Page 1

60 GALLON STEAM

E

MODEL: □ MT-60EO

SIZE: 48” Wide x 33” Front-to-Back

(

DESCRIPTION:

Shall be a Market Forge Model MT-60EO steam jacketed tilting kettle with self-contained electric generator.

Kettle shall be of stainless steel mounted in an enclosed cabinet base containing a 24 kW electrically

powered steam generator for operation of the kettle.

Cooking temperature shall be controlled with a steam

control valve located on the right side of cabinet top.

A hot and cold water ll faucet with swing spout shall

be located on cabinet top. Kettle shall be equipped

with a 2” (51mm) sanitary draw-off valve which shall

be enclosed for sanitary purposes. This valve will

empty into a swing drain which shall be removable

without tools and shall be equipped with a removable

stainless steel strainer. Unit shall include a one-piece

counter-balanced stainless steel cover.

Cabinet base shall be of modular design to match

other Market Forge equipment and enclose steam

generator. Kettle base shall have 6” (152mm) stain-

less steel legs with hold-down feet in the rear. The

base front shall have reinforced die-formed stainless

steel doors with magnetic latches.

Kettle shall tilt upright to allow complete emptying of

contents under positive control by turning the removable crank. Kettle is equipped with a steam trap located on bottom of kettle. A pan support, removable

without tools, shall maintain pan in horizontal position

not more than 2” (51mm) from kettle lip throughout

tilting angle.

Pan support shall hold: one 12” x 20” x 2 1/2” deep

pan (305mm x 508mm).

JACKETED ELECTRIC KETTLE

1219mm Wide x 838mm Front-to-Back

JOB NAME: ___________________________

ITEM NO.: ____________________________

NO. REQUIRED: _______________________

)

MT-60EO Shown

OPERATION SHALL BE BY:

Self-contained high speed 24 kW electric self-generating steam generator of the following characteristics:

□ 208 volt AC, 3 phase 60 Hz

□ 240 volt AC, 3 phase 60 Hz

□ 480 volt AC, 3 phase 60 Hz (

The steam generator shall generate 15 PSI steam in

5 minutes with kettle empty. The MT-60EO shall

bring 50 gallons of water to a boil, with cover down,

in approximately 65 minutes. Steam generator shall

be mounted independent of kettle within the cabinet

base and allow for separate replacement of heat-

ing elements. Unit shall include as standard: electric

controls, low water cut-off, pressure gauge, air vent,

safety relief valve, water level sight gauge, automatic

cold water steam condenser system, automatic cold

water generator ll and electric solenoid valves for

steam, drain and water. Steam generator shall be

ASME constructed and National Board Registered.

OPTIONAL AT EXTRA COST:

optional at extra cost

□ Tilting Kettle Accessory Kit.

□ Power Lift.

□ Nickel Plated Boiler.

□ Total Concept Boiler Descaling Chemical Cleaner.

SPEC SHEET: S-2335B

09/08

)

FOOD SERVICE EQUIPMENT

Steam Jacketed Kettle

The manufacturer reserves the right to modify materials and specications without notice.

PRINTED IN U. S. A. 35 Garvey Street • Everett • MA • 02149

Tel: (617) 387-47100 • Toll Free: (866) 698-3188 • Fax: (617) 387-4456 • Outside MA Fax: (800) 227-2659

E-Mail: custserv@mi.com • Website: w w w . m f i i . c o m

Page 2

E

SPEC SHEET: S-2335B

09/08

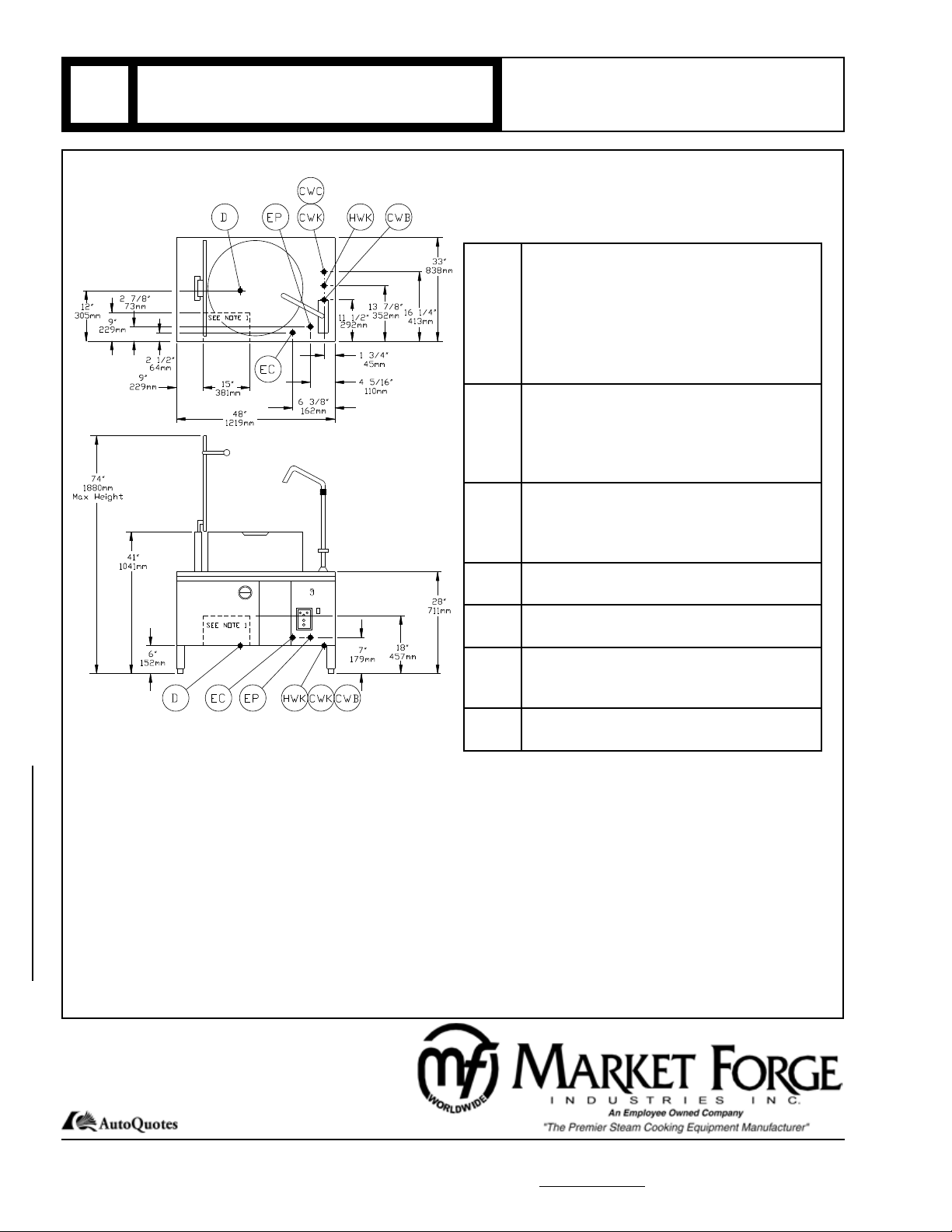

NOTES:

Recess area for kettle draw-off must be

1.

kept free of all piping and connections.

The only available space to supply utili-

2.

ties to the unit is the 6” (152mm) height

between the oor and the cabinet.

Water pressure max 50 PSI (3.5kg/cm2)

3.

and min 25 PSI (1.8kg/cm2).

Steam Jacketed Kettle

60 GALLON STEAM

JACKETED ELECTRIC KETTLE

DETAILS & DIMENSION

SERVICE CONNECTIONS

Electrically Operated

EP Power Supply - Use wire suitable for at

least 90OC, Nominal amps per line wire at

24 KW:

Volts

208

240

480

EC Electrical Controls - 115 Volts Ac, 60Hz,

40 watts, 1/2” (13mm) conduit connection

or equivalent. Use wire suitable for at least

90OC. Draws less than 1 AMP with power

lift.

D Drain - Pipe full 2” (51mm) NPT to oor

drain. DO NOT MAKE SOLID CONNEC-

TION TO FLOOR DRAIN. PVC and CPVC

are not acceptable materials for drains.

HWK Hot Water - 3/8” (10mm) NPT Female for

Hot Water to Kettle Facuet (See Note 3)

CWK Cold Water - 3/8” (10mm) NPT Female for

Cold Water to Kettle Facuet (See Note 3)

CWB Cold Water - 3/8” (10mm) NPT Female for

Cold Water to Boiler. Water may be ltered

(See Note 3).

CWC Cold Water - 3/8” (10mm) NPT Female for

Cold Water Condenser (See Note 3)

CAUTION:

Before connecting water to this unit, have water supply analyzed to make sure hardness i no greater than

2.0 grains and pH level is within the range of 7.0-8.5.

Water which fails to meet these standards should be

treated by installation of a water conditioner. EQUIP-

MENT FAILURE CAUSED BY INADEQUATE WATER QUALITY IS NOT COVERED UNDER WARRANTY.

Phase

3

3

3

Amps

66.6

57.7

28.8

FOOD SERVICE EQUIPMENT

It is our policy to build equipment which is design certied by U.L., A.S.M.E. and N.S.F. However, a continuing program of product improvement makes

it necessary to submit new models to the agencies as they are developed and consequently not all models bear the appropriate agency labels at all times.

Tel: (617) 387-47100 • Toll Free: (866) 698-3188 • Fax: (617) 387-4456 • Outside MA Fax: (800) 227-2659

35 Garvey Street • Everett • MA • 02149

E-Mail: custserv@mi.com • Website: w w w . m f i i . c o m

Loading...

Loading...