Page 1

Page 2

Page 3

Page 4

PROBLEM

Probable Cause Remedy

a. Power to kettle off. a. Located external Shut-Off (circuit breaker) for incoming

power & place in ON position.

b. Low water level in kettle reservoir. b. Fill reservoir.

c. Power ON/OFF light burned out. c. Replace switch.

d. Faulty power ON/OFF switch. d. Replace switch.

e. Faulty water level control.

e. Replace control (

see subsection 2.3.5

)

f. Faulty wiring. f. Inspect condition of wire & tightness of all connectors.

Correct as required.

a. Air in kettle reservoir. a. Replace steam trap as needed.

b. Faulty (weeping) safety relief valve. b. Replace valve.

c. Burned out heating elements.

c. Replace as required. (

see subsection 2.3.4

)

d. Pressure switch faulty.

d. Recalibrate or replace as required. (

see subsection 2.3.2

)

a. Low water level in reservoir. a. Fill reservoir.

b. Faulty wiring. b. Inspect & repair as required.

c. Defective water level control. c. Replace control as required.

a. Bearing loose or lacking lubrication. a. Repair or replace as required.

a. Water main shut-off. a. Turn off.

b. Power not reaching unit. b. Check main fuse.

c. lack of water level probe sensitivity due to lime build-up.

c. Clean probe.(

see subsection 2.3.5.4

)

d. Defective water fill valve. d. 1. Clean strainer.

2. Check oil for continuity. Replace if defective.

e. Defective water switch (

marked power switch on control box

).

e. Check continuity. Replace if defective.

f. Defective warrick controller. f. Replace controller

g. Water pressure to low. g. Increase water pressure to 25-50 PSI.

a. Lack of water level probe sensitivity due to lime build-up.

a. Clean probe. (

see subsection 2.3.5.6

)

b. Water fill valve fails to close. b. Clean valve seat & strainer.

c. Defective warrick controller. c. Replace controller.

d. Water pressure to high. d. Check pressure. If above 25-50 PSI, decrease pressure.

6. BOILER OVERFILLS WITH WATER.

2. KETTLE NOT HOT ENOUGH TO BOIL WATER.

3. LOW WATER LIGHT ON.

4. KETTLE HARD TO TILT.

5. WATER DOES NOT ENTER BOILER.

1. POWER ON/OFF SWITCH FAILS TO LIGHT WITH SWITCH IN ON POSITION.

Table 2-1

GENERAL TROUBLE-SHOOTING GUIDE

Page 5

PROBLEM

Probable Cause Remedy

a. Dirty strainer screen in water fill valve. a. Clean or replace strainer screen.

b. Dirt or lime accumulation of water fill valve seat. b. Clean valve seat.

c. Water pressure to low. c. Increase pressure to 25-50 PSI.

a.Circuit breaker in main not turned on.

a. Clean probe. (

see subsection 2.3.5.6

)

b. Contactors not pulling in. b. Check continuity of coil. If open replace.

c. Defective steam trap. c. Replace trap.

d. Heating elements defective. d. Replace if continuity check through the circuitry of each

element shows deficiency. (

see subsection 2.3.4

)

a. Pressure gauge reads inaccurately. a. Replace pressure gauge.

b. Operating pressure control & high limit control switches

b. Readjust or replace as required. (

see subsection 2.3.2.1

)

out of adjustment.

c. Safety valve not seating properly. c. Clean or replace as required.

d. Contactor coils (1 or both) not energizing & closing d. 1. Check contactor. Replace either contactor coils or

circuits to the heating elements. complete contactor as required.

2. Measure amperage at terminal block. Check to ensure

that there is an even draw on all 3 Phases. See wiring

diagram for correct amperage draw. If uneven or '0'

amp draw is found on 1 of the 3 phases, check for blown

fuse. If fuse not blown, shut off power.

3. Remove wires from heating elements & run continuity

check. Replace as required.

a. Incorrect supply voltage. a. Check to see that voltage supply matches with coil in

connectors.

b. Dirty or worn contactor points. b. Clean or replace contactor.

c. Weak coil. c. Replace with correct voltage coil.

a. Pressure set to high. a. Readjust pressure switch.

b. Pressure gauge reads incorrectly. b. Replace pressure gauge.

c. Lime or dirt on valve seat. c. Clean valve seat.

d. Weak spring in valve. d. Replace valve.

a. High limit switch set to low or operating pressure control

a. Readjust or replace as required. (

see subsection 2.3.2.1

)

switch to high.

a. Not closing. a. Replace.

a. Main water line shut-off. a. Turn on.

b. Thermostat out of adjustment or defective. b. Readjust for proper operation or replace if defective.

(

see subsection 2.3.2.2

)

c. Loose fit. c. Tighten coil as close to body of valve as possible.

d. Coil not continuous. d. If open, replace.

11. SAFETY VALVE BLOWS OFF PREMATURELY.

12. BOILER BUILDS UP TO PRESSURE, THEN SHUTS DOWN & FAILS TO COME BACK ON.

13. AIRVENT LEAKING.

14. COLD WATER CONDENSER DOES NOT FUNCTION.

9. BOILER FAILS TO REACH FULL OPERATING PRESSURE (OF APPROX. 15 LBS).

10. CONTACTOR CHATTERS.

7. WATER ENTERS BOILER VERY SLOWLY.

8. BOILER FAILS TO BUILD UP PRESSURE WHEN WATER LEVEL IS PROPER & HEAT SWITCH IS TURNED ON.

Table 2-1

GENERAL TROUBLE-SHOOTING GUIDE (CONTINUED)

Page 6

PROBLEM

Probable Cause Remedy

CONTACTOR

a. Low Voltage. a. 1. Check voltage condition. Check momentary voltage dip

during starting. Low voltage prevents magnet sealing.

2. Check coil voltage rating. Correct voltage condition as

required.

b. Defective or incorrect coil. b. Replace coil. Rating of coil must match the line voltage

a. Abnormal inrush of current. a. Check for grounds or shorts in system. Correct as required.

b. Low voltage preventing magnet from sealing. b. Correct voltage condition.

c. Short circuit. c. Remove short fault & check that fuse or breaker size is

correct. Correct as required.

a. Filling or dressing. a. Do not file silver tips. Rough spots or discoloration will not

harm tips or impair their efficiency. Replace as required.

b. interupting excessively high current. b. Check for grounds, shorts or excessive current. Correct.

c. Discolored contacts caused by insufficent contact c. 1. Check contact carrier for deformation or damage.

pressure, loose connections, etc. Replace as required.

2. Clean & tighten connections.

d. Dirt or foregin matter on contact surface. d. Clean contact surface with carbon tetrachloride.

e. Short circuit. e. Check that fuse or breaker size is correct.

Remove fault. Correct as required.

COLIS

a. Mechanical damage. a. Handle & store carefully. Do not handle coils by leads.

Replace as required.

b. Burnt out coil due to over voltage or defect. b. Replace coil.

a. Over voltage or high ambient temperature. a. Check application & circuit. Correct as required.

b. Incorrect coil. b. Check rating ( voltage/frequency) If rating correct replace

with proper coil.

c. Short turns. c. Replace coil.

d. Voltage shortage (faiure of magnet to seal in). d Correct system voltage. Install NEW coil.

4. OPEN CIRCUIT.

5. OVERHEATED COIL.

2. WELDING OR FREEZING.

3. SHORT CONTACT BUTTON LIFE &/OR OVERHEATING OF CONTACTS.

1. CONTACT CHATTER.

Table 2-2

CONTACTOR TROUBLE-SHOOTING GUIDE

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

3-3

Page 14

Page 15

Page 16

Page 17

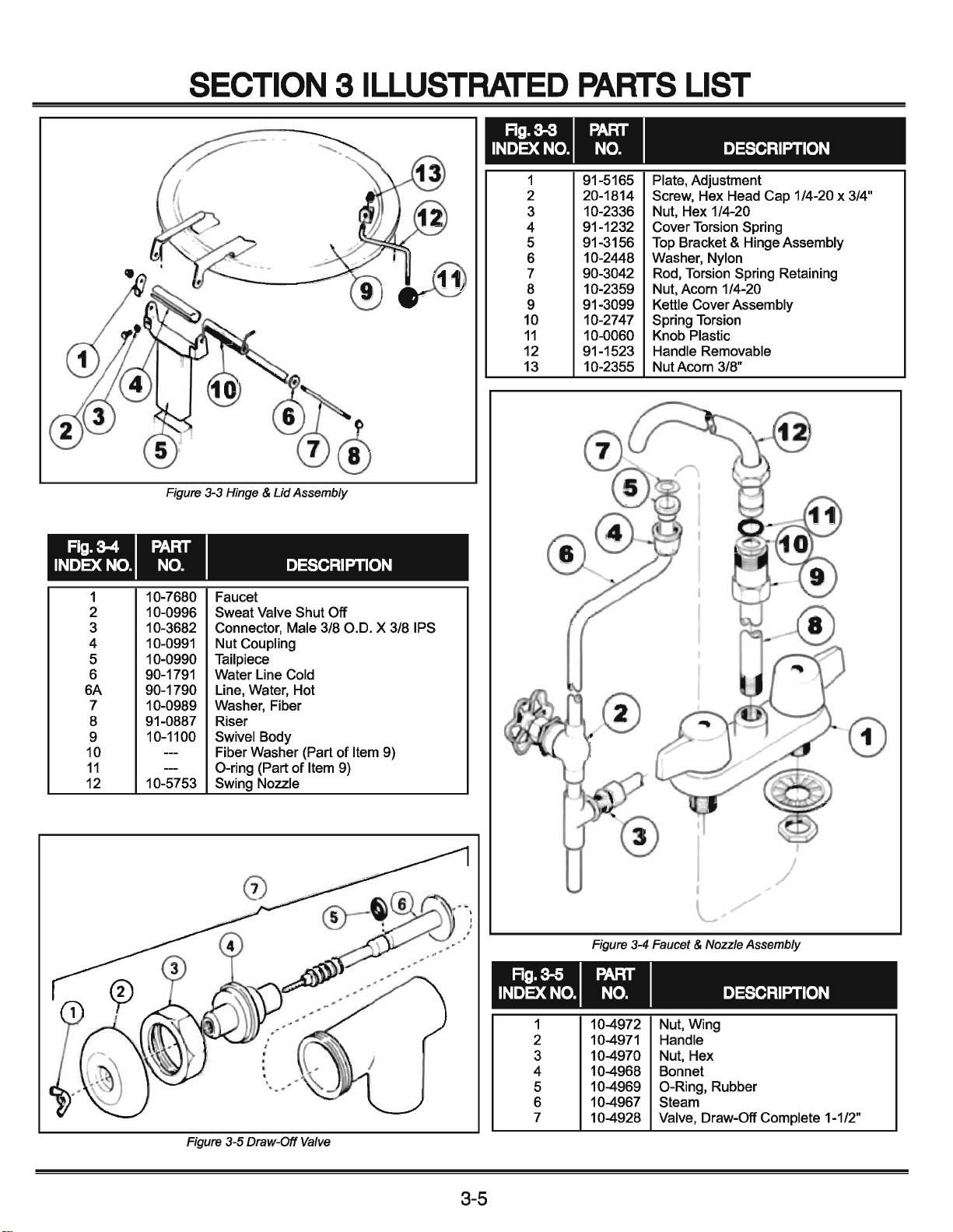

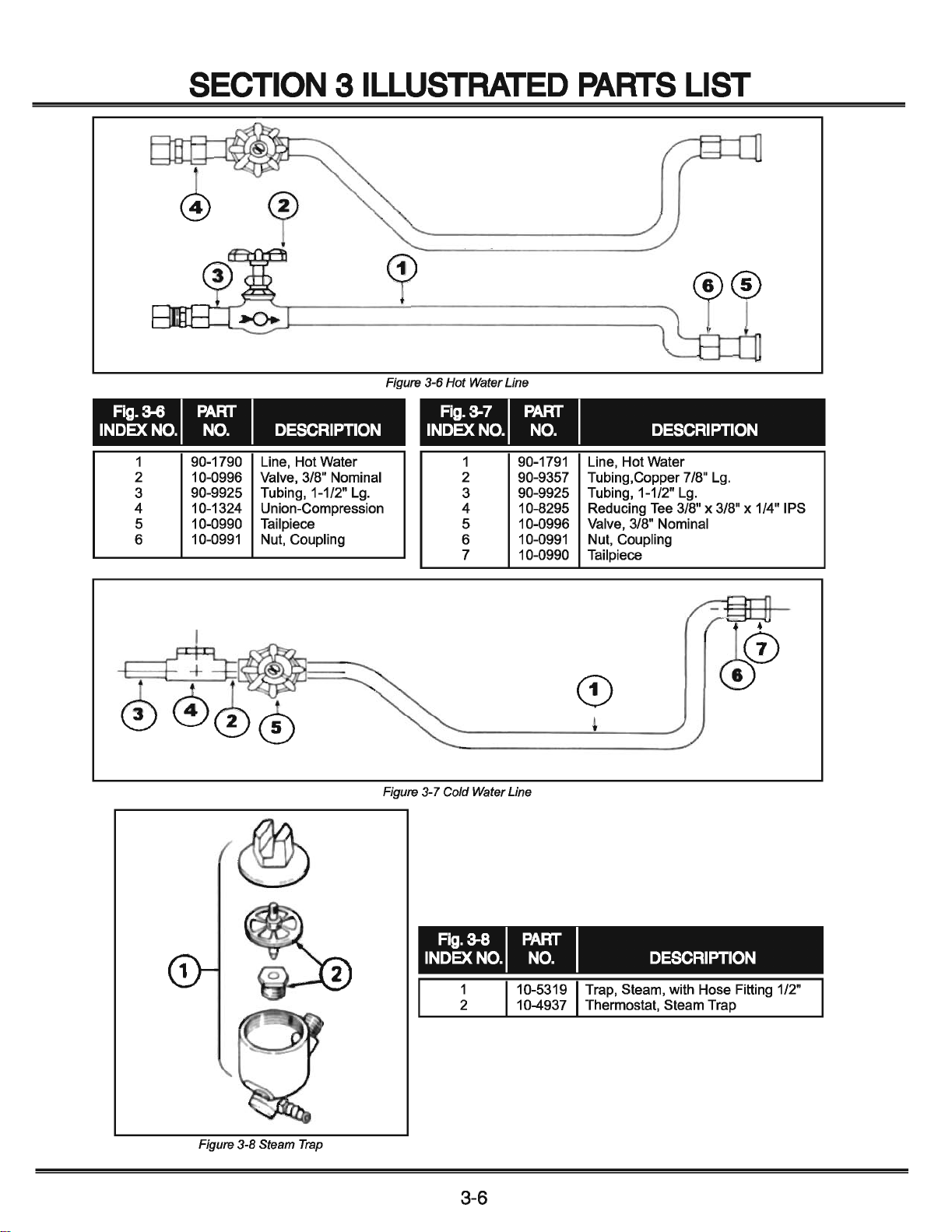

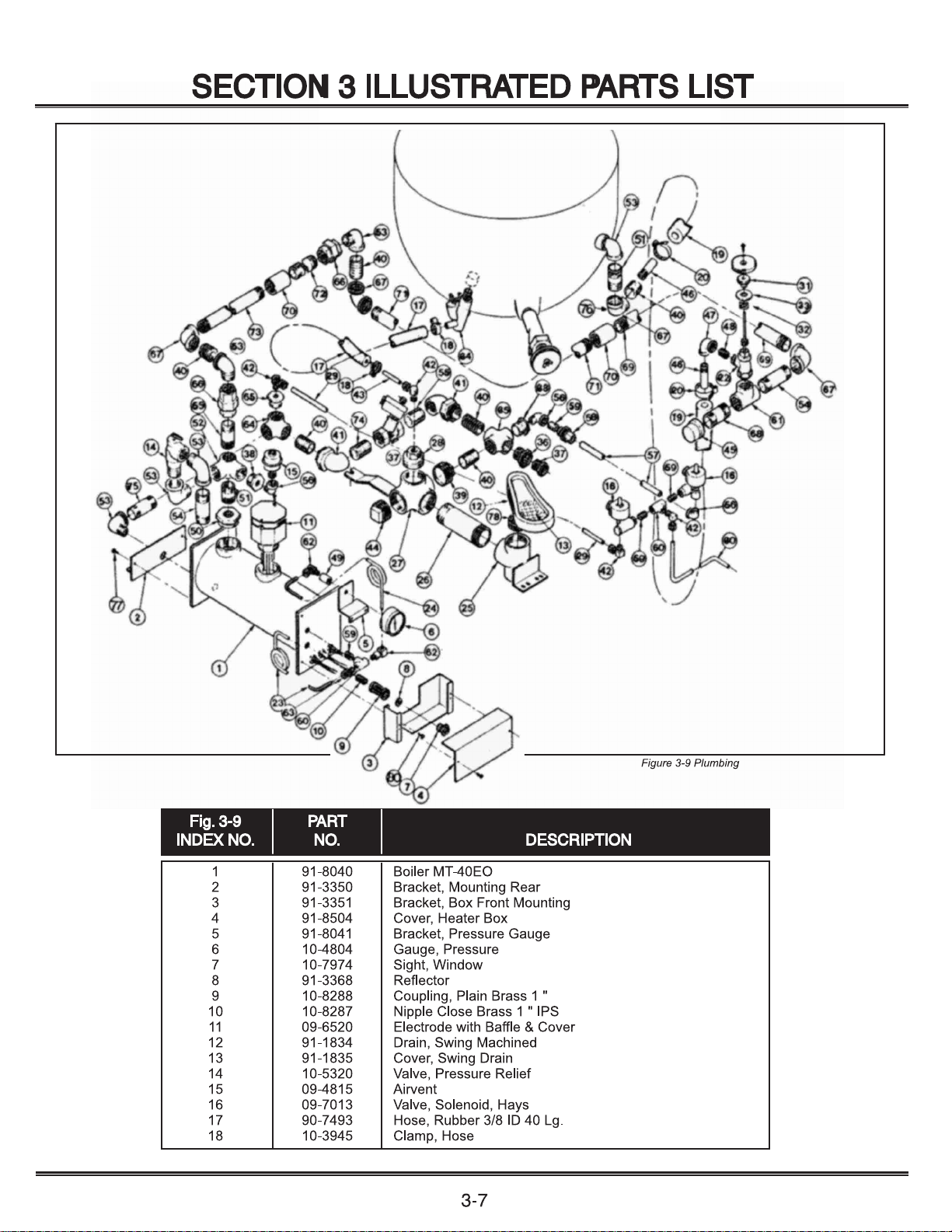

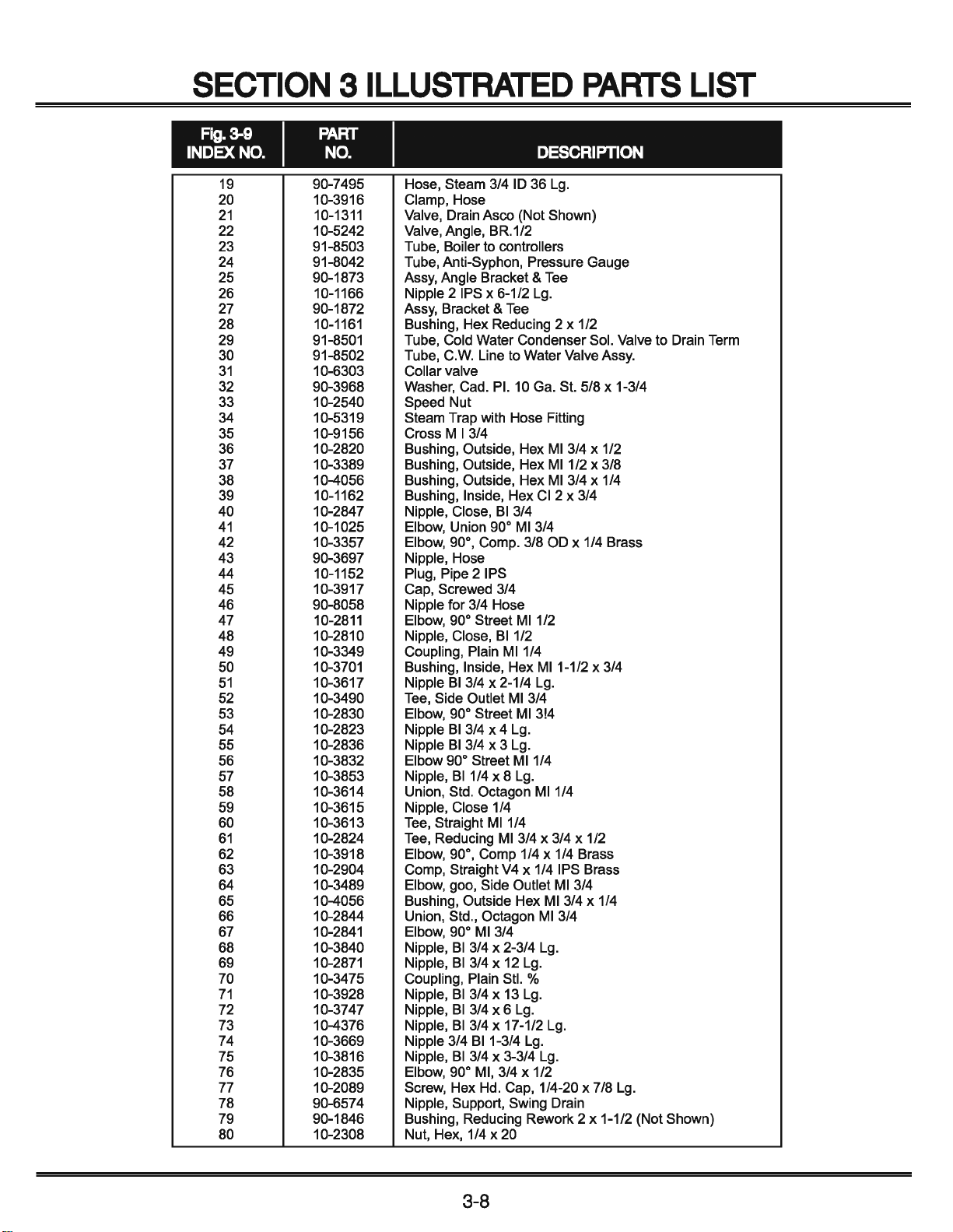

SECTION 3 ILLUSTRATED PARTS LIST

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

9

10

1

2

3

8

7

6

5

9

10

10

9

6

1

4

4

1

7

2

2

8

3

3

9

10

6

7

8

11

1

2

5

3

4

Page 25

1

Page 26

Page 27

Loading...

Loading...