Market Forge MT10T6E24A User Manual

ONE 10-GALLON & ONE 6-GALLON

E

MODELS: □ MT10T6E24A

□ MT10T6E36A

□ MT10T6E42/48A

SIZE: 36” x Wide x 33” Front-to-Bac

(914mm Wide x 838mm Front-to-Back)

DESCRIPTION:

Maret Forge Model __________ Tilting Steam Jaceted Trunnion Kettle. Kettles will be mounted on a 28”

(711mm) high cabinet base. Hot and cold water ll faucet,

depressed area and drains, and steam control valves will

be located on stainless steel marine-edged countertop.

A 4” (102mm) deep 12” x 10” (305mm x 254mm) clean-

up pan with removable splash guard will be standard

(Splash guard will be removable so that it may also be

attached to a food receiving pan). Kettles are made from

#316 stainless steel and will be A.S.M.E.- Approved and

National Board Registered.

ELECTRIC TILTING KETTLES

JOB NAME: ________________________

ITEM NO.: _________________________

NO. REQUIRED: ____________________

SPEC SHEET: S-2366C

05/12

Cabinet base, constructed of a stainless steel frame,

which houses the electric steam generator, will be of modular design to match other Maret Forge cooing equipment. Base with stainless steel frame will be equipped

with 6” (152mm) stainless steel legs and adjustable bullet

feet, reinforced die-formed stainless steel marine-edged

countertop, and hinged doors with magnetic latches. Unit

will be polished stainless steel.

CAPACITY:

■ MT10T6E One 10 Gallon (38 liters)

One 6 Gallon (23 liters)

OPERATION SHALL BE BY:

Electrically operated, 15 PSI (1kg/cm2), built in accordance with A.S.M.E. codes, equipped for operation with:

□ 208 Volt, 3 phase

□ 240 Volt, 3 phase

□ 480 Volt, 3 phase (optional at extra cost)

□ 220/380 Volt

□ 240/415 Volt, 50 Hz, 3 phase, 15 Amps

The manufacturer reserves the right to modify materials and specications without notice.

Steam generator will be automatically lled with hot water

and brought to 15 PSI (1kg/cm2) pressure when heat and

water switches are turned on and automatically drained

under pressure when switches are turned off. Cold water

condenser will automatically condense exhausted steam

into water before releasing it to drain. Unit also includes

safety valve, low water cut-off, water strainer, and des-

caler.

OPTIONAL AT EXTRA COST:

□ 480 Volt, 3 phase

□ One-piece lift-off stainless steel cover

□ Stainless steel wire baset

□ Clean-up brush

□ Steam Tae-Off it

□ Total Concept Boiler Descaling Chemical

FOOD SERVICE EQUIPMENT

Tilting Electric Kettles

Tel: (617) 387-4100 • Fax: 1-800-227-2659 (Ex. MA) • (617) 387-4456 (MA and Overseas)

E-Mail: CUSTSERV@mi.com • Website: www.mi.com

35 Garvey Street • Everett • MA • 02149

ONE 10-GALLON & ONE 6-GALLON

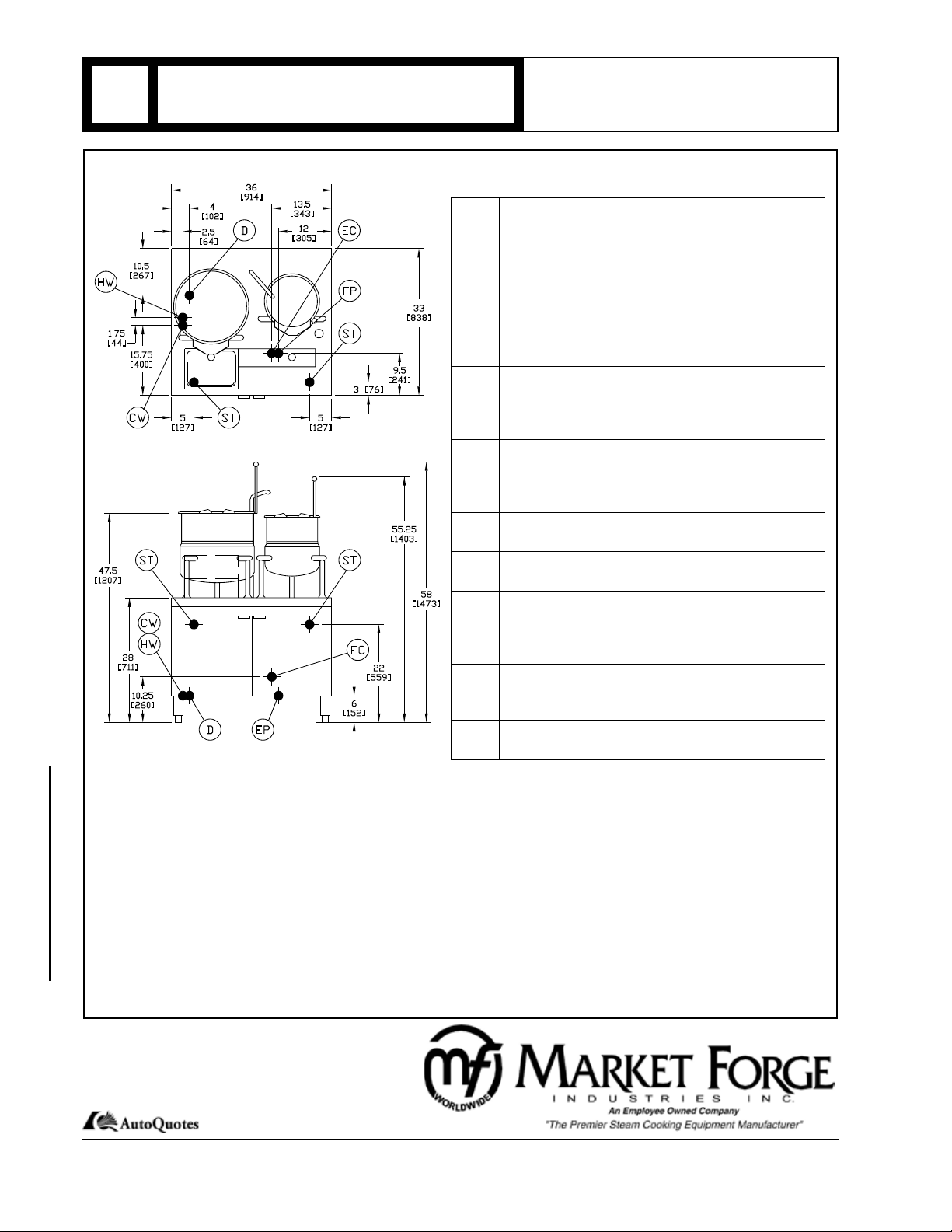

36

[914]

13.5

[343]

12

[305]

4

[102]

2.5

[64]

10.5

[267]

1.75

[44]

HW

D

EC

EP

ST

STCW

15.75

[400]

5

[127]

5

[127]

9.5

[241]

33

[838]

3 [76]

HW

D

EC

EP

ST ST

CW

47.5

[1207]

28

[711]

10.25

[260]

6

[152]

22

[559]

55.25

[1403]

58

[1473]

E

SPEC SHEET: S-2366C

05/12

FOOD SERVICE EQUIPMENT

CAUTION:

Before connecting water to this unit, water supply

should be analyzed to mae sure hardness is no

greater than 2.0 grains per gallon and pH level is within the range of 7.0-8.5. Water that fails to meet these

Tilting Electric Kettles

standards should be treated by installation of water

conditioner. EQUIPMENT FAILURE CAUSED BY INADEQUATE WATER QUALITY IS NOT COVERED

UNDER WARRANTY.

It is our policy to build equipment which is design certied by A.G.A., U.L., A.S.M.E., N.S.F., C.G.A. and C.S.A. However, a continuing program of product improvement

maes it necessary to submit new models to the agencies as they are developed and consequently not all models bear the appropriate agency labels at all times.

PRINTED IN U.S.A.

ELECTRIC TILTING KETTLES

Electrically Operated

EP Power Supply—Use wire suitable for at least

HW

CW

HWK

CWK

D

EC

ST*

* Steam supply connection available on either side of cabinet base.

NOTES: Units supplied for use in Canada require only one

electrical connection at “EP” for both power and control

circuits.

PVC and CPVC pipe are not acceptable materials for drains.

The only available space to supply utilities to the steam gen-

erator is the 6” (152mm) space between the oor and the

cabinet base. Allow 3” (76 mm) spacing from side wall and 6”

(152mm) from rear wall if adjoining wall is combustible.

Tel: (617) 387-4100 • Fax: 1-800-227-2659 (Ex. MA) • (617) 387-4456 (MA and Overseas)

DETAILS & DIMENSIONS

SERVICE CONNECTIONS

90°C. Nominal amp per line wire:

Volts

208

240

480

(197-219)

(220-240)

(360-500)

24W

3pH

66

60

32

36W

3pH

100

91

47

42W

3pH

117

--

--

48W

3pH

--

116

58

Details of other electrical systems available upon

request.

Hot Water - 3/8” (9.5mm) O.D. tubing for hot water to

generator. Hot water lines will have a maximum of 50

PSI (3.5kg/cm2) and a minimum of 25 PSI (1.8kg/cm2)

water pressure.

Cold Water - 3/8” (9.5mm) O.D. tubing for cold water to

condenser. Cold water lines will have a maximum of 50

PSI (3.5kg/cm2) and a minimum of 25 PSI (1.8kg/cm2)

water pressure.

1/2” (13mm) O.D. tubing for hot water to ettle ll

faucet.

1/2” (13mm) O.D. tubing for cold water to ettle ll

faucet.

Drain - Pipe full 2” (50mm) I.P.S. to ush oor drain ca-

pable of receiving water owing at a maximum rate of

5 gallons (19 liters) per minute. DO NOT MAKE SOLID

CONNECTION TO FLOOR DRAIN.

Electrical Connection - 115 VAC, 60 Hz, 2 amps, 1/2”

(13mm) conduit connection or equivalent. Use wire

suitable for at least 90°C.

Steam Tae-Off - Connection for operation of adjacent

steam-powered equipment

35 Garvey Street • Everett • MA • 02149

E-Mail: CUSTSERV@mi.com • Website: www.mi.com

Loading...

Loading...