Page 1

STEAM COIL

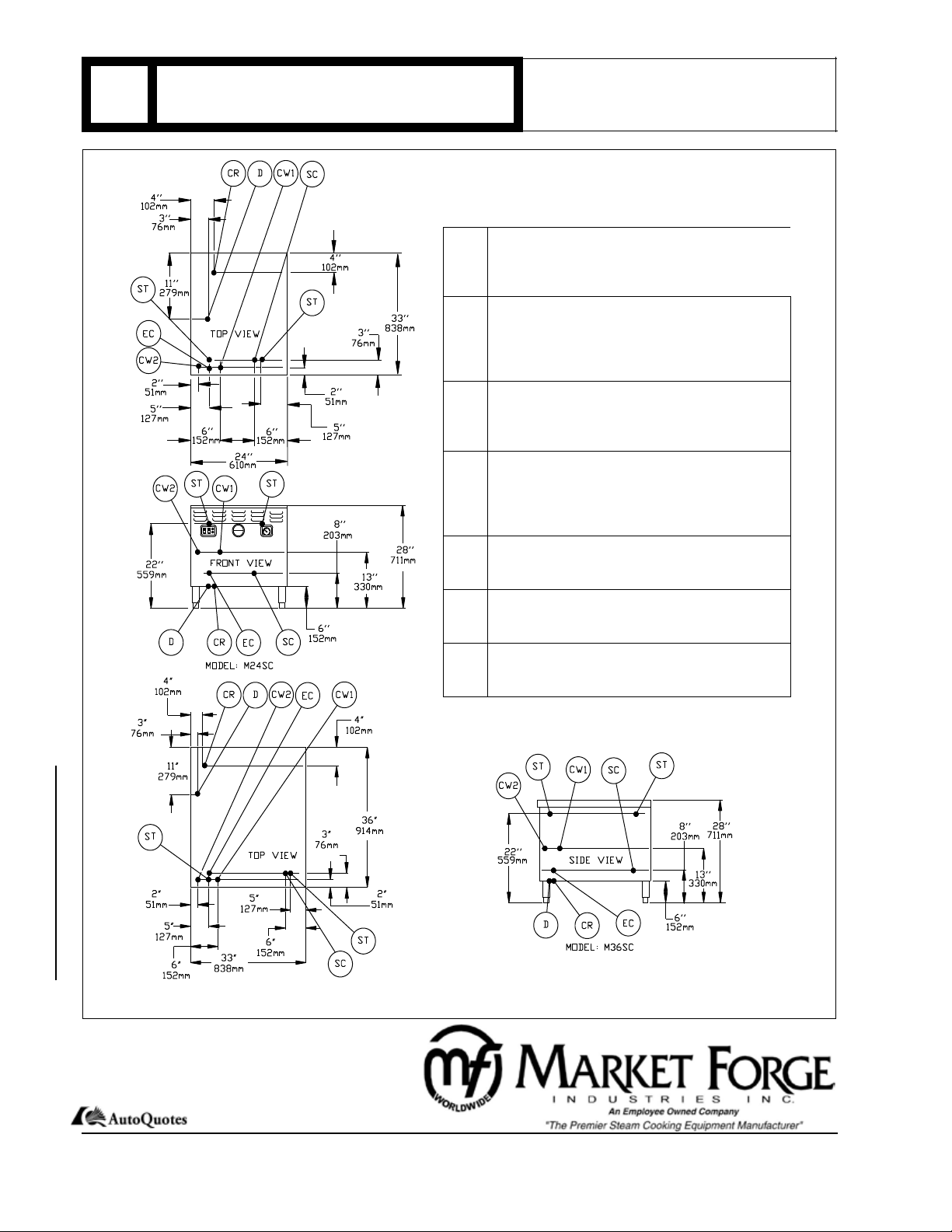

SC

MODELS: □ M24SC □ M36SC

DESCRIPTION:

Shall be a Market Forge Model _________ Stainless

Steel Steam Coil Operated Steam Generator mounted

in a cabinet base.

OPERATED BOILER

JOB NAME: ________________________

ITEM NO.: _________________________

NO. REQUIRED: ____________________

M24SC

SPEC SHEET: S-4889

07/11

□ 24” 610mm Wide Cabinet Base - M24SC

□ 36” 914mm Wide Cabinet Base - M36SC

Polished stainless steel cabinet base shall be of modular

design to match other Market Forge cooking equipment,

and equipped with 6” (152mm) stainless steel legs, ad-

justable bullet feet, reinforced stainless steel counter-top

and stainless steel lift-off front panel.

Stainless steel steam coil generator equipped for operation at 15 PSI (1kg/cm2). Unit shall include as standard

an automatic drain, cold water condenser, automatic water level control, low water cut off, pressure control, air

vent, and a safety relief valve.

Steam generator shall be National Board Registered,

and shall be suitable for installation tight against a non-

combustable wall. Steam generator shall be ASME constructed of 15 PSI operation.

Steam generator shall be automatically lled with cold

water and brought to pressure when heat and water

switches are turned on and automatically drain under

pressure shall automatically condense exhausted steam

into water before releasing it to drain.

The manufacturer reserves the right to modify materials and specications without notice.

M36SC

OPERATION SHALL BE BY:

Unit equipped for operation with minimum incoming

pressure of 20 PSI (1.4kg/cm2) and a maximum incoming

pressure of 50 PSI (3.5kg/cm2), producing a minimum

output of 2.6 BHP and 88 pounds of steam per hour.

OPTIONAL AT EXTRA COST:

□ Pressure Reducing Valve (if two operating pressures

are required, such as 15 PSI

pressure reducing valve to provided 5 PSI operating

pressure

).

(1kg/cm2) to one

□ Condensate Return Kit

□ 8” Legs

□ 10” Legs

□ 12” Legs

FOOD SERVICE EQUIPMENT

Steam Coil Boiler

35 Garvey Street • Everett • MA • 02149

Printed in U.S.A.

Tel: (617) 387-4100, (866) 698-3188 • Fax: (800) 227-2659, (617) 387-4456

custserv@mi.com • w w w . m f i i . c o m

Page 2

SC

SPEC SHEET: S-4889

07/11

STEAM COIL

OPERATED BOILER

JOB NAME: ________________________

ITEM NO.: _________________________

NO. REQUIRED: ____________________

SERVICE CONNECTIONS

Steam Coil Operated

SC Steam Supply - 1/2” (13mm) IPS connection for

incoming steam at a minimum pressure of 20

PSI (1.4kg/cm2) and a maximum pressure of 50

PSI (3.5kg/cw2).

CW1 Cold Water - 3/8” (10mm) NPT for cold water

to boiler. Cold water lines will have a maximum

of 50 PSI (3.5kg/cw2) and a minimum of 25 PSI

(1.8 kg/cw2) water pressure (Water may be l-

tered).

CW2 Cold Water - 3/8” (10mm) NPT for cold water to

condenser. Cold water lines will have a maxi-

mum of 50 PSI (3.5kg/cw2) and a minimum of

25 PSI (1.8 kg/cw2) water pressure.

D Drain - Pipe full 2” (50mm) I.P.S. to ush oor

drain capable of receiving water owing at a

maximum rate of 5 gallons (19 liters) per min-

ute. DO NOT MAKE SOLID CONNECTION TO

FLOOR DRAIN.

ST Steam Take-off - Connection for operation of

adjacent steam powered equipment (optional

at extra cost).

CR Condensate Return - 1/2 (13mm) IPS conden-

sate return from steam generator connected to

condensate return line (optional at extra cost).

EC Electrical Connection - 120 Volt AC, 60 Hz, 2

Amps, 1/2 (13mm) conduit connection or equiv-

alent. Use wire suitable for at least 90oC.

Steam Coil Boiler

FOOD SERVICE EQUIPMENT

It is our policy to build equipment which is design certied by N.S.F., N.E.M.A. and C.S.A. However, a continuing program of product improvement

makes it necessary to submit new models to the agencies as they are developed and consequently not all models bear the appropriate agency labels.

35 Garvey Street • Everett • MA • 02149

Tel: (617) 387-4100, (866) 698-3188 • Fax: (800) 227-2659, (617) 387-4456

custserv@mi.com • w w w . m f i i . c o m

Loading...

Loading...