Page 1

OWNER’S MANUAL

MARINE STEAM-IT

ELECTRIC COUNTER MODEL

MODEL: ● SB-ST-E

WARNINGS:

BE SURE TO GROUND THE COOKER CHASES FROM

THE GROUND TERMINAL BOX TO THE OUTSIDE

GROUND. REFER TO WIRING DIAGRAM C95-3914.

DO NOT OPEN THE DRAIN VALVE WHILE THE STEAM

COOKER IS OPERATING. PREMATURE OPENING MAY

RESULT IN SCALDING OF THE OPERATOR.

DO NOT LEAVE HAND ON HANDLE.

TO PREVENT SCALDING, THE OPERATOR SHOULD

KEEP HANDS OFF THE DOOR HANDLE WHILE EXCESS STEAM/VAPOR IS ESCAPING.

THE ELECTRIC POWER SUPPLY MUST BE DISCONNECTED PRIOR TO PERFORMING ANY MAINTENANCE/REPAIR WORK.

CAUTION:

HELP PREVENT PITTING OF THE ALUMINUM INTERIOR. DO NOT USE STRONG DETERGENT OR ABRASIVE CLEANERS.

NOTES:

TO ASSURE A PROPER PRESSURE SEAL, THE DOOR

DISTRIBUTION STATEMENT

THIS PUBLICATION IS REQUIRED FOR OFFICIAL USE FOR ADMINISTRATIVE OR OPERATING PURPOSES. DISTRIBUTION IS LIMITED

TO U.S. GOVERNMENT AGENTS ONLY. OTHER

REQUEST FOR THIS DOCUMENT MUST BE REFERRED TO COMMANDER, NAVAL SEA SYSTEMS COMMAND, SEA 09, WASHINGTON, DC

20362.

GASKET MUST BE FREE OF SOIL, SCALE AND

BREAKS.

SHOULD THE COOKING CYCLE BE STARTED WITH

INSUFFICIENT WATER IN THE COMPARTMENT, THE

SAFETY ACTION OF THE LOW WATER CUT-OFF WILL

SHUT THE UNIT DOWN. WHEN ADEQUATE WATER

(TOTAL: 6 QUARTS) IS ADDED TO THE CHAMBER,

THE COOKING CYCLE MAY BEGIN AGAIN.

FEDERAL SPEC S-C-1474B S6161-PA-FSE-010-/38379

TYPE SC1474-3106MA1 0910-LP-436-6200

44 Lakeside Avenue, Burlington, Vermont 05401 USA

Telephone: (802) 658-6600 Fax: (802)864-0183

www.mi.com PN 14-0299 Rev B (12/15)

© 2015 - Market Forge Industries Inc.

Page 2

S6161-PA-FSE-010-/38379

0910-LP-436-6200

DISTRIBUTION STATEMENT:

THIS PUBLICATION IS REQUIRED FOR OFFICIAL USE FOR ADMINISTRATIVE OR OPERATIONAL PURPOSES. DISTRIBUTION IS LIMITED TO U.S. GOVERNMENT AGENTS ONLY.

OTHER REQUEST FOR THIS DOCUMENT MUST BE REFERRED TO COMMANDER, NAVAL

SEA SYSTEMS COMMAND, SEA 09, WASHINGTON, DC 20362.

TABLE OF CONTENTS

INSTALLATION

SERVICE CONNECTIONS..................................1

ELECTRICALLY OPERATED ............................. 1

CERTIFICATIONS ..............................................1

UNPACKING & ASSEMBLY ...............................1

ELECTRICAL CONNECTIONS ..........................2

TERMINAL BOX LOCATION (FIG. 1) ................. 2

INSTALLATION CHECK-OUT ............................2

INITIAL CONTROL SETTINGS ..........................2

COOKER CHECK-OUT ...................................... 2

SHUTDOWN PROCEDURE ...............................2

PRINCIPLES OF OPERATION

GENERAL ........................................................... 3

OPERATION SEQUENCE .................................. 3

PRELIMINARY PROCEDURES .........................3

WIRING DIAGRAM (FIG. 2) ................................4

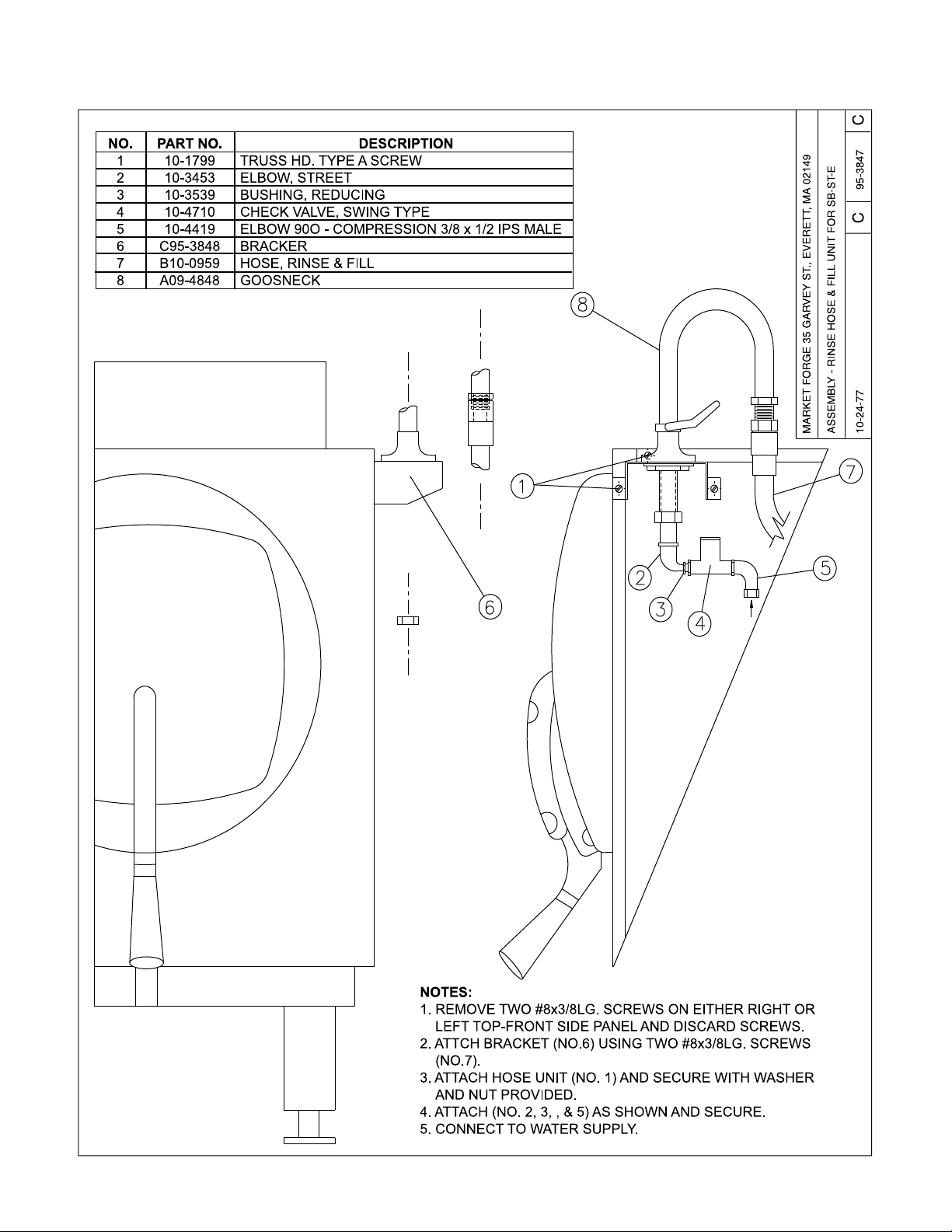

HOSE ASSEMBLY (FIG. 3) ................................ 5

PREHEATING ..................................................... 6

FACTS ON PARADE .......................................... 6

RECOMMENDED COOKING TIMES ................. 7

THE FLUE ..........................................................10

TO REMOVE THE FLUE .................................... 10

STEAM GAUGE .................................................10

STEAM TRAP ...................................................... 10

HOW IT WORKS ................................................10

TROUBLE TEST AND REMEDIES .....................10

FLUE REMOVAL ITEMS (FIG. A) ....................... 10

MAINTENANCE

PREVENTIVE MAINTENANCE .......................... 11

DOOR ASSEMBLY ............................................. 11

GASKET REPLACEMENT .................................11

DOOR SEAL TENSION ADJUSTMENT .............. 12

DOOR LIFT SPRING REPLACEMENT .............. 12

STEAM EXHAUST VALVE & TRAP

REPLACEMENT ................................................. 12

DAILY CLEANING ..............................................12

WEEKLY CLEANING .......................................... 12

CLEANING EXHAUST SILENCER .....................13

CLEANING TROUBLE-SHOOTING GUIDE

(STAINLESS STEEL) ..........................................13

ILLUSTRATED PARTS LIST

COOKER COMPARTMENT (FIG. 7) .................. 14

DOOR HANDLE ASSEMBLY (FIG. 8) ................ 17

THE COOKER DOOR ASSEMBLY .................... 18

DOOR ASSEMBLY (FIG. 9) ................................ 18

FULCRUM & DRAIN ASSEMBLY ....................... 18

ROLLER ASSEMBLY .......................................... 18

OLD STYLE FULCRUM & DRAIN

ASSEMBLY (FIG. 10) .........................................19

NEW STYLE FULCRUM & DRAIN

ASSEMBLY (FIG. 11) .......................................... 19

SAFETY VALVE .................................................. 19

CHECKING SAFETY VALVE .............................. 19

EXHAUST VALVE (FIG. 12) ...............................20

NEW EXHAUST VALVE, BUILT AFTER

JULY 1983 (FIG. 13) ............................................ 21

TROUBLE-SHOOTING

OLD STYLE BUILT PRIOR TO

SEPTEMBER 1980 (FIG. 14) .............................22

ELEMENT CONTROL SWITCH .........................22

HOW IT WORKS ................................................22

DIAL ADJUSTMENT ........................................... 22

NEW STYLE BUILT AFTER

SEPTEMBER 1980 (FIG. 15) .............................22

RECALIBRATING ELEMENT CONTROL

SWITCH .............................................................. 22

PRESSURE CONTROL SWITCH

(BARKSDALE) .................................................... 22

OPERATING PRESSURE ADJUSTMENT

(BRAKSDALE) .................................................... 22

RECALIBRATING PRESSURE CONTROL

SWITCH .............................................................. 23

LOW WATER CUT-OFF .....................................23

HOW IT WORKS ................................................23

TIMER ................................................................. 23

TROUBLE TEST & REMEDIES .......................... 23

TIMER CONTROL SWITCH ................................ 23

HOW IT WORKS ................................................23

DIAL ADJUSTMENT ........................................... 23

RECALIBRATING TIMER CONTROL

SWITCH ...............................................................23

PILOT LIGHT ...................................................... 23

TROUBLE-SHOOTING GUIDE .......................... 24

i

Page 3

INSTALLATION

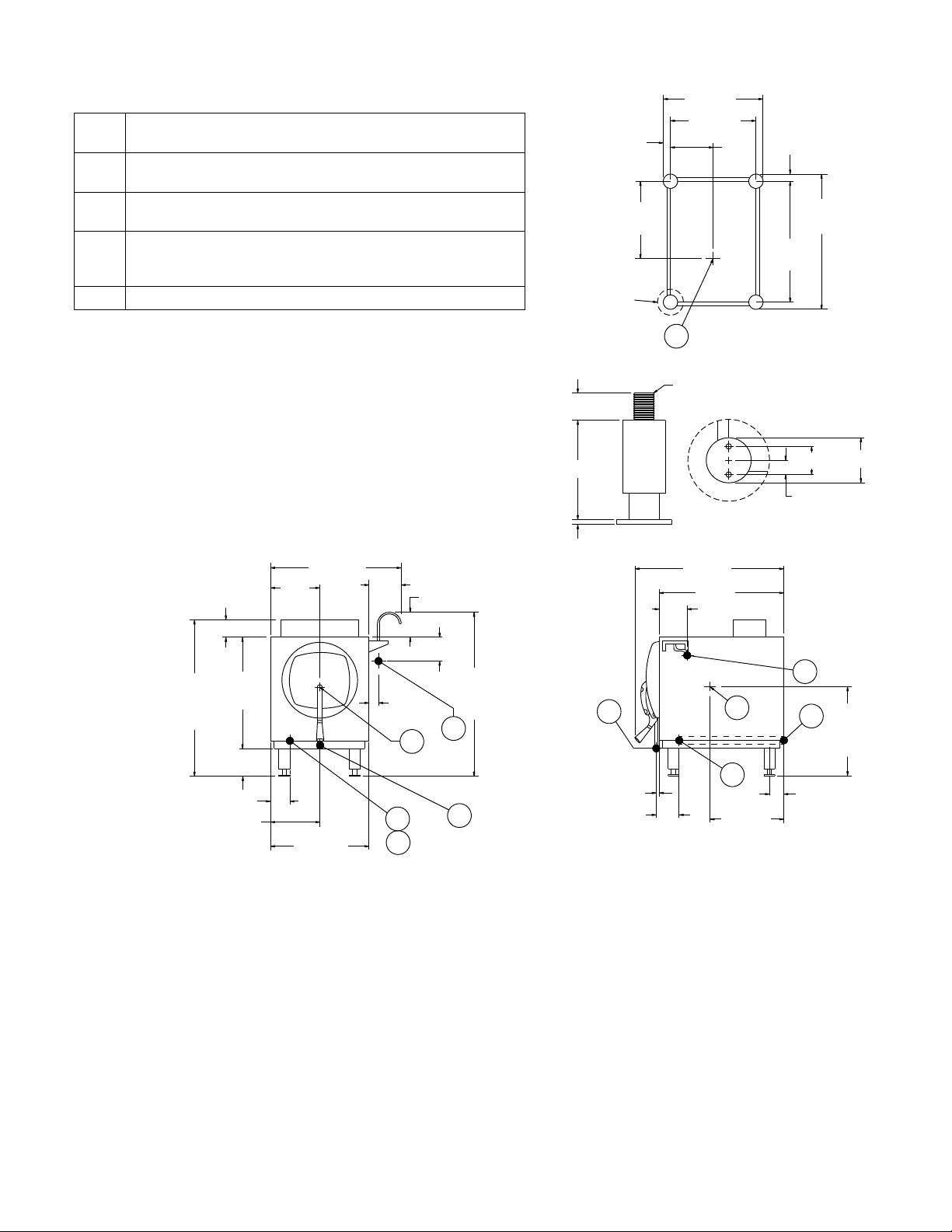

SERVICE CONNECTIONS

EC Electrical Connection - Connection for incoming power supply

wires on terminal block

EP Power Supply - 1-1/4” threaded access hole for power supply wires.

Use wire suitable for at least 90°C. Nominal amps per line.

D Drain - 1/2” 13mm O.D. tubing. Air break required for drain connec-

tion supplied by others

CW Cold Water - 3/8” 10mm O.D. tubing connection to fill hose. Cold

water line shall have a max of 50 PSI 3.5kg/cm2 and a min of 25 PSI

1.7kg/cm2 water pressure

CG Center of Gravity - with flanged feet

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water quality must be

within the following general guidelines.

TDS: 40-125 ppm Hardness: 35-100 ppm Chlorine: <0.2 ppm

Silica: <13 ppm Chlorides: <25 ppm

Chloramine: <0.2 ppm pH: 7.0 - 8.5

The best defense against poor water quality is a water treatment system

designed to meet your water quality conditions.

Appliance to be installed with backflow protection according to federal, state or

local codes.

DIMENSIONS ARE IN INCHES [MM]

23.75 [603]

3.25

[83]

9.88

[251]

5

[127]

4.38 1[20]

5.25 [133]

1 [25]

6 [152]

0.38 [3]

1.5 [38]

SEE

DETAIL A

MARINE FOOT

12.8

[325]

17.88 [454]

14.88 [378]

CG

BOTTOM VIEW

1/3-13THD

31.5 [800]

25 [640]

6.25

[158]

7.94

[378]

DETAIL A

1.5

[38]

21.13

[536]

24.13

[612]

2.13 [54]

1.06 [27]

CW

3 [76]

23 [584]

31.75 [806]

6 [152]

3.25 [83]

9.38 [240]

18.75 [480]

1.25 [32]

CG

EP

EC

CW

D

UNPACKING AND ASSEMBLY:

The Steam-It cooker is shipped in a carton with protective

padding and mounted on a wooden pallet. Carefully remove the carton, padding and the bolts securing the unit

to the wooden pallet. Inspect assemblies as follows:

1. Inspect unit overall for dents or deformations in stainless steel cabinet enclosures.

2. Make sure visible attaching hardware for all assemblies are not missing or damaged.

3. Inspect timer, indicator light, RESET switch and pressure gauge to see they are not damaged.

4. Install pan supports so that the horizontal keyhole

is at the rear of the cooking chamber and so that

the ange and embossments face the middle of the

chamber.

32.25 [819]

D

0.75 [19]

3 [76]

CG

Conduit

EC

14.38 [375]

EP

16.88 [429]

2.5 [69]

5. Install the set (4 each) of Marine anged feet (3” di-

ameter anged plates) so the steam cooker can be

mounted on a counter top (refer to spec sheet S-

2160) for anged feet details.

6. Install the part number 95-3849 rinse and ll hose unit

on the shipboard steam cooker. Refer to the enclosed

drawing C95-3897 Rev A for installation details.

NOTE: The cooker is carefully inspected and packaged

before leaving the factory. If there are missing components or unit is damaged, notify the carrier immediately.

Should repairs be required, a network of authorized service agencies is available to assist with prompt service. If

necessary, please contact:

1

Page 4

INSTALLATION

Product Service Department Market Forge

Toll Free: (866) 698-3188

Parts, Service and Availability Toll Free No.:

(888) 259-7076

custserv@mi.com, www.mi.com

The Model and serial numbers must be referenced when

corresponding with Market Forge. The data plate containing the serial number pertaining to the equipment is located on the front top of the cabinet.

ELECTRICAL CONNECTION:

The electrical connection may be made at the terminal

box located at the lower left side of the Steam-It removing

the small covering panel (see gure 1 below, and service

connections on previous page).

FIG. 1

REMOVE THIS

PLATE TO ELECTRICAL

CONNECTION

Power input is 12 kW at 208, 236 or 440 Volt, 60 cycle

A.C. Equipment is adaptable for single ir three phase. Unit

must be grounded. Wires should be brought up through

conduit at bottom of cooker (see wiring diagram c95-3914

Rev A (440V/6pH/60Hz) for instructions on making connection. Unit must be fused separately.

NOTE: Refer to the spec sheet, side 2 on page 2 for the

complete list and location of the required service connection and electrical details.

WARNING: BE SURE TO GROUND THE COOKER

CHASES FROM GROUND TERMINAL BOX TO AN

OUTSIDE GROUND. REFER TO WIRING DIAGRAM

C95-3914 REV A ENCLOSED. ALL RECOMMENDED

SAFETY PRECAUTIONS SHOULD BE OBSERVED

WHEN CONNECTION THIS UNIT TO THE EXISTING

POWER SUPPLY.

INSTALLATION CHECK-OUT:

After the Steam-It cooker is completely assemblies and

properly located with electrical supply connected, the

cooker must be given a thorough checkout before being

put into cooking operation.

Before making this checkout the operator must be thoroughly familiar with the operating procedures in Section

3 and with the function of each control described in principles of operation in Section 3. Reference Figure 4 for

identication of controls required in the following procedures. If the unit fails to perform as described below, con-

sult the trouble shooting guide for corrective action.

INITIAL CONTROL SETTINGS:

Before beginning cooker checkout procedures, perform

the following steps:

1. Check to see that the timer is off.

2. Visually check interior of cooking compartment and

remove any materials, papers, etc. Check to see that

pan supports are properly installed (refer to principles

of operation in Section 3, step 5) and secured.

3. Check pressure gauge to see that it registers zero

pounds.

COOKER CHECK-OUT:

The cooker checkout procedures are as follows:

1. Secure the drain valve (refer to operating instruc-

tions S-202B gure No. 4 on page 7) then pour six

(6) quarts of water into the steam-it cooking compartment through the door opening.

WARNING: BE CERTAIN THE DRAIN VALVE IS

CLOSED AND DO NOT OPEN IT WHILE THE UNIT

IS OPERATING, PREMATURE OPENING MAY RESULT IN’ SCALDING OF’ THE OPERATOR.

2. Close the door and lock in position by placing the

tongue of the door lock under the roller on the drain

casting and pressing downward until door lock comes

to a rm stop. This lock makes the initial seal. (When

steam pressure builds up in the compartment it will

force the door to a tighter closed position.)

3. Turn the Steam-It en. by setting the timer to the desired cooking time. Observe pressure increase indicated by pressure gauge.

4. At the close of the preset cooking period, the timer

pointer will stop at the “0” position on the dial. This

will shut down the Steam-It and automatically open

the exhaust valve. The Buzzer will continue to sound

until the dial pointer is manually turned to the “OFF”

position.

5. Observe that the indicator light goes out when timer is

at the “O-minute” position. Check the pressure gauge

to see that the pressure reads zero. The door will not

open while there is steam pressure working against it

from wi thin the cooking compartment. The door must

be kept locked until the cooking cycle has completely

nished, then the door opened to allow vapor to clear.

Shut off gas supply by closing the gas shutoff valve.

SHUTDOWN PROCEDURE:

No special shutdown procedures are required with the exception that the door is left open, timer must be in the OFF

position and the gas supply valve closed, (consult local

codes for daily shut-off requirement.

NOTE: Before using the Steam-It for cooking, it is recommended that checkout operations be performed 2 or 3

times in order to determine that. it is working properly and

to insure cleanliness of the cooking compartment.

2

Page 5

PRINCIPLES OF OPERATION

PLEASE READ CAREFULLY THE FOLLOWING INFORMATION AND THE OPERATING INSTRUCTIONS ON

THE FOLLOWING PAGES.

CAUTION: The model SB-ST-E Steam-It pressure

cooker cylinder is constructed of a corrosion resistant alclad aluminum alloy. The protective properties of this material afforded to the interior portion of, the cylinder which

is exposed to water may be destroyed by allowing a lm

to form. Such a lm can be caused by salt. or other con-

taminants in the water. If the water supply is known to be

hard or corrosive, a source of treated water should be

used. Corrosion may also occur if water is not drained

daily. Do not use distilled water.

NOTE: Market Forge will not be responsible for damage

resulting from the use of hard or corrosive water, from

failure to drain the unit daily, or from inadequate cleaning

procedures.

GENERAL:

The model SB-ST-E Marine Electric Steam-It pressure

cooker (15 PSI operation) consists of one (1) cooking compartment into which pans of food product are

loaded through an inwardly opening door. The self-con-

tained cooker is tted with electric heating elements for

440V/3PH/60HZ operation (16 amps) rated at 12KW impute

OPERATION SEQUENCE:

With water placed in the Steam-It to the recommended

six quart level and the door rmly locked to make a tight

seal, a cooking cycle will automatically be performed with

the act of setting the timer to the length of cooking time

desired. The automatic sequence of operation is:

STEP 1 Upon setting the timer, a current ows to: The

exhaust valve solenoid, activating it to close the exhaust

valve: The element pressure control switch, which relays

a current ow to the contactor coil causing the contactor to close and direct electricity to the heating elements:

The cooking cycle light, which remains in circuit while the

heating elements are on.

STEP 2 As steam is produced within the cooking cylinder,

trapped air escapes through the steam trap. The steam

trap is induced to close thermostatically when live steam

fully replaces the trapped air passing through it. Freeventing will automatically cease and cooking cylinder will

become steam-tight. A build-up of cooking cylinder steam

pressure will occur.

STEP 3 When the steam pressure build-up reaches 10

PSI, the timer control switch will activate the timer to start

its timing cycle.

STEP 4 When the steam pressure build-up reaches 14

PSI, the element control switch will cut off the current ow

to the contactor, causing it to open and cut off electricity

to the heating elements. When cooling causes the pressure to drop to 13 PSI, the element control switch will

again activate the contactor to close and restore the ow

of electricity to the heating elements. Thus, by controlling

the contactor to open and close intermittently, the element

control switch, in effect, maintains the cooking cylinder

steam pressures between 13 and 14 PSI.

STEP 5 (Timer reaches “Zero” position) When the timer

reaches “Zero” (the end of the cooking cycle), a circuit

is completed to the buzzer allowing it to sound while the

circuit t to the pilot light is broken. The steam exhaust

valve will open and the cooking chamber is automatically

exhausted of steam. The buzzer will continue to sound

until the timer knob is turned to the “Off” position. The

door will not open while there is steam pressure working

against it from within the cooking cylinder. The door must

be kept locked until the cooking cycle has completely nished, then open the door, allow a second or two for the

vapor to clear and remove the foods.

PRELIMINARY PROCEDURES:

1. Ensure that electric supply is connected and operating at until See Installation Instructions.

2. Close drain valve (g. 4, No. 3) by turning valve handle Clockwise.

3. Hang pan supports (g. 4, No. 2) on pan support

studs (cylinder side walls). The horizontal keyhole

on the support should be at rear or compartment and

vertical keyhole near front.

4. Pour approximately six quarts of water directly into

Steam-It cylinder.

NOTE: In geographical locations where a high amount

or lime and alkaline (salt-lime substance) deposits are

present in water Supply, add two tablespoons or vinegar

directly into six quarts of water in Steam-It compartment

prior to starting cooking cycle. It more water is added to

maintain required level, an occasional table Spoon of vinegar may be added as well, in order to compensate for

new mineral deposits fresh water.

CAUTION: A high degree or mineral salts in water can

cause pitting of cooking compartment unless above directions (See NOTE) are followed; the cooking compartment thoroughly cleaned and drained each night; and the

door left open. Also, go not scour cylinder With abrasive

cleanser.

WARNING: DO NOT OPEN DRAIN VALVE WHILE

UNIT IS OPERATING. PREMATURE OPENING MAY

RESULT IN SCALDING OF OPERATOR.

3

Page 6

PRINCIPLES OF OPERATION

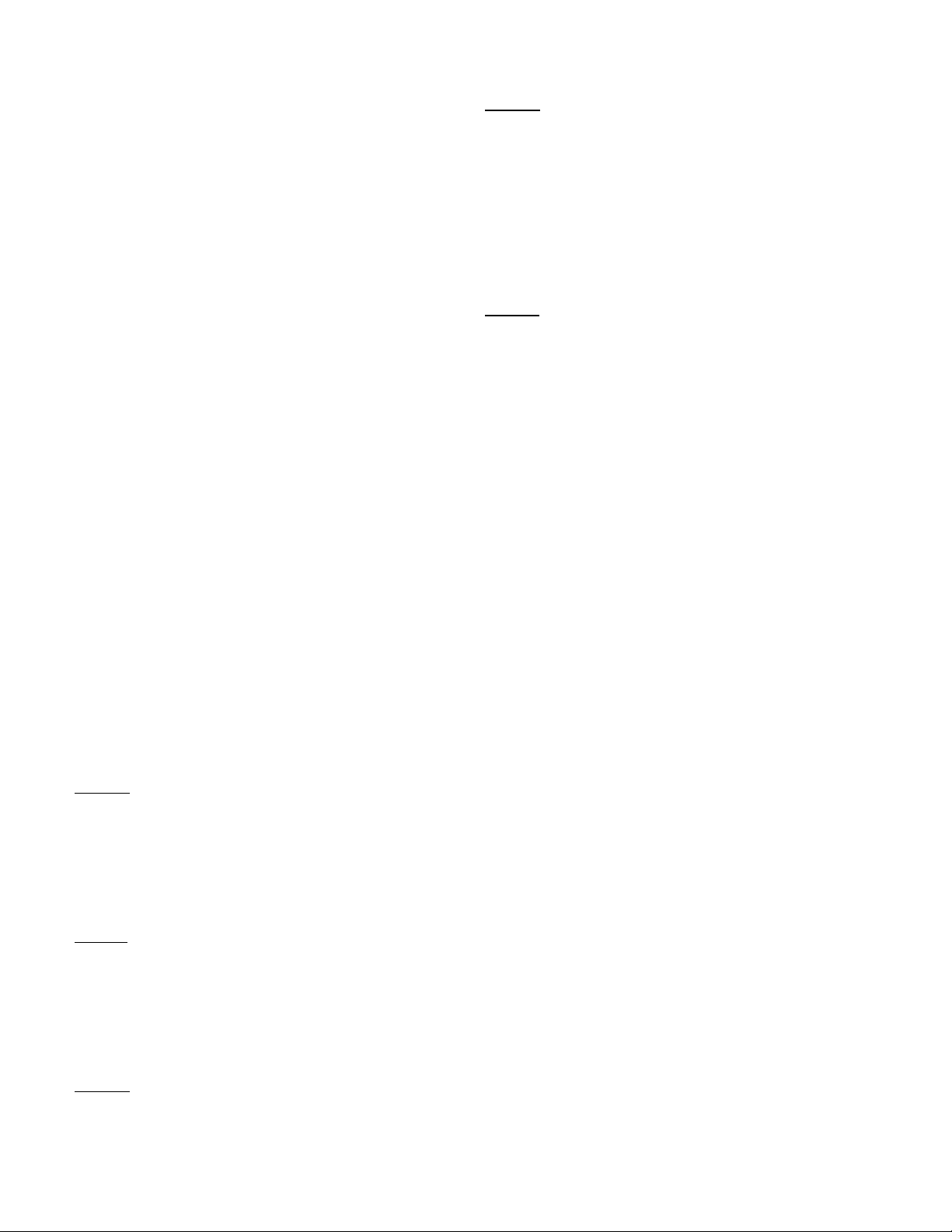

FIG. 2

4

Page 7

PRINCIPLES OF OPERATION

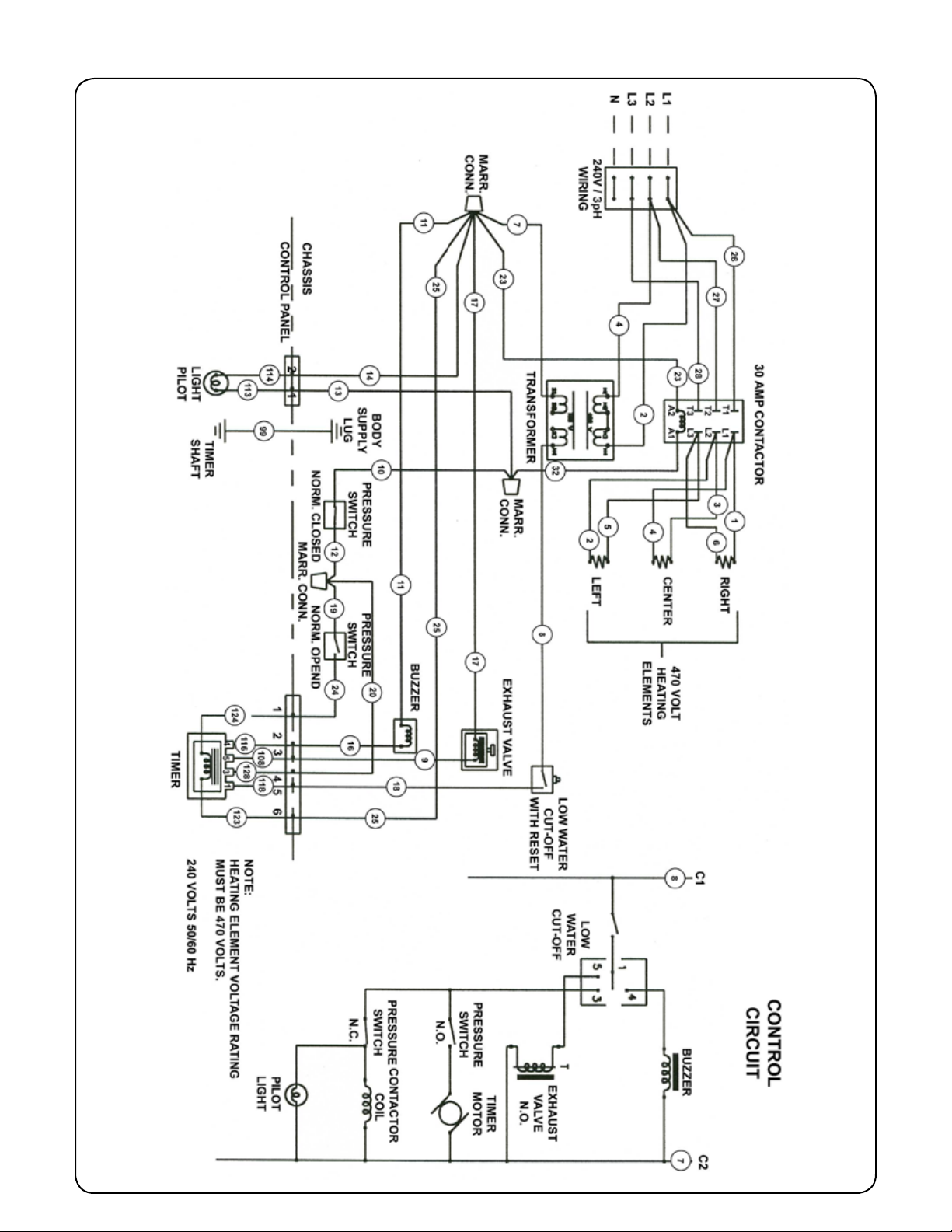

FIG. 3

5

Page 8

PRINCIPLES OF OPERATION

PREHEATING:

Before each Initial operation of cooker and at any time

when compartment is cold, a 5 to 8 minute preheating

period is required. To preheat cooking compartment. Proceed as follows:

1. Close door and lock in position by placing door handle tongue (Fig. 4 No. 4) under roller on drain casting

(Fig. 4 No. 5) press downward on door handle until

door is secured

2. Set minute timer (Fig. 4 No. 7) to 5 minutes by turning

past 10 and back to 5 to ensure proper setting. Indicator light will come on.

3. When preheating is ended (approximately 5 minutes)

and buzzer sounds. turn timer to OFF and allow pressure to return to 0 PSI on pressure gauge (Fig. 4 No.

8).

4. Open compartment door slightly by pulling up on latch

handle (g. 4. No. 6) to allow remaining vapor to escape before raising door to full open position.

WARNING: DO NOT LEAVE HAND ON HANDLE

WHILE EXCESS VAPOR IS ESCAPING. SCALDING OF

HAND MAY RESULT.

shut the unit down. When the required amount of water is added, the unit will be operational again after

the LOW WATER CUT-OFF BUTTON is pressed.

However, if the unit does not start after pressing the

reset button, more time will be needed before the reset button starts the unit. Should a cooking cycle be

interrupted by the low water cut off, the food in the

process of cooking will be affected. Proper compensation should be made for cooking already performed

and a new cook cycle determined. Clean the unit

thoroughly at the end of each day the cooker is used.

Ensure that the cylinder is left dry and the compartment door is left open.

Once the preheating cycle is completed, the cooker compartment may be loaded. The following procedures should

be followed:

1. Insert the pans of food into the pan support located

on the right and left side of the cylinder.

2. Close the door and lock in position by placing the

door handle tongue under the roller on the drain cast-

ing (refer to gure 4). Press downward on the door

handle until the door is secured.

3. Set the timer for the desired cooking time (refer to

Facts on Parade) by timing the timer past the desired

setting and then back. NOTE: The timer will not start’

until the unit is at a minimum of 9 PSI as indicated on

the pressure gauge.

4. At the completion of the required cooking cycle,

steam will automatically exhaust. When the pressure

reaches zero PSI on the pressure gauge, the cooker

compartment door can be released by pulling on the

door latch handle. The operator should allow a few

seconds for the remaining vapor to leave the cylinder before completely opening the door. To stop the

buzzer, turn the timer to the OFF position.

5. The next step is to remove the cooked food, add

any desired seasoning and transfer it to - the serving area. If perforated pans are used, they should be

underlined with a solid pan.

6. Check the’ water level in the cooker before starting

‘another cooking cycle. The water should be at the

six quart level. NOTE: If the unit is operated with an

insufcient amount of water the low water cut-off will

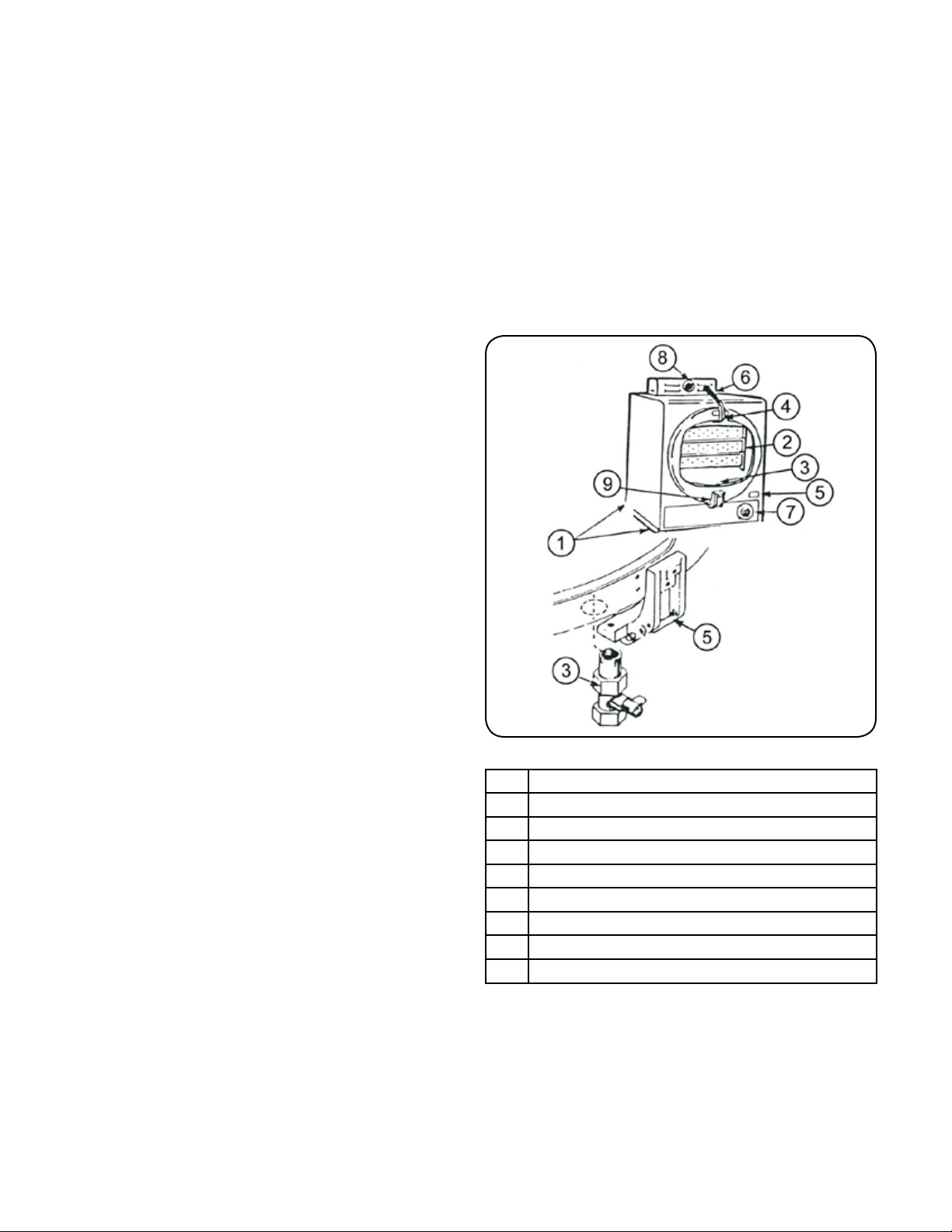

FIG.4

NOTE:

WATER RETAINER & SPRAY HOSE NOT SHOWN.

1 Electrical Connection Box

2 Pan Supports

3 Drain Valve

4 Door Handle Tongue

5 Roller on Drain Casting

6 Door Handle

7 Timer

8 Pressure Gauge

9 Low Water Cut-off Reset Button

FACTS ON PARADE:

1. All foods, except cakes and pastry, can be cooked in

a steam cooking unit.

2. Steam cooked meals have greater nutritional value

since they retain most of their vitamins and minerals.

3. Because foods are cooked faster by the higher temperatures of steam cooking, they can be prepared

closer to serving time, insuring maximum freshness.

6

Page 9

PRINCIPLES OF OPERATION

4. Steam cooked food has a higher percent yield - more

portions per dollar spent.

5. The principle upon which the steam cooker is based

can be likened to the domestic pressure cooker.

6. The principle upon which the steam jacketed kettle is

based can be likened to the domestic double boiler.

7. Food may be served from the same pan in which it

is steam cooked, thus reducing food breakage since

there is no extra handling or transferring of food from

cooking pans to serving pans. It also reduces pot,

washing tasks.

8. Some important advantages of steam cooking are: labor saving, reducing operating costs, space saving

and the lifting of heavy stock pots is eliminated.

9. Rice and spaghetti products, if thoroughly wet at

the start of the cooking process, are very easily prepared.

10. Foods such as potatoes, poultry, seafood and some

meats may be blanched in the steam cooker, thus reducing the total cooking time and grease absorption.

11. Fuel is used only when the steam cooking unit is in

operation.

12. The steam cooker will loosen foods burned on pans

making washing easier.

13. Solid pans are recommended when liquid is to be retained and perforated pans when the liquid is not to

be retained.

14. Eggs may be cooked out of the shell if they are to be

chopped which eliminates peeling after steaming.

15. Frozen or stale bread may be readied for serving with

a small amount of steam.

16. Meats may be sautéed in the kettle before any liquid

is added. Sautéing seals in the meat juices and helps

to retain avor.

17. The steam cooker can be opened during the cooking

period (by rst releasing the steam pressure) to add

or remove items. If any time is lost, an adjustment

may be made on the timer.

18. All frozen foods must be thoroughly defrosted in order

to retain the most satisfactory results.

19. Steam cooking information, including recommended

pan size and type, weight per pan, cooking times and

pan yields are given on the following pages of this

bulletin.

RECOMMENDED COOKING TIMES:

Approx.

Recommended

12” x 20”

Food Item

VEGETABLES, FROZEN, DEFROSTED

Asparagus,

Spears 2.5” 65mm 5# 2.3kg12-3

Beans, Green

Regular 2.5” 65mm 5# 2.3kg12-3

Breans, Green

French Cut 2.5” 65mm 5# 2.3kg12-3

Lima Beans 2.5” 65mm 5# 2.3kg12-3

Broccoli 2.5” 65mm 4# 1.8kg12-3

Brussels,

Sprouts 2.5” 65mm 5# 2.3kg12-3

Carrots,

Diced 2.5” 65mm 5# 2.3kg12-3

Cauliower 2.5” 65mm 5# 2.3kg12-3

Corn 2.5” 65mm 5# 2.3kg12-3

Peas 2.5” 65mm 5# 2.3kg12-3

* All portions are equivalent to approximately 1/2 cup cooked.

Perforated Pan

Raw

Weight

Per Pan

Pans

No.

of

Approximate

Timer

Setting

in

Minutes

7-8

8-10 23-25

7-8

8-10 23-25

7-9

9-10 23-25

6-7

7-8 23-25

5-6

6-7 18-20

6-7

8-10 23-25

5-6

7-9 23-25

7-8

8-10 23-25

5-6

7-8 23-25

2-3

4-5 23-25

No. Cooked

2oz. (55g)

Servings

Per Pan*

7

Page 10

PRINCIPLES OF OPERATION

Recommended

12” x 20”

Food Item

VEGETABLES, FRESH

Beans, Wax

Green 2.5” 65mm 6# 2.7kg12-3

Broccoli,

1/2” - 3/4” Stalk 2.5” 65mm 6# 2.7kg12-3

Cabbage,

Cored - 1/4, 1/6 of head 2.5” 65mm 5# 2.3kg12-3

Carrots,

Sliced 2.5” 65mm 9# 4.1kg12-3

Cauliower 2.5” 65mm 6# 2.7kg12-3

Corn on Cob,

Husked 2.5” 65mm 1 dozen12-3

Potatoes,

French Fry Cut 2.5” 65mm 10# 4.5kg12-3

Potatoes,

Regular Cut 2.5” 65mm 10# 4.5kg12-3

Spinach,

Cut and Cleaned 4” 100mm 3# 1.4kg12-3

Squash,

Summer, 1” Sliced 2.5” 65mm 7# 3.2kg12-3

Squash,

Winter Diced 2.5” 65mm 9# 4.1kg12-3

Turnip,

Diced 2.5” 65mm 5# 2.3kg12-3

Perforated Pan

Approx.

Raw Weight

Per Pan

No.

of

Pans

Approximate

Timer

Setting

in

Minutes

4-6

7-8 30-35

4-5

5-6 25-30

7-9

10-12 12-20

6-8

10-12 35-40

5-6

6-7 30-35

5-6

6-8 12

7-9

10-12 50

13-15

17-19 50

1-2

2-3

5-7

8-10 30-35

7-9

10-12 30-35

10-15

15-20

No. Cooked

2oz. (55g)

Servings

Per Pan*

4 oz. - 110g

10-12

4 oz. - 110g

20-25

VEGETABLES, CANNED

Canned,

Vegetables 2.5” 65mm 7.5# 3.4kg12-3

MISCELLANEOUS

Eggs,

Out of Shell 2.5” 65mm 4 dozen12-3

Rice,

1 Gallon Water - 3.78 lts 4” 100mm 4# 1.8kg12-3

Spaghetti,

1.5-2 Gallons Water - 5.7-7.6 lts 4” 100mm 3# 1.4kg12-3

* All portions are equivalent to approximately 1/2 cup cooked.

8

4-5

5-7 26-30

3

3-4

17-20

21-25

17-20

21-25

60/3oz. - 85g

Portions

40-45/4oz. -

110g Portions

48

48

Page 11

PRINCIPLES OF OPERATION

Approximate

Approx.

Recommended

12” x 20”

Food Item

MEAT - POULTRY - FISH

Chicken, Cut-Up

Blanched 2.5” 65mm 8# 3.6kg

Chicken,

Whole 4” 100mm

Fish,

Fillets 2.5” 65mm 3# 1.4kg

Fowl,

Whole 4” 100mm

Frankforts 2.5” 65mm 5# 2.3kg

Hamburgers,

3oz. - 85g 2.5” 65mm 5# 2.3kg

Lobster,

1# Size - 450g 2.5” 65mm 10# 4.5kg

Meatballs**

1oz. Size - 28g 2.5” 65mm 6# 2.7kg

Meatloaf** 2.5” 65mm 15# 6.8kg

Pork Chops,

loin, 4oz. - 114g with Bone 2.5” 65mm 6# 2.7kg

Sausages,

10 per pound - 45g each 2.5” 65mm 6# 2.7kg

Turkey,

on Carcass 4” 100mm

Turkey,

off Carcass 2.5” 65mm

* All portions are equivalent to approximately 1/2 cup cooked.

** Raw weight for meatballs and meatloaf includes and extenders and yields 2 oz. - 56g protein plus extenders for

3 oz. - 85g total portion.

Perforated Pan

Raw Weight

Per Pan

(3)

4# 1.8kg

(2)

5# 2.3kg

20-

22# 9-10kg 1 75-90

10-

4.5-

12#

50.4kg12

No.

of

Pans

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

Timer

Setting

in

Minutes

10-15

15-20

35-40

45-50

7-8

8-10

40-45

45-60

1-2

2-3

8-10

12-15

3-6

5-8

15-17

18-20

25-30

30-35

15-20

20-25

14-16

17-19

40-45

45-50

No. Cooked

2oz. (55g)

Servings

Per Pan*

15-20

Protein

25-30

Protein

12-15

Protein

20-25

Protein

35-40

Protein

20-25

Protein

10 - 1#

450g

20-25

Protein

50-60

Protein

24

Protein

18-20

Protein

50-60

Protein

55-65

Protein

9

Page 12

PRINCIPLES OF OPERATION

THE FLUE: (FIG. A)

The Flue serves as a protection shield for the Steam

Trap (B), safety Valve (A), Exhaust Valve (D), as well as

8 front-facing mount for the Steam Gauge (E). ks servicing 0’ these parts may at times require the removal of the

ue. an exploded view drawing is provided to show their

proper relative positions within the ue and the method of

their assembly to the cooking cylinder.

TO REMOVE THE FLUE: (FIG. A)

1. Unscrew and remove the exhaust silencer (F).

2. Detach the 3/16” copper tube connector (C) from the

Steam Gauge (E) at the ferrule nearest the steam

gauge. Then, remove the copper tube entirety by

freeing It at the other ferrule.

3. Apply inward pressure at either sides of the Flue at

points (1) and (2) with a screwdriver. This will collapse

the side walls slightly to allow the small uted sections

0’ sheet metal to clear the edges of the ue opening

provided in the outer Shell of the Steam-it. With the

restrictions of the utes removed, the Flue may then

be lifted up over the pans it houses.

4. To replace the Flue, reverse the above steps.

TROUBLE TEST AND REMEDIES:

The rst indication of defective steam trap operation will

usually be evidence by uneven cooking. If working properly, the steam temperature will be even and cooking will

be uniform through the cooking compartment. Trouble

may occur either through premature closing of the steam

trap before all the cold air has been exhausted or by its

failure to close sufciently to enable a proper steam pressure build-up. Either case warrants the replacement of

the steam trap.

STEAM GAUGE:

Located at the top rear of the steam-it and mounted into

the forward face of the ue for visibility, the steam gauge

registers the pressure within the steam-it cooking chamber. To replace this unit it is necessary to disconnect the

3/16” copper tube connector and remove the two nuts

holding the gauge framework in place.

STEAM TRAP:

The steam trap is located within the ue at the top rear

of the steam-it. It has the very important automatic, dual

function of exhausting all cold air from the cooking compartment and making a suitable seal to allow a pressure

build-up of live steam during the cooking cycle. Failure of

this unit to operate properly will result in uneven cooking.

HOW IT WORKS:

With the introduction of steam into the cooking compartment, the cold air escapes through the steam trap. When

sufcient generated steam displaces the cold air, it passes through the steam trap, and the thermostatic element

becomes heated and expands to “make” a seal against

the seat. This action encloses the live steam within the

cooking compartment and allows a steam pressure buildup to occur.

FIG. A FLUE REMOVAL ITEMS:

A. Safety Valve

B. Steam Trap

C. 3/16” Copper Tube Connector

D. Exhaust Valve

E. Steam Gauge

F. Exhaust Silencer

1 & 2 Flue Release Pressure Points

10

Page 13

MAINTENANCE

PREVENTIVE MAINTENANCE:

This section contains both preventive and corrective

maintenance information. Preventive maintenance may

be performed by maintenance personnel at the establishment in which the cooker is installed. It is recommended

that user personnel never attempt to make repairs or replacements to the equipment without the assistance of

authorized service agent.

CAUTION: UNDER NO CIRCUMSTANCES SHALL

HARDWARE (OR PARTS) BE REPLACED WITH A DIFFERENT LENGTH, SIZE OR TYPE OTHER THAN SPECIFIED IN THE PARTS LIST. THE HARDWARE USED

IN THE STEAM-IT COOKER HAS BEEN SELECTED

OR DESIGNED SPECIFICALLY FOR THEIR APPLICATIONS AND THE USE OF HARDWARE OTHER THAN

THOSE SPECIFIED MAY DAMAGE THE EQUIPMENT

AND WILL VOID ANY WARRANTY.

WARNING: THE ELECTRIC POWER SUPPLY MUST

BE DISCONNECTED PRIOR TO PERFORMING REPAIR/SERVICE WORK ON THE MODEL SB-ST-E ELECTRIC STEAM-IT PRESSURE COOKER DISASSEMBLY

AND CLEANING

bly Figure 15.

GASKET REPLACEMENT:

The door gasket (Figure 16, item 6) is readily replaced

by rst removing the door assembly from the cooking

compartment as explained in disassembly and cleaning

The door assembly must be removed from the cooker

compartment for weekly cleaning. Though no tools are

needed, care in following procedure is necessary to insure. that the door will pass through the compartment

opening.

1. With cooking compartment door open, lift pan supports up and forward to disengage from mounting

studs. Remove from compartment. .

2. Disengage left and right ends of door seal spring by

counter-acting the force of the door lift spring with one

hand while disengaging studs with the other hand.

3. Push door lift springs to the rear and off studs.

4. Rotate the door assembly out through the door open-

ing, door handle rst.

5. Inspect door gasket for cleanliness and wear. If food

soil has become lodged behind the gasket or the gasket is torn, push it off perimeter of door and clean with

mild detergent-water solution, or replace as needed.

A gasket which is stuck to the door is easily removed

by rst soaking the entire door in hot soapy water. To

assure a pressure seal, the gasket must be cleaned

of soil and scale, and be free of breaks.

6. Replace gasket on door and reassemble door assembly in compartment. Open and close door several

times to check for correct operation and tight seal of

door in closed position.

FIG. 5

FIG. 6

instructions. The worn gasket is removed in the same

manner as described for cleaning and a replacement sub-

stituted. A new gasket which is difcult to stretch onto the

door can be made pliable by rst soaking it in hot soapy

water. Remounting the door in the compartment completes the replacement.

DOOR ASSEMBLY:

The door assembly consists of the door latch and the latch

fulcrum assembly. All parts are replaceable as shown in

gure 17, Door Assembly Figure 16, Door Handle assem-

NOTE: The critical function of the makes it imperative that

the in good condition. For this is recommended that at

least gasket be kept at all times door seal gasket be reason it one spare.

11

Page 14

MAINTENANCE

DOOR SEAL TENSION ADJUSTMENT:

An adjustment screw is built into the door anchor and fulcrum assembly to allow compensation for normal variation in gasket thickness caused by wear. The adjustment

screw is shown in Figure 6. If steam escapes from around

the door, sealing tension against the door opening can

be increased by loosening the 1/4-20 jam nut and turning the socket head adjustment screw counterclockwise

with an allen wrench. Installation of a replacement door

gasket may result in excessive door latching tension and

require clockwise adjustment of the screw. Trial and error

will achieve the screw adjustment which both seals the

door against the compartment opening yet allows door

latching with only moderate force applied to the handle.

The nal position is set by holding the cap screw with an

allen wrench while tightening the 1/4-20 jam nut.

DOOR LIFT SPRING REPLACEMENT:

Should either spring become damaged, it is necessary to

replace both left and right springs as a set (Figure 16). The

door assembly is removed from the cooking compartment

as explained in the Disassembly and Cleaning Instructions. Springs are installed by removing spring bearings

(2), screws (1), and worn springs (3 and 4) and mounting

replacements. Springs are marked with tabs indicating

the left and right side replacement springs for installation

on the appropriate side as viewed from the front of the

compartment.

EXTERIOR PANEL REMOVAL:

Access to all internal plumbing assemblies is from the top

and front of the Steam-It cabinet. Whenever internal repairs or replacements are required, the applicable panels

must rst be removed. These parts are shown in Figure

14. The following procedure is required for removal of ex-

terior panels.

1. Raise the cooking compartment door.

2. Remove screws (7) in lower front panel (11) and timer

knob

3. Slide lower front panel (11) down from cylinder and

lift off.

4. To gain access to terminal block (for primary power),

remove screws (1) securing terminal box cover to

side panel.

3. Apply inward pressure at either side of the ue with

a screwdriver. This will collapse the side walls slightly

to allow the small uted sections of the sheet metal

to clear the edges of the ue opening provided in the

outer shell of the Steam-It. With the restrictions of the

utes removed, the ue may then be lifted up over the

components.

4. Replacement of safety valve, trap plumbing and

exhaust valve assembly (as required) may now be

made. The components of the steam exhaust valve

assembly.

CAUTION: IF THE WATER SUPPLY IS KNOWN TO

BE HARD OR CORROSIVE, A SOURCE OF THREADED

WATER SHOULD BE USED. CORROSION MAY ALSO

OCCUR IF WATER IS NOT DRAINED DAILY. DO NOT

USE DISTILLED WATER.

MARKET FORGE SB-ST-E MARINE STEAM-IT MUST

BE CLEANED ONCE A DAY!

DAILY CLEANING: Remove pan supports by lifting

the front up and off the stud. Pull back of pn support forward and off stud. Wash with mild detergent and water.

Rinse and dry throughly.

CAUTION: DO NOT USE STRONG DETERGENT OR

ABRASIVE CLEANERS. PITTING OF ALUMINUM INTERIOR WILL OCCUR.

WEEKLY CLEANING: Remove the door. Raise the

door to a fully open position and disengage the door spring

from each of the door spring studs. Do this by counteracting the force of the door lift spring with one hand while

working the end of the door spring off the door assembly with the free hand. Do this on both side of the door

assembly. When the ends of the door spring have been

completely freed from their respective door spring studs,

the door lift springs on either side of the door assembly

can easily be slipped off their studs. All Equipment is located on the top and at the back of the SB-ST-E Cooker

ONLY. Check the vavle. Lift the handle on valve when SBST-E is under pressure. Steam should escape.

NOTE: Dirty water may escape for a few seconds, but

then the steam should ow freely.

STEAM EXHAUST VALVE AND TRAP REPLACEMENT: The components of the steam ex-

haust valve assembly, trap, safety valve, silencer, pressure gauge and associated plumbing and hardware are

replaced by rst removing ue assembly and pressure

gauge. To remove ue assembly proceed as follows:

1. Unscrew and remove exhaust silencer.

2. Detach the 3/16” copper tube connector from the pressure gauge at the ferrule nearest the pressure gauge.

Then, remove the copper tube entirely by freeing it at

the other ferrule.

Steam trap should rst allow air to escape and then slowly close as all air is forced out of the compartment. The

sound of air escaping is quite noisy, but subsides once

steam pressure is built up and cooking takes place. If

steam trap does not close, it should be replaced. Exhaust

silencer must be cleaned by rinsing in mild detergent and

water or changed whenever clogged.

Your particular unit may be equipped with a different trap

- old style or new style. Replace steam traps will be of the

new style. Do this weekly if using new style.

12

Page 15

MAINTENANCE

CLEANING EXHAUST SILENCER:

The exhaust silencer should be removed and cleaned periodically. As the cooking chamber is exhausted of steam

through the silencer, impurities can build up from food particles. Cleaning should be frequent enough to prevent clogging to occur. For this reason, the exhaust silencer is made easily accessible and simple to remove.

To Clean:

1. Remove the one piece exhaust silencer from the unit by unscrewing it in a counterclockwise direction.

2. Clean the silencer by sloshing it in hot soapy water and rinse in clear water. if dirt has clogged the silencer presoak

it in an alkaline cleaning solution.

3. After cleaning, stand the silencer on edge to allow it to drain.

4. Screw it back into the elbow of the exhaust valve counterclockwise.

CLEANING TROUBLE-SHOOTING GUIDE (STAINLESS STEEL):

Routine Cleaning: Soap, ammonia or detergent with hot water. Clear water will rinse.

Overall “straw” color lm: Caused by water and detergent residue. Use mild phosphoric acid-type cleaner.

Stubborn spots, stains and

baked on splatter:

Heavy tinting, or heavy

discoloration:

Hard water spots, scale: Vinegar.

Grease and oil: 5% oxalic acid, 5% sulfamic acid, 5-10% phosphoric acid, dilac, oakite #33, texo 90,

Allchem concentrate, samae, cameo, coper cleaner, liquid or paste Nu-Steel or DuBois temp, gobbard’s or revere stainless cleaner, scouring powder (rinse thoroughly),

steel bright, lumin or zud.

Penny-brite, copper-brite, DubBois temp, tarnite, gobbard’s or revere stainless

cleaner.

texo 91, or organic solvents (acetone, bensene, alcohol, trichlorethane, cloroethane n.

u,).

NOTE: Clear water rinsing followed by wipe-down with soft cloth is recommended after all cleaning procedures.

These recommendations are based on tests and studies done by the Armco Reserch Center and

provided through the courtesy of American Iron and Steel, Institue’s Stainless Steel, Producer’s

Committee.

WARNING:

DO NOT HOSE DOWN UNIT AS IT CONTAINS ELECTRICAL COMPONENTS.

13

Page 16

ILLUSTRATED PARTS LIST

FIG. 7 Cooker Compartment

14

Page 17

ITEM FIG. 7 Cooker Compartment PART

NO. DESCRIPTION NO.

1 BASEPLATE ASSY - FIXED 95-3301

2 TRANSFORMER 440/480 V UNITS 10-5234

3 NO. 10 LOCKWASHER STAINLESS STEEL *

4 NO. 10-32 x 1/2” BINDING HD SCREW STAINLESS STEEL *

5 LEAD ASSY, TRANSFORMER 95-3394

6 PLUG BUTTON 10-3095

7 PLATE -TREM, STRIP SUPPORT 95-3289

8 COVER - TERM. BOX 95-3484

9 NO. 8-32 x 1/8” RD HD SCREW STAINLESS STEEL *

10 GROUND LUG 10-6969

11 CONNECTOR 95-3500

12 REDUCING WASHER 10-6967

13 JUNCTION BOX COVER 95-3489

14 TERM. STRIP SECTION 10-6962

15 TERM. STRIP END SECTION 10-6963

16 BASEPLATE SUB ASSY - MOVABLE 95-3302

17 CONTACTOR 280V, 50/60 Hz CYCLE, COMPLETE 10-5466

CONTACTOR 230/240V, 50/60 Hz CYCLE, COMPLETE 10-5467

18 COIL 208V, 50/60 Hz CYCLE 10-5470

COIL 230V, 50/60 Hz CYCLE 10-5471

19 LOW WATER CUT-OFF 10-5990

20 NO. 6-32 x 1/4” TRUSS HD SCREW STAINLESS STEEL *

21 CONNECTOR 10-6966

22 PRESSURE CONTROL - OPEN ON RISE 95-0998

23 PRESSURE CONTROL - CLOSE ON RISE 95-0999

24 NO. 10-32 x 1/2” RD SCREW STAINLESS STEEL *

25 ADAPTER - STRAIGHT 1/4” OD - 1/2” IPSM 10-2904

26 ADAPTER - TEE 1/8” IPS - 1/4” OD - 1/4” ODM 10-3426

27 REDUCING BRUSH 1/4-1/8 IPS 00-3652

28 TUBE 95-3305

29 TUBE - PRESSURE CONTROL 95-3304

30 UNION - COMPR. FITTING 1/4 OD 10-1154

31 TUBING - STEAM PRESSURE LINE 95-3387

32 TIMER, 60 MINUTE 95-3404

33 BRACKET, TIMER 95-3277

34 KNOB, DIAL 10-6307

35 BRACKET - PILOT LIGHT 95-3403

36 LOCK WASHER 10-2509

37 HEX NUT 10-32 10-2340

38 PILOT LIGHT 10-6669

39 EXHAUST SILENCER 10-4963

40 CAGE, ELECTRIC WIRE 95-0483

41 CONDUIT - NIPPLE 10-6964

42 SPEEDNUT 6-32 10-4110

43 WASHER 95-0463

44 NO. 10-32 x 1/8 HEX SOCKET HD CAP SCREW STAINLESS STEEL *

15

Page 18

45 DOOR HANDLE ASSY - COMPLETE 95-0144

46 DRAIN PLUG ASSY - COMPLETE 95-0154

47 HANDLE BUMPER 10-0226

48 NO. 8-32 x 1/8 BINDING HD SCREW TY ‘Z’ STAINLESS STEEL *

49 SAFETY VALVE 10-4636

50 STEAM TRAP 10-6156

51 ADAPTER 10-6158

52 OLD STYLE - EXHAUST VALVE 208V, 60 Hz CYCLE COMPLETE 95-0944

OLD STYLE - EXHAUST VALVE 230/480V, 60 Hz CYCLE COMPLETE 95-0945

OLD STYLE - EXHAUST VALVE 230V, 50 Hz CYCLE COMPLETE 95-0946

OLD STYLE - EXHAUST VALVE 208V & 230V, 50 Hz CYCLE COMPLETE 95-0946

52A NEW STYLE - EXHAUST VALVE (NOT SHOWN) N/A

NEW STYLE - EXHAUST VALVE 220/240V, 50/60 Hz 09-6545

NEW STYLE - EXHAUST VALVE 208V, 50/60 Hz 09-6536

53 NIPPLE, 1/8 IPS 10-3852

54 ELBOW, 1/8 IPS ST’D 90O 10-3851

55 BUZZER - COMPLETE 10-6665

56 FULCRUM & CRAIN ASSY 95-0115

57 5/16-18 x 1 1/2” SQ HD SCREW STEEL CAD. PL. *

58 5/16 FLAT WASHER, 1/8 ID x #16 GA ST’D STEEL CAD. PL. *

59 HEX NUT 5/16-18 ST’D STEEL CAD. PL. *

60 CONNECTOR, 1/8-90O 10-5036

61 FRONT LOWER PANEL ASSY 95-3388

62 NAMEPLATE PANEL 60 CYCLE 10-6595

63 NAMEPLATE PANEL 50 CYCLE 10-7096

64 ROD 95-0466

65 PAN INSULATION 95-0465

66 STUD 10-1937

67 PAN RACK ASSY - RIGHT SIDE 95-2545

68 PAN RACK ASSY - LEFT SIDE 95-2546

69 1/4 SHAKEPROOF INT. TOOTH LOCKWASHER STAINLESS STEEL *

70 1/4-20 x 3/4” RD HD SCREW STAINLESS STEEL *

71 1/4-20 x 1/84” HEX HD SCREW STAINLESS STEEL *

72 CASE - TOP FONT UPPER 95-3131

73 CASE - LEFT SIDE 95-3140

74 CASE - RIGHT SIDE 95-3141

75 CASE- BACK 95-3490

76 NO. 8 x 1/8” PHIL. TRUSS HD SCREW TY ‘A’ *

77 FLUE ASSY 95-3135

78 PRESSURE GAUGE 10-0883

79 TUBING PRESSURE GAUGE 95-3270

80 DOOR ASSY, COMPLETE 95-0124

81 BODY ASSY 208V & 236V 95-0478

BODY ASSY 470V 95-0479

82 RETAINER, WATER (NOT SHOWN) 91-2601

83 ASSY, HOSE FILL (NOT SHOWN) 95-3849

84 FOOT, FLANGED 4” (NOT SHOWN) 91-2449

* THESE PARTS ARE AVAILABLE AT LOCAL HARDWARE, PLUMBING AND ELECTRICAL OUTLETS. IF NOT

OBTAINABLE, SPECIAL PRICES WILL BE QUOTED BY MARKET FORGE UPON REQUEST.

16

Page 19

ILLUSTRATED PARTS LIST

FIG. 8 Door Handle Assembly

ITEM PART

NO. DESCRIPTION NO.

1 NO. 10-32 ACORN NUT 10-2318

2 #10 SHAKEPROOF LOCKWASHER 10-2514

3 LOCKING SCREW 10-1999

4 BEARING SPACER 95-0120

5 3/8” SHAKEPROOF LOCKWASHER 10-2517

6 DOOR LOCK KNOB 10-0050

7 DOOR HANDLE CASING 95-0134

8 1/4”-20 ACORN NUT 10-2359

9 DOOR HANDLE BEARING STUD 95-0658

10 DOOR HANDLE BEARING BRACKET 95-0659

11 1/4” SHAKEPROOF LOCKWASHER 10-2513

12 1/4”-20 x 5/8” RD HD SCREW * 10-1731

13 DOOR LOCK ASSY 95-3223

14 DOOR LOCK KNOB ASSY (ITEMS 1-6 PLUS 13) 95-0145

15 COMPLETE DOOR HANDLE ASSY (ITEMS 1-13) 95-0144

* OBTAIN AT LOCAL HARDWARE STORE.

17

Page 20

ILLUSTRATED PARTS LIST

THE COOKER DOOR ASSEMBLY

The door of the Cooker has been engineered to establish a positive method of sealing the steam pressure within the

cooking cylinder. As steam pressure builds up within the cylinder, the door seal will tend to become more positive.

However, the door should be adjusted to make a good initial seal between the door gasket and the door opening

without the added assistance of “internal cylinder steam pressures. With the simple action of securing the door handle

down in a locked position, the door gasket should be sufciently compressed against the door opening, all the way

around, to prevent any steam leakage from occurring.

ITEM FIG. 9 Door Assembly PART

NO. DESCRIPTION NO.

1 PIVOT SPRING BEARING 10-6765

2 DOOR LIFT SPRINGS - PAIR 10-2718

3 10-32 MACHINE SCREW 1/2” LONG 10-1776

4 DOOR GASKET 10-2666

5 DOOR & DOOR SPRING ASSY 95-3204

6 DOOR SPRING 95-0127

-- COMPLETE DOOR ASSEMBLY (ITEMS 1-6) 95-0124

FULCRUM & DRAIN ASSEMBLY:

The Fulcrum and Drain Assembly is located at the lower front of the cooking cylinder and furnishes a sturdy anchorage for the door locking system of the door handle. Also provided In this assembly is a means of adjustment for the

door seal. The drain port and drain plug provide a means of discharging accumulations of water from !.he cooking

cylinder.

ROLLER ASSEMBLY:

Built Prior to 10/85 (Items 5. 6. 7. 8. & 9.)

Built after 10/85 (Items 2. 8. 9. 13. & 14.)

The Roller Assembly must be kept free-rolling at all times. Should this assembly be allowed to become frozen due to

lack of lubrication undue strain will be put on the door handle and the fulcrum casting while the door is being locked.

Use only a dry lubricant such as graphite, as oil Of grease will tend to attract dirt to this area.

18

Page 21

ILLUSTRATED PARTS LIST

FIG. 10 Old Style Fulcrum & Drain Assy

ITEM PART

NO. DESCRIPTION NO.

1 FULCRUM & DRAIN CASTING 95-0116

2 1/4-20 x 3/8 HELICOIL 10-3111

3 1/4” SHAKEPROOF WASHER 10-2513

4 1/4-20 CAP SCREW, 1/8” LG. * 10-1790

5 10-32 ACORN NUT 10-2318

6 #10 SHAKEPROOF LOCKWASHER 10-2518

7 BRONZE BEARING 95-0198

8 BEARING SPACER 95-0120

9 10-32 MACHINE SCREW, 1.5” LG. 10-1999

10 ROLLER ASSY (ITEMS 5-9) 95-0149

11 1/4-20 MACHINE SCEW, 3/4” LG. * 10-1763

12 1/4-20 ALLEN SET SCREW 10-2087

13 1/4-20 JAM NUT 10-2358

14 1/4-20 x 3/8 HELICOIL 10-3116

-- COMPLETE FULCRUM ASSY

(ITEMS 1-14)

15 DRAIN PLUG HANDLE 95-0658

16 DRAIN PLUG 10-2227

17 1/4-20 ACORN NUT 10-2359

18 DRAIN & PLUG HANDLE ASSY

- COMPLETE

* OBTAIN AT LOCAL HARDWARE STORE.

95-0115

95-2604

FIG. 10

FIG. 11

FIG. 11 New Style Fulcrum & Drain Assy

ITEM PART

NO. DESCRIPTION NO.

1 1/4-20 x 3/8 HELICOIL 10-3116

2 10-32 MACHINE SCREW, 1 3/8” LG. 10-1999

3 1/4-20 FULCRUM NUT 10-2358

4 1/4-20 ALLEN SET SCREW 10-2087

5 1/4-20 x 3/8 HELICOIL 10-3111

6 1/4” SHAKEPROOF WASHER 10-2513

7 1/4-20 MACHINE SCEW, 3/4” LG. * 10-1763

8 BEARING SPACER 95-0120

9 BRONZE BEARING 95-0198

10 1/4-20 x 3/8 HELICOIL 10-3111

11 1/4” SHAKEPROOF WASHER 10-2513

12 1/4-20 CAP SCREW, 1/8” LG. * 10-1790

13 #10 SHAKEPROOF LOCKWASHER 10-2514

14 10-32 ACORN NUT 10-2318

15 FULCRUM & DRAIN CASTING 95-3850

16 BALL VALVE 10-1041

-- FULCRUM & DRAIN ASSY

(ITEMS 1-5)

* OBTAIN AT LOCAL HARDWARE STORE.

95-3992

SAFETY VALVE: The Safely Valve is set to automati-

cally relieve the cooking compartment of excessive pressure build-ups by opening at a point between 15 1/2 Ibs.

and 16 lbs.

CHECKING SAFETY VALVE: If the Safely Valve

should leak continually with a pressure build-up, or should

it cause an interruption of the Cooking cycle prematurely

(less than 15 1/2 Ibs. on the steam gauge), it must be

determined to be defective and be replaced. However,

the steam gauge should rst be checked for accuracy before making this determination. The steam gauge should

register absolute zero with no pressure in the cooking

cylinder. If the normal zero setting has advanced some

what through usage (a characteristic of steam gauges),

the amount of advancement from absolute zero must be

subtracted from its registered reading 10 determine the

true steam pressure.

19

Page 22

ILLUSTRATED PARTS LIST

ITEM FIG. 12 Exhaust Valve PART

NO. DESCRIPTION NO.

1 TEE ASSEMBLY 95-0756

2 BALL & PIN ASSEMBLY 95-0372

3 DIAPHRAGM BODY ASSEMBLY 95-2077

4 NO. 10 FLAT WASHER 3/16” ID x 1/2 OD x0.086 ( CAD. PI ) 10-2425

5 SPRING, COMPRESSION 10-4675

6 PIN, COTTER 1/16 x 1/2 STAINLESS STEEL 10-1663

7 SOLENOID BRACKET ASSEMBLY 95-0431

8 NO. 10-32 x 3/8” RD. HD. SREW ( CAD. PI ) 10-1759

9 NO. 10 LOCKWASHER ( CAD. PI ) 10-2505

10 1/4-20 x 3/8” RD. HD. SCREW ( CAD. PI ) 10-1701

11 1/4 LOCKWASHER ( CAD. PI ) 10-2500

12 CHANNEL 95-0755

13 PIN, ROLL 1/8 x 1-1/8” ( CAD. PI ) 10-1678

14 PIN, SOLENOID 95-0760

15 COIL - 208V, 60 CYCLE 10-6663

15 COIL - 208V, 50 CYCLE 10-6664

15 COIL - 230V, 60 CYCLE 10-6656

15 COIL - 230V, 50 CYCLE 10-6657

16 SOLENOID - 208V, 60 CYCLE, COMPLETE 10-6662

16 SOLENOID - 208V, 560 CYCLE, COMPLETE 10-6667

16 SOLENOID - 230V, 60 CYCLE, COMPLETE 10-6666

16 SOLENOID - 230V, 50 CYCLE, COMPLETE 10-6660

-- EXHAUST VAVLE - 208V, 60 CYCLE, COMPLETE 95-0944

-- EXHAUST VAVLE - 208V, 50 CYCLE, COMPLETE 95-0947

-- EXHAUST VAVLE - 230-480V, 60 CYCLE, COMPLETE 95-0945

-- EXHAUST VAVLE - 230V, 50 CYCLE, COMPLETE 95-0946

-- ASSEMBLY ( ITEMS 1 THRU 6 ) COMPLETE 95-3197

20

Page 23

ILLUSTRATED PARTS LIST

ITEM FIG. 13 NEW Exhaust Valve, Built after July 1983 PART

NO. DESCRIPTION NO.

1 ASSY PIPLIN EXHAUST, 208-240V, 50/60Hz C95-3996

2 HEAT DEFLECTOR PLATE C95-3990

3 TUBING, PRESSURE GAUGE A95-3270

4 PEM., CORN, BRASS 1/8 IPS x 3/16 OD 10-3361

5 90 DEGREE COMP., 1/8 IPS MALE 3/16 OD 10-3360

6 TEE REDUCING BRASS (EXSITING) 10-3432

7 NIPPLE, BRASS CHR. PL (EXSITING) 10-3420

8 MARR CONNECTOR 10-5143

9 PLUG, COUNTERSINK, 1/4 IPS BR. CHR. PL. P09-4843

10 PACKING CORRUGATED CARTON (8x8x6) 10-1643

11 SILENCER EXHAUST STEAM-IT A10-4963

12 EXHAUST VALVE ONLY 220-240V, 50/60Hz 09-6545

12 EXHAUST VALVE ONLY 208V, 50/60Hz 09-6536

21

Page 24

TROUBLE-SHOOTING

FIG. 14

ELEMENT CONTROL SWITCH: The element

control switch, located under the removable front lower

panel, just left of center, governs the ow of current to the

heating elements to maintain cylinder pressures at a near

constant 14 PSI.

HOW IT WORKS: A copper tube extending from the

top of the cylinder to the rear portion of the element control switch constantly reects internal cylinder steam pressure upon to built-in bellows of the element control switch

to cause it to open os close an electrical circuit to the

contactor coil. With little or no pressure applied to the bellows, the circuit to the contactor will be closed and proving

the timer is set to cycle the contactor will click in and cur-

rent will ow to the heating elements. When the pressure

rises to 14 PSI (original factory setting) the bellows will be

sufciently compressed by the steam back pressure to

break the circuit to the contactor coil will click out and cur-

rent ow to the heating elements will cease. When cooling

allows the pressure to drop below 13 pounds the bellows

will again complete the contactor coil circuit activate the

contactor to click in and allow the heating elements to energize. Thus, by working intermittently to open and close

the contactor coil circuit the element control switch in ef-

fect regulates current ow to the heating elements.

DIAL ADJUSTMENT: Two dial settings determine

the operational range of the element control switch. The

larger dial (FIG 14, D) determines the maximum build-up

of cylinder steam pressure while the smaller dial (FIG 14,

E) governs the range of differential between the switch’s

cut-in and cut-off points.

Should a lower cylinder cooking pressure be desired, adjust the large dial (FIG 14, D) by inserting a screwdriver

into slot (FIG 14, B) found at the center by turning it slightly counterclockwise to lower pressure. Clockwise rotation

will increase the pressure. Pressure must not be adjusted

to exceed 14 pounds as the safety valve is set to automatically open just above this point.

The cut-in and cut-off points of the element control switch

may be adjusted by rotating the small screw at the center

of the smaller dial (FIG 15, E). Normally factory setting

is for a one pound differential between cut-in and cut-off.

To increase the range of differential, rotate screw clockwise to decrease the range of differential, rotate the screw

FIG. 15

counterclockwise. Check adjustments through a trial cycle

by observing pressure gauge pressure and again when it

clicks in after cylinder cooling. The difference on pressure

as read on the pressure gauge should, at these points be

approximately one pound.

RECALIBRATING ELEMENT CONTROL

SWITCH: The element control switch may be recali-

brated should it vary some whet through usage from its

original factory setting. At the precise moment of contactor “click-out” the dial setting of the element control switch

and the steam pressure gauge reading should both be at

14 pounds. A slight override of steam pressure buildup will normally occur and indicate itself on the pressure

gauge after the contactor has “clicked-out”. This is normal

and is not to be interpreted as an element control switch

out of calibration.

PRESSURE CONTROL SWITCH (BARKSDALE):

Models built after September 1980 use 2 Barksdale pressure switches in place of the White-Rogers element con-

trol switch and the timer control switch.

OPERATING PRESSURE ADJUSTMENT

(BARKSDALE): The operating pressure is determined

by setting the right switch (FIG 15, A) at approximately

10 PSI and the left switch (FIG. 15, B) at approximately

14 PSI. Both switches were set at the factory. These set-

tings can be veried by looking through the slot (in the

red rectangular) and observing the alignment of the black

line inside the white scales on either side of the slot. To

readjust turn white knob in approximate direction to raise

of lower pressure.

WARNING: Because power must be on to adjust

pressure switches, be sure to protect against electrical

shock.

Check adjustments through a trial cycle and observe pressure readings on pressure gauge when (FIG. 15, B) clicks

off at maximum cylinder pressure and when (FIG. 15, A)

clicks on after cooling. Making adjustments as needed

being careful not to let switch (FIG. 15, B) pressure be

set to exceed 14 pounds. Since the safety valve is set to

automatically open just above this point.

22

Page 25

TROUBLE-SHOOTING

RECALIBRATING PRESSURE CONTROL

SWITCH:

and cannot be recalibrated.

The actuation valve (differential) is factory set

LOW WATER CUT-OFF: The low water cut-off is

mounted above the timer assembly under the front lower

panel with its thermostat bulb extending an inserting into

a channel provided for it at the outer edge of the cast-in

heating elements. It functions as a safety feature to shut

off the complete unit in event the water runs dry.

HOW IT WORKS: If the Steam-It operated with no

water or the water has evaporated away, the temperature

of the cooking cylinder will rise by heat induction effect the

thermostat bulb of the low water cut-off. Electrical current

ow will be broken at the low water cut-off and the unit will

shut down. With the replacement of water into the cooking

cylinder the thermostat bulb will be cooled at the unit will

then again be operative after pressing the reset button,

more time will have to allowed for further cooling.

NOTE: Should a cooking cycle be started with insufcient

water, and interrupted due to safety action of the low water cut-off, the food in the process of cooking will be affected. Proper compensation will have to be made for the

cooking performed and with proper amount of water in

the cooking cylinder, a new cycle determined and set to

complete the process.

the timer count only that portion of the cycle when cylinder steam pressure is actually acting on the foods. This,

of course is important when processing foods which only

required very short periods of cooking time.

HOW IT WORKS: The copper tube which extends the

top of the cylinder to the rear portion of the timer control

switch constantly reects internal cylinder steam pressure

upon the timer control switch’s built-in bellows. While cylinder free-venting is occurring the switch keeps the timer

circuit open. After free-venting has terminated and when

the cylinder pressure has built-up to approximately 10 PSI

the contacts will be forced closed by back-pressure working on the bellows, the timer circuit will be completed and

the timer will then start its countdown.

DIAL ADJUSTMENTS: The cut-in point of the timer

control switch has been factory set at its maximum setting

of 10 pounds and should not be altered unless it is found

that the timer does not start until well after 10 pounds of

steam pressure has been realized on the pressure gauge.

in this case insert a screwdriver into the center slot (FIG.

14, H) of the larger dial (FIG. 14, G) and rotate slightly

counterclockwise to adjust timer to start at 10 PSI.

RECALIBRATING TIMER CONTROL SWITCH:

Should the timer control switch vary through usage from

its original factory setting it may be restored to proper

working order by recalibrating.

TIMER: The timer located at the lower right front of the

Steam-It provides a means of manual control. The SteamIt is put into an automatic cycle of cooking with the setting

of the timer to any of its calibrated periods of cooking.

Its timing cycle however, is automatically delayed by the

timer control switch until free venting has occurred and a

cylinder pressure build-up to 10 PSI has been reached.

TROUBLE TEST AND REMEDIES: If the timer

should fail to operate the STEAM-IT and a check shows

all wiring to be in good order, and should the timer control switch be found in good order as ascertained by a

continuity check the timer must be regarded as defective

and must be replaced. The timer is replaceable only as a

complete unit.

TIMER CONTROL SWITCH: The timer control

switch, located under the removable front lower panel is

right of center, automatically delays the timer count-down

at the beginning of the cycle until the Steam-It has fully

free-vented out all cold air from within the cooking cylinder and pressure has reached 10 PSI. This delay insures

A visual check of the timer control switch during a trial cycle

will quickly determine the need of recalibration. With the

timer control switch dial set at 10 pounds (fully clockwise)

the timer motor should cut-in when 10 pounds of steam

pressure is registered on the steam pressure gauge. By

watching the smaller dal (FIG. 14, F) on the timer control

switch the cut-in of the switch may be observed and heard

to click forward at the moment the circuit is made to the

timer motor. At that precise moment the pressure gauge

should measure 10 pounds.

CAUTION: If problem develops during the cooking

cycle of this electric steam pressure (15 PSI operation)

consult the trouble-shooting guide on page 24.

PILOT LIGHT: The pilot light is located at the lower

right front of the front panel. This unit is wired to operate

when the heating elements are on. The circuit will be broken when the timer returns to the “0” position. Thus, when

the pilot light is on and off it signies that the heating elements are cycling on and off to maintain cooking pressure

in the cooking chamber.

23

Page 26

TROUBLE-SHOOTING

TROUBLE-SHOOTING GUIDE

POSSIBLE CAUSE CORRECTION

A. Unit fails to operate at all (no pressure build-up).

1. Blown fuse.

2. Wiring faulty.

3. Not installed correctly.

4. Element control switch or contactor coil not in circuit.

5. Current not passing through timer to start unit.

B. Unit operated but fails to build-up steam to 14 pounds pressure.

1. Steam trap fails to operate properly.

2. Exhaust valve fails to hold pressure at 14 pounds.

3. Steam leaks around door.

4. Safety valve blows off below 15 pounds pressure.

5. Element control switch not properly adjusted.

C. Unit releases pressure before cooking cycle has terminated on timer.

1. Power loss.

2. Low water cut-off has functioned prematurely.

D. Timer does not function at 10 PSI of cylinder pressure to start countdown.

1. Loose or broken electrical leads to the timer or timer

control switch.

2. Timer motor defective.

3. Timer control switch defective or out of adjustment.

E. Uneven cooking.

1. Steam trap closing prematurely, preventing removal

of air from the cooking chamber.

F. Heating elements cutting out before 13 pounds pressure is reached.

1. Pressure cutting off electric at the element control

switch too soon.

G. indicator light fails to light with 60 minute timer set.

1. Power to unit off.

2. Indicator light burned out.

3. Faulty wiring.

4. 60 minute timer contact faulty.

H. Excessive steam pressure in compartment above 15 pounds.

1. Safety valve fails in closed position.

2. Pressure switch contacts fail to closed position.

I. Buzzer fails to sound at end of cooking cycle.

1. Faulty wiring.

2. Faulty buzzer.

3. Faulty timer.

1. Replace fuse. If it blows again, check that source of

electricity supply is 60 AMPS.

2. Check all wiring. Replace as needed.

3. Check wiring diagram for correct hookup.

4. Check both elements for continuity. Replace or

repair as needed.

1. Replace the steam trap.

2. Check for correct adjustment or strip down, clean

and repair.

3. Clean seating surfaces and gasket to make sure

they are free of food particles. Check for worm gasket or make door adjustment.

4. Replace safety valve.

5. Readjust.

1. Check for disruption at source of electric supply.

2. Adjust or replace low water cut-off.

1. Repair or replace defective wiring.

2. Check timer motor for continuity. Replace complete

timer if found defective.

3. Make continuity check, adjust, replace is needed.

1. Replace the steam trap.

1. Make adjustments on the dial of the element control

switch to remedy.

1. Locate external circuit breaker for incoming power

and place in on position.

2. Replace light.

3. Inspect wiring, replace if needed.

4. Replace 60 minute timer.

1. Replace valve.

2. Replace switch.

1. Check wiring from buzzer to terminal block and

timer.

2. Replace buzzer.

3. Replace timer.

24

Loading...

Loading...