Page 1

Self-Contained, GAS OPERATED

Models:

35

Garvey St., Everett, MA

02149

-

4403

Tel.

(617) 387

-

Steam-Jacketed Kettles

OWNERS MANUAL

FACSIMILE # (617) 387-4456

OUTSIDE MA (800) 227-2659

Form No. S-2377 Printed in U.S.A. 11 /89

STATIONARY

4100, Telex 94-9414, Cable MAFORCO

MFGB-20

MFGB-30

MFGB-40

MFGB-60

MFGB-80

MFGB-20-5

MFGB-30-5

MFGB-40-5

MFGB-60-5

MFGB-80-5

Page 2

Market Forge Co.

Everett, Massachusetts 02149-4403

LIMITED ONE YEAR WARRANTY

We warrant that Market Forge® cooking equipment will be free from defects in material and factory workmanship for a

period of one year from the EFFECTIVE WARRANTY DATE, which shall be the date the equipment is placed in service or

15 months from date of shipment from our factory, whichever comes first. Providing the equipment is unaltered, has been

properly installed, maintained and operated, we will repair or replace, at our option, F.O.B. Everett, Massachusetts, that

part of any such equipment that becomes defective due to defects in material and/or factory workmanship during the

applicable warranty period, subject to the following limitations.

Market Forge® will replace, repair, or adjust at no cost any part of all equipment which becomes defective due to material

or factory workmanship within ninety (90) days of the EFFECTIVE WARRANTY DATE. Any labor required for any such

repair, replacement or adjustment after ninety (90) days shall be paid by the user or dealer, unless our extended labor

warranty contract has also been purchased to cover this particular equipment Adjustments are only covered in the first

30 days of the one-year warranty.

With respect to STEAM BOILER SHELLS only, there is an additional four (4) year warranty limited to the replacement of

such shells. Whenever we replace a steam boiler shell after one (1) year from the EFFECTIVE WARRANTY DATE, the

user shall pay a pro-rata share of the then selling price thereof based on the number of months elapsed from the

EFFECTIVE WARRANTY DATE. There is no labor compensation when boiler shells are pro-rated. Boiler shells which

have not been properly maintained will not be considered for proration. Factory inspection may be necessary. *Boiler

shells should be descaled every 90-120 days, by an authorized service agent to insure efficiency and avoid premature

failure.

There is only a 90 day parts and labor warranty on the following: gaskets, steam traps, air vents, knobs, dynaseal

washers, rubber washers, cathodic descalers or anodes, sight glass. Any parts used in conjunction with a boiler descaling

(cleaning) are the responsibility of the owner/user regardless of time in use.

All warranty service, labor or parts (shipped or replaced) must be performed by the appointed Market Forge authorized

service agent for your area. Any repairs performed by non-authorized services will void the warranty. We reserve the right

to disallow any request for reimbursement of charges incurred by others.

WITH RESPECT TO EQUIPMENT REQUIRING WATER CONNECTIONS, WATER SUPPLY SHOULD BE ANALYZED

TO MAKE SURE HARDNESS IS NO GREATER THAN 2.0 GRAINS PER GALLON, PH LEVEL IS WITHIN THE RANGE

OF 7.0-8.5 AND TDS LEVEL NO GREATER THAN 250 P.P.M., WATER WHICH FAILS TO MEET THESE STANDARDS

SHOULD BE TREATED BY INSTALLATION OF A WATER CONDITIONER. EQUIPMENT FAILURE CAUSED BY

INADEQUATE WATER QUALITY IS NOT COVERED UNDER WARRANTY.

THIS WARRANTY IS LIMITED TO COOKING EQUIPMENT INSTALLED WITHIN THE CONTINENTAL UNITED STATES

AND CANADA, IN ALASKA, HAWAII, AND ELSEWHERE OUTSIDE CONTINENTAL U.S. AND CANADA. THIS

WARRANTY IS LIMITED TO THE REPLACEMENT OF PARTS ONLY.

THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, MADE BY MARKET FORGE® FOR ITS COOKING

EQUIPMENT EXCEPT THIS WARRANTY, WHICH IS EXPRESSLY IN LIEU OF ANY OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE AND IN LIEU OF ALL OTHER OBLIGATIONS OR LIABILITY ON THE PART OF MARKET

FORGE®, INCLUDING LI ABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES OR FOR LOSS OF PROFITS

OR GOODWILL NO OTHER WARRANTIES ARE AUTHORIZED ON BEHALF OF MARKET FORGE®. MARKET

FORGE® COOKING EQUIPMENT IS NOT DESIGNED FOR PERSONAL, FAMILY OR HOUSEHOLD PURPOSES, AND

ITS SALE FOR SUCH PURPOSES IS NOT INTENDED, BUT IN THE EVENT THAT OUR COOKING EQUIPMENT IS

SO USED, THEN THIS WARRANTY SHALL NOT APPLY AND THE EQUIPMENT SHALL BE SOLD AS IS, WITHOUT

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

Page 3

TABLE OF CONTENTS

Page

SECTION 1 INSTALLATION & OPERATION 1 -8

SECTION 2 INTRODUCTION 9

SECTION 3 TROUBLESHOOTING & MAINTENANCE 10-18

WIRING DIAGRAMS 19-20

SECTION 4 ILLUSTRATED PARTS LIST 21 -29

Page 4

INSTALLATION INSTRUCTIONS

1. Mounting and Location:

Unpack unit carefully, check for any damage that may have occurred during shipment. Notify

the carrier and Market Forge Co. if any damage was sustained.

The kettle must be installed on a non -combustible floor. Minimum clearance from combustible

construction to be six (6) inches from side and back, and two (2) inches from the draft hood.

Provide a minimum clearance of fifteen (15) inches for servicing controls. Position kettle in its

designated area.

Level kettle by adjusting feet.

2. Flue

Connect draft hood furnished to the kettle flue outlet. Connect to the draft hood a vertical run

of flue pipe at least four (4) feet — can be shorter if positioned under kitchen hood. It is

recommended that flue gases be vented to a ventilating hood or directly to the atmosphere

(outside air).

Kettles have seven (7) inch diameter flue pipe except 20 gal. (MFGB 20) which has six (6)

inch diameter.

3. Gas

Connect gas control valve to gas supply line minimum of 1/2" IPS.

NOTE: It is important that the gas supply line be capable of furnishing sufficient supply of gas

required. Use threaded pipe joint compound resistant to the action of LP gases for all

installations including those for natural gas. Check for gas leakage at piping

connections with soapy water. Do not use an open flame to check for gas leaks.

Required BTU of gas per hour is indicated on kettle rating plate.

4. Electrical Connection

Connect a 120 volt 60 HZ 1 PH power supply (input) at the control enclosure.

NOTE: Wire used for electrical installation must be of rated temperature of 90 degrees C

minimum, 14 AWG minimum.

CAUTION: Kettle must be electrically grounded for safe operation. An electrical ground

connection is provided.

A wiring diagram is located inside the controls housing.

5. Water Feed Connection

Manual Fill:

No external water connections are necessary.

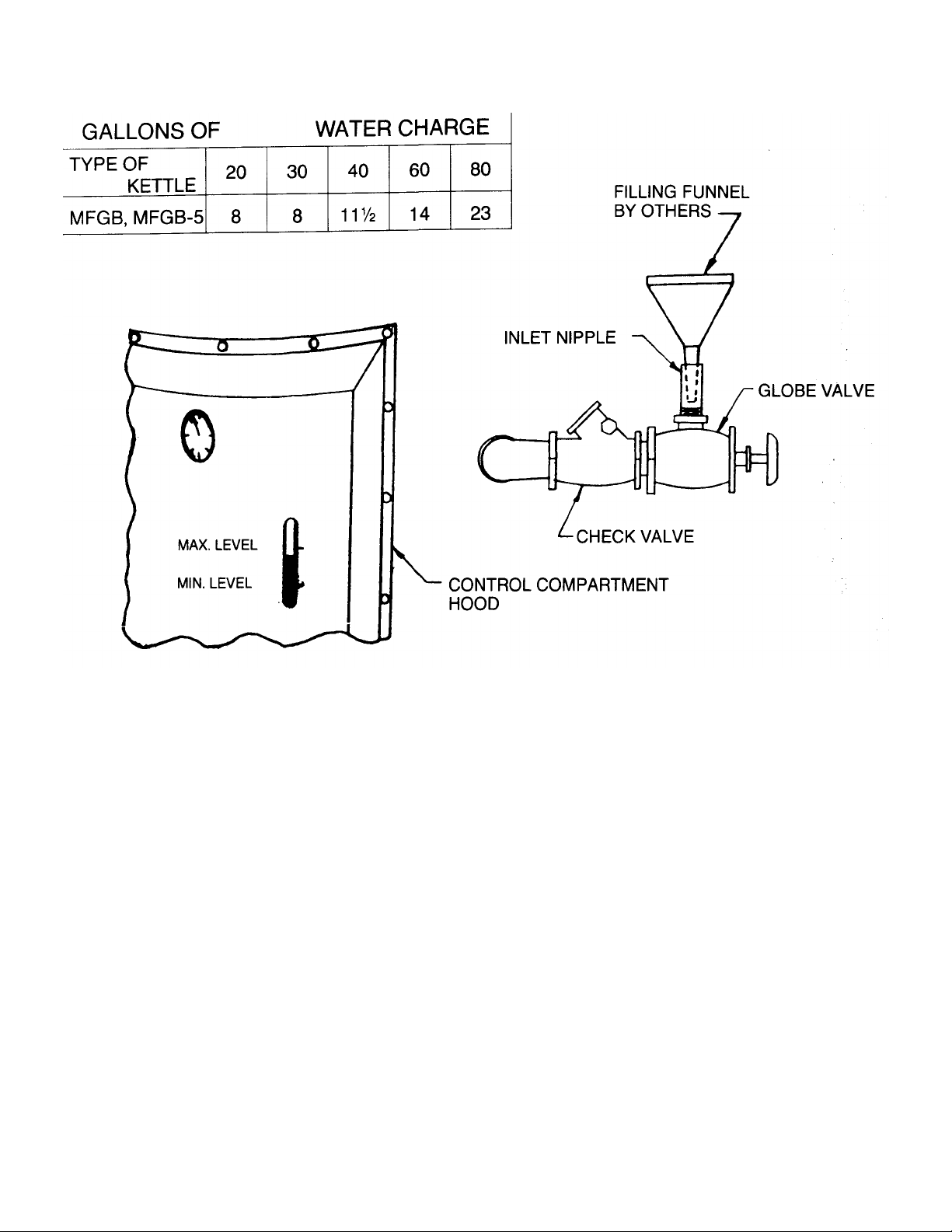

6. Water Fill Procedure

Manual Fill Models:

To fill, open valve and place a funnel in the inlet nipple. Add water to the maximum level on the

gauge glass. Remove funnel and close valve tightly.

Page 5

CAUTION: Steam jacket should be filled with water having a hardness no greater than 2.0 grains and

a pH between 7.0 and 8.5 only. See the above table for the quantity of water required to fill

the steam jacket to the proper level.

TO ADD WATER TO THE STEAM JACKET

1. Allow kettle to cool. Never attempt to add water to a hot kettle.

2. Lift the safety valve lever to release any residual steam contained in the steam jacket.

3. Place the thermostat in the off position. Disconnect electric power at the customer supplied

electrical cut off device.

4. Open the globe valve and place a funnel in the inlet nipple. See the above sketch.

5. Pour water into funnel. Lift safety valve lever to allow air to escape from the jacket. Continue adding

water until water in the jacket exceeds the minimum level. Do not fill above maximum level.

6. Remove the funnel, close the globe valve tightly, and restore power to the kettle.

CAUTION: Drain the steam jacket if the kettle is stored in an unheated area. Water freezing in the

steam jacket may result in permanent damage to the unit.

APPLIANCE FAILURE CAUSED BY INADEQUATE WATER QUALITY IS NOT COVERED UNDER

WARRANTY.

Page 6

INSTALLATION INSTRUCTIONS

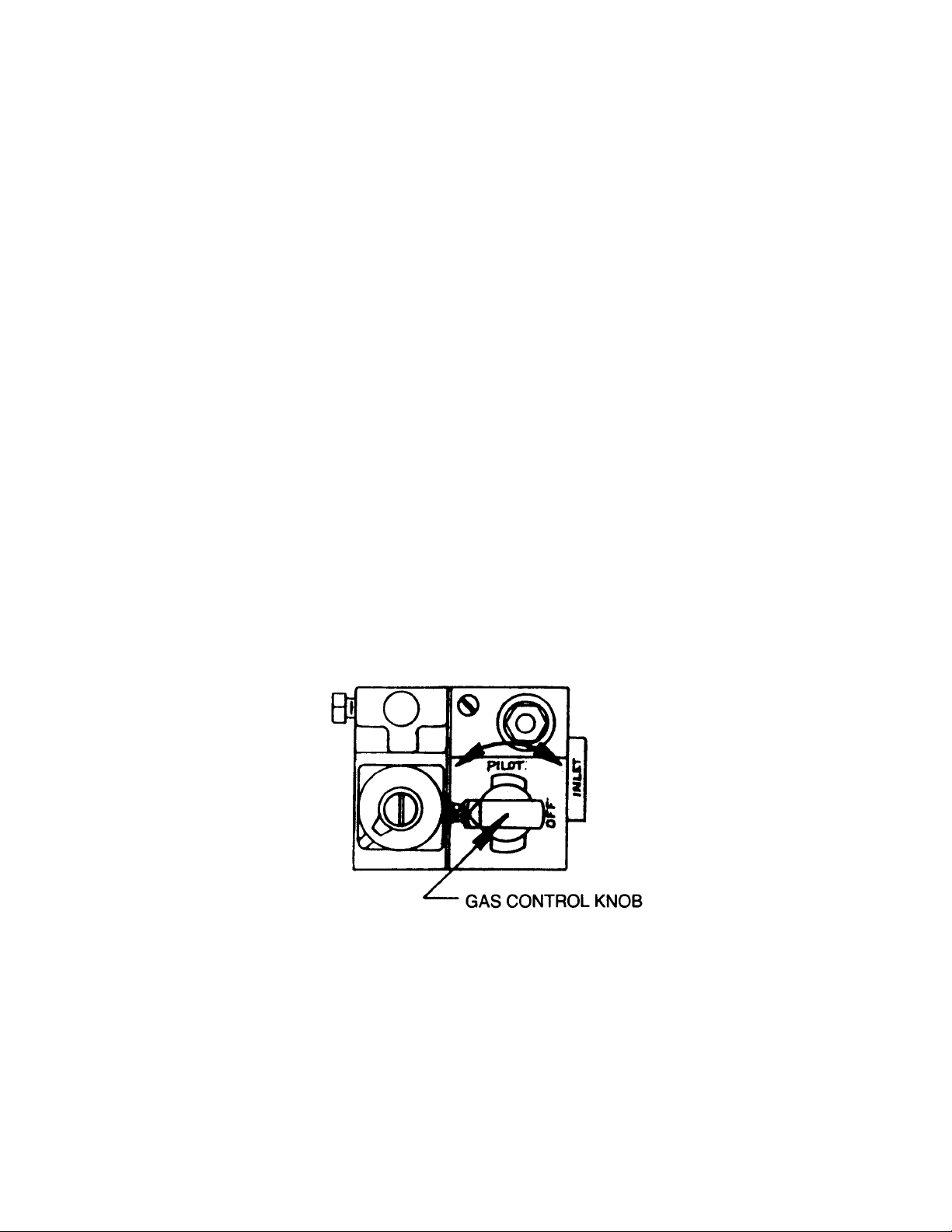

7. Burner Operating Procedure For (Standing) Pilot (MFGB MODELS)

1. Turn thermostat dial to "off".

2. Turn gas control knob on valve to "off".

3. Wait 5 minutes for gas to vent.

4. Light match. Turn gas control knob to "pilot", depress and hold down.

5. Light pilot and continue holding knob depressed for one (1) minute.

6. Release and turn knob to "on".

NOTE: If pilot does not stay on repeat Steps 1 thru 5.

7. Burner lights when thermostat is set to desired temperature.

Burner Shut Down Procedure

1. Turn thermostat dial to "off".

2. Turn gas control knob to the "pilot" position, depress slightly, and then turn to the "off" position.

GAS VALVE-MODEL MFGB

Page 7

INSTALLATION INSTRUCTIONS

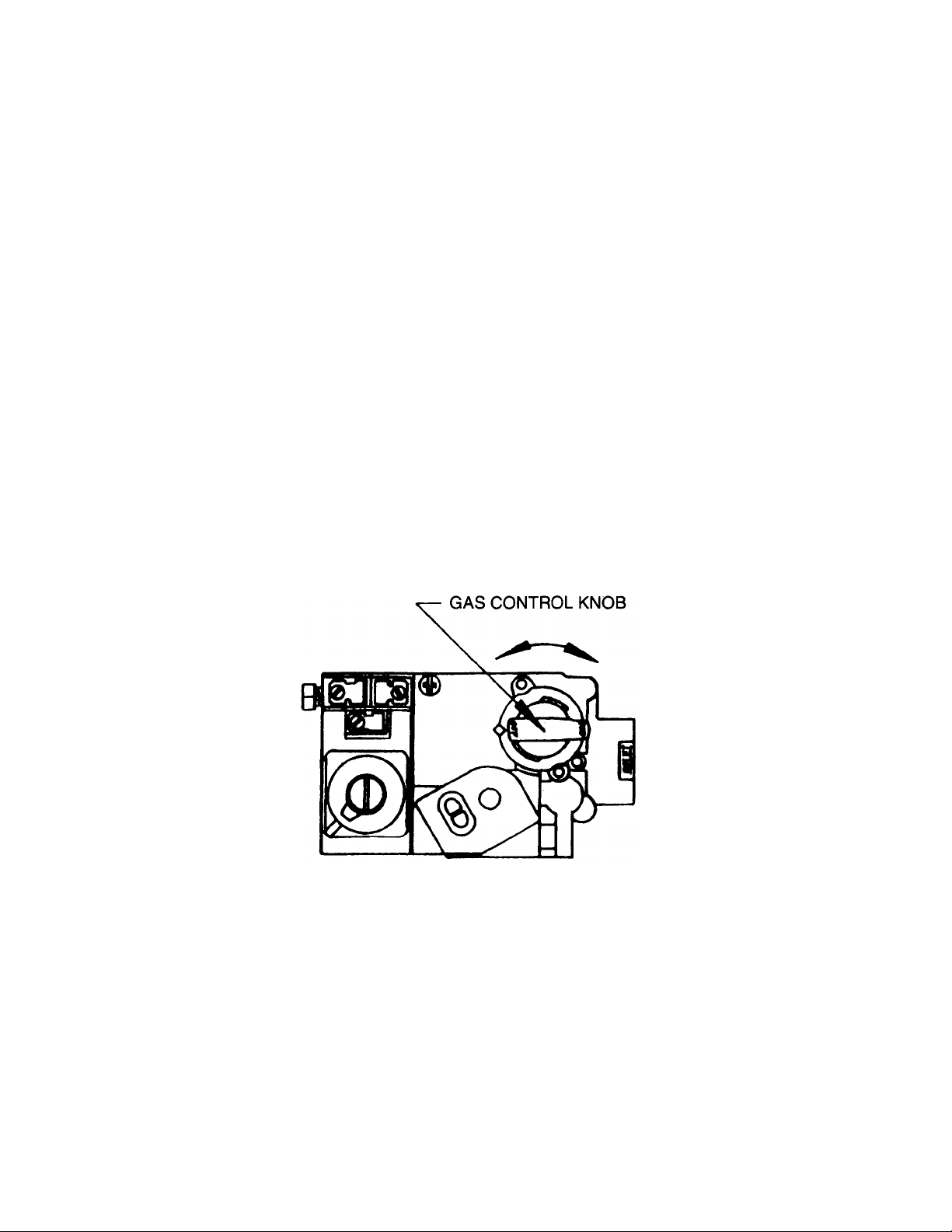

8. Burner Operating Procedure For Intermittent Pilot Spark Ignition (MFGB-5 MODELS)

CAUTION

This Kettle is equipped with Electronic Spark Ignition, DO NOT attempt to light manually.

1. Turn thermostat dial to "off".

2. Turn gas control knob to "on".

3. Burner lights when thermostat is set to desired temperature.

Burner Shut Down Procedure

1. Turn thermostat dial to "off".

2. Turn gas control knob to "off".

GAS VALVE-MODEL MFGB-5

Page 8

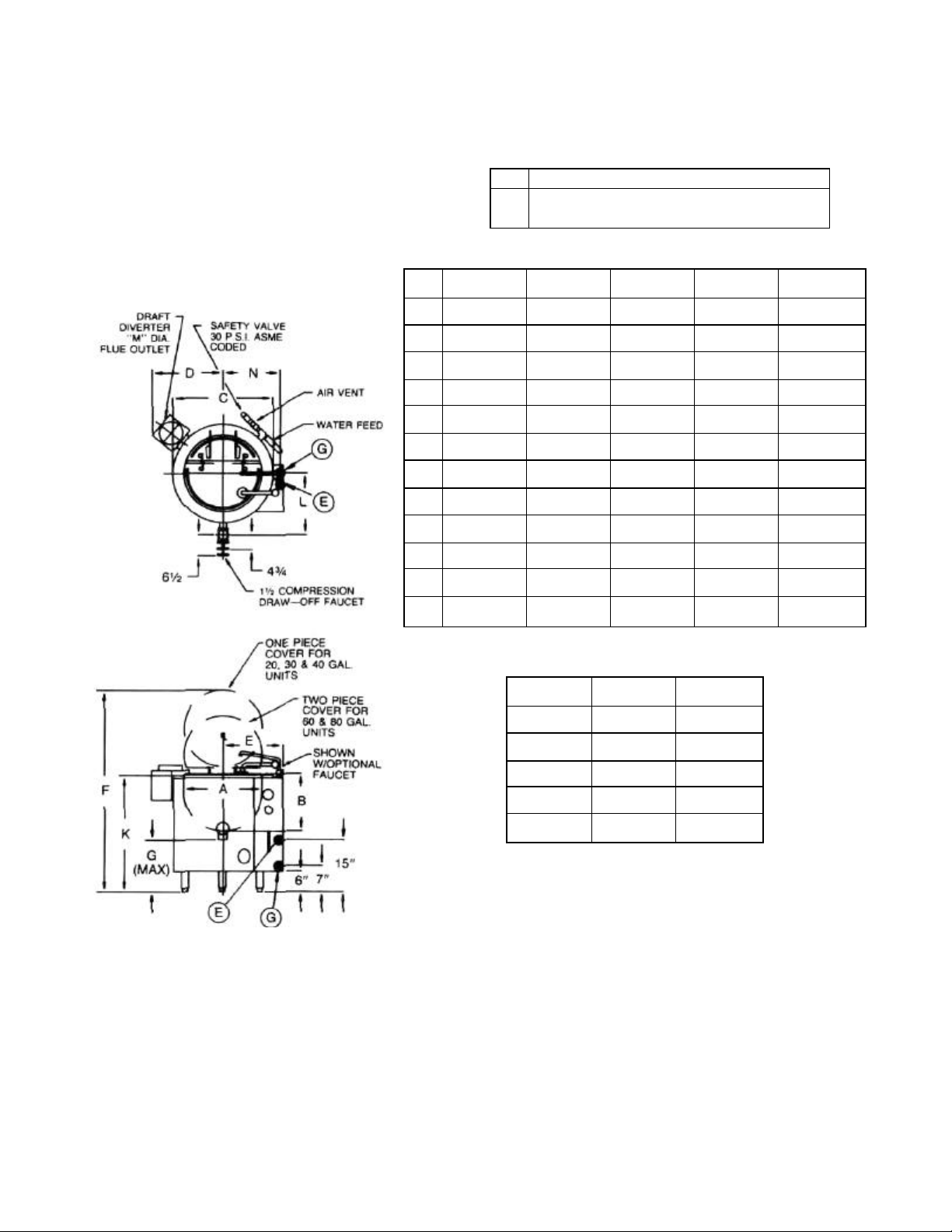

NOTES:

1. Clearance from combustible construction 6"

(152mm) sides and back; 2" (51mm) from flue.

2. T&S b 206 cold water 12" swing nozzle V4 N.P.T.

inlet with integral faucet —available as shown if

specified, other T&S water fill devices also

available if specified.

GAL

A 22 /559 23 /584 25 1/2 / 648 29% / 749 32 1/2 / 826

B 16 /406 20 1/4/514 22'/4/572 25 /635 27% / 702

C 28'/4/718 29 1/4/743 31 3/4/806 35% / 908 38% / 984

D 21 /533 22 /559 23 /584 25 /635 26 /660

E 17 /432 17 /432 21 /533 22 /559 23% / 597

F 56 /1422 63 /1600 66 /1676 76 /1930 82 /2083

G 15 /381 14 3/4/375 15 1/4/387 16 1/2/419 17 1/4/438

K 33% / 851 37 1/2 / 953 40 /1016 44 /1118 47 1/4/1200

L 171/4/438 17 3/4/451 19 /483 21 /533 22% / 572

M 6 /152 7 /178 7 /178 7 /178 7 /178

SERVICE CONNECTIONS Gas Fired

G

Gas Connection—1/2" (13mm) I.P.S.

Electrical Connection—115 VAC, 60Hz, single

E

phase, 1 amp. Use wire suitable for at least 90°C.

DIMENSIONS

20 30 40 60 80

IN./MM IN./MM IN./MM IN./MM IN./MM

N 1614/410 16 5/5/422 17 7/8/454 197, / 505 21 3/8/518

FIRING RATE BTU/HR

SIZE NATURAL PROPANE

20 GAL. 90,000 90,000

30 GAL. 120,000 110,000

40 GAL. 120,000 110,000

60 GAL. 125,000 125,000

80 GAL. 125,000 125,000

CAUTION:

Before connecting water to this unit, have water supply analyzed to

make sure hardness is no greater than 2.0 grains and pH level is no

greater than 7.0-8.5. Water which fails to meet these standards

should be treated by installation of a water conditioner.

EQUIPMENT FAILURE CAUSED BY INADEQUATE WATER

SUPPLY IS NOT COVERED UNDER WARRANTY.

Page 9

OPERATING INSTRUCTIONS

Daily Operation

1. Check water level in the water gauge glass. Refilling the steam jacket is seldom necessary,

however should the water level go below the minimum level, add water to the maximum level mark.

IMPORTANT: Use soft water. DISCONNECT ELECTRIC POWER.

CAUTION: NEVER ATTEMPT TO FILL KETTLE WHEN IT IS HOT.

To fill, open valve and place a funnel in the inlet nipple - add water. Remove funnel and close valve

tightly. See instructions on page 2 for filling instructions.

2. Set the thermostat dial to the desired cooking temperature, the main burner will light. The kettle will

heat the product in the cooking chamber to the pre-set temperature and automatically maintain the

temperature for an indefinite period of time.

New Temperature Setting:

If a new temperature is desired during cooking operation simply turn thermostat dial to new setting.

Should the new temperature desired be more than 60 degrees F. lower than the initial setting, it will be

necessary to wait for the kettle temperature to drop. Unit will again maintain temperature setting.

Page 10

OPERATING AND MAINTENANCE

INSTRUCTIONS

Maintenance

1. Wash kettle before and after each use with hot soapy water and rinse thoroughly with clean water.

Dry thoroughly.

2. Periodically, the main burner and the surrounding attached parts should be cleaned with a damp

cloth.

3. In the event the controls require cleaning, care must be taken to prevent moisture from settling on

the controls.

4. The stainless steel surface of the kettle may be polished with any recognized commercial stainless

steel cleaner.

5. Steel wool should not be used.

6. The safety relief valve should be tested daily when the kettle is under pressure. To test, raise lever

and discharge steam.

CAUTION: VALVE IS HOT!

If opening lever fails to discharge steam, notify service personnel at once.

7. Examine the venting system once or more a year and clean as required.

Servicing

Contact the factory at the address shown on the front of this manual, the factory representative or a

local authorized service company to perform maintenance or repairs.

Page 11

SAFETY PRECAUTIONS

THIS INSTALLATION MUST CONFORM WITH LOCAL CODES OR IN THE ABSENCE OF LOCAL CODES,

THE NATIONAL FUEL GAS CODE, ANSI Z223.1 - LATEST EDITION.

1. This appliance and its individual shutoff valve must be disconnected from the

gas supplying piping system during any pressure testing of that system at test

pressures in excess of 1/2 psig (3.45 kPa).

2. The appliance must be isolated from the gas supply piping system by closing

its individual manual shutoff valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/ 2 psig (3.45 kPa).

THIS UNIT MUST BE ELECTRICALLY GROUNDED IN ACCORDANCE WITH LOCAL CODES OR IN THE

ABSENCE OF LOCAL CODES, THE NATIONAL ELECTRIC CODE, ANSI/NFPA NO. 70 -LATEST EDITION.

KEEP THE AREA AROUND THE APPLIANCE FREE AND CLEAR OF COMBUSTIBLE MATERIAL.

PROVIDE ADEQUATE CLEARANCE FOR AIR OPENINGS INTO THE COMBUSTION CHAMBER. KEEP

BOXES, BAGS OR CONTAINERS CLEAR OF APPLIANCE. DO NOT OBSTRUCT THE FLOW OF AIR INTO

THE COMBUSTION CHAMBER.

ADEQUATE MAKE UP AIR MUST BE PROVIDED FOR EXHAUST SYSTEMS IN THE AREA WHERE THE

APPLIANCE IS TO BE INSTALLED.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER GAS APPLIANCE.

Page 12

INTRODUCTION

Market Forge Co. gas fired kettles are widely used the world over in schools, restaurants, commissaries, cafeterias, mess halls, and wherever an external steam source is not available.

Inner kettle shells are seamless die drawn of not less than 14 GA. (.078) stainless steel.

External stainless steel jackets are fully fiberglass insulated.

Standard equipment includes a full compliment of automatic controls including an automatic air

eliminator, thermostat, floatless electronic liquid level control, combination gas valve with pressure

regulator and safety shut-off, and 30 PSI safety valve. Accessories include a 1 1/2" tangent draw-off

valve, strainer, flue diverter, compound vacuum-pressure gauge and a visible water level indicator.

All kettles are A.G.A. design certified, and constructed in compliance with A.S.M.E. code requirements

for gas fired vessels at 30 P.S.I, max. design pressure. All bear the seal of the National Sanitation

Foundation and are so listed.

Page 13

TROUBLE SHOOTING

See Corrective Maintenance for test and replacement procedures.

SYMPTOM POSSIBLE CAUSE REMEDY

NO HEAT AMBER LIGHT "ON"

NO HEAT AMBER LIGHT "OFF"

No Gas To Unit Open Manual Gas Valve

Pilot Flame Out

Thermocouple Failure Replace Thermocouple

Gas Valve Failure Replace Gas Valve

No Power To Unit Connect To Electrical Supply

Transformer Failure (220V

Option Only)

Water Level In Jacket Too Low

Scale On Low Water Probe Clean Probe

Relight (See Burner Operating

Procedure)

Replace transformer

Fill Jacket To Above Minimum Level

Mark

Thermostat Failure Replace thermostat

Pressure Switch Failure Replace Pressure Switch

Low Water Relay Failure Replace Low Water Relay

10

Page 14

CORRECTIVE MAINTENANCE

WARNING: DISCONNECT POWER BEFORE ATTEMPTING TO SERVICE THIS EQUIPMENT. DO NOT

SERVICE A KETTLE THAT IS HOT.

All controls are located inside the instrument console at the front of the kettle. They are accessed by

removing the side panel of the console. All ignition system components, except the gas valve, are

located on the ring burner beneath the kettle. See wiring diagram and electrical schematic.

Control System

The thermostat and pressure switch may be recalibrated in the field. Most electrical component

failures can be easily diagnosed by following a logical process of elimination. The pressure switch,

thermostat and primary coil on the transformer (optional) can be tested for continuity. An open circuit

indicates that the componen t has failed. The coils on the low water control relay, the secondary coil of

the transformer (optional), and the thermostat indicator light can also be tested for continuity;

however, it will be necessary to disconnect these components from the circuit before testing. Also

check the transformer for coil to coil snorting, if any control circuit components have failed.

IMPORTANT: Mark or note wiring connections before removing wires from components.

To replace the thermostat, mark and disconnect wiring terminals and remove the thermobulb from its

kettle coupling. Remove mounting screws and defective component. Install new thermobulb in kettle

coupling and mount thermostat in position. Reinstall mounting screws and replace wiring terminations.

To replace the low water control relay, pressure switch, or transformer, mark and disconnect wiring

terminals. Remove mounting screws and defective component from the console. Mount new

component in position, reinstall mounting screws, and replace wiring terminations.

Remove the low water electrode probe and visually check the porcelain insulator for cracks or scale

build up on the tip. Clean if scale is present and reinstall. Replace probe if any cracking is evident.

The low water cutoff control is a non -adjustable probe and relay type that uses the water in the steam

jacket to complete the circuit to the High Voltage secondary coil. In absence of water the relay in the

circuit drops out, cutting off the power to the gas valve.

Make sure all covers are replaced after all repairs are completed.

11

Page 15

Ignition System

The automatic continuous pilot ignition system consists of the gas valve, the pilot burner, and the

thermocouple. The thermocouple consistently monitors the flame of the pilot burner. During a call for

heat by the thermostat, the thermocou ple must sense pilot burner flame before the gas valve can open

and allow gas to the main burner. If the thermocouple fails to sense a flame the gas valve

automatically closes.

If the pilot burner ever extinguishes for any reason, relight per "Burner Operating Procedure". If the

pilot burner will not light at all, the pilot burner orifice may be clogged. It can be cleared by gently

tapping it on the side to dislodge any particles. If the pilot burner still will not light at all the gas valve is

faulty and must be replaced.

If during repeated attempts the pilot burner will not remain lit when the gas control knob is released or

goes out after a short period of time, the thermocouple is defective and must be replaced.

NOTE: In order to function properly the pilot flame should envelop % to 1/2 inch of the tip of the

thermocouple. To increase the size of the pilot flame remove the pilot adjustment cover screw

from the gas valve and turn the inner screw counter clockwise.

The pilot burner orifice is removed by unscrewing it from the pilot burner and the gas supply

tubing. The gas valve is removed by disconnecting its wires and unscrewing it from the gas

piping. The thermocouple is removed by unscrewing it from the gas valve and from the pilot

burner bracket.

12

Page 16

13

Page 17

THERMOSTAT CALIBRATION

Type

This thermostat is a snap-action, single pole, single throw cycling control, with silver contacts. Contacts

break on temperature rise and make when temperature falls below dial setting.

Rating

This control is rated for 50 volt-amperes, pilot duty 120-277 volts AC. U/L recognized for 100,000 test

cycles.

Function

The temperature sensing bulb is immersed in the pressurized steam jacket of the kettle and is

responsive to selected dial temperatures from 100° to 300°F. The food temperature in the kettle can be

correlated to the selected temperature of the steam as the active cooking medium.

Calibration

The KXP thermostat is an extremely reliable control and it is carefully calibrated at the factory. Field

recalibration is seldom necessary, and should not be resorted to unless considerable experience with

equipment proves that the control is not maintaining the temperatures to which the dial is set.

Should recalibration be required, use the following procedure:

1) Allow kettle to come to a stable temperature.

2) Turn dial and compare setting on dial with the reading of thermometer* when control turns off. (It

will make an audible click and pilot light will go off.)

3) If thermostat and thermometer agree within the users degree of accuracy , no recalibration is

necessary. If they do not agree, continue as follows.

4) Set dial to thermometer reading. Pull off dial and with a small screwdriver turn small adjusting screw

until thermostat clicks off. (Adjusting screw is in the center of the dial shaft. See drawing.)

A. CAUTION - Always use extreme care so that the slot in the center adjusting screw is not

damaged.

B. Hold dial shaft tightly while turning center screw.

* To check kettle temperatures when recalibrating, use a precision test instrument or a reliable mercury

thermometer. Place the thermocouple of test instrument or thermometer in the middle of the kettle.

14

Page 18

CONT'D

C. Turning center adjusting screw in a clockwise direction will decrease the temperature; and in a

counterclockwise direction will increase the temperature. Each quarter turn of the screw will

change the calibration approximately 30°F.

5) Recheck calibration and repeat process if closer calibration is required.

NOTES: The thermostat has an internal stop to limit the selection of temperature to 270°F.

This is required in order to prevent premature blow -off of the safety valve furnished with the

kettle. The safety valve is set at 30lbs. and has a tolerance of ±10%.

Servicing of this equipment should be referred to qualified service technicians with reputable

experience. Market Forge Co. is not responsible for any equipment serviced or installed by

non -qualified personnel.

15

Page 19

PRESSURE CONTROL ADJUSTMENT

FUNCTION:

This pressure control is used when specified, as a limit

switch in addition to the thermostatic selective cycling

control. When the limit switch is furnished on original

equipment, it is factory set to trip at bet ween 25 to 27

p.s.i. The cycling of the switch can be maintained within a

differential from 2 to 15 p.s.i.

GENERAL DESCRIPTION:

This type pressure switch is activated by the steam

pressure generated against a compression spring and a

bellow. When the sprin g compression is overcome by the

generated pressure within the bellows, the single pole,

double throw electric switch breaks the electric circuit of

the normally closed side (N.C.) of the switch, thus deenergizing the control circuit and cutting off power to the

heating elements or gas supply. As pressure drops, the

spring compression will overcome the steam pressure

within the bellow and the switch will return to its normally

closed position (N.C.) restoring current to the control

circuit.

ADJUSTMENT:

When a replacement switch is installed in the field, the

cutout and cut-in pressure setting may require calibration.

Observe pressure gauge for desired operation of the

switch. To raise both cut-in and cut-out pressure turn

slotted range adjustment screw clockwise, to decrease

turn counter-clockwise. A quarter of a turn adjustment

may change the pressure by as much as 5 p.s.i. in the 25lbs range.

To reduce the differential, turn slotted differential adjustment screw clockwise, to increase the differential turn counter-

clockwise.

Page 20

Draw-off Faucet

Various components of the draw -off faucet may be replaced. The complete draw-off

faucet may also be replaced in the field.

Safety Relief Valve

The relief valve should be manually operated at least once a day by lifting the lever and

visually verifying that steam is discharged from the valve. If steam is not discharged

remove the kettle from service immediately.

17

Page 21

In order to install a new faucet of the plug or compression type, remove all parts from

the faucet leaving only the faucet body on the draw -off tube.

1. Heat up solder joints in rear of the faucet with a blow torch until the solder starts

dripping. Tap faucet body gently from the rear while welding; use a rubber mallet or a

piece of wood and make sure the faucet is not allowed to drop.

2. After the faucet body has been removed, add acid to the draw-off tube. Heat it slightly

and add solder for retinning. Wipe off excess solder so that the draw-off tube is

completely tinned and smooth.

3. To install new faucet, likewise remove all inner parts and handles and brush acid on the

recessed seating opening in the back of the faucet and add solder. Wipe inside clean so

that the entire recessed bore is tinned. This coat of tin must be very thin and care must

be taken that neither acid nor tin find their way into the valve body.

4. Now, brush acid on the faucet and draw -off tube and slip faucet body gently onto drawoff tube making sure that the body bottoms on the draw -off tube.

5. Apply the blow torch and heat slightly all around. Add solder while heating. Very little

solder is needed. If too much solder is applied, it will enter into the valve seat region and

this must be avoided. When finished, cool water and wash clean.

6. It is helpful to tilt the kettle forward so that the draw -off tube is close to a vertical

position.

Page 22

18

Page 23

Page 24

WIRING DIAGRAM

MODEL MFGB-5

Page 25

1 97-5264

Wing Nut

6 97-5269

Stem

Item Part No. Description

2 97-5265 Heat Resistant Handle

3 97-5266 Faucet Gland

4 97-5225 Hexagon Bonnet Nut

5 97-5268 Neoprene "0" Ring

21

Page 26

Faucet Ass'y

Item Part No. Description

1 97-5229 Faucet w/12" Swing Spout

22

Page 27

Item Part No.

4

97-5235

Flue Diverter

80

Gal Kettle

Exhaust Flue Diverter

Description

1

2

3

97-5233

97-5234

97-5235

Flue Diverter 20 Gal Kettle

Flue Diverter 40 Gal Kettle

Flue Diverter 60 Gal Kettle

23

Page 28

Front Control Panel

Item Part No. Description

1 97-5208 Pressure Gauge

2

3 97-5223 Water Level Gauge Glass

97-5206

Thermostat Temp Range 100 to 300° F

24

Page 29

1 97-5243

Knob (Black)

Handle & Cover Assy.

Item Part No. Description

2

3

4

5

97-5236

97-5237

97-5238

97-5240

Cover (1) PC - 20 Gal

Cover (1) PC - 40 Gal

Cover (2) PC - 60 Gal

Cover (2) PC - 80 Gal

25

Page 30

Size

1 1/2" Draw

-

Off Faucet

Draw-Off Valve

Item Part No. Description

1 97-5225

2 97-5226 Size 2" Draw-Off Faucet

3 97-5227 Size 3" Draw-Off Faucet

26

Page 31

Item Part No. Description

1 97-5206

Thermostat Temp Range

100

to

300°

F

"

2 97-5255 Transformer Step-Down (Optional)

3 97-5207 Liquid Level Control L.W.C.O

4 97-5205 Spark Ignition Control Board (Optional)

5 97-5232

6 97-5210 Gas Control Valve (Nat'l Gas)

7 97-5210 Gas Control Valve (Propane Gas)

8 97-5211 Gas Regulator (Propane)

Right Side Control Box

Gas Cock - 1/2

27

Page 32

1 97-5220

Air Eliminator Vent

Water Fill & Safety Valves

Item Part No. Description

2 3

4 97-5230 Globe Valve

97-5221 97-5231

Safety Relief Valve (30 P.S.I.) Check Valve

28

Page 33

Combustion Chamber

1 97-5214

Burner

20

Gal.

3

4

5

6

7

8

9

10

11

Item Part No. Description

2

97-5215

97-5216

97-5216

97-5217

97-5218

97-5219

97-5219

97-5214

97-5215

97-5216

Burner 40 Gal.

Burner 60 Gal.

Burner 80 Gal.

Burner Orifice 20 Gal. (Propane)

Burner Orifice 40 Gal. (Propane)

Burner Orifice 60 Gal. (Propane)

Burner Orifice 80 Gal. (Propane)

Burner Orifice 20 Gal. (Natural)

Burner Orifice 40 Gal. (Natural)

Burner Orifice 60 Gal. (Natural)

29

Loading...

Loading...