Page 1

GAS TWIN GENERATOR

G

MODELS

ST10-2G - (2) five pan convection steamer with separate gas steam

generators

DESCRIPTION

Shall be a Market Forge Convection Steamer with an Individual Gas

Steam Generator for each cavity.

The steamer shall be constructed of a satin finish stainless steel type

304. The cooking chamber is a one piece all welded type 316 stainless

steel with coved corners. The heavy duty door shall have an inner liner

of stainless steel with a full perimeter gasket seal, an outer liner of one

piece all welded stainless steel, and a positive lock and seal mechanism

with spring release. Each compartment shall be provided with removable stainless steel pan supports. A stainless steel drip trough shall be

integrally connected to drain to collect condensate when the doors are

opened.

The control housing shall be constructed of stainless steel with a full

access removable panel. Each compartment shall have individual

controls which include an illuminated three way power switch (On/Off/

De-lime), a pilot ready light, a pilot cooking light, an ignition light, a 60

minute electric timer which sounds an audible signal at the end of the

cooking cycle, solid state generator controls and electronic ignition for

each generator. Steam flow to the cooking chamber shall be cut off when

the door is opened and reactivated when the door is closed.

The steamer shall be mounted on a 24” cabinet base constructed of #4

Two Compartment Steamer

stainless steel with exterior hinged door and 6” (152mm) stainless steel

FOOD SERVICE EQUIPMENT

legs with adjustable flanged feet. The cabinet shall house the two generators, automatic blowdown and drain box.

STANDARD FEATURES:

De-lime mode power setting

Constant Steam

Automatic blow-down

Split water lines

Thermostatically controlled drain

Single drain connection

Electronic ignition

(4) 6” flanged feet

Redundant controls and generator for each compartment

All stainless steel constructed steam generator(s)

Safety relief valve

Left side access panel

De-liming ports on front of each generator

OPERATION SHALL BE BY:

190,000 BTU Gas fired, stainless steel steam generator(s) operating at 0

psi (0 kg/cm2) with controls equipped for operation on 120V, 1 pH, 60 Hz.

Natural gas.

L.P. gas.

CONVECTION STEAMER

JOB NAME: ___________________________

ITEM NO.: ____________________________

NO. REQUIRED: _______________________

CAPACITY

PAN DEPTH

1” 2-1/2” 4” 6”

20 10 6 4

SHIPPING WEIGHT

700 lbs (318 kg)

OPTIONS & ACCESSORIES

(at additional charge)

Pans & Covers

12” x 20” pan cover

12” x 20” x 1” solid pan

12” x 20” x 1” perforated pan

12” x 20” x 2-1/2” solid pan

12” x 20” x 2-1/2” perforated pan

12” x 20” x 4” solid pan

12” x 20” x 4” perforated pan

12” x 20” x 6” solid pan

12” x 20” x 6” perforated pan

Prison package, includes lockable stainless steel hinged

control cover, tamper proof screws

KleenSteam Filter System

Quick disconnect water lines ( 2) required

44 Lakeside Avenue, Burlington, VT 05401 USA • Tel: (802) 658-6600 • Fax: (802) 864-0183

www.mfii.com

Page 2

G

GAS TWIN GENERATOR

CONVECTION STEAMER

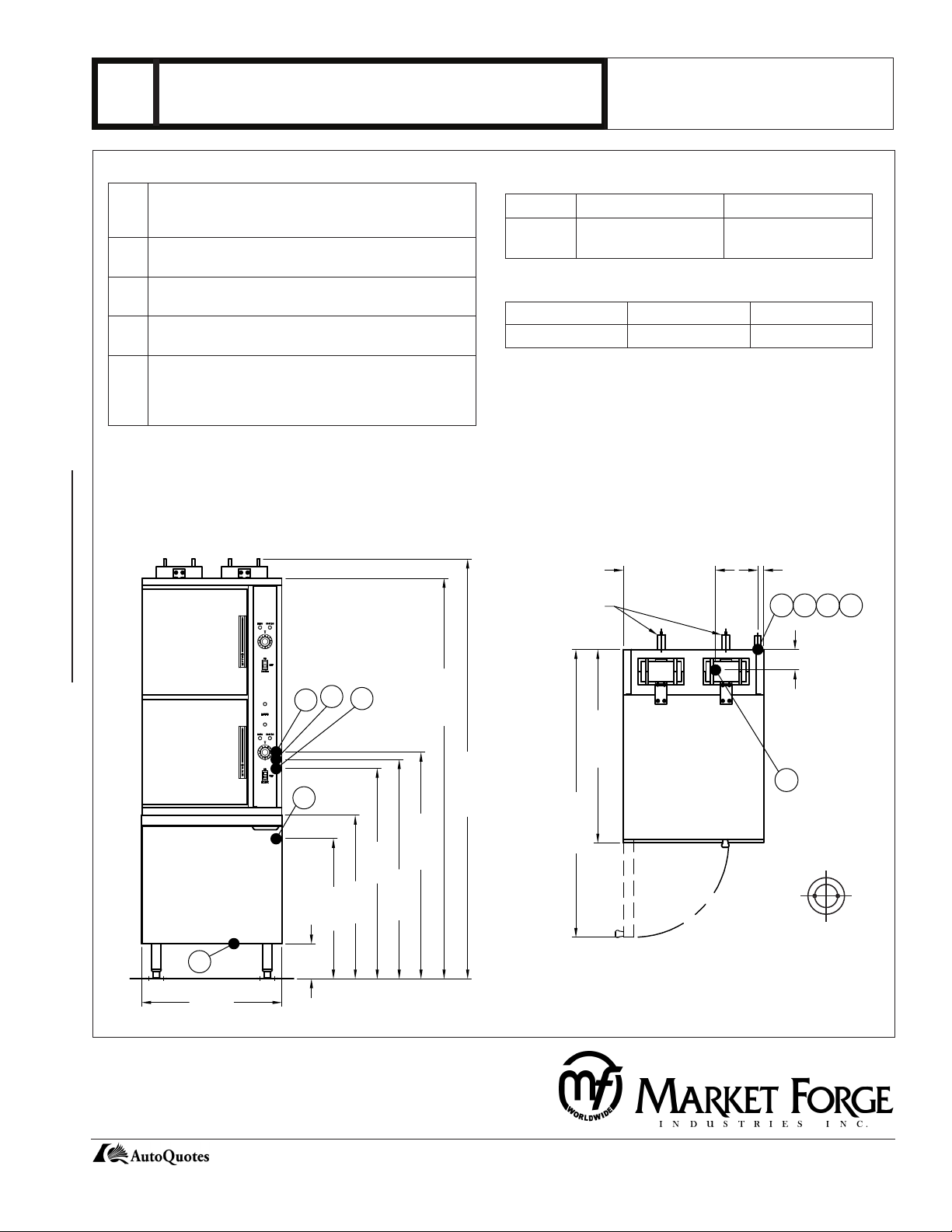

DETAILS & DIMENSIONS

SERVICE CONNECTIONS

EC Electrical Connection - 120V, 60 Hz, 1 pH with ground.

Unless otherwise specified. Furnished with a 6 foot cord

with 3 prong plug. Max 4.0 AMPS. 56 kW.

G Gas Connection - 3/4” (19mm) NPT Supply line

GAS SPECIFICATIONS

BTU/HR. NATURAL GAS (W.C.) PROPANE GAS (W.C.)

190,000 6” - 14”

(152-356mm)

12” - 14”

(305-356mm)

required.

C Condensing Cold Water - 3/8” (10mm) OD Tubing at

25-50 PSI (1.8-3.5 kg/cm2)

G1 Generator Water - 3/8” (10mm) OD Tubing at 25-50

PSI (1.8-3.5 kg/cm2)

D Drain - 2” (51mm) NPT pipe to open floor drain. DO

OVEN CLEARANCES

LEFT RIGHT BACK

0 0 6” (152mm)

* Use on non-combustible floors only.

NOT MAKE SOLID CONNECTION TO FLOOR DRAIN.

Max Length before open air gap opening: 24” (610mm)

NO BENDS OR ELBOWS.

IMPORTANT: Before connecting water to this unit, have water supply analyzed to make sure that hardness is no greater than 2.0 grains

per gallon and a pH level is within the range of 7.0–8.5. Water which fails to meet these standards should be treated by installing a filter

or conditioner. Equipment failure caused by inadequate water quality is not covered under warranty. Do not make solid connection to floor

drain. PVC and CPVC pipe are not acceptable materials for drains.

DIMENSIONS ARE IN INCHES [MM]

15.75 [400]

SAFETY RELIEF

VALVES

1 [25]

G1 C

EC

G

Two Compartment Steamer

FOOD SERVICE EQUIPMENT

D

24 [610]

C

6 [152]

EC

28 [711]

24 [610]

68.5 [1740]

33.13 [841]

71.88 [1825]

49.25 [1251]

38.75 [984]

36 [914]

37.5 [953]

G1

G

The manufacturer reserves the right to modify materials and specifications without notice.

3.5 [89]

D

REAR FLANGED

FOOT DETAIL

2 EQUALLY SPACED

Ø7/16” [11] HOLES

ON 2.5 [63] B.C.

PRINTED IN U. S. A.

SPEC SHEET: 14-0101 Rev B (3/15)

44 Lakeside Avenue, Burlington, VT 05401 USA • Tel: (802) 658-6600 • Fax: (802) 864-0183

www.mfii.com

Loading...

Loading...