Market Forge PS-3E Installation Manual

PREMIERE SERIES

ELECTRIC CONVECTION STEAMERS

INSTALLATION - OPERATION - MAINTENANCE

MODELS

PS-3E

PS-6E

44 Lakeside Avenue, Burlington, Vermont 05401 USA

Telephone: (802) 658-6600 Fax: (802)864-0183

www.mi.com PN 14-0264 Rev A (7/14)

© 2014 - Market Forge Industries Inc.

Your Service Agency’s Address:

Model

Serial number

Oven installed by

Installation checked by

IMPORTANT

TABLE OF CONTENTS

WARNING: Improper installation, adjustment, alternation,

service or maintenance can

cause property damage, injury or death. Read the installation, operation and maintenance instructions thoroughly

before installing or servicing

this equipment.

FOR YOUR SAFETY

Do not store or use gasoline or

other ammable vapors or liquids in the vicinity of this or any

other appliance.

The information contained in this

manual is important for the proper installation, use, and maintenance of this oven. Adherence

to these procedures and instructions will result in satisfactory

baking results and long, trouble free service. Please read

this manual carefully and retain

it for future reference.

INSTALLATION

Service Connections ..................................................... 2

Installation Instructions ................................................... 3

Testing Procedures ....................................................... 6

OPERATION

Operating Instructions .................................................... 7

Control Description ................................................... 7

Cooking with the Steamer ............................................. 7

Shut Down........................................................... 7

Suggested Cooking Guidelines ............................................ 9

MAINTENANCE

Cleaning ............................................................... 11

Condenser Maintenance ................................................. 12

ERRORS: Descriptive, typographic or pictorial errors are

subject to correction. Specications are subject to change

without notice.

Service Connections

SERVICE CONNECTIONS

GW Generator Water - 3/8” (10mm) OD tubing at 25-50 PSI.

CW Cold Water - 3/8” (10mm) OD tubing at 25-50 PSI.

D Drain - 1” (25mm) IPS piped to open floor drain. NO

SOLID CONNECTION TO FLOOR DRAIN. NO BENDS

OR ELBOWS.

EC Electrical Connection - 1-1/8” (29mm) electric connection

to controls.

GW

D

1.75 (44)

27.50 [699]

15.00 [381]

3.00 [76]

1.75 [44]

CW

EC

ELECTRICAL CHARACTERISTICS

AMP/PHASE

SINGLE PHASE

MODEL kW

PS-3E 10

PS-6E 15

MODEL kW

PS-3E 10

PS-6E 15

208V 220V 240V

48 46 42

72 69 63

AMP/PHASE

THREE PHASE

208V 240V 380V 415V 480V 600V

28 24 16 14 12 10

42 36 23 21 18 15

CAUTION:

Before connecting water to this unit, water supply should be analyzed to make sure hardness is no greater than 2.0 grains and pH

level is within the range of 7.0-8.5. Water which fails to meet these

standards should be treated by installation of water conditioner.

EQUIPMENT FAILURE CAUSED BY INADEQUATE WATER

QUALITY IS NOT COVERED UNDER WARRANTY.

17.00 [432]

D

24.00 [610]

20.00 [508]

EC

GW

PS-3E

1.50 [38]

12.50 [318]

CW

PS-6E

19.00 [483]

DIMENSIONS ARE IN INCHES [MM]

1/2 NPT DELIME INLET

23.50 [597]

Figure 1

D

1.00 [25]

2.00 [51]

PS-3E

PS-6E

15.13 [384]

21.62 [549]

4.02 [102]

INSTALLATION

2

Installation Instructions

GENERAL

The PS-3E and PS-6E steamers are single compartment

electric pressureless steam cookers with an internal electric steam generator that maintains standby water temperature at approximately 205°F. PS-3E is rated 10 kW.

PS-6E is rated 15 kW.

At high altitude locations a lower temperature is required

to achieve atmospheric steaming. Contact your autho-

rized service ofce to have the thermostat adjusted if the

steamer will be operated at high altitudes.

UNPACKING

This steamer was inspected before leaving the factory.

The transportation company assumes full responsibility

for safe delivery. Immediately after unpacking the steamer, check for possible damage. If the steamer is found to

be damaged after unpacking, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, verify that the electrical service agrees

with the specications on the machine data plate which is

located on the left side panel.

LOCATION

Allow space for plumbing and electrical connections.

Minimum clearances are 0” on the sides and 6” (152 mm)

on the back for proper air circulation. Allow adequate access for operating and servicing the steamer, 36” (915

mm) at the front of the steamer and 15” (381 mm) above

the steamer.

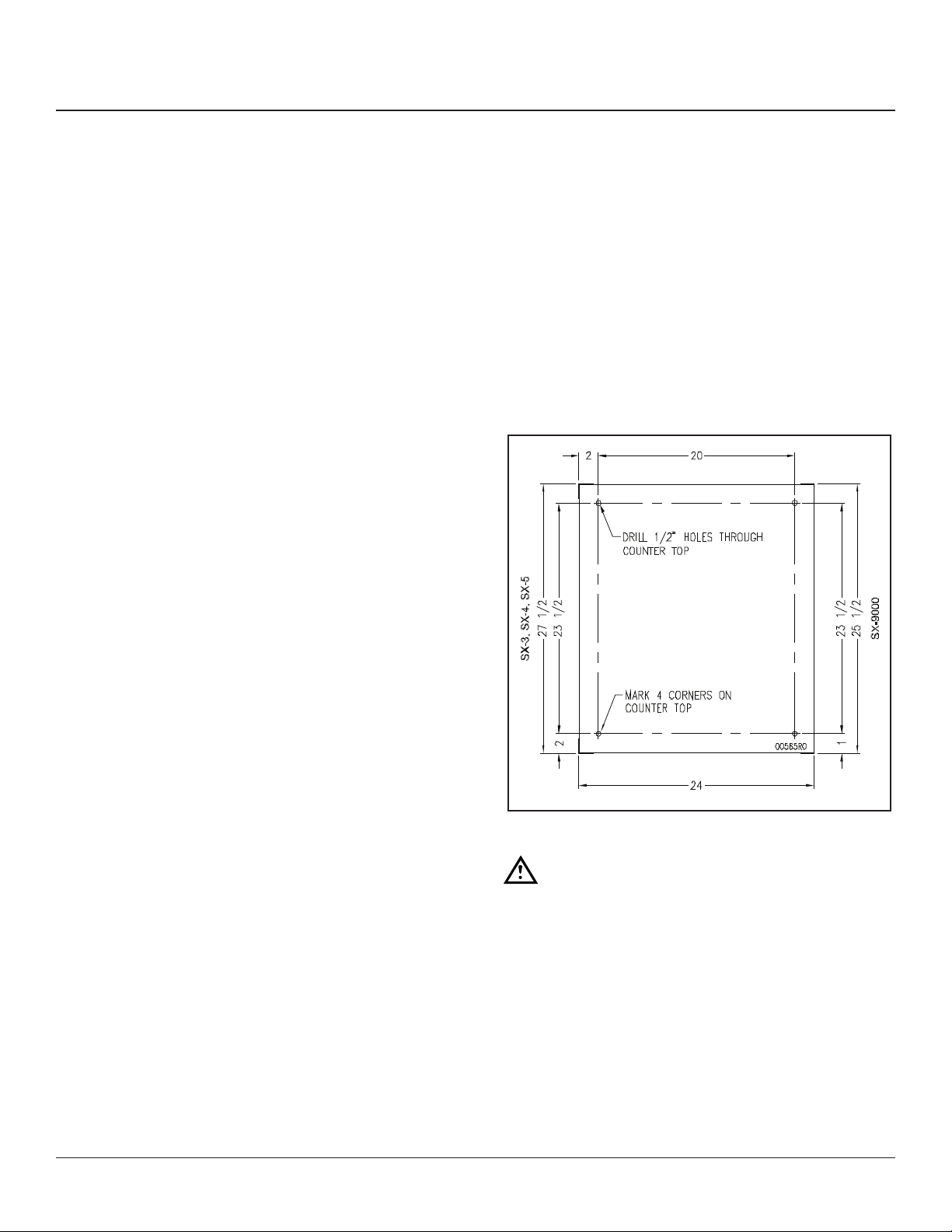

ANCHORING STEAMER (WITHOUT LEGS)

1. Place steamer in the desired location on the levelled

counter top and mark four corners. Remove the

steamer and drill 1/2” holes as indicated in “Figure 2”.

2. Apply a bead of RTV or other equivalent sealant

around bottom perimeter edge of the steamer. If anchoring the steamer, this bottom seal is necessary to

meet NSF requirements.

3. Set steamer on counter and bolt down securely with

3/8 - 16 bolts (not supplied).

STACKING KIT

Follow instructions in the stacking kit when installing

stacked convection steamers.

LEVELING FEET (STANDARD) OR 4” ADJUSTABLE

LEGS (OPTIONAL)

Thread the four 2” levelling feet shipped in a bag inside

the steamer cabinet into the threaded holes on the bottom corners of the steamer. Or, thread the four optional

4” adjustable legs into the threaded holes on the bottom

corners of the steamer.

LEVELING

Using a spirit level or pan of water in the bottom of the

steamer, adjust the levelling feet or the feet on the adjustable legs to level the steamer front-to-back and sideto-side. After the drain is connected, check for level by

pouring water onto the oor of the compartment. All water

should drain through the opening at the back of the compartment cavity.

Figure 2

WARNING

Disconnect the power supply to the appliance

before cleaning or servicing.

Make electrical connection through the 1-1/8” (29 mm) diameter hole provided using 3/4” (19 mm) trade size conduit. Refer to the wiring diagram located inside the right

side panel. Use 90°C minimum insulated wire.

3

INSTALLATION

Loading...

Loading...