Page 1

OWNER’S MANUAL

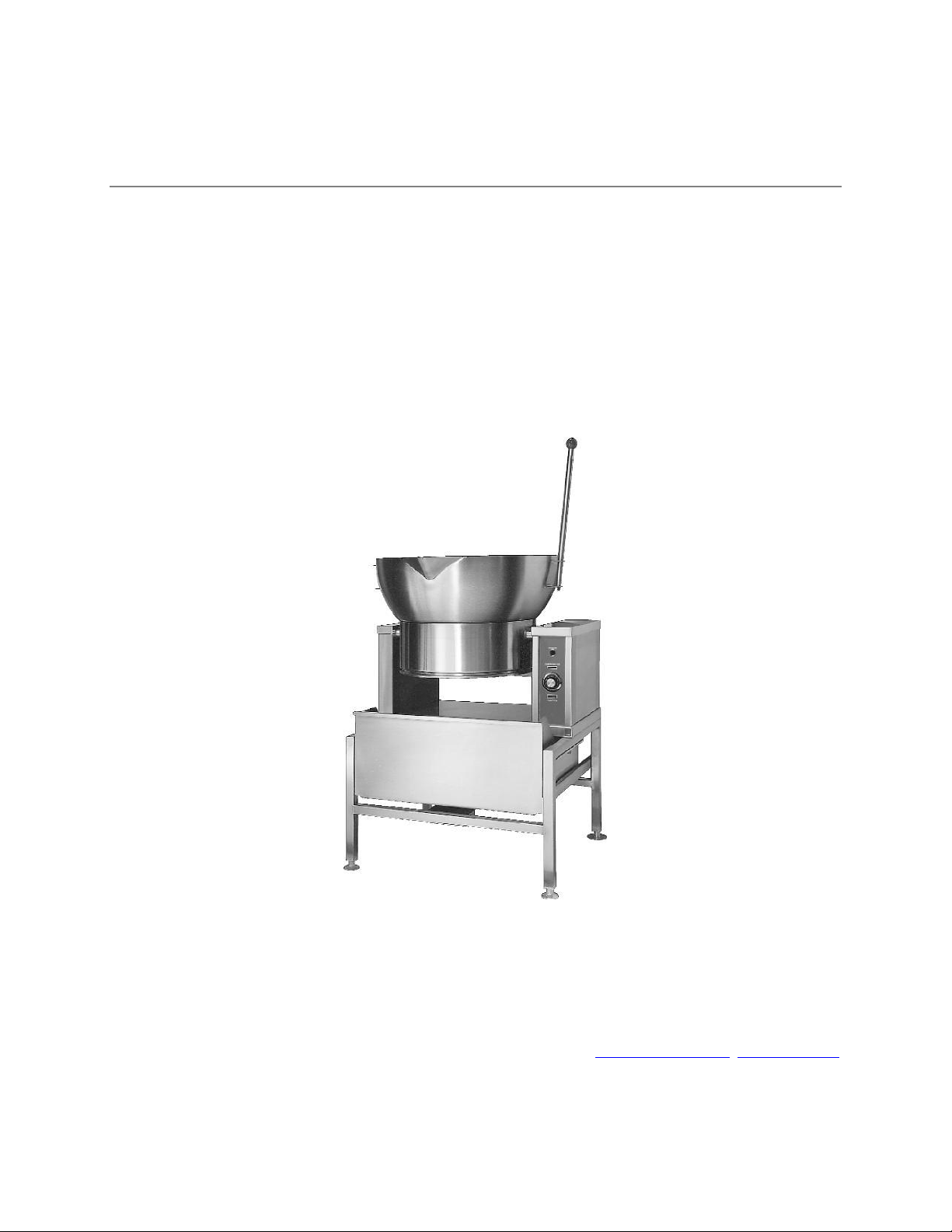

ROUND GAS COUNTER TILTING SKILLET

MODEL: □ R-1600G

Market Forge Industries Inc.

35 Garvey Street, Everett, MA 02149-4403

Telephone: (617) 387-4100, Toll Free: (866) 698-3188

Fax: (617) 387-4456, Outside MA Fax: (800) 227-2659

custserv@mfii.com, www.mfii.com

12/12 REV. B Form Number S-6001

1

Page 2

Table of Contents

Important Notes for Installation and Operating .......................................................................................... 3

Installation Instructions ............................................................................................................................ 4-5

Service Connections ...................................................................................................................................... 4

Installation Instructions ............................................................................................................................... 5

Operating Instructions .................................................................................................................................. 6

To Tilt Skillet .................................................................................................................................................. 6

Maintenance ................................................................................................................................................ 7

Periodic Maintenance .................................................................................................................................. 7

Cleaning ........................................................................................................................................................ 7

Adjustments ................................................................................................................................................ 7

Trouble-Shooting ......................................................................................................................................... 8

Parts List ................................................................................................................................................. 9-14

New Exploded View, After 11/2012 ............................................................................................................. 9

Old Exploded View, Before 11/2012 .......................................................................................................... 13

2

Page 3

IMPORTANT NOTES FOR INSTALLATION AND OPERATION

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

WARNING: Improper installation, operation, adjustment, alteration, service or maintenance

can cause property damage, injury or death.

Read the installation, operating and maintenance instructions thoroughly before installing,

operating or servicing this equipment.

Keep the appliance area free and clear from combustibles.

Do not obstruct the flow of combustion and ventilation air.

Adequate clearances must be maintained for servicing and proper operation.

This manual should be retained for future reference.

WARNING: For your safety do not store or use gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

PURCHASER: Instructions to be followed in the event that the operator of this appliance

smells gas must be posted in a prominent location. This information shall be obtained by

consulting the local gas supplier.

Contact the factory, the factory representative or a local service company to perform

maintenance and repairs should the appliance malfunction. Refer to warranty terms.

3

Page 4

INSTALLATION INSTRUCTIONS

4

Page 5

Installation

Installation must conform with local codes, or in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Installation Code,

CSA B149.1, as applicable.

1. The appliance and its individual shut off valve must be disconnected from the gas supply

piping system during any pressure testing of that system at pressures in excess of 1/2

psi (0.035 kg/cm2).

2. The appliance must be isolated from the gas supply piping system by closing its

individual manual shut off valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psi (0.035 kg/cm2).

Electrical grounding must be provided in accordance with local codes, or in the absence of local

codes, with the National Electric Code ANS1/NFPA 70, or the Canadian Electrical Code, CSA

C22.2, as applicable.

Ventilation must be provided in accordance with local codes, or in the absence of local codes,

with ANSI/SFPA 96 Standard for Ventilation and Fire Protection of Commercial Cooker

Operations.

WARNING: Electrical grounding instructions - units equipped with a three-prong (grounding)

plug for your protection against shock hazard and should be plugged directly into a properly

grounded three-prong receptacle. Do not cut or remove the grounding prong from this plug.

(120 volt units only).

WARNING: Never use an open flame to check for gas leaks. Check all connections for leaks

using soapy water before use.

1. Ideally an exhaust system should be located directly above the appliance to remove combustion

gases and steam generated by the unit.

2. Appliance is intended for use on noncombustible floors but may be installed on combustible

floors provided it is installed on the optional 18" stand, model SD-30-16. Minimum clearance

from combustible and noncombustible wall construction, 3" (76 mm) on sides and 6" (152 mm)

from back.

3. Set the appliance in place and level using spirit level.

4. Appliance location must allow air supply to unit and obstruction free clearance for air opening

into the combustion chamber.

5. Make service connections as indicated.

5

Page 6

OPERATING INSTRUCTIONS

WARNING: In the event of main burner ignition failure, a 5 minute purge period must be

observed prior to re-establishing ignition source.

WARNING: In the event you smell gas, shut down equipment at the main shut off valve and

contact the local gas company or gas supplier for service.

CAUTION: The appliance and its parts are hot. Use care when operating, cleaning and

servicing the appliance.

1. Open manual gas shut off valve located on back of right-hand console facing front of unit.

2. Ensure skillet pan is in the down position.

3. Turn power switch ON. Set thermostat dial to desired setting. RED pilot light will come ON.

4. This will turn on electronic ignition. When the glow coil has reached temperature, the gas

solenoid valve will open, supplying gas to the burner. GREEN pilot light will come ON.

5. Gas in burner is ignited by the glow coil.

6. When ignition is complete, the flame sensor signals the controller to shut off the glow coil.

7. When the skillet has reached set temperature, the pilot lights will go off and the burner will shut

off. The unit will cycle “ON” and “OFF” to maintain set temperature.

8. Turn power “OFF” and thermostat “OFF” when skillet not in use.

NOTICE: If gas supply is interrupted during operation, a five minute period of complete shut

off of gas supply is required before restarting.

TO TILT SKILLET

1. Lift lid.

2. Pull handle forward slowly to desired position. Do not release handle as pan will fall forward and

could cause hot product to splash operator.

NOTE: When the pan is tilted a safety switch will automatically turn off gas supply. The skillet

will not operate once the pan has been tilted.

3. To return pan to down position, push handle up until pan rests on support.

4. DO NOT ATTEMPT TO TILT PAN WITH LID ON.

6

Page 7

MAINTENANCE

PERIODIC MAINTENANCE

NOTICE: Contact the factory, the factory representative or local service company to perform

maintenance and repairs.

NOTICE: As a safety precaution, disconnect the power supply during cleaning or servicing.

CLEANING

CAUTION: Do not use cleaning agents that are corrosive.

The gas fired tilting skillet should be cleaned after each use.

1. Keep exposed cleanable areas of unit clean at all times.

2. Thoroughly wash pan and lid. If necessary soak pan to remove product that is stuck to pan

surface. Use mild detergent and water.

3. Clean around burner air mixer and orifice if lint has accumulated. Bottom cover must be

removed to clean this area.

4. Rinse entire unit and dry. Do not get water in electrical box or any electrical component.

ADJUSTMENTS

WARNING: At least twice a year, have an authorized service person clean and adjust the unit

for maximum performance.

All units are adjusted at the factory. In case of problems in operation at initial installation, check

type of gas and manifold pressure and compare it with information on rating plate.

7

Page 8

TROUBLESHOOTING

Burner does not come on:

1. Gas supply to unit is “OFF”.

2. Manual shut off valve is “OFF.”

3. Thermostat is not turned “ON.”

4. Pan not in lowest position.

5. Glow coil not functioning.

Burner produces carbon deposits:

1. Wrong orifice size.

2. Increase primary air. Clean air opening.

3. Wrong gas supply.

4. Incorrect pressure at supply.

8

Page 9

PARTS LIST

NEW EXPLODED VIEW, AFTER 11/2012

9

Page 10

ITEM

MARKT

FORGE

PART NO.

DESCRIPTION

QTY.

1

97-5995

Pan Cover

1

2

97-5337

Knob - Red

1

3

97-5778

Handle

1

4

97-5116

Acorn Nut, 3/8 - 16

1

5

97-5997

Bearing

2

6

97-6012

Actuator Collar

1

7

97-6013

Bottom Cover

1

8

97-6015

High Limit Thermo Switch

1

9

97-7211

Burner

1

9A

97-5584

Hex Nut, 3/8-16

1

10

97-6016

Sensor

1

11

97-6017

Orifice, Natural Gas

1

97-6018

Orifice, LP

1

97-6018

Orifice, Propane

1

12

97-6019

Glow Coil

1

13

97-5702

Cord Set, 120V

1

14

97-6020

Left Hand Console Cover

1

15

97-6021

Right Hand Console Cover

1

16

97-5052

Ground Lug

1

17

97-5851

Gas Swivel Joint Assembly

1

18

97-5857

Elbow, 1/2" NPT

1

19

97-7208

Combination Control Valve

1

20

97-6518

Actuator Collar**

1

21

97-5856

Street Elbow, 1/2" NPT

1

22

97-7209

Nipple, 1/2" x 3" NPT

1

23

97-7210

Nipple, 1/2” x 3-1/2” NPT

1

24

09-4884

Union Elbow, 1/2"

1

10

Page 11

25

97-5847

Ball Valve, 1/2” NPT

1

26

97-5859

Reducer Coupling

1

27

97-6027

Access Panel

1

28

97-6028

Ignition Module, HSI, 8.5 Seconds

1

29

97-6029

Transformer

1

30

10-6963

Terminal Block Section

2

31

10-6962

Terminal Block, End Section

1

32

97-6030

Thermostat c/w Potentiometer, 120V**

1

97-6031

Thermostat c/w Potentiometer, 240V

1

33

97-6032

Component Mounting Plate

1

34

97-6033

Potentiometer Spacer

1

35

97-6034

Retaining Bracket

1

36

97-5414

Limit Switch

1

37

97-6035

Switch Mounting Bracket

1

38

97-6036

Control Label

1

39

97-6008

Power Switch

1

40

97-6037

Dial Assembly (°F)**

1

97-6038

Dial Assembly (°C)

1

41

97-5012

Bezel

1

42

97-5709

Pilot Light - Red, 120V

1

43

97-5719

Pilot Light - Green, 28V

1

44

98-6111

Nipple, 1/2" NPT x 1-1/2"

1

45

97-5490

Union, 1/2"

1

46

97-7212

Pan Head Screw, 1/4" - 20 x 1-1/2"

1

47

98-6086

Flat Washer, 1/4"

2

48

97-7213

Bushing

1

49

97-6774

Knob

1

50

97-7214

Handle Bar

1

51

97-6585

Hex Nut, 1/4" - 20 UNC

1

52

97-7215

Split Lock Washer, 1/4"

1

53

97-7216

Spacer

1

54

97-7217

Stop Bar

1

55

97-7218

Socket Head Screw, 1/4" - 20 x 3/8"

1

11

Page 12

56

97-7219

Nipple, 1/2" x 4"

1

*57

97-6039

Wire Harness for 9024-1, HSI Module

1

*58

97-5852

Terminal Block, 6 Pole

2

*59

97-6040

Thermocouple Extension

1

*60

97-6041

Thermocouple

1

*61

97-6042

Operation Label (English)

1

97-7220

Operation Label (French)

1

*62

97-6043

Rotary Shaft Seal

1

*63

97-5864

Fuse Holder (120V Units)**

1

97-5864

Fuse Holder (208-240V Units)

2

*64

98-6146

Fuse, 2 Amp, 250V (120V Units)**

1

98-6140

Fuse, 1 Amp. 250V (208-240V Units)

2

*65

97-7221

Cover, High Limit & Thermocouple

1

*66

97-6011

Pan Assembly

1

* NOT SHOWN.

** SELECT AS REQUIRED.

12

Page 13

OLD EXPLODED VIEW, BEFORE 11/2012

13

Page 14

ITEM

PART NO.

DESCRIPTION

QTY.

1

97-6015

Burner

1 2 97-6002

Gas Solenoid

1

3

97-6023

Gas Regulator, Natural

1

97-6024

Gas Regulator, LP

1 4 97-5490

Union, 1/2“

1 5 97-6025

Reducing Bushing, 3/4”-1/2”

1 6 97-6026

Union Elbow Assembly

1

OLDER EXPLODED VIEW, BEFORE 11/2012

14

Loading...

Loading...