface of food. Controls

for each compartment will include a 60-minute load compensating timer with constant steam position, a steamer

ready indicator light, steam inlet solenoid valve, pressure

relief valve, vacuum breaer, and an automatic cold water

steam condenser system, and a removable drip trough.

Each compartment will be independently and auto-matically controlled by setting the cooing time on the 60minute timer. At the end of cooing time, indicator light

will turn off and a continuous signal will sound. Signal is

silenced by returning the timer to the OFF position.

Stainless steel cabinet base will match other Maret Forge

stainless steel equipment and enclose steam generator.

Base with stainless steel frame will be equipped with 6”

(152mm) stainless steel legs and adjustable bullet feet,

reinforced stainless steel counter-top, and stainless steel

lift-off front cover. A cold water condenser will automatically condense all exhausted steam into water before it is

released from the cooker and steam generator drain.

* The manufacturer reserves the right to modify materials and specications without notice.

COOKING CAPACITIES:

Each compartment will accommodate the following:

■ Eight 12” x 20” x 1” deep pans

■ Five 12” x 20” x 2 1/2” deep pans

■ Four 12” x 20” x 4” deep pans

OPERATION WILL BE BY:

Direct steam at a minimum of 15 PSI (1kg/cm2). Unit will

be equipped with ball oat trap to remove condensate

from incoming steam line and a 3/4” (19mm) IPS pressure

reducing valve which will reduce initial pressure of 20 to

50 PSI (1.3 to 3.5kg/cm2) to required 15 PSI (1kg/cm2)

operating pressure. Minimum BHP required: 3.0 BHP.

OPTIONAL AT EXTRA COST:

□ 12” x 20” x 1 perforated stainless steel pans

□ 12” x 20” x 2 1/2” perforated stainless steel pans

□ 12” x 20” x 2 1/2” solid stainless steel pans

□ 12” x 20” x 4” perforated stainless steel pans

□ 12” x 20” x 4” solid stainless steel pans

□ Digital countdown timer

□ Steam take off kit

10 Pan Convection Steam Cooker

FOOD SERVICE EQUIPMENT

Tel: (617) 387-4100 • Fax: 1-800-227-2659 (Ex. MA) • (617) 387-4456 (MA and Overseas)

E-Mail: CUSTSERV@mi.com • Website: www.mi.com

35 Garvey Street • Everett • MA • 02149

Page 2

D

ST-10 CONVECTION STEAMER

COOKER DIRECT CONNECT

Direct Connected

ST Steam Take-off - Connection for operations of

adjacent steam powered equipment. Requires

steam take-off kit (optional at extra cost).

CW Cold Water - 3/8” (10mm) N.P.T. female for cold

water to condenser. Cold water lines will have a

maximum of 50 PSI (3.5kg/cm2) and a minimum

of 25 PSI (1.8kg/cm2) water pressure

D

Drain - Pipe full 2” (50mm) N.P.T. female to ush

oor drain capable of receiving water owing at

a maximum rate of 5 gallons (19 liters) per minute. DO NOT MAKE SOLID CONNECTION

TO FLOOR DRAIN. INSTALL NO ELBOWS IN

DRAIN LINE.

EC

Electrical Connection - 120 VAC, 60 Hz, 1/2”

(13mm) conduit connection or equivalent. Use

wire suitable for at least 90°C.

Amp draw for cooer and boiler controls: 6 amps.

DETAILS & DIMENSIONS

SERVICE CONNECTIONS

SPEC SHEET: S-2478B

04/11

FOOD SERVICE EQUIPMENT

10 Pan Convection Steam Cooker

It is our policy to build equipment which is design certied by U.L., A.S.M.E., N.S.F., and C.S.A. However, a continuing program of product improvement

maes it necessary to submit new models to the agencies as they are developed and consequently not all models bear the appropriate agency labels at all times.

NOTE: The only available space to supply utilities to the

generator is the 6” (152mm) space between the oor and

the cabinet base. PVC & CPVC Pipe are not acceptable

materials for drains.

CAUTION: Before connecting water to this unit,

have water supply analyzed to make sure hardness

is no greater than 2.0 grains and pH level is within

the range of 7.0-8.5. Water which fails to meet these

standards should be treated by installation of a water conditioner. EQUIPMENT FAILURE CAUSED BY

INADEQUATE WATER QUALITY IS NOT COVERED

UNDER WARRANTY.

PRINTED IN U.S.A.

Tel: (617) 387-4100 • Fax: 1-800-227-2659 (Ex. MA) • (617) 387-4456 (MA and Overseas)

35 Garvey Street • Everett • MA • 02149

E-Mail: CUSTSERV@mi.com • Website: www.mi.com

Loading...

Loading...