Page 1

SIRIUS II GAS CONVECTION

G

MODELS: □ Sirius II - 8

□ Sirius II - 10

□ Sirius II - 12

DESCRIPTION: Sirius II is a Market Forge convection/

circulating boilerless steam oven with automatic water-ll, featuring internally preheated water for fast recovery, clean water reservoir system, and rear drain.

Sirius II models are efciently heated by a burner external to the water reservoir. Sirius II steamers use

27,000 BTU per compartment.

Cooking Compartment: Operation occurs from steam

generated in the cooking compartment. The walls

and ceiling of the cooking compartment are heated to

reduce steam condensing on these surfaces and to

reheat and revitalize partially condensed steam. The

steamer cavity has a convection fan that increases

steam velocity and provides efcient steam distribution throughout the cavity by pulling steam past

the cooking pans, then forcing it against the heated

cooking chamber walls to be reheated. The cooking

compartment is constructed of cast aluminum with a

food-grade non-stick hard anodized nish. The cooking compartment acts as a heat sink, allowing for heat

retention, quick recovery, and reduced energy con-

sumption.

STANDARD FEATURES:

Controls:

4-Position Cooking Mode Selector: Off and Three Cook-

•

ing Positions

Clean Probe Indicator Light

•

Heating Indicator Light

•

60-Minute Timer

•

Construction:

304 Stainless, #4 Finish (Cabinet)

•

356 Aluminum Cast Cooking Compartment with Hard-

•

Anodized Finish

Other:

Manual Front Drain Valve

•

Internally Preheated Incoming Water for Quick Recovery

•

Redundant Safety Systems

•

UL/CUL Safety & Sanitary (NSF-4)

•

One-Year Parts and Service

•

Controls: Standard controls include three cooking

modes that are preset at the factory or can be set to

custom specications up to 230oF (110oC). A Clean

Probe indicator light, heating indicator light and a 60-

minute mechanical timer are included. The control

panel pulls out in drawer fashion for easy service access.

BOILERLESS STEAMER

JOB NAME: ________________________

ITEM NO.: _________________________

NO. REQUIRED: ____________________

Sirius II - 10 Sirius II - 12Sirius II - 8

Doors: The door is insulated. Safety shut-offs are pro-

vided by a hidden magnetic door switch, low water/

high limit heat switch, temperature probe, water sensing probe and water-ll timer.

Characteristics:

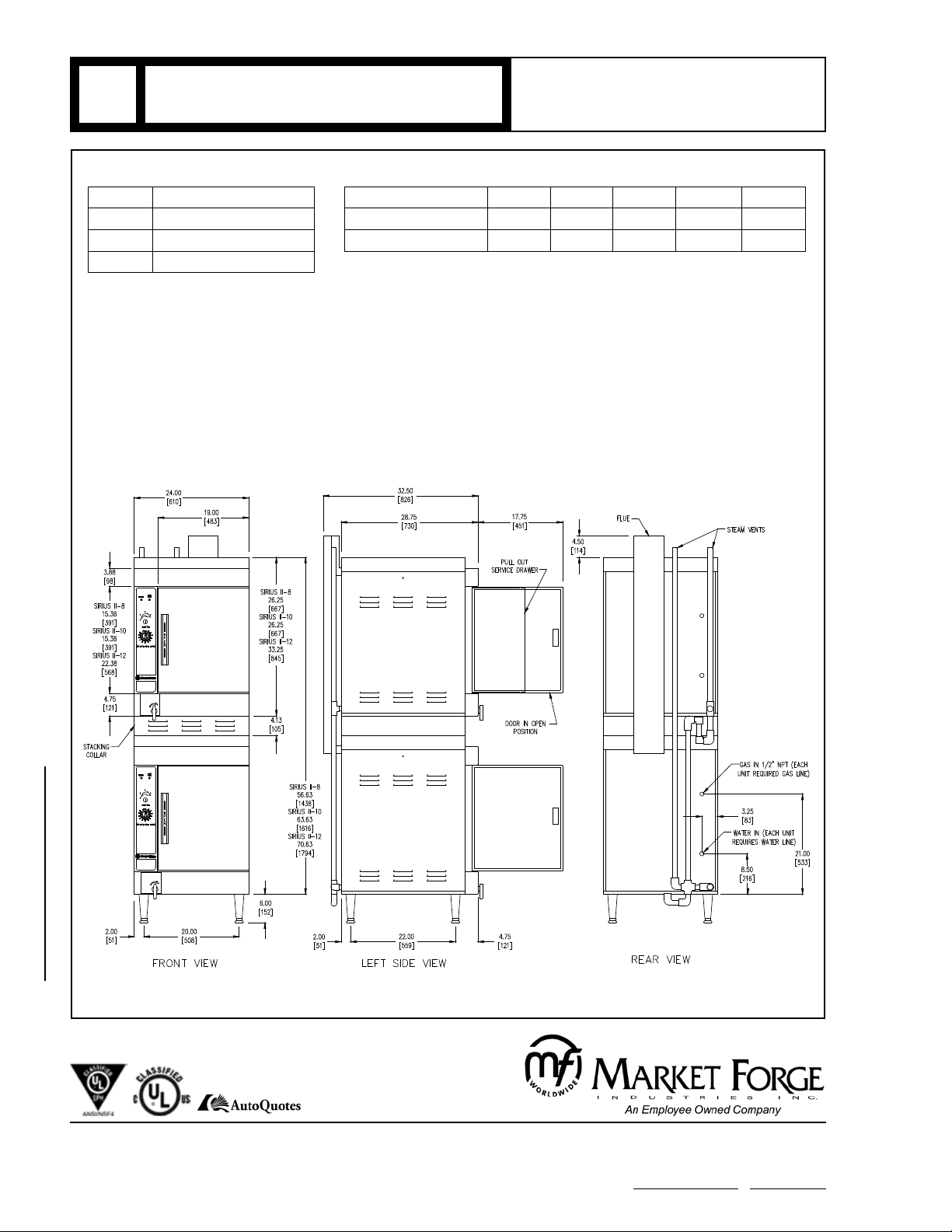

Dimensions Sirius II-8 Sirius II-10 Sirius II-12

Overall Height 56.63” 63.63” 70.63”

+ Legs

Overall Width 24” 24” 24”

Overall Depth 28.75” 28.75” 28.75”

+ Door Latch

Doors Open 90

Capacity:

Pans Sirius II-8 Sirius II-10 Sirius II-12

12” x 20” x 2.5” 8 10 12

12” x 20” x 4” 4 6 8

12” x 20” x 6” 2 3 4

OPTIONAL AT ExTRA COST

PP-4 (92-1004) Prison Package (per compartment)

□

PP-6 (92-1005) Prison Package (per compartment)

□

HWS-4 (92-1002) Left Side Heat and Water Shield

□

HWS-6 (92-1003) Left Side Heat and Water Shield

□

CA HD (92-1000) Casters (set of 4, 2 with Brakes)

□

SKG (92-1017) Stacking Kit

□

5” Heavy-Duty Swivel Casters with Brakes

□

STSS (92-1015) Stationary 12” High Stand (for 6 & 8-pan)

□

56.63”+ 6-9” 63.63”+ 6-9” 70.63”+ 6-9”

28.75”+ 1.5” 28.75”+ 1.5” 28.75”+ 1.5”

o

46.5” 46.5” 46.5”

:

SPEC SHEET: S-6060A

05/12

FOOD SERVICE EQUIPMENT

Gas Boilerless Steamer

The manufacturer reserves the right to modify materials and specications without notice.

35 Garvey Street • Everett • MA • 02149-4403

Tel: (617) 387-4100 • Toll Free: (866) 698-3188

Fax: (617) 387-4456 (MA and Overseas) • Fax: (800) 227-2659 (Ex. MA)

E-mail: custserv@mi.com • www.mi.com

Page 2

G

SIRIUS II GAS CONVECTION

BOILERLESS STEAMER

DETAILS & DIMENSION

SPECIFICATIONS

Model Sirius II - 8, 10 & 12

Voltage 120V

BTU’s 27,000

Gas NPT 1/2”

Gas Pressure (natural) inlet:

3.5” WC required, not to exceed 13.5”

Gas Pressure (propane) inlet:

9” WC required, not to exceed 13.5”

Connections for all Sirius II sizes

Water in: 3/4” male garden hose

•

Drain out: 1” FNPT

•

Gas pipe size: contact local authority

•

having jurisdiction.

SPEC SHEET: S-6060A

05/12

Crated Dim. & Wts. Height Width Depth Cu.Ft. Lbs.

Sirius II - 8 65.5” 34.25” 43” 55.4” 450

Sirius II - 10 72.5” 34.5” 43” 61.3” 475

Sirius II - 12 79.5” 34.5” 43” 67.2” 500

NOTES:

Each single compartment has a separate rear exiting drain plumbed directly

•

into the stacked steamers main drain/vent line.

Each compartment, stacked or single, requires a separate power and gas con-

•

nections.

Each compartment, stacked or single, requires a separate water connection.

•

Water pressure should be set to ll reservoir in 45 seconds.

•

4” clearance left mandatory, right and rear is recommended.

•

Location near a oor drain is recommended.

•

Stacked units require 4” stacking collar between units (included when 8-, 10-,

•

or 12-pan units are ordered).

Single and stacked units require hood for ventilation of ue products.

•

Gas Boilerless Steamer

FOOD SERVICE EQUIPMENT

It is our policy to build equipment which is design certied by U.L., C.S.A. and N.S.F. However, a continuing program of product improvement makes it necessary

to submit new models to the agencies as they are developed and consequently not all models bear the appropriate agency labels at all times.

PRINTED IN U. S. A. 35 Garvey Street • Everett • MA • 02149-4403

Tel: (617) 387-4100 • Toll Free: (866) 698-3188

Fax: (617) 387-4456 (MA and Overseas) • Fax: (800) 227-2659 (Ex. MA)

E-mail: custserv@mi.com • www.mi.com

Loading...

Loading...