Page 1

SERVICE & PARTS MANUAL

Steam

-

Jacketed, Electric

Models:

ULTRA KETTLES®

Self-contained Counter-Top,

MFT6CE

MFT10CE

Form No. S-2287 8/83 Printed in U.S.A.

Market Forge Co.

35 Garvey St., Everett, MA. 02149

Tel. (617) 387-4100, Telex 94-9414, Cable MAFORCO

Page 2

TABLE OF CONTENTS

Paragraph Page

Paragraph Page

SECTION 1 INTRODUCTION

1.1 Description ..............……………….... 1-1

1.2 Basic Functioning ...........………….... 1-1

1.3 Service .....................………………... 1-1

SECTION 2 OPERATION

2.1 Operating Controls and Indicators. .. 2-1

2.2 Operating Procedures ........………... 2-1

2.3 Reservoir Fill Procedure ...………..... 2-1

2.4 Automatic Venting............…….…….. 2-1

2.5 Kettle Washing ................. …………..2-3

LIST OF ILLUSTRATIONS

Figure Page

SECTION 2 OPERATION

2-1 Controls and Indicators. ....…………….... 2-2

2-2 Temp. and Pressure Control Settings . . . 2-3

SECTION 3 MAINTENANCE

3-1 Wiring Label #A09-5932. .....……………. 3-3

3-2 Wiring Label #A09-5933. ...……………... 3-4

3-3 Wiring Label #A09-5934. ...……………... 3-5

3-4 Schematic Diagram ...........……………... 3-6

3-5 Access Panel To Heating Element …….. 3-10

SECTION 3 MAINTENANCE

3.1 General .....................……………………...3-1

3.2 Trouble-Shooting Guide ...…………….... 3-1

3.2.1 Electrical Fault Isolation ..……………...... 3-2

3.2.2 Water Level Control. .........………… ….. 3-6

3.2.2.1 Circuit Operation .........……………..... 3-6

3.2.2.2 Control Fault Isolation. ...…………..... 3-6

3.3 Repair and Replacement. ....………... 3-6

3.3.1 Console Control Components. ..……….. 3-6

3.3.2 Temperature and Low Water Probes. …. 3-7

3.3.3 Heating Element ...........………………... 3-7

SECTION 4 ILLUSTRATED PARTS LIST

4.1 General ....................……………………….. 4-1

4.2 Ordering Information....…………………...... 4-1

Figure Page

SECTION 4 ILLUSTRATED PARTS LIST

4-1 Kettle Exterior Controls and Indicators….. 4-2

4-2 Kettle Bottom View..........………………….. 4-4

4-3 Control Bracket Assembly. .……………...... 4-6

4-4 Control Box - Top View. ....……………….... 4-8

4-5 Control Box -

Rear View and Bottom View …………... 4-10

LIST OF TABLES

Table Page

SECTION 2 OPERATION

2-1 Controls and Indicators. ......……….... 2-2

2-2 Temperature Control Setting Guide ... 2-4

Table Page

SECTION 3 MAINTENANCE

3-1 General Trouble-Shooting Guide . . . 3-1

3-2 Electrical Ratings .............…………... 3-7

ii S-2287

Page 3

SECTION I INTRODUCTION

THIS SERVICE AND PARTS MANUAL CONTAINS DESCRIPTIVE INFORMATION, OPERATING INSTRUCTIONS, AND

MAINTENANCE AND TROUBLE -SHOOTING INFORMATION FOR MODELS MFT6CE AND MFT10CE STEAM-JACKETED

ULTRA KETTLES® PARTS LISTS ARE ALSO INCLUDED IN WHICH EACH REPLACEABLE PART IS IDENTIFIED AND

SHOWN IN AN ACCOMPANYING ILLUSTRATION.

1.1 DESCRIPTION

Market Forge Models MFT6CE (6 gallon capacity)

and MFT1 OCE (10 gallon capacity) are selfcontained, counter-top, tilting Ultra Kettles® Each

model has a jacket of double-wall construction

forming a sealed reservoir around the lower two-thirds

of the kettle. The reservoir is charged with water and

anti-freeze solution. Kettles are equipped with a

removable electric heating element and controls,

including a low water cutoff device for protection of

the heating element. Both models are of identical

construction, except for kettle size and element

heating capacity.

1.2 BASIC FUNCTIONING

Self-contained kettles operate by generating steam

in the kettle reservoir. The sequence of operation is

as follows:

1. Operator presses the power switch to the ON

position and sets the temperature control dial at

the desired setting from 1 to 10 (100°F to 300°F,

38°C to 149°C, jacket temperature).

2. Control circuit is normally completed to the temp-

erature controller if the following conditions exist:

a. Water level in kettle reservoir is adequate to

prevent circuit interruption by the low water cutoff

device. An activated cutoff is indicated by the

buzzer sounding, amber low water light turning on,

and the heating element shutting off.

b. Kettle is in vertical position with circuit completed through the tilt interlock switch (Micro

switch).

3. Thermostatic control contacts close to energize

contactor coils.

4. Power is supplied to the elements through closed

power contactors.

5. As the temperature of water rises in the kettle

reservoir, increase in steam pressure is indicated

on the pressure gauge. Models after 1982 have the

automatic venting feature (Vent -Rite Air Valve).

6. When the temperature of steam in the reservoir

reaches the setting shown on the temperature

control dial, the temperature controller opens to

break the contacts and shut off the heating

element. On/off cycles will occur as required to

maintain temperature control.

1.3 SERVICE

Required service, both preventive and corrective, is

explained in Section 3. Should repairs be required, a

network of authorized agencies is available to assist

with prompt service. A current Directory of Authorized

Service Agencies may be obtained by contacting:

Product Service Department

MARKET FORGE CO.

35 Garvey Street

Everett, Massachusetts 02149

Telephone: (617) 387-4100

The model and serial numbers must be referenced

when corresponding with Market Forge. These

numbers can be found on the data plate located on

the back of the control box.

1-1 S-2287

Page 4

SECTION 2 OPERATION

TABLE

2-1

TEMPERATURE CONTROL SETTING

2.1 OPERATING PROCEDURES

Instructions for operating the self -contained kettles are as

follows:

1. Check that the external electrical shut -off to the kettle

(such as a main circuit breaker) is on.

2. Push power switch to ON position; switch will glow red in

ON position.

3. To preheat kettle, set temperature control dial at 10, and

wait until pressure gauge reads 50 psi. (Do not preheat

when cooking milk and products which cook onto hot

cooking surfaces. These foods should be put into the

kettle before heating.) Figure 2-1 shows the correct

settings for the temperature control dial and the pressure

gauge.

4. Put food to be cooked into kettle.

5. Set temperature control dial at the required setting from 1

to 10 coinciding with a temperature range from roughly

100°F to 300°F, 38°Cto 149°C, in the jacket. Table 2-1

Temperature Control Setting Guide, shows the

relationship between the temp erature control setting and

the water temperature.

6. When finished cooking, set temperature control knob to

OFF, and push the power switch to OFF.

7. Pour finished product from kettle using tilt handle, being

careful to avoid splashing.

8. Wash kettle thoroughly. See subsection 2.5 for

instructions.

2.2 OPERATING CONTROLS AND INDICATORS

The controls and indicators used to operate the MFT6CE

and MFT10CE tilting Ultra Kettles® are discussed in this

section. Figure 2-2 shows the physical location of the controls

and indicators. Table 2 -2 lists each control and indicator and

its function.

2.3 RESERVOIR FILL PROCEDURE

The reservoir water level must be maintained at or above

the minimum needed to submerge the heating element. If the

amber low water light turns on and the buzzer sounds during

use, the water level is not adequate and the low water

protection control has automatically shut off the heating

element. Low water light will stay lit and buzzer will sound until

the jacket reservoir has again been filled to a safe water level.

WARNING: Before connecting water to this unit,

water supply should be analyzed to make sure

hardness is no greater than 2.0 grains per gallon

and pH level is within the range of 7.0 - 7.5 Water

which fails to meet these standards should be

treated by installation of a water conditioner.

EQUIPMENT FAILURE CAUSED BY INADEQUATE WATER QUALITY IS NOT COVERED

UNDER WARRANTY.

Fill Procedure

The following procedure must be completed before further use.

CAUTION: THERE SHOULD BE NO PRESSURE IN THE

KETTLE DURING THE FILL PROCEDURE.

TO FILL:

1. Push in low water switch.

2. Turn elbow on safety valve upright.

3. Pull lever on safety valve up and add water through elbow

until low water light goes out and buzzer stops. CAUTION:

Be sure to turn elbow to down position to avoid injury from

escaping steam.

4. Push low water switch to reset.

NOTE

If the kettle is to be subjected to temperatures below 32°F,

0°C, it is essential that either the proper proportion of 1 part

(104 oz.) anti-freeze to 3 parts (31 2 oz.) water be

maintained in the kettle jacket, or that the jacket be

emptied.

Temp. °F

Temp. °C

1 2 3 4 5 6 7 8 9 10

GUIDE

Control Number

90 125 160 195 231 273 300

32 52 71 91 110 134 149

2-1 S-2287

2.4 AUTOMATIC VENTING

If there is any air in the kettle jacket after filling, it will be

relieved by the Automatic Venting system.

Page 5

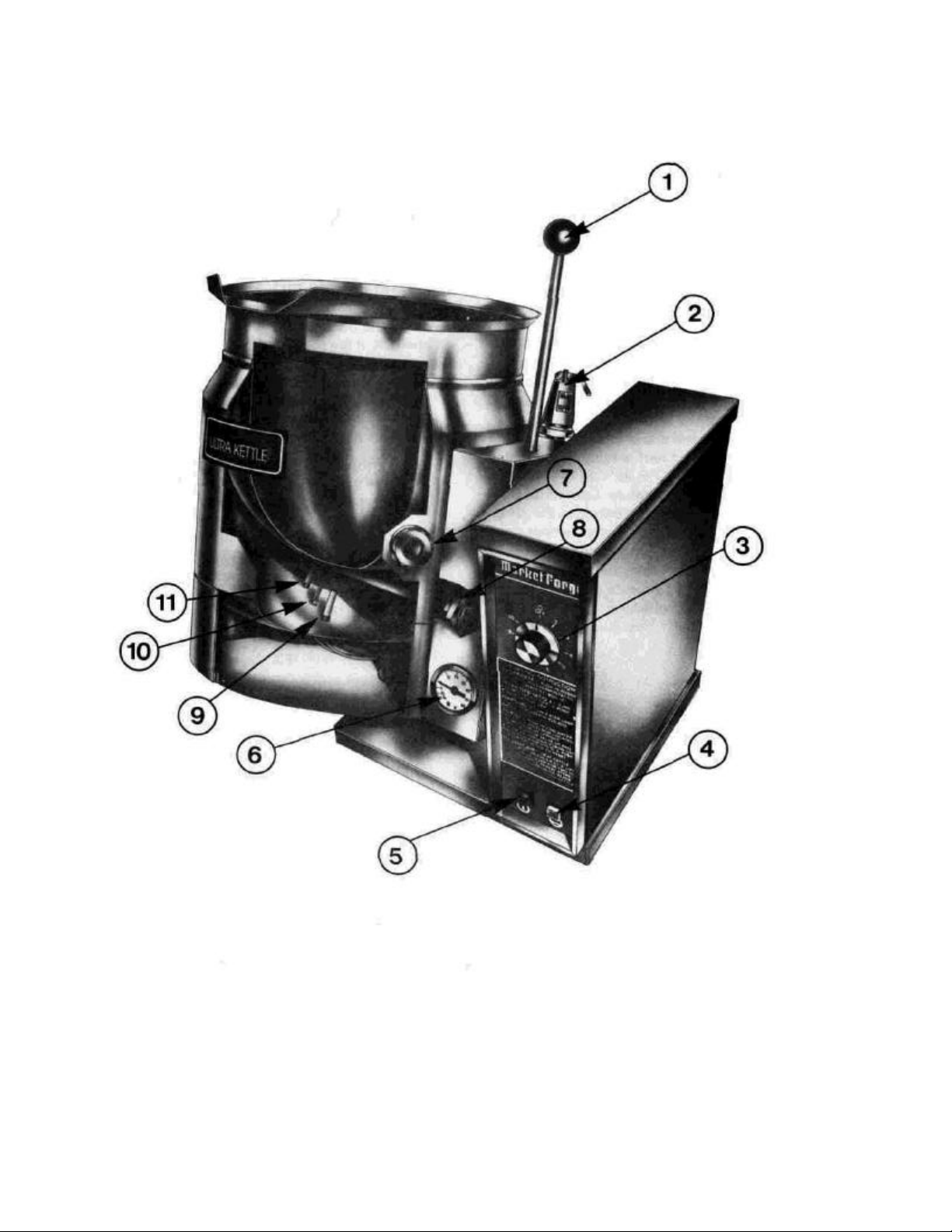

Figure 2-2. Controls and Indicators.

Page 6

TABLE 2-2

CONTROLS AND INDICATORS

2-3

Figure 2.2

Ref. No. Description Function

1 Tilt Handle Used to move kettle to upright or downward position for ease in

pouring and washing.

2 Safety Relief Valve Safety relief va lve opens automatically to release excessive steam

pressure in kettle reservoir. (Located on rear of kettle.)

3 Temperature Control

Knob

Allows operator selection of kettle temperature in increments from 1

to 10, 100°F to 300°F, 38°C to 149°C steam jacket temperature and

OFF.

4 Low Water Switch Glowing amber light indicates that the low water protective device

has cut off power supply to controls and heating element.

5 Power ON/OFF Switch Controls power to kettle.

6 Pressure Gauge Indicates pressure in pounds per square inch (PSI) inside kettle.

7 Water Level Sight

Sight glass shows water level in kettle reservoir.

Window

8 Heating Element Heats water to desired temperature.

9 & 11 Fittings , Electrode

(Water Probes)

Low water probe in conjunction with the low water cutoff protects the

kettle from a low water condition.

10 Temperature Sensor Measures water temperature.

Not Shown Vacuum Breaker Breaks hazardous vacuum. (Located on rear of kettle.)

Not Shown Vent-Rite Air Valve Automatically vents air from kettle. (Located on rear of kettle.)

2.5 KETTLE WASHING

The kettle interior and exterior should be thoroughly

washed after each use. The kettle can be moved from

an upright to a downward position by pulling the tilt

knob forward and pushing the tilt handle downward. To

move the kettle to the upright position, simply reverse

the procedure. To wash the kettle follow the directions

below:

1. Fill kettle with water immediately after each use to

facilitate cleaning even if kettle is not going to be

washed at that time.

2. Prepare a warm water and mild detergent solution

in the kettle.

3. Remove food soil using a nylon brush. CAUTION:

Do not scrape inside of the kettle with metal tools

steel scouring pads, or abrasive cleaners.

Scratches will result which ruin the general

appearance of the kettle, make it harder to clean

and maintain in sanitary condition.

4. To loosen food which is stuck to the kettle, allow

it to soak at a low temperature setting.

5. Rinse with clear water and dry interior of ket tle.

6. Wipe down exterior of kettle, rinse, and dry.

CAUTION: Never get water into the electrical

controls.

S-2287

Page 7

SECTION 3 MAINTENANCE

PROBLEM

CONTROLLER SET.

b. Kettle tilted.

Retur

n kettle to full vertical position.

c. Low water level in kettle reservoir.

Fill reservoir (

see subsection 2.3

).

g. Faulty interlock switch (Micro switch).

Replace interlock switch.

c. Burned out heating elements.

See

s

ubsection 3.3.3

.

d. Faulty contactor.

Replace contactor.

b. Defective low water controller.

Replace control (

see subsection 3.2.2

).

5.

KETTLE HARD TO TILT.

3.1 GENERAL

This section contains trouble-shooting and main-

tenance information intended for use by authorized

personnel. It is recommended that the operator never

attempt to make repairs without such assistance. A

current Directory of Authorized Service Agencies may

be obtained from Market Forge (see subsection 1.3).

3.2 TROUBLE-SHOOTING GUIDE

Table 3-1 gives information to assist service per-

sonnel in locating the general source of problems

which may occur with the self-contained kettles.

Before attempting to locate the source of difficulty, the

technician should be familiar with the operating

instructions in Section 2 and the basic functioning

described in subsection 1.2.

TABLE 3-1 GENERAL TROUBLE-

SHOOTING GUIDE

Probable Cause Remedy

1. POWER ON/OFF SWITCH FAILS TO LIGHT WITH SWITCH IN ON POSITION AND TEMPERATURE

a. Power to kettle off. Locate external shut -off (circuit breaker) for

incoming power and place in ON position.

d. Power ON/OFF light burned out. Replace light.

e. Faulty power ON/OFF switch. Replace switch.

f. Faulty temperature controller. Replace temperature controller.

h. Faulty water level control. Replace control (see subsection 3.2.2).

i. Faulty wiring. Inspect condition of wire and tightness of all

connectors. Correct as required.

2. KETTLE NOT HOT ENOUGH TO BOIL WATER WITH TEMPERATURE CONTROLLER SET AT 10

a. Air in kettle reservoir Replace Vent -Rite valve.

b. Faulty weeping safety relief valve. Replace valve.

e. Faulty temperature controller. Replace temperature controller.

3. SAFETY RELIEF VALVE WEEPS OR OPENS REPEATEDLY.

a. Before reaching 55 psi. Change valve.

b. Faulty safety relief valve. Replace valve.

4. LOW WATER LIGHT ON.

a. Low water level in reservoir. Fill reservoir (see subsection 2.3).

c. Defective low water probe. Replace probe (see subsection 3.3.2).

d. Faulty wiring. Inspect and repair as required.

a. Bearings loose or lacking lubrication. Repair or replace as required.

3-1 S-2287

Page 8

3-2

3.2.1 Electrical Fault Isolation

Correction of an electrical failure first requires isolation of

the fault to a single circuit or component. In most cases, the

nature of the failure and its effect upon the operation of the

kettle will be sufficient to

isolate it to one or more circuit elements. The General

Trouble-Shooting Guide (Table 3-1), 3 Wiring Diagrams

(Figures 3-1, 3-2, and 3-3), and the Schematic Diagram

(Figure 3-4) are provided as guides for isolation of electrical

faults.

Figure 3-1. Wiring Label #A09-5932.

S-2287

Page 9

3-3

Figure 3-2. Wiring Label #A09-5933.

S-2287

Page 10

3-4

S-2287

Figure 3-3. Wiring Label #A09-5934.

Page 11

Figure 3-4. Schematic Diagram.

S-2287

Page 12

3-6

The electrical ratings are shown in Table 3-2, below:

ELECTRICAL RATINGS

KETTLE SZ KW VOLTS AMPS PHASE ELEMENT PT #

6 GALLON 8 208 39 1 09-6500

6 GALLON 8 208 23 3 09-6494

6 GALLON 8 240 34 1 09-6501

6 GALLON 8 240 20 3 09-6487

6 GALLO N 8 480 17 1 09-6502

6 GALLON 8 480 10 3 09-6488

6 GALLON 8 380 13 3 09-6584

6 GALLON 8 415 12 3 09-6586

10 GALLON 12 208 58 I 09-6503

10 GALLON 12 208 34 3 09-6495

10 GALLON 12 240 50 1 09-6504

10 GALLON 12 240 29 3 09-6489

10 GALLON 12 480 25 1 09-6505

10 GALLON 12 480 15 3 09-6490

10 GALLON 12 380 19 3 09-6585

10 GALLON 12 415 17 3 09-6587

3.2.2 Water Level Control

3.2.2.1 Circuit Operation

The low water circuit includes a low water controller,

water level probe, and low water light. The water level

controller provides circuit cutoff to the heating element. The

amber low water light will go on and the buzzer will sound

when the reservoir water level is not in contact with the

probe.

Detailed wiring labels, including internal control wiring,

are shown in Figures 3-1, 3-2, and 3-3. In normal operation,

with adequate water level, the relay coil circuit is completed

between the ground and water contacting the probe. The

energized integral relay opens contacts 3-4 (N.C.) and

closes contacts 7-8 (N.O.). Should the water level recede

below the probe, the relay coil is de-energized causing

contacts 7-8 to open and 3-4 to close. If this occurs with the

kettle in the vertical position and the water level (as viewed

through the sight window) Is low, normal operation is

restored by adding water to the reservoir. (See subsection

2.3.) The same level control interruption of operation is

normal if it occurs when the kettle is tilted. Returning the

kettle to the upright position re-energizes the control relay.

3.2.2.2 Control Fault Isolation

First determine that the reservoir water level is

adequate. If other electrical controls (power switch,

S-2287

TABLE 3-2

tilt interlock switch, temperature controller and heating

element contactors) are not defective, and the interconnecting wiring is complete but the control fails to operate

as described in subsection 3.2.2.1, the trouble is due to a

malfunction of the level control. The level control, with

Integra! relay and transformer, is replaced as a unit. It is

essential to proper control checkout that probe and ground

integrity are verified. Check to be sure the control is firmly

grounded from terminal to kettle, If the control is not

grounded, the relay coil circuit cannot be completed. Always

be sure that the probes are clean to insure proper operation.

3.3 REPAIR AND REPLACEMENT

3.3.1 Console Control Components

Console control components can be accessed by the

following procedure:

1. Remove screw from console cover.

2. Lift off console cover to expose controls. Wiring labels

are located on the console cover for reference.

3. Lift off control bracket assembly.

4. Slide mounting plate into support guide angle for easy

access.

5. Repair as required.

6. After servicing, replace components, and screw console

cover into place.

Page 13

3.3.2 Temperature and Low Water Probes

To gain access to the temperature and low

water probes:

1. Place kettle downward position.

2. Remove screws and lift off bottom cover

plate.

3. Remove or replace probes as needed.

4. After servicing, resecure bottom cover plate.

5. Return kettle to upright position and lock into

place.

3.3.3 Heating Element

The kettle is equipped with three separate

protective features: (1) a low water controller, (2)

a tilt shutoff interlocking switch, and (3) the

temperature controller. As a result of these

safeguards, the probability of element failure is

negligible. However, if the possibility of a

defective element does exist, test the element

with a voltmeter. Note: Test replacement element

with a dielectric strength meter (Hypot).

1. If voltage potential is at the element leads and

unit does not heat, replace the heating

element.

2. If voltage potential is not at the element leads,

refer to subsection 3.2. (See Figure 3-5).

The heating element can be changed easily

by following the procedure below:

1. Release tilt lock (optional feature) by pulling

the knob forward.

2. Push tilt handle forward until kettle locks into

downward position. Access panel is now

visible on the side of the console. (See Figure

3-5).

3. Remove 3 screws holding access panel in

place and rotate panel to the right to gain

access to the heating element.

4. Remove and replace heating element.

5. Reposition access panel and screw securely

into place.

6. Return kettle to locked upright position.

3-7

Figure 3-5. Access Panel to Heating

Element

S-2287

Page 14

SECTION 4

ILLUSTRATED PARTS LIST

4.1 GENERAL

This section contains a complete listing of replaceable parts for the self-contained, steam-jacketed Ultra

Kettles® MFT6CE and MFT10CE. The units are illus trated with circled reference numbers to identify

specific parts. The illustrations immediately precede

the applicable parts list. Each parts list includes the

figure reference number, the Market Forge part

number, and a brief description.

4.2 ORDERING INFORMATION

Orders for replacement parts should be directed to

the nearest authorized parts distributor. For a current

Market Forge Authorized Parts Distributor List

contact:

Product Service Department

MARKET FORGE CO.

35 Garvey Street

Everett, Massachusetts 02149

Telephone: (617) 387-4100

All orders must include the Market Forge part

number(s), part description(s), and the kettle model

and serial numbers.

4-1

S-2287

Page 15

1 09-2800

Knob, Ball,

1 -

1/2"

Dia.,

1 -

1/2

Ht.

4-2

S-2287

Figure 4-1. Kettle Exterior Controls and Indicators.

Fig. 4-1

Ref. No. Part No. Description

2 97-0818 Handle

3 97-0583 Cover, Control Box

4a 09-5245 Knob, Tilt Lock (Assembly) (Optional Feature)

4b 97-0588 Lock & Pin

4c 10-2763 Spring

4d 10-2502 E Clip

5 10-6307 Knob, Temperature Control

6 09-6514 Switch, Low Water/Fill

7 09-6522 Switch, Power ON/OFF

8 09-4840 Gauge, Vacuum/Pressure

9 10-7974 Window, Sight

10 09-7014 Valve, Safety Relief, 55 PSI

11 09-4880 Breaker, Vacuum, 1/8 IPS, BRS, CR, PL

12 10-7978 Valve, Vent -Rite, 1/8 Male

Page 16

Fig. 4-2

1 09-4840

Gauge, Vacuum/Pressure

4-3 S-2287

Ref. No. Part No. Description

2 09-6515 Connector, Female, Flare

3 97-0533 Assembly, Connector (Copper Tubing, Flared)

4 09-4843 Elbow, Male, Brass 1/4 Thd. X 1/4 Flare

5 & 8 09-6506 Fittings, Electrode, 5" (Water Probe)

6 09-6474 Sensor, Temperature

7 09-4842 Connector, 3/1 6 to 1/4" X 1/4" - 1 8 Thd.

9a 09-6500 Heater, Cartridge, 2 wire, 208V, 8KW

9b 09-6501 Heater, Cartridge, 2 wire, 240V, 8KW

9c 09-6502 Heater, Cartridge, 2 wire, 480V, 8KW

9d 09-6503 Heater, Cartridge, 2 wire, 208V, 12KW

9e 09-6504 Heater, Cartridge, 2 wire, 240V, 12KW

9f 09-6505 Heater, Cartridge, 2 wire, 480V, 12KW

9g 09-6494 Heater, Cartridge, 3 wire, 208V, 8KW

9h 09-6487 Heater, Cartridge, 3 wire, 240V, 8KW

9i 09-6488 Heater, Cartridge, 3 wire, 480V, 8KW

9j 09-6495 Heater, Cartridge, 3 wire, 208V, 12KW

9k 09-6489 Heater, Cartridge, 3 wire, 240V, 12KW

9I 09-6490 Heater, Cartridge, 3 wire, 480V, 12KW

9m 09-6584 Heater, Cartridge, 3 wire, 380V, 8KW

9n 09-6586 Heater, Cartridge, 3 wire, 415V, 8KW

9o 09-6585 Heater, Cartridge, 3 wire, 380V, 12KW

9p 09-6587 Heater, Cartridge, 3 wire, 415V, 12KW

10 09-0592 Cover, Bottom

Page 17

Fig. 4-3

1 10-6665A

Buzzer

4-4 S-2287

Figure 4-3. Control Bracket Assembly.

Ref. No. Part No. Description

2 10-5503

3 10-5070

Block, Terminal Section, Buchanan, 4

HD212

Block, Terminal Section, End, Buchanan

230

4a 10-5476 Contactor, 208V

4b 10-5943 Contactor, 240V

5 10-7934 Controller, Low Water, Warwick

6 09-6493 Controller, Temperature

Page 18

1 97-0562

Bearing, Trunnion

4-5

S-2287

Figure 4-4. Control Box - Top View.

Fig. 4-4

Ref. No. Part No. Description

2 97-0563 Collar, Locking, with switch cam

3a 09-6510 Raceway, Insulation, Electric, Vinyl, Size 3/4

3b 09-6509 Raceway, Insulation, Electric, Vinyl, Size 2

4 10-6859 Switch, Interlocking (Micro Switch)

5 09-6512 Resistor, 35K ohm

6 97-0572 Assembly, Remote Potentiometer

Loading...

Loading...