Page 1

0

OWNER’S MANUAL

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THESE

INSTALLATION, OPERATION AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING

OR SERVICING THIS EQUIPMENT.

Form Number: S-2110 REV. D 04/14

Printed in USA 35 Garvey Street, Everett, MA 02149

Telephone (617) 387-4100, (866) 698-3188, Fax (617) 387-4456, (800) 227-2659

custserv@mfii.com, www.mfii.com

WARNING:

DO NOT UNDER ANY CIRCUMSTANCE CONNECT THE

EXHAUST DRAIN LINE DIRECTLY TO A SEWER LINE.

WARNING:

DO NOT HOSE DOWN UNIT AS IT MAY CONTAIN

ELECTRICAL COMPONENTS.

CAUTION: Before connecting water to this unit, water

supply should be analyzed to make sure hardness is

no greater than 2.0 grains and pH level is within the

range of 7.0-8.5. Water which fails to meet these

standards should be treated by installation of water

conditioner or filter system. EQUIPMENT FAILURE

CAUSED BY INADEQUATE WATER QUALITY IS NOT

COVERED UNDER WARRANTY.

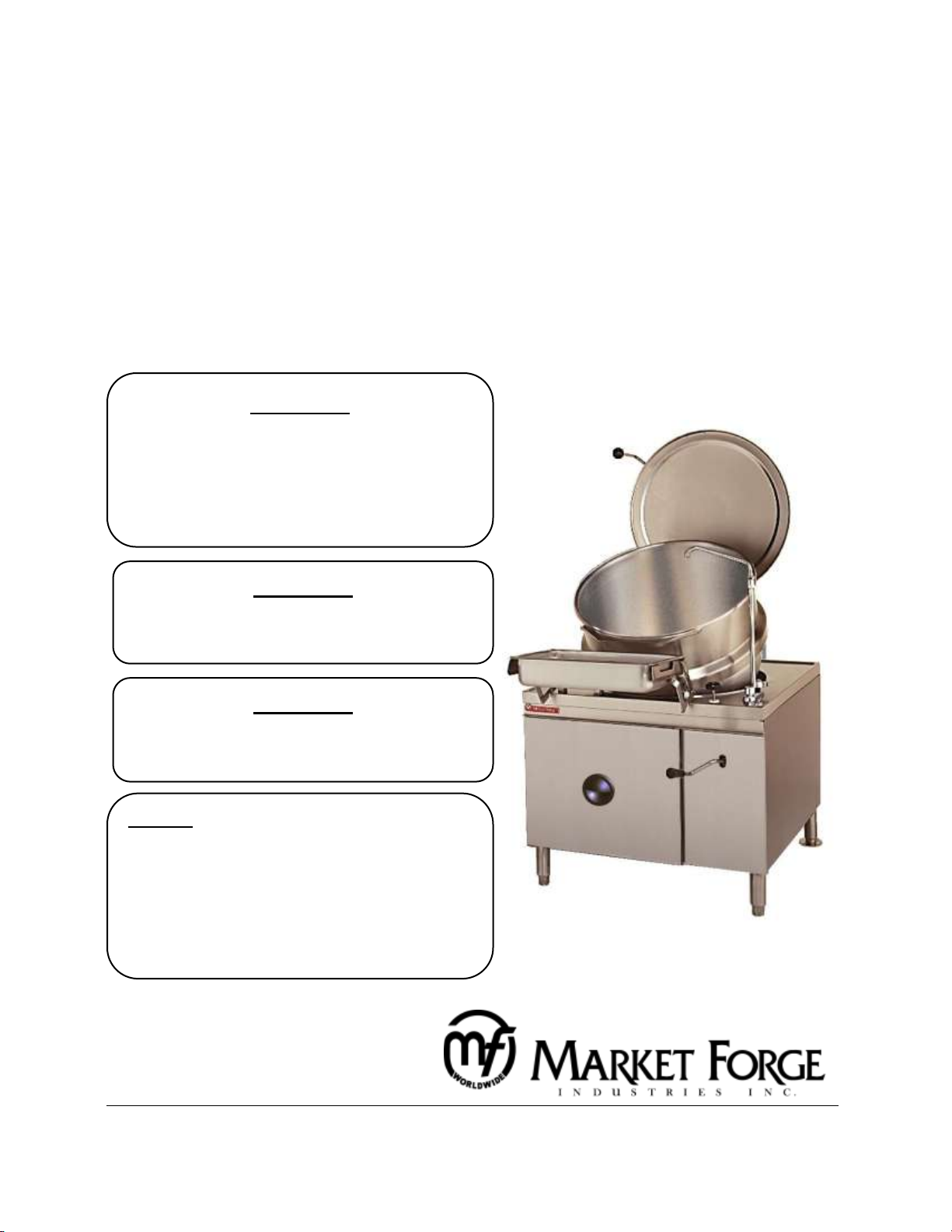

Modular Tilting Direct Steam Jacketed Kettle

MODELS: □ MT-25

□ MT-40

□ MT-60

Page 2

1

Table of Contents

INTRODUCTION ......................................................... 1

INSTALLATION INSTRUCTIONS

SERVICE CONNECTIONS – MT-25EO, MT-40EO ......... 2

SERVICE CONNECTIONS – MT60EO ........................... 3

WIRING DIAGRAM ..................................................... 4

SCHEMATIC ................................................................ 5

OPERATING INSTRUCTIONS

START-UP ................................................................... 6

CONTROL PANEL ........................................................ 6

OPERATING THE STEAM BOILER ................................ 6

COOKING ................................................................... 7

INSTALL PAN SUPPORT .............................................. 8

SHUT-DOWN .............................................................. 9

DAILY CLEANING ........................................................ 9

COOKING GUIDE ................................................ 10-12

TROUBLESHOOTING .......................................... 13-15

ADJUSTMENTS

REPAIR & REPLACE ................................................... 16

PRESSURE CONTROL SWITCH ADJUSTMENTS ......... 16

COLD WATER CONDENSER ADJUSTMENT ............... 17

LID COUNTERBALANCE ADJUSTMENT ................ 17-18

HEATING ELEMENT REPLACMENT ........................... 18

WATER CONTROL BOARD TESTING PROCEDURE .... 19

WATER LEVEL CONTROL .......................................... 20

CIRCUIT OPERATION ................................................ 20

WATER LEVEL CONTROL OPERATION ...................... 20

LOW WATER CUTT OFF ............................................ 20

WATER LEVEL CONTROL MAINTENANCE AND

CLEANING ................................................................ 21

PROBE CLEANING .................................................... 21

DRAW OFF VALVE REPAIR ........................................ 22

COMMON LEAK REPAIRS ......................................... 22

VALVE SEAT LAPPING ............................................... 22

TILTING MECHANISM REPAIR .................................. 22

LIFT SCREW ASSEMBLY REMOVAL ........................... 22

GENERAL INSPECTION AND CLEANING .................... 23

CRANK SLEEVE REPLACEMENT ................................ 23

TILTING MECHANISM LUBRICATION ....................... 23

MAINTENANCE

PREVENTIVE MAINTENANCE ................................... 24

DAILY CLEANING ...................................................... 24

APPLICATION INSTRUCTIONS – TOTAL CONCEPT

DESCALER ............................................................ 25-26

ILLUSTRATED PARTS LIST

PRESSURE SWITCHES ............................................... 27

DRAIN ASSEMBLY ..................................................... 28

TILTING MECHANISM .............................................. 29

PISTON ASSEMBLY ................................................... 30

VALVE AND FAUCET ................................................. 31

LOW WATER CUT OFF .............................................. 32

CRANK SHAFT........................................................... 33

BOILER BASE ASSEMBLY .......................................... 34

ELECTRICAL COMPONENTS ...................................... 35

VALVE ASSEMBLY ..................................................... 36

KETTLE JACKET ASSEMBLY ....................................... 37

Page 3

1

INTRODUCTION

This service and parts manual contains descriptive and maintenance information (including

trouble shooting guide) for modular kettles. A Parts list is also included in which each

replacement part is identified and shown in an accompanying illustration unless otherwise

stated.

Description:

Market Forge tilting direct steam jacketed kettles of three capacities, each mounted in a

modular stainless steel cabinet.

Double wall construction around the lower half of the kettle forms a surrounding chamber into

which steam is introduced as a source of heat for cooking.

Steam input plumbing is equipped with a manual control valve. Condensate is removed through

a steam trap connecting with the kettle drain plumbing assembly. A swivel spout, hot-cold

combination faucet provides a source of water for addition to the kettle for cooking and

cleaning.

An optional 12” spacer unit with faucet and sink may be used instead of the standard built-in

faucet.

Large capacity kettles are fitted with heavy duty tilting mechanisms operated by removable

hand crank. Each model is equipped with a pan support which maintains continuous alignment

of serving pans under the pouring spout at all levels of kettle elevation. Counterbalanced

hinged lids cover the kettles in the lowered position. All are plumbed for direct connection to a

remote steam source. An optional cold water circuit to the steam jacket is available for use with

all models for quick cooling of foods after cooking.

Applicable model designation includes: MT-25 (25-gallon) – 36” wide (914mm) cabinet base,

MT-40 (40-gallon) – 36” wide (914mm) cabinet base, and MT-60 (60-gallon) – 48” wide

(1219mm) cabinet base.

Service:

Required service, both repair, replacement, and adjustment is explained in Adjustments section

of this manual. Other service help can be found in the Trouble Shooting and Maintenance

sections of this manual. Should repairs be required, a network of Authorized Service Agents is

available to assist with prompt service. A current list of Authorized Service Agencies may be

obtained by contacting Market Forge direct of going on our website:

Call us toll free at (866) 698-3188 or (617) 387-4100

Email us at custserv@mfii.com or go to http://www.mfii.com/company/service

The model and serial number must be referenced when corresponding with Market Forge.

These numbers can be found on the data plate located on the upright frame behind the cabinet

base door. If you require further assistance in obtaining these numbers, please contact us

directly.

Page 4

2

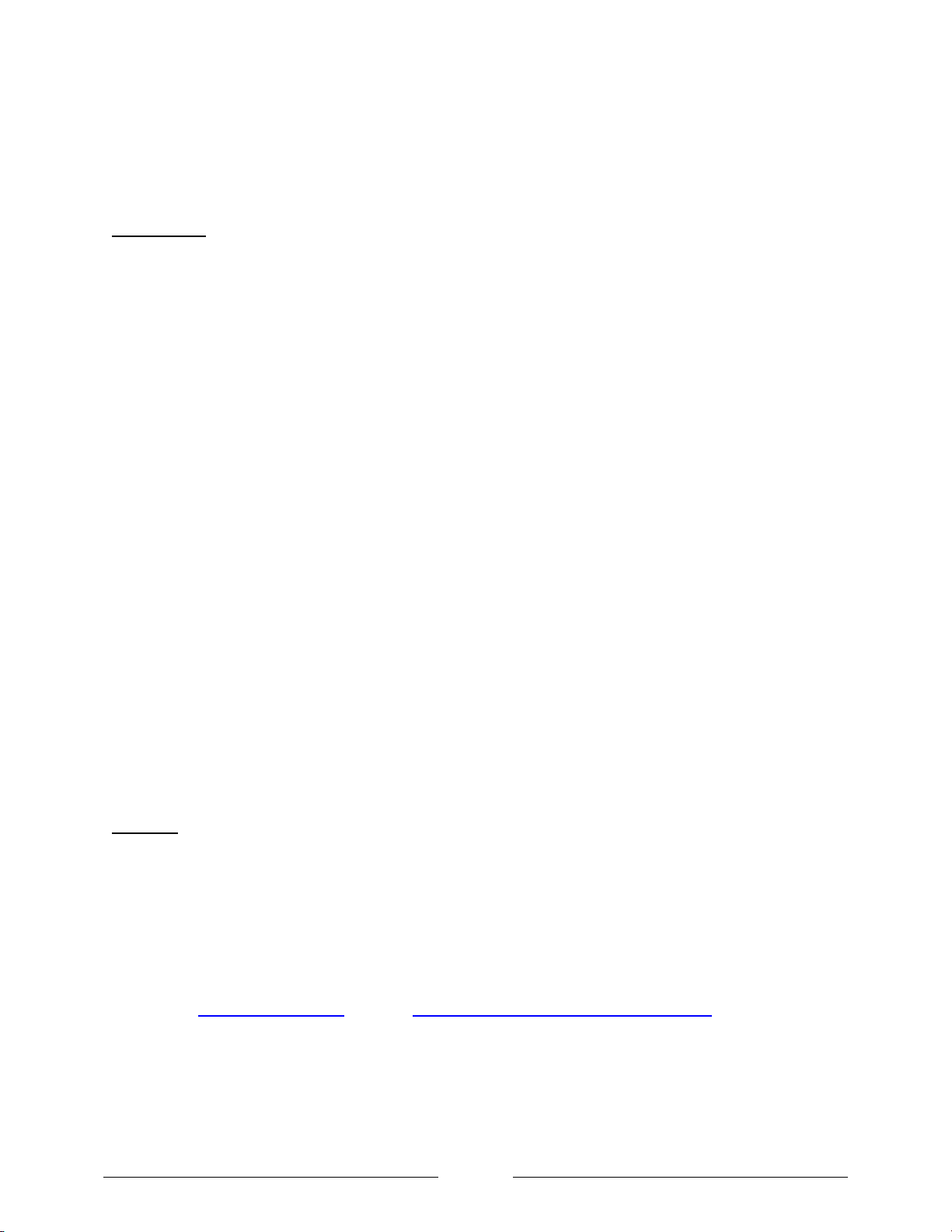

S

Steam Supply - 3/4” (19mm) NPT, 15 P.S.I

(1.0 kg/cm2) minimum; 30 P.S.I (2.1 kg/cm2)

maximum.

HW

Hot Water - 3/8” (10mm) OD tubing to hot

water for kettle fill faucet.

CW

Cold Water - 3/8” (10mm) OD tubing to cold

water for kettle fill faucet.

D

Drain - Pipe full 2” NPT (51mm) to flush floor

drain. Do not make solid connection to

drain.

CR*

Condensate Return - 1/2” I.P.S. (13mm)

connection for condensate return from

kettle when specified.

EC*

Electrical Controls - 115 volts AC, 60 Hz, 40

watts, 1/2” (13mm) conduit connection or

equivalent. Use wire suitable for at least

90OF. Draws less than 1 Amp with power lift.

* Optional.

MT-60

SERVICE CONNECTIONS:

MT-25 and MT-40

INSTALLATION INSTRUCTIONS

NOTES:

1. Pressure-reducing valve is required if incoming

pressure exceeds 30 PSI (2.1 kg/cm2).

2. Recess area for kettle draw-off (dotted line) must

be kept free of all piping and connections.

3. PVC and CPVC pipe are not acceptable materials for drains.

4. Separate height for 25-, 40-, and 60-gallon kettles.

Page 5

3

OPERATION INSTRUCTIONS

CAUTION: FOOD MUST EITHER BE REMOVED FROM THE KETTLE IMMEDIATELY OR COOLED BY

A KETTLE JACKET COOLING SYSTEM TO PREVENT OVER COOKING.

OPERATING CONTROLS & INDICATORS

All of the controls required to operate the kettles are listed in table on page 4, together with an

explanation of location and a short functional description.

OPERATING PROCEDURE

All kettles must be supplied with steam from a generator which is remotely located. Consult steam

generator information or instruction plate and complete all start-up instructions. Proceed with

kettle operating procedure as follows:

1. Check pressure gauge of steam supply source to insure steam input is at 15 PSI (1.0 kg/cm

For direct connected steam, turn on external steam supply valve.

2. Check that Draw-Off Valve is tightly closed.

3. Lift kettle lid and place either a Solid or Perforated Drain Disc over the drain inside kettle.

Use solid disc to retain liquids; perforated to strain liquids from food.

4. Load kettle with foods to be cooked.

5. Add water for cooking by swinging spout over kettle and using Combination Faucet.

6. Turn Steam Control Valve to full counter-clockwise position to heat kettle content to an

initial rapid boil.

7. Adjust subsequent cooking temperature by turning Steam Control Valve. Turn clockwise to

reduce heat and counter-clockwise to increase.

8. Close Steam Control Valve (full clockwise position) when cooking is complete.

2

).

9. Remove food from tilting kettles. With Pan Support mounted (see section pan support

mounting tilting kettles, on page 4), food pan in support, and Crank installed in front of

cabinet, turn crank clockwise to elevate kettle for pouring. (Tilting mechanism is infinitely

adjustable and non-coasting in kettle elevation and lowering). Liquid foods may also be

removed by use of the Draw-Off Valve as explained in step 11 for stationary kettles.

10. Complete cleaning procedures (see cleaning procedure section below).

CLEANING PROCEDURE

As with cleaning food soil from any cookware, an important part of kettle cleaning is to prevent

foods from drying on. For this reason cleaning should be completed immediately after cooked

foods are removed. If time can not be allotted for immediate complete cleaning the kettle should

be soaked by filling it with warm detergent water solution.

Cleaning

1. Wash the kettle with a long handled nylon bristle kettle brush (Part No. 10-5308).

2. Empty wash water by opening Draw-Off Valve over Swing Drain.

3. Remove Drain Disc (solid or perforated) from inside kettle and clean.

4. Rinse kettle by flushing with hot water from the Swivel Spout.

5. Loosen hex nut on Draw-Off Valve and carefully remove all parts. Clean and reassemble (see

figure 11, on page 17).

Page 6

4

OPERATION INSTRUCTIONS

6. Rotate Swing Drain to left and push up off drain assembly. Clean drain and screen.

Reassemble on kettle.

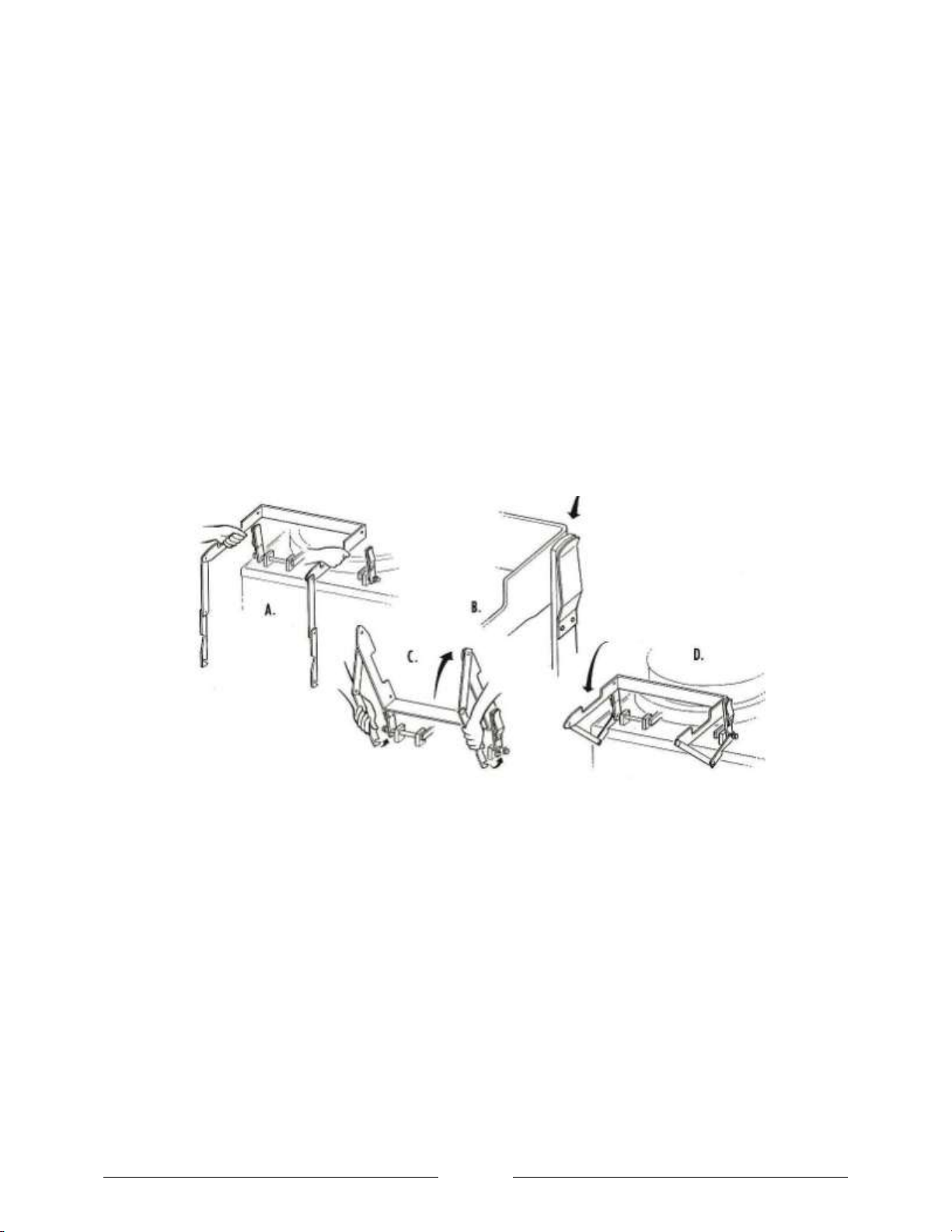

Pan Support Mounting Tilting Kettles

For convenience during cooking, the pan support need not be installed until needed for removing

food from the kettles. To Insure correct operation and to prevent spills the support must be

securely installed as shown in Figure 1 below and as explained below:

1. Hold the pan support in front of the upright as shown at A.

2. Place the stud of the left-hand support upright into the hole in the left side of the pan

support. Then push the right side of the support in until it engages the spring loaded pin of

the right-hand support upright, shown at B.

3. Rotate the pan support upward (C) and engage the slotted ends of the support links in the

studs at the base of each support upright as in D.

The removal procedure is the reverse of installation with the exception that in step 2 support

upright springs must be pushed out to release the support from studs.

Figure 1, Mounting Pan Support

Page 7

5

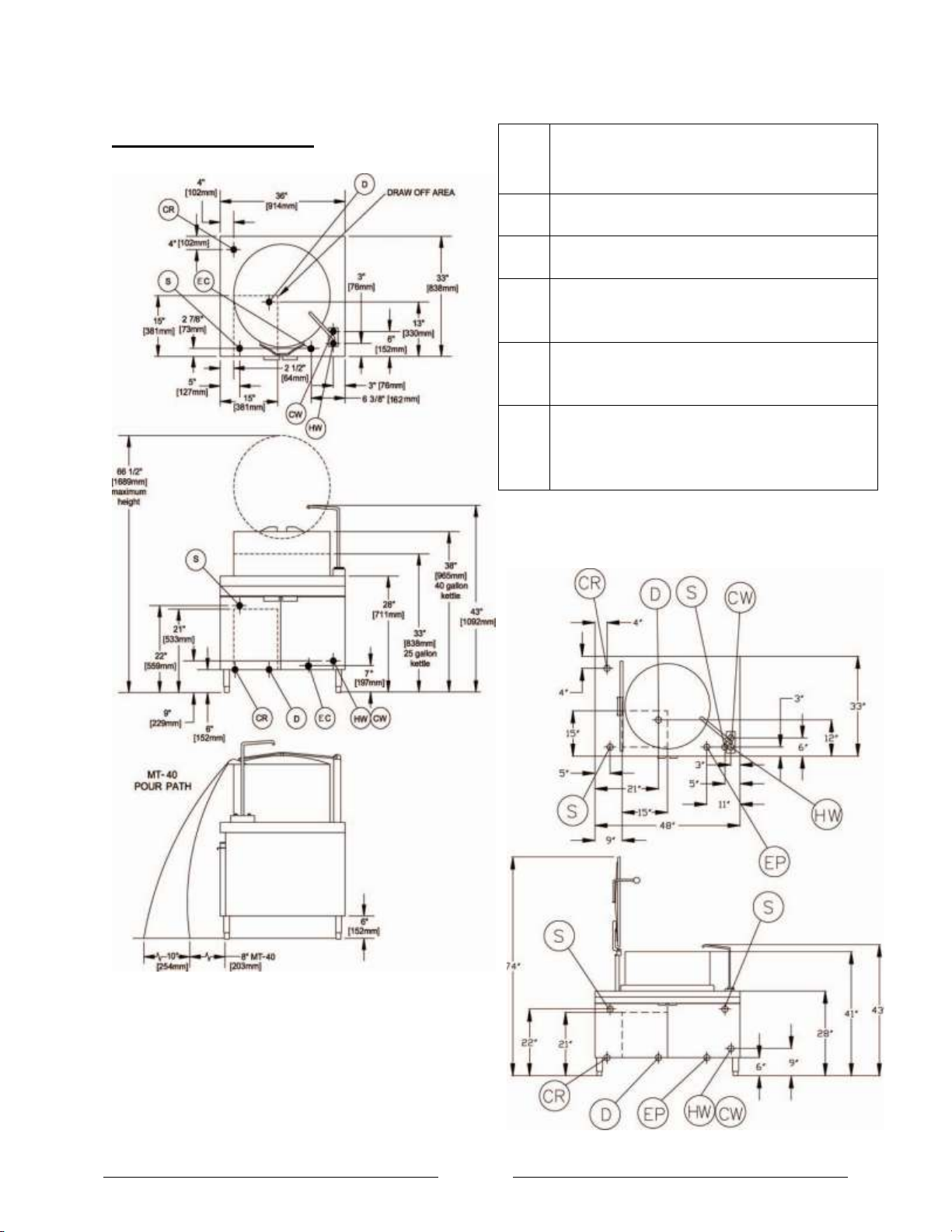

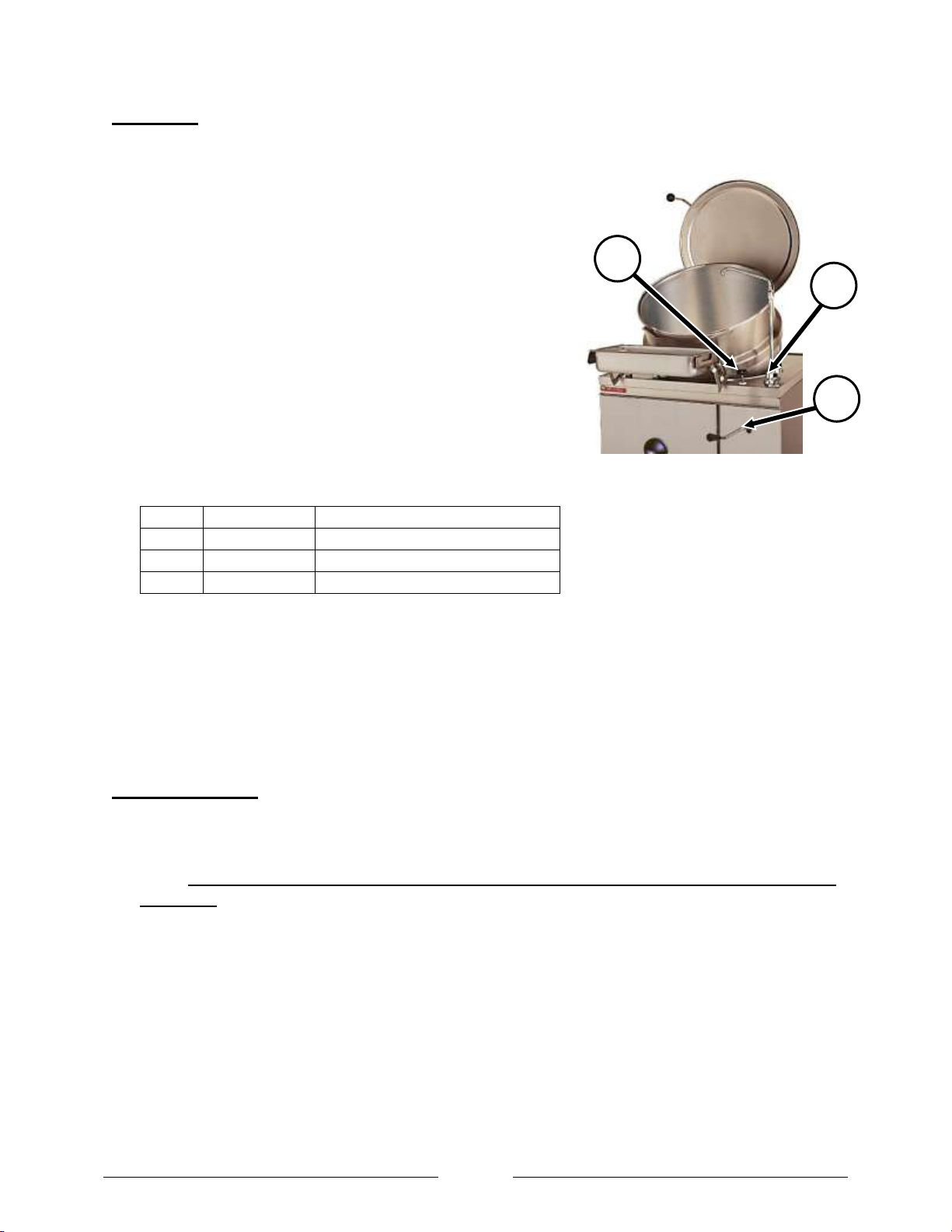

Figure 2, Steam Jacketed Kettle

1 3 2

OPERATION INSTRUCTIONS

ITEM

PART NO.

DESCRIPTION

1

10-7680

HOT AND COLD FILL FAUCET

2

10-5242

STEAM CONTROL VALVE

3

98-1568

CRANK HANDLE (MANUAL TILT)

COOKING:

1. Check pressure to ensure that boiler is up to operational pressure of 10-12 PSI (0.7-0.8kg/cm

2. Check that draw-off valve is tightly closed by turning it

clockwise.

3. Place solid disc or perforated disc in drain opening

inside kettle.

NOTE: Use solid disc if liquid is to be retained; use

perforated disc if liquid is to be discarded.

4. Fill kettle to desired level with food to be cooked or

water from hot and cold fill faucet (Figure 2, No. 1).

NOTE: Refer to Cooking Guide (page 10) for cooking

procedures that address individual food products.

5. Turn kettle steam control valve (Figure 2, No. 2)

counterclockwise to full ON position for faster results.

2

).

NOTE: The volume of steam going into the kettle jacket can be controlled at any time by adjusting

the kettle steam control valve in either direction.

6. When food is cooked, turn steam control valve clockwise to stop steam flow. Remove food

immediately to prevent over cooking.

7. Prior to removing foods from kettle, the pan support should be placed in a position to establish

a firm support for receiving pan.

DAILY CLEANING:

1. Fill kettle with water and mild detergent immediately after removing food from kettle.

2. Scrub kettle interior with a nylon brush.

NOTE: NEVER SCRAPE KETTLE INTERIOR WITH METAL TOOLS, STEEL SCOURING PADS OR ABRASIVE

CLEANERS. Scratches will result, which will ruin the kettles general appearance and make it harder to

clean and maintain in a sanitary condition.

3. Loosen food which is stuck to kettle by allowing it to soak. Also, a small amount of steam may

help.

4. Position swing drain under draw-off valve. Open draw-off valve to drain soapy water.

5. Wipe down exterior, rinse and dry. Avoid getting water into electrical controls.

Page 8

6

OPERATION INSTRUCTIONS

WARNING: DO NOT HOSE DOWN UNIT AS IT CONTAINS ELECTRICAL COMPONENTS.

6. Remove strainer from inside kettle. Wash and rinse thoroughly.

7. Disassemble draw-off valve by first turning valve handle counterclockwise. Then, turn hex nut

counterclockwise until valve handle and stem are free.

8. Wash inside of draw-off valve with a nylon brush.

9. Rinse kettle valve interior and reassemble valve.

NOTE: Leave draw-off valve open when kettle is not in use.

10. Remove swing drain and its strainer. Wash, rinse and replace.

Cooking Facts for Steam Jacketed Kettles:

A Steam Jacketed Kettle is a stainless steel kettle jacketed or encapsulated by a second outer kettle,

creating a space between the two kettles. Cooking is achieved by allowing steam to flow within this

space. The jacket or outer kettle usually covers 2/3 of the inner kettle, although some kettles are fully

jacketed

The steam flowing in the space between the kettles condenses on the cold inner kettle wall and releases

heat through the wall to the food in the kettle. The condensate drains to the bottom of the kettle and is

released through a steam trap without any loss or variation in steam pressure. The amount of steam

allowed to flow Into the Jacket controls the heat of the kettle. In use, the Steam Jacketed Kettle provides

consistent heat distribution and is energy efficient using steam only to maintain pressure, unlike top of

the range cooking in which energy (gas or electricity) is used during the entire cooking process.

Steam Jacketed Kettles can sauté, simmer, or boil a wide variety of products, such as soups, gravies,

sauces, pasta, stews, mixed casserole type dishes, vegetables, shellfish, cereals, hot beverages, and

puddings. A Steam Jacketed Kettle will not burn foods. However, foods that caramelize at relatively low

temperatures, such as eggs and milk based products, will coat and cook onto the sides of the kettle.

Care should be taken to use the smallest flow of steam, to lessen the possibility of scorching these

products. To achieve this, allow products to come up to desired temperature, stirring frequently, then

turn off steam flow and gradually turn on a small flow of steam - just enough to allow food to cook.

Steam Jacketed Kettles eliminate much range top cooking and greatly reduce the number of pots and

pans required. Because they are made of stainless steel, they are durable, non-porous and easy to clean.

Estimate actual cooking capacity of Steam Jacketed Kettles at 3,4 of its volume, to allow stirring

without spillage.

Plan an adequate drain arrangement. This is very important for ease of use and to minimize wet

floors. A grated gutter type drain located in front of the kettles is preferred as it eliminates the

hazards of tripping over a curb or stumbling into a recessed drain area.

Locate a source of water (swivel faucet or flexible hose type) near the kettle to facilitate filling

and cleaning.

Cover products whenever possible to save energy. Covered water boils 25 to 30% faster.

Use the tangent draw off valve to drain off products from the kettle such as sauces and

puddings, or cooking liquids that are being discarded (as in the case of the water used to cook

pasta)

Page 9

7

OPERATION INSTRUCTIONS

ITEM

COOKED PORTION

SIZE

KETTLE SIZE

25 GALLON

(95 LITERS)

40 GALLON

(150 LITERS)

60 GALLON

(225 LITERS

BEVERAGES

Cocoa or Coffee

6 oz or 3/4 cup (180 ml.)

Yield: 20 gal. (75 l.)

Portions = 425

Yield: 35 gal. (132 l.)

Portions = 745

Yield: 50 gal. (190 l.)

Portions = 1065

BREAKFAST FOODS

Cereal

6 oz or 3/4 cup (180 ml.)

Amt. Raw: 20# (9 kg.)

Portion =

270

Amt. Raw: 36 #

(16.3 kg)

Portion =

480

Amt. Raw: 48 #

(21.7 kg.)

Portion =

640

Scrambled Eggs

4 oz or 2 eggs each

(115 g.)

Eggs: 90 dz. 18 gal.

(120 l.)

Portions = 540

Eggs:

160 dz.

, 32 gal.

(166.5 l.)

Portions =

960

Eggs: 220

dz.

44 gal.

Portions = 1320

DESSERTS

Cornstarch

Pudding

4 oz. or 1/2 cup

(120 ml.)

Yield: 17 gal. (64.3 l.)

Portions = 545

Yield: 30 gal. (113.5l.)

Portions = 960

Yield: 40 gal. (151 l.)

Portions = 1280

Gelatin

4 oz. or 1/2 cup (120 g.)

Yield: 20 gal. (75 l.)

Portions = 640

Yield: 35 gal. (132 l.)

Portions = 1120

Yield: 50 gal. (190 l.)

Portions = 1600

MAIN ENTREES

*

Macaroni, Beef

and Tomato

6 oz. or 3/4 cup

(170 g.)

Yield: 17 gal. (65 l.)

Portions = 360

Yield: 30 gal. (113 l.)

Portions = 640

Yield: 45 gal. (170 l.)

Portions = 960

Baked Beans

5 oz. or 2/3 cup

(140 g.)

Yield: 20 gal. (75 l.)

Portions = 500

Yield: 32 gal. (120 l.)

Portions = 800

Yield: 50 gal. (190 l.)

Portions = 1250

Beef Stew

8 oz. or 1 cup

(225 g.)

Yield: 17 gal. (65 l.)

Portions = 270

Yield: 30 gal. (113 l.)

Portions = 480

Yield: 45 gal. (170 l.)

Portions = 725

Macaroni and

Cheese

5 oz. or 2/3 cup

(140 g.)

Yield: 17 gal. (64 l.)

Portions = 425

Yield: 30 gal. (113 l.)

Portions = 750

Yield: 45 gal. (170 l.)

Portions = 1125

Turkey A La King

4 oz. or 1/2 cup

(115 g.)

Yield: 17 gal. (64 l.)

Portions = 545

Yield: 30 gal. (113 l.)

Portions = 960

Yield: 45 gal. (170 l.)

Portions = 1280

MISCELLANEOUS

Gravy/Sauce

2 oz. or 3/4 cup

(60 ml.)

Yield: 20 gal. (75 l.)

Portions = 1200

Yield:

35 gal. (132 l.)

Portions = 2000

Yield:

50 gal. (190 l.)

Portions = 3000

Remove the tangent draw off valve after each use for cleaning, using a brush to clean draw off

as bacteria will readily multiply in this area if it is not thoroughly cleaned.

Use the optional solid kettle disk when product is not going to be dispensed through the draw

off valve, and the perforated disk when draining off liquids through the draw off valve and

retaining the solid product in the kettle.

COOKING CHART

This chart merely shows single load capacities as it is felt that in most cases the kettle would be used

only once per meal.

* All main entree figures are given in terms of raw ingredients.

Page 10

8

OPERATION INSTRUCTIONS

ITEM

COOKED PORTION

SIZE

KETTLE SIZE

25 GALLON

(95 LITERS)

40 GALLON

(150 LITERS)

60 GALLON

(225 LITERS

MACARONI AND RICE

Noodles

4 oz. or 3/4 cup

(115 g.)

Amt. Raw:

20 gal.

(9kg.)

Portions = 220

Amt. Raw:

35 #

(15.8kg.)

Portions = 385

Amt. Raw:

50 #.

(22.6kg.)

Portions = 555

Rice

3 oz. or 1/2 cup

(85 g.)

Amt. Raw:

20 gal. (9

kg.)

Portions = 320

Amt. Raw:

35 # (15.8

kg.) Portions = 560

Amt. Raw:

50 #. (22.6

kg.) Portions = 800

Spaghetti or

Macaroni

4 oz. or 3/4 cup

(115 g.)

Yield: 20 gal. (9 kg.)

Portions = 320

Amt. Raw:

35 #

(15.8kg.)

Portions = 385

Amt. Raw:

50 #.

(22.6kg.)

Portions = 555

SOUPS

Basic Cream Soup

6 oz. or 3/4 cup

(180 ml.)

Yield: 20 gal. (75 l.)

Portions = 400

Yield:

35 gal. (132 l.)

Portions = 700

Yield:

50 gal. (190 l.)

Portions = 1000

Broth Type Soup

8 oz. or 1 cup

(240 ml.)

Yield: 20 gal. (75 l.)

Portions = 325

Yield:

35 gal. (132 l.)

Portions = 560

Yield:

50 gal. (190 l.)

Portions = 800

VEGETABLES

Fresh

4 oz. or 1/2 cup

(115 g.)

Amt.Raw: 80#.

(36.3kg.)

Portions = 335

Amt. Raw:120 # (54.4

kg.)

Portions = 500

Amt.Raw: 180#. (81.6

kg.)

Portions = 750

Frozen Loose

Pack

4 oz. or 1/2 cup

(115 g.)

No. Of Packages: 50

Portions = 550

No. Of Packages: 80

Portions = 880

No. Of Packages: 120

Portions = 1320

Frozen Solid Pack

4 oz. or 1/2 cup

(115 g.)

No. Of Packages: 25

Portions = 275

No. Of Packages: 40

Portions = 440

No. Of Packages: 60

Portions = 660

COOKING CHART (Continued)

Page 11

9

ADJUSTMENTS

Figure 3, Ball Nut Assembly

General Inspection & Cleaning

The screw assembly should run smoothly throughout the entire stroke. If operation is not uniform,

remove the screw assembly and proceed as follows:

1. Inspect screw shaft for accumulation of foreign

matter in the ball grooves.

2. Using cleaning fluid or solvent, remove dirt from

ball grooves. Be sure to flush the ball nut

assembly thoroughly.

3. Cycle the ball nut along the screw shaft several

times. Then, wipe with a dry, lint less cloth and

lubricate immediately.

Cabinet Exterior Removal

Side and rear panels of all cabinets in which kettles are

mounted are easily removed without the use of tools.

Each panel is grasped at the bottom edge and lift up and

out towards you to release it from the panel mounting

brackets

Replacement is completed by pushing panel up under

cabinet top allow hook to fall in place at the bottom

until panel mounting brackets are engaged. Door may be

removed to improve access to cabinet interior for

repairs.

The two flat head screws and nuts holding cabinet hinge are removed and the door lifted out. When

doors are remounted the final tightened position of hinge determines the alignment of the door and

must be set with care.

Draw-Off Valve – Common Leak Repairs

To repair a valve leak, the source must first be determined. Leaks from around the valve stem are

corrected by replacing the rubber “0” ring .Dripping from the valve outlet which occurs with the valve

tightly closed indicates faulty seating of the valve disc against the valve seat. Dripping is often corrected

by cleaning residue from disc and seat using very fine emery.

Draw-Off Valve – Valve Seat Lapping

Should either the disc, or seat be found damaged it is necessary to either replace the entire valve or

perform the lapping procedure as follows:

1. Disassemble the valve and clean both the disc and the valve seat.

2. Attach the handle to the stem with the valve bonnet removed.

3. Apply a good grade of fine lapping compound to the disc and insert it into the valve to make

light contact against the seat.

4. Rotate the stem disc against the seat by turning the handle, allowing the stem to wobble in the

space the bonnet would normally occupy. Continue with light pressure until compound dries.

5. Reassemble and test for leaks with valve closed. If dripping occurs repeat the lapping procedure

as many times as required to obtain a watertight seal.

Page 12

10

Swing Drain

MAINTENANCE

GENERAL

This section contains both preventive and corrective maintenance information. Preventive maintenance

may be performed by maintenance personnel at the establishment in which the kettle is installed.

It is recommended that user personnel never attempt to make repairs or replacements to the

equipment without the assistance of authorized service. Assistance in service methods or, a current

Directory of Authorized Service Agencies may be obtained from Market Forge (see service section on

page 1).

PREVENTIVE MAINTENANCE

Preventive maintenance may be performed by maintenance

personnel at the establishment in which the kettle is installed.

The most important preventive maintenance operation

on the steam jacketed kettle is the cleaning procedure

after each use. Additional preventive maintenance

operations are presented in this section.

Cleaning

All kettle cleaning procedures should be faithfully completed by the end of each day's operation. (refer

below for daily cleaning procedure). In addition, cabinet doors, top, fixtues, kettle lid, etc., should be

washed and rinsed to remove all food spills.

DAILY CLEANING:

1. Fill kettle with water and mild detergent immediately after removing food from kettle.

2. Scrub kettle interior with a nylon brush.

NOTE: NEVER SCRAPE KETTLE INTERIOR WITH METAL TOOLS, STEEL SCOURING PADS OR

ABRASIVE CLEANERS. Scratches will result, which will ruin the kettles general appearance and

make it harder to clean and maintain in a sanitary condition.

3. Loosen food which is stuck to kettle by allowing it to soak. Also, a small amount of steam may

help.

4. Position swing drain (refer to figure above) under draw-off valve. Open draw-off valve to drain

soapy water.

5. Wipe down exterior, rinse and dry. Avoid getting water into electrical controls.

WARNING: DO NOT HOSE DOWN UNIT AS IT MAY CONTAIN ELECTRICAL COMPONENTS.

6. Remove strainer from inside kettle. Wash and rinse thoroughly.

7. Disassemble draw-off valve by first turning valve handle counterclockwise. Then, turn hex nut

counterclockwise until valve handle and stem are free.

8. Wash inside of draw-off valve with a nylon brush.

9. Rinse kettle valve interior and reassemble valve.

NOTE: Leave draw-off valve open when kettle is not in use.

10. Remove swivel drain and its strainer. Wash, rinse and replace.

Page 13

11

MAINTENANCE

Tilting Mechanism Lubrication

Lubrication of the tilting mechanism is the only required preventive maintenance other than daily

cleaning. Inspect the screw of the tilting mechanism annually for adequate lubrication.

Should screw appear “dry” apply a good grade of ball bearing grease directly on the threads so that the

threads appear to be barely damp. If mechanism fails to run smoothly (see tilting mechanism

maintenance below).

REPAIR & REPLACEMENT

In the event that the kettle fails to operate correctly, the difficulty should first be isolated to either the

kettle itself or the steam supply which heats the kettle. While mechanical problems are obvious faults of

the kettle, any deficiencies in volume and pressure of steam should be traced to the steam generator

and the cause determined.

Steam input requirements are listed in Appendix A, Modular Kettle Steam Requirements. Additional

information may be found in separate service publications for steam generators.

Tilting Mechanism Maintenance

Tilting kettles are equipped with tilting mechanisms shown in Figure 4 on page 11. Utilize the same

screw assembly, only Figure 4 on page 11 includes brake disassembly detail and serves as the reference

view for tilting mechanism repairs which follow.

Page 14

12

ILLUSTRATED PARTS LIST

ITEM NO.

PART NO.

DESCRIPTION

1

91-9335

POWER TILT MOTOR WELD ASSEMBLY

2

91-9336

MOTOR MOUNTING PLATE

3

98-1726

POWER LIFT FOOT BRACKET

4

91-9353

POWER TILT NYLON STRIP

5

98-0555

LIFTING LEVER ARM

6

91-9387

LEVER ARM

7

91-9324

LIFT SCREW ASSEMBLY

8

90-4131

CONDENSER HOSE

9

90-3490

HINGE BLOCK

10

08-5217

VALVE RETAINER COLLAR

11

10-5242

VALVE

12

98-4128

FAUCET HOSE

13

98-3676

MOTOR

Manual Tilt

Power Tilt

(optional)

7 7 3 5 2

4 6 1 8 9

10

12

11

13

Figure 4, Tilting Mechanism

Page 15

13

ILLUSTRATED PARTS LIST

ITEM NO.

PART NO.

DESCRIPTION

1

08-5894

MARKET FORGE NAMEPLATE LOGO

2

91-5795

HANDLE, FRONT

3

98-3992

PANEL, FRONT ASSEMBLY, 24”

3

98-3993

PANEL, FRONT ASSEMBLY, 36”

3

98-3986/98-1621

PANEL, FRONT ASSEMBLY, 48” (60-Gallon)

4

10-0631

LEG, 6”

*4

08-5211

LEG, 10”

*4

08-5206

LEG, 8” 5 98-3994

PANEL, SIDE ASSEMBLY

6

91-9103

HAND CRANK PANEL

7

08-5208

LEG, FLANGED 6”

*8

98-3996

PANEL, REAR ASSEMBLY, 36”

*8

98-3995

PANEL, REAR ASSEMBLY, 48” (MT-60) (NEED QTY. OF 2)

*9

10-0326

CASTER, 5” (OPTIONAL)

2 1 3

4 5 7

6

* NOT SHOWN.

Figure 5, Kettle Cabinet Base(MT-40 Shown)

Page 16

14

ILLUSTRATED PARTS LIST

ITEM NO.

PART NO.

DESCRIPTION

1

--

HINGE AND LID ASSEMBLY

2

--

FAUCET AND SPOUT ASSEMBLY

3

10-0412

SWING DRAIN

4

97-5063

2” DRAW OFF VALVE

5

10-5242

1/2” ANGLE STEAM VALVE

6

10-3945

CLAMP, CONDENSATE HOSE

7

08-5469

STEAM TRAP WITH HOSE FITTING

8

90-7493

CONDENSATE HOSE, 3/8” ID 36” LG.

9

90-8725

SPLASH GUARD ASSEMBLY

10

90-7495

STEAM HOSE, 3/4” ID

11

10-3916

CLAMP, STEAM HOSE

12

--

36” CABINET

13

90-3788

PAN SUPPORT UPRIGHT, LEFT

14

90-3783

PAN SUPPORT UPRIGHT, RIGHT

15

10-1791

MACHINE SCREW, 1/4” x 7/8” LG.

16

10-2403

WASHER, 1/4”

17

10-6784

SPACER, SMALL

18

90-3476

SPACER, LARGE

19

90-3389

PAN SUPPORT, REMOVABLE

20

--

TILT MECHANISM

Figure 6, Cabinet Base, MT-25 and MT-40

Page 17

15

ILLUSTRATED PARTS LIST

ITEM NO.

PART NO.

DESCRIPTION

1

--

SWING DRAIN

2

10-3945

CLAMP, CONDENSATE HOSE

3

08-5469

STEAM TRAP WITH HOSE FITTING

4

90-7493

CONDENSATE HOSE, 3/8” ID

5

10-4928

1-1/2” DRAW OFF VALVE

6

--

48” CABINET

7

10-5242

1/2” ANGLE STEAM VALVE

8

10-6796

HINGE AND LID ASSEMBLY

9

10-3916

CLAMP, STEAM HOSE

10

91-1977

STEAM HOSE, 3/4” ID

11

--

FAUCET AND SPOUT ASSEMBLY

12

91-1839

PAN SUPPORT UPRIGHT, LEFT

13

91-1838

PAN SUPPORT UPRIGHT, RIGHT

14

10-1791

MACHINE SCREW, 1/4” x 7/8” LG.

15

10-2403

WASHER, 1/4”

16

10-6784

SPACER, SMALL

17

90-3476

SPACER, LARGE

18

91-1983

PAN SUPPORT, REMOVABLE

19

90-8725

SPLASH GUARD ASSEMBLY

20

--

TILTING MECHANISM

Figure 7, Cabinet Base, MT-60

Page 18

16

ILLUSTRATED PARTS LIST

ITEM NO.

PART NO.

DESCRIPTION

1

10-4804

PRESSURE GAUGE

2

10-7974

SIGHT WINDOW

3

10-0412

SWING DRAIN

4

90-7475

SUPPORT, NIPPLE, DRAIN

5

08-6553

LOW WATER CUT OFF

6

91-1835

STRAINER

3

6

4

2 5 1

Figure 8, Drain Assembly

Page 19

17

ILLUSTRATED PARTS LIST

ITEM

NO.

PART

NO.

DESCRIPTION

QTY.

1

98-0530

Housing-Compression Rod &

Spring 1 2

98-0535

Compression Rod

1

3

08-4606

Compression Spring

1 4 98-0537

Floating Nut

1 5 98-0536

End Guide

1 6 08-4200

Rivet, Barbed

4

7

08-3205

Hooking Pin, Driv Lok Type “E”

7/32 x 2

1

8

08-1208

Plug, Plastic

1 9 98-0529

COMPLETE PISTON ASSEMBLY

1

Figure 9A, Piston Assembly for Kettle Cover

Figure 9B, Piston Assembly

1

9

PISTON ASSEMBLY

Page 20

18

ILLUSTRATED PARTS LIST

ITEM NO.

PART NO.

DESCRIPTION

1

10-0105A

KNOB 2 10-6303

VALVE RETAINER COLLAR

3

10-5242

VALVE

4

90-3490

HINGE BLOCK

5

91-4795

RUBBER HOSE, 3/4” ID X 36” LONG

6

90-3210

MAGNETIC BRACKET

7

10-5561

DOOR MAGNET

8

10-5753

NOZZLE, SWIVEL SPOUT

9

91-0887

RISER, 15” LONG

10

10-7680

FAUCET SET

11

08-5467

ADAPTER

1 4 2

3 7 6

5 8 10

9

11

Figure 10, Valve and Faucet

Page 21

19

ILLUSTRATED PARTS LIST

ITEM NO.

PART NO.

DESCRIPTION

1

08-7906

Handle with Knob

2

08-7911

Screw, Set 1/4 – 20, 3/8” Long

3

98-1537

Assembly, Crank Shaft

4

90-8878

Clip, Bracket, Universal

5

10-1735

Screw, #8-32, Sheet Metal

6

10-2508

Washer, Stainless Steel

Figure 11, Crank Shaft

Page 22

20

ILLUSTRATED PARTS LIST

ITEM NO.

PART NO.

DESCRIPTION

1

08-4822

WATER VALVE

2

08-4979

CHECK VALVE

3

08-4131

CONDENSER HOSE

4

98-4030

FILL HOSE

5

98-4128

FAUCET HOSE

2

1 4 5

3

Figure 12, Valve Assembly

Page 23

21

ILLUSTRATED PARTS LIST

ITEM NO.

PART NO.

DESCRIPTION

1

10-5319

STEAM TRAP

2

90-7493

RUBBER HOSE, 3/8 ID X 40” LONG

3

91-4795

RUBBER HOSE, 3/4 ID X 36” LONG

4

10-7680

FAUCET SET

5

98-0771

LIFT ARM, FOR 40 GALLON KETTLE

5

98-0599

LIFT ARM, FOR 25 & 60 GALLON KETTLE

1 2 3 5 4

Figure 13, Kettle Jacket Assembly

Page 24

22

ILLUSTRATED PARTS LIST

ITEM NO.

PART NO.

DESCRIPTION

1

10-0105

STEAM VALVE HANDLE

2

10-5242

1/2” ANGLE STEAM CONTROL VALVE

ITEM NO.

PART NO.

DESCRIPTION

1

91-1835

STRAINER, SWING DRAIN

2

10-0412

SWING DRAIN, CASTING

1

2 1 2

Figure 14, Steam Supply Valve

Figure 15, Swing Drain

Page 25

23

ILLUSTRATED PARTS LIST

ITEM NO.

PART NO.

DESCRIPTION

97-5063

2” DRAW OFF VALVE ASSEMBLY (STANDARD)

1

98-6155

ACORN NUT, 10-24 UNC

2

97-5566

HANDLE, STAINLESS STEEL

3

97-5069

GLAND NUT

4

97-5072

BONNET

5

97-5078

“O” RING

6

97-5075

STEAM ASSEMBLY

7

98-6156

VALVE BODY

97-5605

3” DRAW OFF VALVE ASSEMBLY (OPTIONAL)

1

97-5066

ACORN NUT, 10-24 UNC

2

97-5067

HANDLE, STAINLESS STEEL

3

97-5068

GLAND NUT

4

97-5073

BONNET 5 97-5079

“O” RING

6

97-5076

STEAM ASSEMBLY

7

97-6497

VALVE BODY

Figure 16, Draw-Off valve

Page 26

24

ILLUSTRATED PARTS LIST

ITEM NO.

PART NO.

DESCRIPTION

1A

08-5469

TRAP ONLY (NEW STYLE)

1B

98-4494

1/2” STEAM TRAP KIT (TO CHANGE OLD STYLE TO CURRENT STYLE)

2

10-4937

THERMOSTAT, STEAM TRAP

Figure 17, Steam Trap

Loading...

Loading...