Market Forge MT-60 Service Manual

OWNER’S MANUAL

MODULAR TILTING KETTLES

MODELS: □ MT-25

□ MT-40

□ MT-60

INSTALLATION, OPERATION, MAINTENANCE, SERVICE AND PARTS

Form Number: S-2110 Rev: C 06/12

PRINTED IN U.S.A. 35 Garvey Street • Everett • MA • 02149

Tel: (617) 387-47100 • Toll Free: (866) 698-3188 • Fax: (617) 387-4456 • Outside MA Fax: (800) 227-2659

E-Mail: custserv@mi.com • Website: w w w . m f i i . c o m

TABLE OF CONTENTS

INTRODUCTION

DESCRIPTION .......................................................................................................................................................1

25-, 40-, & 60-GALLON TILTING KETTLES ..........................................................................................................1

SERVICE ................................................................................................................................................................1

SERVICE CONNECTIONS ....................................................................................................................................2

OPERATION

OPERATING CONTROLS & INDICATORS ...........................................................................................................3

OPERATING PROCEDURE 25-, 40- & 60-GALLON KETTLES ............................................................................3

CLEANING PROCEDURE .....................................................................................................................................3

CLEANING 25-, 40- & 60-GALLON KETTLES.......................................................................................................3

OPERATING CONTROLS ......................................................................................................................................4

PAN SUPPORT MOUNTING TILTING KETTLES ..................................................................................................5

MAINTENANCE

GENERAL ..............................................................................................................................................................6

PREVENTIVE MAINTENANCE ..............................................................................................................................6

CLEANING .............................................................................................................................................................6

TILTING MECHANISM LUBRICATION ..................................................................................................................6

REPAIR & REPLACEMENT ...................................................................................................................................6

LID COUNTERBALANCE ADJUSTMENT .............................................................................................................6

CABINET EXTERIOR REMOVAL ..........................................................................................................................6

DRAW OFF VALVE REPAIR ..................................................................................................................................7

COMMON LEAK REPAIRS ....................................................................................................................................7

VALVE SEAT LAPPING ..........................................................................................................................................7

TILTING MECHANISM REPAIR .............................................................................................................................7

SAGINAW SCREW ASSEMBLY REMOVAL ..........................................................................................................7

GENERAL INSPECTION & CLEANING .................................................................................................................7

BALL NUT DISASSEMBLY ....................................................................................................................................7

BALL NUT INSPECTION........................................................................................................................................8

BALL NUT REASSEMBLY & BEARING REPLACEMENT .....................................................................................9

CRANK SLEEVE REPLACEMENT ........................................................................................................................9

BRAKE MECHANISM DISASSEMBLY & REPAIR .................................................................................................9

ILLUSTRATED PARTS

GENERAL .............................................................................................................................................................10

ORDERING INFORMATION .................................................................................................................................10

FIG 4 25- & 40-GALLON TILTING KETTLES ........................................................................................................11

FIG 5 TILTING MECHANISM FOR 25- & 40-GALLON KETTLES ........................................................................12

FIG 6 60-GALLON TILTING KETTLES .................................................................................................................13

FIG 7 TILTING MECHANISM FOR 60-GALLON KETTLES ..................................................................................14

FIG 8

HINGE & LID ASSEMBLY ..........................................................................................................................15

FIG

9 STEAM SUPPLY VALVE ............................................................................................................................16

FIG 10 SWING DRAIN ..........................................................................................................................................16

FIG 1

1 DRAW OFF VALVE ....................................................................................................................................17

FIG 12 STEAM TRAP ............................................................................................................................................17

FIG 13

FIG 14

FIG 15 CABINET BASE (NEWER VERSION) ......................................................................................................20

FIG 16 24” CABINET (OLDER VERSION) ............................................................................................................21

FIG 17 36” CABINET (OLDER VERSION) ............................................................................................................22

FIG 18 48” CABINET (OLDER VERSION) ............................................................................................................23

FIG 1

FAUCET & SPOUT ASSEMBLY, 25-, 40- & 60-GALLON KETTLES (NEWER VERSION) .......................18

FAUCET & SPOUT ASSEMBLY, 25-, 40- & 60-GALLON KETTLES (OLDER VERSION) ........................19

9 ACCESSORIES FOR STEAM JACKETED KETTLES ..............................................................................24

INTRODUCTION

This service and parts manual contains general information, operation, and maintenance information

for Market Forge modular kettles. A parts list is included in which each replaceable part is identied and

shown in an accompanying drawing. Accessories for use with the kettles are also described.

DESCRIPTION

Market Forge tilting steam jacketed kettles of three

capacities, each mounted in a modular stainless

steel cabinet.

Double wall construction around the lower half of the

kettle forms a surrounding chamber into which steam

is introduced as a source of heat for cooking.

Steam input plumbing is equipped with a manual control valve. Condensate is removed through a steam

trap connecting with the kettle drain plumbing assembly. A swivel spout, hot-cold combination faucet

provides a source of water for addition to the kettle

for cooking and cleaning.

An optional 12” spacer unit with faucet and sink may

be used instead of the standard built-in faucet.

25-, 40-, & 60-Gallon Tilting Kettles

Large capacity kettles are tted with heavy duty tilting mechanisms operated by removable hand crank.

Each model is equipped with a pan support which

maintains continuous alignment of serving pans under the pouring spout at all levels of kettle elevation.

SERVICE

Modular kettles are exceptionally reliable and durable

cooking equipment requiring a minimum of service

other than routine cleaning and preventive methods

explained in the maintenance section. Should repairs

be required, a network of authorized service agencies is available to assist with prompt service.

A current Directory of Authorized Service Agencies

may be obtained by contacting:

Customer Service Department, Market Forge

35 Garvey Street, Everett, Massachusetts 0214

Telephone: (617) 387-41 00, (866) 698-3188

custserv@mi.com, www.mi.com

The model and serial numbers must be referenced

when corresponding with Market Forge.

The data plate containing model and serial numbers

pertaining to the equipment is located inside the cabinet door on the right vertical frame member.

9

Counterbalanced hinged lids cover the kettles in the

lowered position. All are plumbed for direct connection to a remote steam source. An optional cold water

circuit to the steam jacket is available for use with all

models for quick cooling of foods after cooking.

Applicable model designation include:

MT-25 A 25-gallon (94 liter) capacity tilting

kettle mounted in a 36” (914mm) wide

cabinet base.

MT-40 A 40-gallon (152 liter) capacity tilting

kettle mounted in a 36” (914mm) wide

cabinet base.

MT-60 A 60-gallon (228 liter) capacity tilting

kettle mounted in a 48” (1219mm) wide

cabinet base.

1

INTRODUCTION

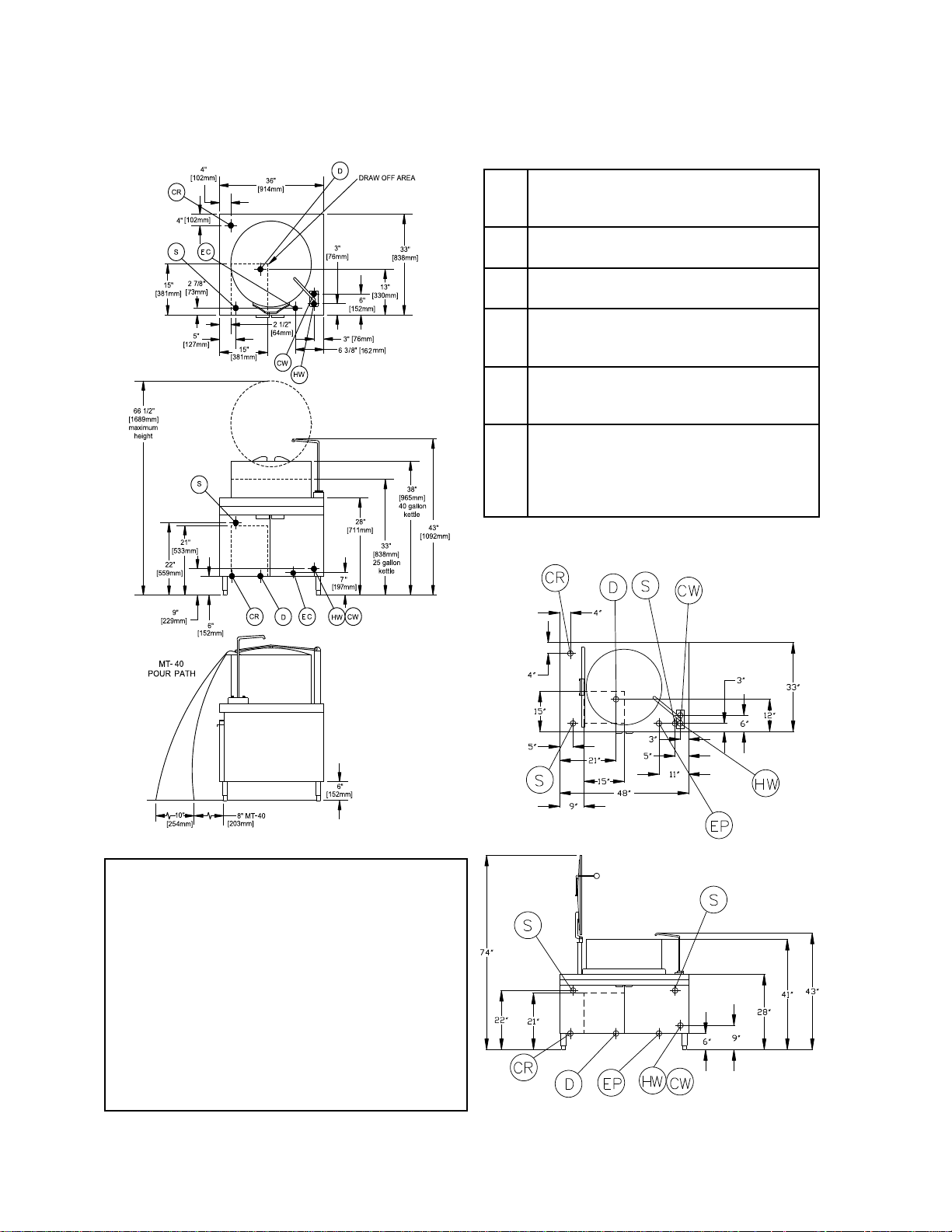

SERVICE CONNECTIONS

Direct Connected

S Steam Supply - 3/4” (19mm) NPT, 15 P.

S.I (1.0 kg/cm2) minimum; 30 P.S.I (2.1

kg/cm2) maximum.

HW Hot Water - 3/8” (10mm) OD tubing to

hot water for kettle ll faucet.

CW Cold Water - 3/8” (10mm) OD tubing to

cold water for kettle ll faucet.

D Drain - Pipe full 2”

oor drain. Do not make solid connection to drain.

MT-25

MT-40

CR* Condensate Return - 1/2”

connection for condensate return from

kettle when specied.

EC* Electrical Controls - 115 volts AC, 60 Hz,

40 watts, 1/2” (13mm) conduit connection or equivalent. Use wire suitable for

at least

with power lift.

* Optional

90OC. Draws less than 1 Amp

NPT (51mm) to ush

I.P.S. (13mm)

NOTES:

Pressure-reducing valve is required if incoming pressure exceeds 30 PSI (2.1 kg/cm

Recess area for kettle draw-off (dotted line) must be

kept free of all piping and connections.

PVC and CPVC pipe are not acceptable materials for

drains.

2

).

MT-60

Separate height for 25-, 40-, and 60-gallon kettles.

2

OPERATION

OPERATING CONTROLS & INDICATORS

All of the controls required to operate the kettles are

listed in table on page 4, together with an explanation

of location and a short functional description.

OPERATING PROCEDURE 25- 40- & 60-GALLON

KETTLES

All kettles must be supplied with steam from a generator which is remotely located. Consult steam generator information or instruction plate and complete

all start-up instructions. Proceed with kettle operating

procedure as follows:

Check pressure gauge of steam supply source to

1.

insure steam input is at 15 PSI (1.0 kg/cm2). For

direct connected steam, turn on external steam

supply valve.

Check that Draw-Off Valve is tightly closed.

2.

Lift kettle lid and place either a Solid or Perforated

3.

Drain Disc over the drain inside kettle. Use solid

disc to retain liquids; perforated to strain liquids

from food.

Load kettle with foods to be cooked.

4.

Add water for cooking by swinging spout over

5.

kettle and using Combination Faucet.

Turn Steam Control Valve to full counter-clock-

6.

wise position to heat kettle content to an initial

rapid boil.

Adjust subsequent cooking temperature by turn-

7.

ing Steam Control Valve. Turn clockwise to reduce heat and counter-clockwise to increase.

Close Steam Control Valve (full clockwise posi-

8.

tion) when cooking is complete.

CAUTION: FOOD MUST EIThER BE RE-

MOVED FROM ThE KETTLE IMMEDIATELy

OR COOLED By A KETTLE jACKET COOLING

SySTEM TO PREVENT OVER COOKING.

3427) can be used to support pan during lling.

12.

Remove food from tilting kettles. With Pan Support mounted (see section pan support mounting

tilting kettles, on page 5), food pan in support, and

Crank installed in front of cabinet, turn crank clockwise to elevate kettle for pouring. (Tilting mecha-

nism is innitely adjustable and non-coasting in

kettle elevation and lowering). Liquid foods may

also be removed by use of the Draw-Off Valve as

explained in step 11 for stationary kettles.

13.

Complete cleaning procedures (See section be-

low, cleaning 25-, 40- & 60-gallon kettles).

CLEANING PROCEDURE

As with cleaning food soil from any cookware, an important part of kettle cleaning is to prevent foods from

drying on. For this reason cleaning should be completed immediately after cooked foods are removed.

If time can not be allotted for immediate complete

cleaning the kettle should be soaked by lling it with

warm detergent water solution.

2.4.2 CLEANING

Wash the kettle with a long handled nylon bristle

1.

kettle brush (Part No. 10-5308).

Empty wash water by opening Draw-Off Valve

2.

over Swing Drain.

Remove Drain Disc (solid or perforated) from in-

3.

side kettle and clean.

Rinse kettle by ushing with hot water from the

4.

Swivel Spout.

Loosen hex nut on Draw-Off Valve and carefully

5.

remove all parts. Clean and reassemble. (See g-

ure 11, on page 17).

Rotate Swing Drain to left and push up off drain

6.

assembly. Clean drain and screen. Reassemble

on kettle.

25-, 40- & 60-GALLON KETTLES

For Chill Kettles use an external water source

9.

to ood kettle interior with cold water until all hot

cooking water ow over kettle rim into sink.

For kettles equipped with optional cold water

10.

source water jacket cooling system open the

Jacket Cold Water Valve (full counter-clockwise

position) and leave open until food temperature is

sufciently lowered.

Remove food from stationary kettles. For liquids

11.

rotate the Swing Drain to the side and ll food

containers from the Draw-Off Valve. For solids

which will not pass through the valve, use a ladle.

An optional stationary pan holder (Part No. 90-

3

OPERATION

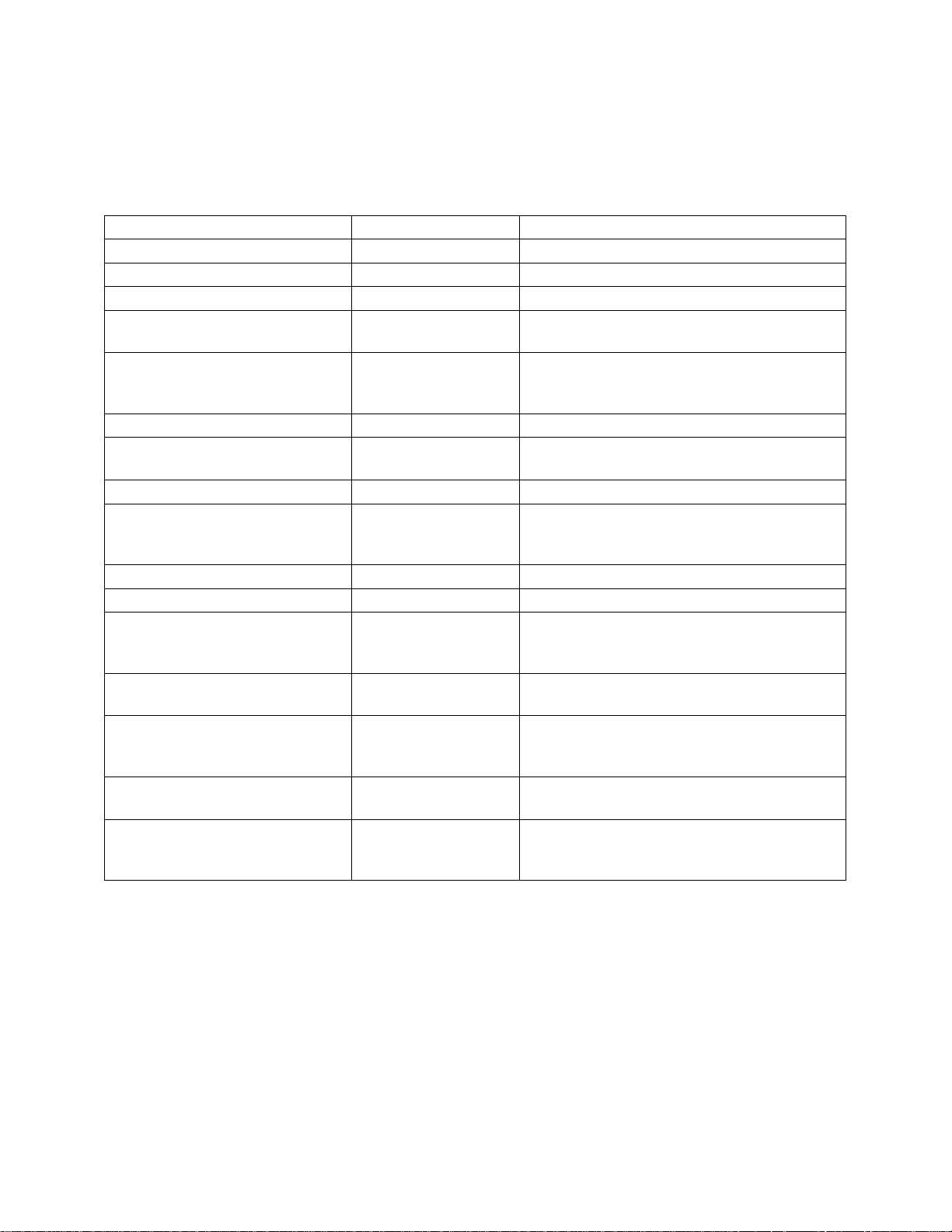

OPERATING CONTROLS

NAME LOCATION FUNCTION

Kettle Handle Kettle Rim Grasped to tilt kettle for pouring.

Steam Control Valve Top, Left Side Controls steam ow to kettle jacket.

Combination Faucet Top, Right Side Controls hot and cold water to swivel spout.

Swivel Spout Top, Beside Kettle Direct water into kettle. Turns away for kettle

tilting.

Sink with Splash Shield Top, Front Accepts kettle drainage. Shield forward pro-

tects operator from splashing, reverses for

storage.

Lid Handle On Lid Grasped to open and close kettle lid.

Perforated Drain Disc Inside Kettle on Drain Covers drain to strain liquids when draw-off

is open.

Solid Drain Disc (Optional) Inside Kettle on Drain Covers drain to block it off.

Crank (Tilting Kettles) Front, Right Side Raises and lowers tilting kettles for pouring.

Stow on back of cabinet door when not in

use.

Steam Control Valve Top, Right Side Controls steam ow to kettle jacket.

Draw-Off Valve Inside Cabinet, Left Controls drainage of kettle.

Swing Drain with Strainer Inside Cabinet, Left Accepts drainage from draw-off valve.

Swings to side to allow serving containers to

be placed under draw-off valve.

Combination Faucet with Swivel

Spout

Cold Water Valve (Chill Kettles

and Others with Optional Jacket

Cooling Systems)

Basin Waste Drain (Chill Kettles

Only)

Pan Support (Tilting Kettles Only) Front, Top Holds serving pan in alignment with kettles

Top, Right Side Control hot and cold water to kettle interior.

Turns away for kettle tilting and access.

Right, Front Controls ow of water to steam jacket for

rapid cooling after cooking.

Left, Top Accepts kettle overow in chill kettle sink.

for pouring (see section pan support mount-

ing tilting kettles, on page 5)

4

OPERATION

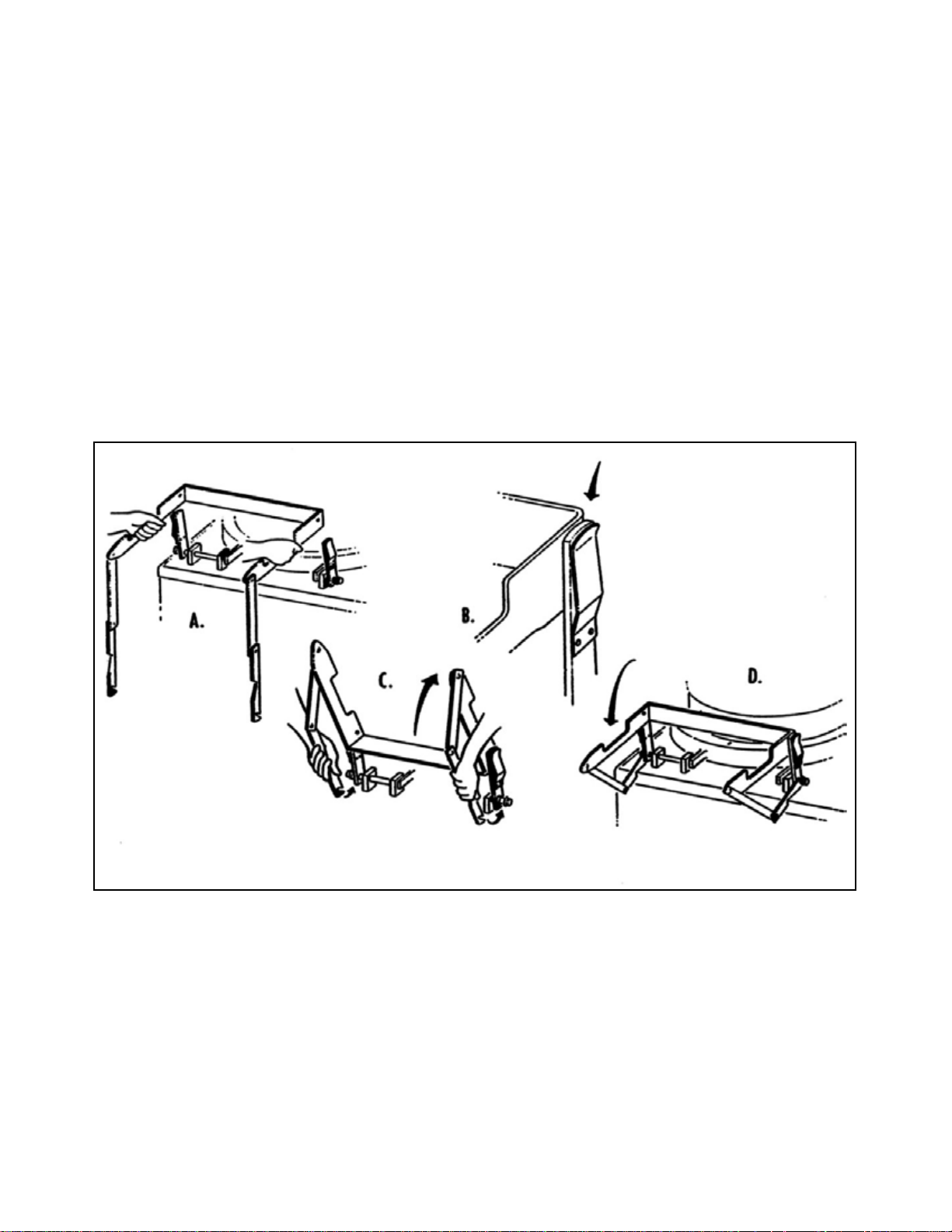

PAN SUPPORT MOUNTING TILTING KETTLES

For convenience during cooking, the pan support

need not be installed until needed for removing food

from the kettles. To Insure correct operation and to

prevent spills the support must be securely installed

as shown in Figure 1 below and as explained below:

Hold the pan support in front of the upright as

1.

shown at A.

Place the stud of the left-hand support upright

2.

into the hole in the left side of the pan support.

Then push the right side of the support in until it

engages the spring loaded pin of the right-hand

support upright, shown at B.

Rotate the pan support upward (C) and engage

3.

the slotted ends of the support links in the studs

at the base of each support upright as in D.

The removal procedure is the reverse of installation with the exception that in step 2 support upright

springs must be pushed out to release the support

from studs.

Figure 1 Mounting Pan Support

5

MAINTENANCE

WARNING:

DO NOT hOSE DOWN UNIT AS IT

CONTAINS ELECTRICAL COMPONENTS.

GENERAL

This section contains both preventive and corrective

maintenance information. Preventive maintenance

may be performed by maintenance personnel at the

establishment in which the kettle is installed.

It is recommended that user personnel never attempt

to make repairs or replacements to the equipment

without the assistance of authorized service. Assistance in service methods or, a current Directory of

Authorized Service Agencies may be obtained from

Market Forge. (See service section on page 1).

PREVENTIVE MAINTENANCE

The most important preventive maintenance operation on the steam jacketed kettle is the cleaning procedure after each use described on page 3. Additional preventive maintenance operations are presented

in this section.

CLEANING

A policy should be faithfully observed of completing,

by the end of each day’s operation, all kettle cleaning

procedures explained in cleaning procedure section

on page 3.

tle itself or the steam supply which heats the kettle.

While mechanical problems are obvious faults of the

kettle, any deciencies in volume and pressure of

steam should be traced to the steam generator and

the cause determined.

Steam input requirements are listed in Appendix A,

Modular Kettle Steam Requirements. Additional information may be found in separate service publications

for steam generators.

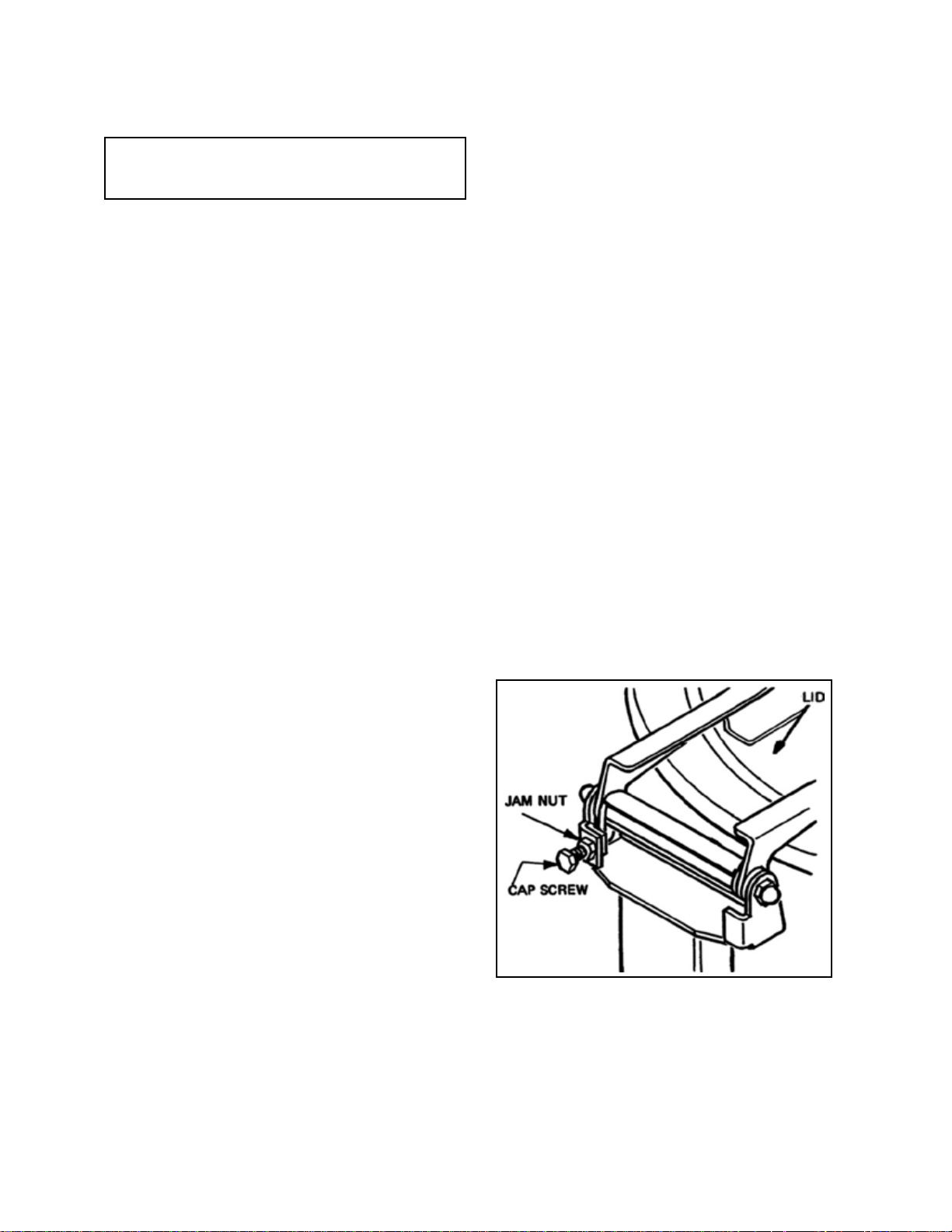

LID COUNTERBALANCE ADjUSTMENT

The kettle lid is equipped with a torsion spring counterbalance device to assist in lid lifting and to prevent

slamming. The device is shown assembled in the

Figure 2 below and exploded in Figure 8, on page 15.

If lid slams closed when handle is released, spring

tension should be increased. If lid lifts up or refuses

to remain down on kettle, tension should be reduced.

To adjust spring tension proceed as follows:

Loosen 1/4” jam nut.

1.

Adjust spring tension by turning 1/4” hex head

2.

cap screw. Tighten to increase tension; loosen to

reduce tension.

Operate lid several times, repeating, step 2 until

3.

desired operation is obtained.

Hold hex head screw rmly in position and tighten

4.

jam nut to lock adjustment.

In addition, cabinet doors, top, xtures, kettle lid, etc.,

should be washed and rinsed to remove all food spills.

For Chill Kettles, extra care must be given to cleaning

the sink surrounding the kettle. Pan support should

be removed as described in pan support mounting

tilting kettles on page 5.

TILTING MEChANISM LUBRICATION

Lubrication of the tilting mechanism of 25-, 40- and

60-gallon tilting kettles is the only required preventive

maintenance other than daily cleaning. Inspect the

screw of the tilting mechanism annually for adequate

lubrication.

Should screw appear “dry” apply a good grade of

ball bearing grease directly on the threads so that

the threads appear to be barely damp. If mechanism

fails to run smoothly (see tilting mechanism repair on

page 7).

REPAIR & REPLACEMENT

In the event that the kettle fails to operate correctly,

the difculty should rst be isolated to either the ket-

Figure 2 Lid Counterbalance Adjustment

CABINET ExTERIOR REMOVAL

Side and rear panels of all cabinets in which kettles

are mounted are easily removed without the use of

tools. Each panel is grasped at the bottom edge and

pulled out sharply to release it from the panel mounting brackets Shown in Figure 8, on page 15.

6

Loading...

Loading...