Page 1

PS-3E AND PS-6E

ELECTRIC CONVECTON STEAMERS

PARTS AND SERVICE MANUAL

EFFECTIVE AUGUST 1, 2014

The Company reserves the right to make substitution in the event that items specied are not available.

ERRORS: Descriptive and/or typographic errors are subject to correction.

Superseding All Previous Parts Lists.

MARKET FORGE

Telephone: (802) 658-6600 Fax: (802) 860-3732

www.marketforge.com

P/N 14-0285 Rev A (8/14)

Page 2

TABLE OF CONTENTS

SERVICE AND ADJUSTMENTS .........................................................3

WIRING DIAGRAMS ...................................................................4

ILLUSTRATED PARTS LIST ............................................................7

Page 3

SERVICE AND ADJUSTMENTS

NOTICE

Contact the factory, the factory representative or local service company to perform any

maintenance and repairs.

ADJUSTMENT FOR HIGH ALTITUDE LOCATIONS

The steamer has been factory set so that when it is ON

and during the READY phase, it will maintain water temperature in the steam generator tank at approximately

205° Fahrenheit (just below water boiling point). However, for high altitude locations, an authorized service agent

must adjust the steamer to achieve this temperature. To

adjust:

1. Remove side panel and turn control panel power

switch to ON.

2. Open compartment door, and after about 15 minutes,

steam will be seen, entering the cooking compartment.

3. Turn thermostat dial counter clockwise to lower temperature until steam just ceases to enter cooking

compartment and READY light goes on.

4. Replace side panel.

• READY light does not come on after about 15 minutes,

• Water begins to overow into cooking compartment,

• Water ll solenoid valve is open, then any or all of

these symptoms may indicate a problem with the

operating probe due to either:

1. A short between the operating probe terminal and

body of the steamer. Call your authorized service

agent.

2. Excessive scale build-up on the operating probe.

This acts as an “insulation” and prevents the probe

from sensing the water level. It is therefore unable

to close the water ll (solenoid) valve to shut off the

water.

As a temporary solution, with power OFF, unscrew

probes, check visually, and clean or chip off scalant. Replace probe.

This problem is an indication of severe harmful water conditions which should be corrected immediately to avoid

damage to the components and ultimate malfunction of

the steamer. (See WATER CONDITIONING in this manual).

5. Follow TESTING PROCEDURES in this manual.

WATER FLOWS INTO DRAIN DURING SHUTDOWN

When steamer is shut down and cold water is running

continuously into the open drain, either or both solenoid

valves did not close when steamer was turned off.

1. Disassemble solenoid valve(s) and examine for scale

or foreign particles lodged in diaphragm or core tube.

2. Clean valve(s) thoroughly and reassemble, or replace

valve(s).

DRAIN WATER TEMPERATURE TOO LOW OR TOO

HIGH

Cooling solenoid valves are adjustable with ne adjustment screw on the bottom of the valve.

1. Run cooking compartment empty until drain temperature stabilizes.

2. Turn ne adjustment screw on cooling solenoid valve

out to decrease drain temperature and in to increase

drain temperature.

WATER OVERFLOWS INTO COOKING COMPARTMENT

When steamer is rst turned on for the day, and the following conditions occur:

HEATER ELEMENTS DO NOT COME ON

When the steamer is turned ON and heater elements do

not activate, and therefore, the READY light does not

come on, then the contactors may be burned out. If a

considerable amount of “chattering” of contactors has

been previously experienced, then the thermostat bulb

may be coated with scalant and unable to sense water

temperature in the boiler accurately, and therefore unable

to control the contactors.

1. Replace contactors.

2. Unscrew operating thermostat bulb, clean off scalants and screw thermostat bulb back in.

This problem is an indication of inadequate water quality

and is not covered under warranty. Have water quality

analysed and corrected immediately to avoid complete

malfunction of the steamer.

UNIT SHUTS DOWN WHILE IN OPERATION

Pressure switch has been activated due to 5 PSI (35 kg/

cm2) pressure in the generator tank. Pressure in the

generator tank is caused due to plugged steam jet tubes

or steam diverters due to scale or poor water conditions.

Steam jet tubes/steam diverter will have to be cleaned or

replaced.

Page 4

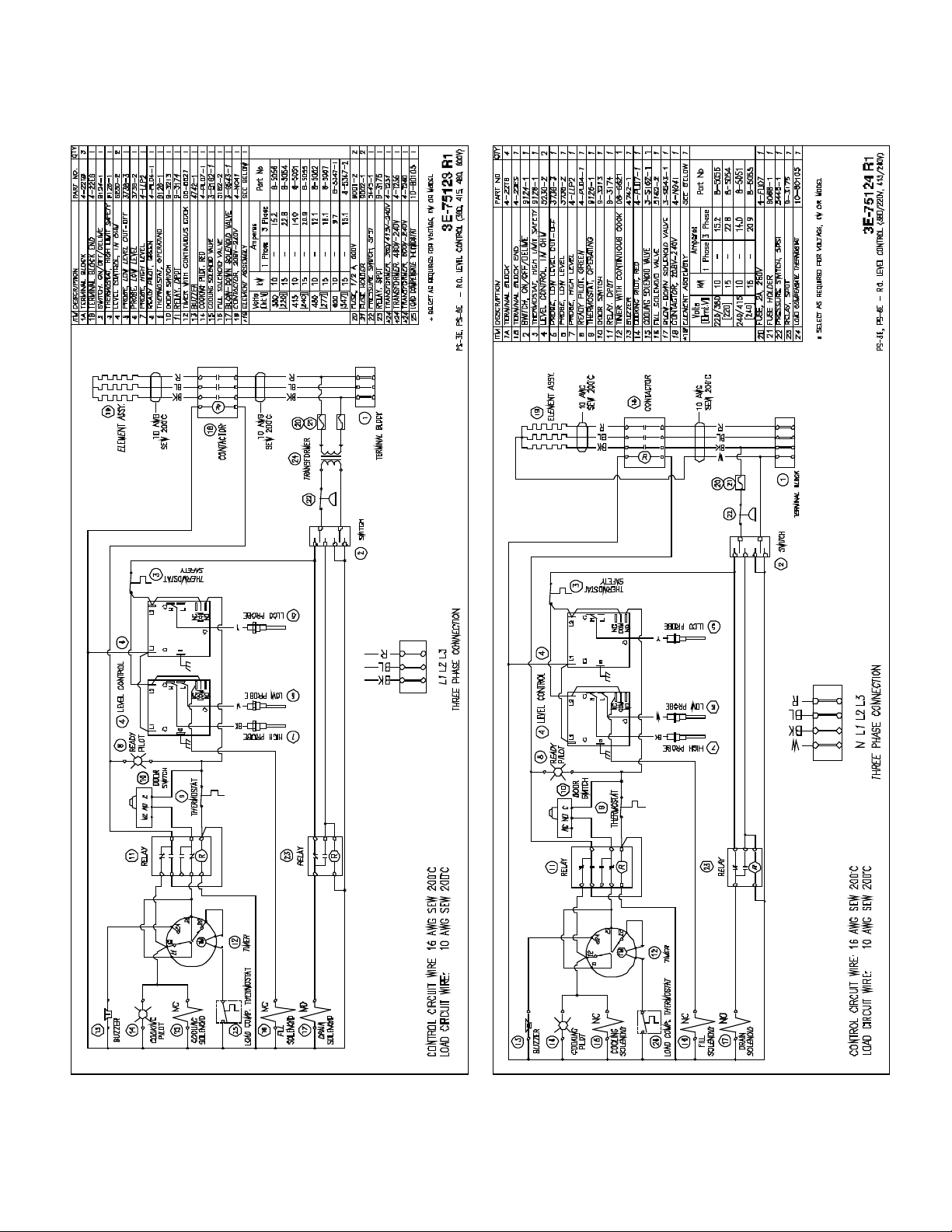

WIRING DIAGRAMS

Page 5

WIRING DIAGRAMS

Page 6

WIRING DIAGRAMS

Page 7

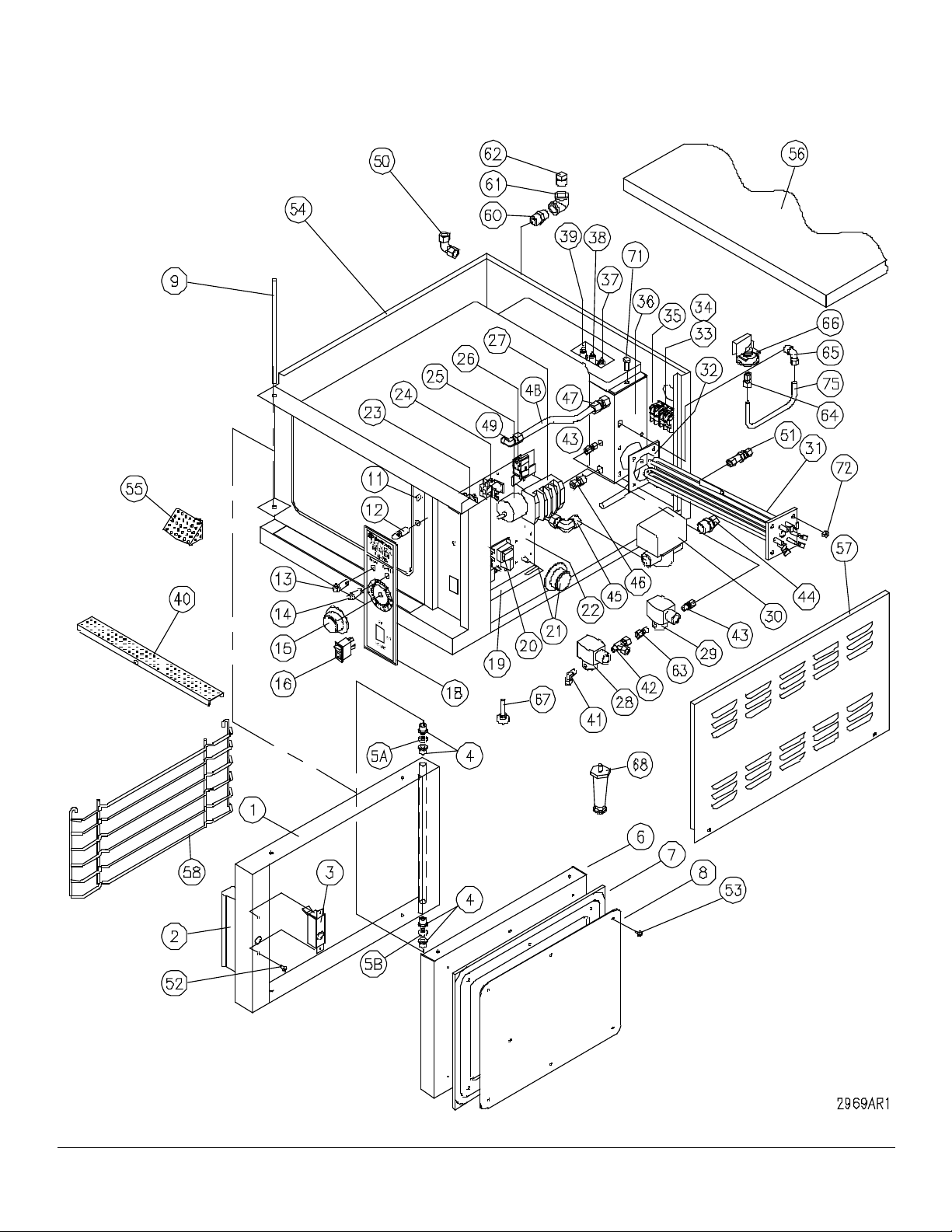

ILLUSTRATED PARTS LIST

AUGUST 1, 2014 7 PS-3E & PS-6E

Page 8

ITEM PART NOL DESCRIPTION PS-3E PS-6E

1A 97-6254 Door Assembly 1

97-6373 Door Assembly 1

1 97-6295 Door Frame 1

97-6227 Door Frame 1

2 97-6231 Door Handle Assembly 1 1

* 97-6235 Decal 1 1

* 97-6258 Door Handle 1 1

* 97-6259 Door Handle Plate 1 1

* 98-9165 Socket Set Screw, 1/4 - 20 x 1-3/4 2 2

* 97-5349 Socket Set Screw, 1/4 - 20 x 3/4 1 1

* 97-6260 Spacer 2 2

* 97-6297 Lock Washer, 1/4 2 2

* 97-6298 Hex Nut, 1/4 - 20 2 2

3 97-6232 Latch Assembly 1 1

4 97-6261 Door Bushing 4 4

5A 97-6734 Spacer - Upper 1 1

5B 97-6735 Spacer - Lower 1 1

6 97-6262 Door Panel 1

97-6230 Door Panel 1

7 97-6264 Door Gasket 1

97-6228 Door Gasket 1

8 97-6266 Gasket Plate, 3-pan 1

97-6229 Gasket Plate, 6-pan 1

9 97-6299 Hinge Rod 1

97-6364 Hinge Rod 1

*10 97-6300 Steam Diverter 2 2

11 97-6301 Actuator Complete With Retaining Rings 1 1

* 97-6191 Door Switch 1 1

12 97-6178 Striker 1 1

* 97-6302 Stainless Steel Washer 1 1

* 97-6650 Lock Washer 1 1

* 97-6651 Nut 1 1

13 97-6270 Pilot Light, Green 1 1

14 97-6271 Pilot Light, Red 1 1

**15 98-6046 Timer Dial 1 1

16 97-6272 Power Switch 1 1

* NOT SHOWN ** SELECT AS REQUIRED

AUGUST 1, 2014 8 PS-3E & PS-6E

Page 9

ITEM PART NOL DESCRIPTION PS-3E PS-6E

*17 97-6303 Label, De-Lime (Rear of Unit) 1 1

**18 97-6304 Control Decal 1

97-6305 Control Decal 1

19 97-6275 Component Mounting Board 1 1

**20 97-6276 Level Control Board, 10K OHM 1 1

97-6277 Level Control Board, 1M OHM 2 2

21 97-5048 Thermostat - Operating 1 1

97-6736 Dial 1 1

22 97-6278 High Limit Thermostat 1 1

23 97-6279 Relay - Single Pole, 240V 1 1

24 97-6280 Relay - Double Pole, 240V 1 1

25 08-6464 Timer, 230 VAC and 240 1 1

26 97-6307 Buzzer, 240V 1 1

**27 98-6189 Contactor - 4 Pole (208, 220, 240V) 1 1

97-5609 Contactor - 380, 415, 480, 600 Volt 1 1

28 97-6285 Cooling Solenoid, 240V, Metering 1 1

29 97-6308 Fill Solenoid, 240V 1 1

30 97-6283 Blow-down Solenoid, 240V 1 1

**31 97-6309 Element Assembly, 10 kW, 208V 1

97-6310 Element Assembly, 10 kW, 220/380V 1

97-6311 Element Assembly, 10 kW, 240/415V 1

97-6312 Element Assembly, 10 kW, 480V (287) 1

97-6313 Element Assembly, 10 kW, 600V (347) 1

97-6314 Element Assembly, 15 kW, 208V 1

97-6315 Element Assembly, 15 kW, 220/380V 1

97-6316 Element Assembly, 15 kW, 240/415V 1

97-6317 Element Assembly, 15 kW, 480V (287) 1

97-6318 Element Assembly, 15 kW, 600V (347) 1

32 97-6319 Element Gasket 1 1

**33 10-6963 Terminal Block, 208-240V, 10 kW, Black 4

98-6185 Terminal Block, 208-240V, 15 kW, White 4

* 97-6737 Terminal Rail, 208-240V, 15 kW 1

10-6963 Terminal Block, 380/220V 415/240V, Black 4 4

10-6963 Terminal Block, 380-600V, Black 3 3

**34 10-6962 End Section, Black 1 1

98-6186 End Section, 208-240V, 15 kW, White 1 1

* NOT SHOWN ** SELECT AS REQUIRED

AUGUST 1, 2014 9 PS-3E & PS-6E

Page 10

ITEM PART NOL DESCRIPTION PS-3E PS-6E

*35 97-5052 Ground Lug 1 1

97-6738 Earth I.D. Tag 1 1

36 97-6321 Steam Generator Tank 1 1

* 97-6322 Tank Cover 1 1

97-6323 Tank Gasket 1 1

37 97-6324 Probe - 5" Low Level Cut Off 1 1

38 97-6325 Probe - 4.25" Low Level 1 1

39 97-6326 Probe - 3.688" High Level 1 1

40 97-6177 Perforated Trough 1 1

41 98-6089 Elbow, 1/4 c x 1/8 MPT 1 1

42 97-6327 Tee, 3/8 c x 1/8 MPT 1 1

43 98-6123 Connector, 1/4 c x 1/8 MPT 1 1

44 97-6328 Connector, 1/2 c x 3/4 MPT 1 1

45 97-6208 Elbow, 1/2 c x 3/4 MPT 1 1

46 97-5619 Thermostat Fitting, 3/8 c x 3/8 MPT 1 1

47 97-6206 Union Coupling, 1/2 c 1 1

48 97-6329 Right Hand Steam Jet Tube 1 1

* 97-6330 Left Hand Steam Jet Tube 1 1

49 97-6331 Elbow, 1/2 c x 1/4 MPT 2 2

50 97-6207 Elbow, 1/2 c 1 1

51 97-6226 Water Connection, 3/8 c 1 1

52 97-6739 Screw, 10-32 x 1/2 SS 6 6

53 97-6233 Screw, (Special), 10-32 x 1/2 6 8

54 97-6332 Left Hand Side and Back 1

54 97-6333 Left Hand Side and Back 1

55 97-6334 Compartment Strainer 1 1

56 97-6335 Top 1 1

**57 97-6336 Side Panel 1

97-6337 Side Panel 1

**58 97-6338 Rack Slides 2

97-6339 Rack Slides 2

*59 97-6340 Rack Pin Assembly 4 4

60 97-6341 Brass Nipple, 1/2 -14 1 1

61 97-6342 Brass Elbow, 1/2 -14 1 1

62 97-6740 Brass Plug, 1/2 - 14, Hex Head 1 1

63 97-6344 Connector, 3/8 c x 1/8 MPT 1 1

* NOT SHOWN ** SELECT AS REQUIRED

AUGUST 1, 2014 10 PS-3E & PS-6E

Page 11

ITEM PART NOL DESCRIPTION PS-3E PS-6E

64 97-6591 Connector, 3/8 c x 1/8 FPT 1 1

65 97-6346 Elbow 90°, 3/8 c x 3/8 MPT 1 1

66 97-6347 Pressure Switch 1 1

67 97-6348 Leveler 4 4

68 97-6211 Adjustable Leg, Optional 4 4

* **69 97-6186 Fuse, 2 Amp., 250V (208, 240V) 2 2

97-6186 Fuse, 2 Amp., 250V (220, 220/380, 240/415) 1 1

* ** 98-6188 Fuse, 1/2 Amp, 600V (380, 415, 480, 600V) 2 2

97-5864 Fuse Holder (208, 240V) 2 2

97-5864 Fuse Holder (220, 220/380, 240/415V) 1 1

98-6187 Fuse Holder (380, 415, 480, 600V) 2 2

* **70 97-5616 Transformer, 380-220V, 50/60 Hz, 100VA 1 1

97-5616 Transformer, 415-240V, 50/60 Hz, 100VA 1 1

97-5613 Transformer, 480-240V, 60 Hz, 100VA 1 1

98-6191 Transformer, 600-240V, 60 Hz, 100VA 1 1

71 97-6663 Hex Blot, 5/16-18 x 1 SS 2 2

72 97-6298 Hex Nut, 1/4 - 20 SS 4 4

*73 97-6349 “Y” Strainer, Optional 1 1

*74 97-6741 Wire Harness 1 1

75 97-6351 Copper Tube, 3/8 1 1

* NOT SHOWN ** SELECT AS REQUIRED

AUGUST 1, 2014 11 PS-3E & PS-6E

Loading...

Loading...