Market Forge M24SC Service Manual

SERVICE & PARTS MANUAL

02149

MODELS:

Modular Steam Coil Steam Supply Generators

M24SC

M36SC

Form Number S-5046A 7/84 Printed in USA

Market Forge Co.

35 Garvey Street

Everett, MA

Tel. (617) 387-4100, Telex 94-9414, Cable MAFORCO

TABLE OF CONTENTS

SECTION 1 INTRODUCTION

1.1 How to use this Manual...................…. ... 1-1

1.2 Operating Instructions for Steam Coil

Boilers..........................................……….. 1- 1

1.3 Service ..............................................……. 1-1

SECTION 2 INSTALLATION INSTRUCTIONS

2.1 Receiving Instructions.....................….. ... 2-1

2.2 Setting in place.............................. …....... 2-1

2.2.1 Installing legs.................................…..... . 2-1

2.2.2 Leveling..........................................…….. 2-1

2.2.3 Panels.............................................….... 2-1

2.3 Important information on Steam Coil Steam

Generators to Steam Fitter.................. … . 2-1

2.4 Boiler horsepower and steam flow

information .......................................…...... 2-2

2.5 Steam Fitter and plumber ................….......2-3

2.5.1 Steam Connection. .........................…...... 2-3

2.6 Setting of Steam Generator Pressure Control

Switches Units before 1979...............….... 2-4

2.7 Pressure Control Switch adjustment (Units after

1979).........................................………..... 2-5

2.8 Water Level Control (Models before Feb.

1984)................................................. .…... 2-6

2.8.1 Disassembly Instructions.................... ... 2-6

2.9 Water Level Control (Models after Feb.

1984)....................................................….. 2- 6

2.9.1 To remove Water Level Control.......…... 2-6

2.10 Watts Pressure Reducing Valves 3/4" ..... 2-7

2.10.1 Operation of Watts 3/4" Reducing

Valve...............................................…... 2- 7

2.10.2 Adjusting Watts 3/4" Reducing Valve.…… 2-7

2.10.3 Inspection , Maintenance, Repairs ..…….. 2-7

2.11 Service Connections ..........................…….. 2-8

Wiring Diagram and Schematic

SECTION 3 OPERATION

3.1 Description...........................................……... 3-1

3.2 Basic Functioning ...............................…….... 3-1

3.3 Start up Instructions............................…….... 3-2

3.3.1 Automatic Drain Steam Generator...…….... 3-2

3.3.2 Daily Operating Instructions..............……... 3-2

3.3.3 Daily Operting Instructions (For units

manufactured after June 1983, equipped with

"Momentary" heat switch)...........…………. 3-2

3.3.4 Daily Shut -down and cleaning.....……........ 3-2

3.3.5 Manual Drain Steam Generator....……....... 3-2

3.3.6 Daily Operating Instructions..........……....... 3-2

3.3.7 Daily Shut -down and cleaning.......……….... 3-2

SECTION 4 TROUBLE-SHOOTING

4.1 General.............................................……....... 4-1

4.2 Electrical Fault Isolation...................………..... 4-1

SECTION 5 ILLUSTRATED PARTS LIST

5.1 General.............................................………..... 5- 1

5.2 Ordering............................................………..... 5- 1

5.3 Index of Illustrated Parts List.............……….... 5-1

ii

Modular Steam Coil Steam Supply Generators

SECTION 1 INTRODUCTION

Market Forge, has designed these boilers with the latest type automatic controls in order to make it

easier for the operator to use and maintain this equipment. This Service and Parts Manual is written

and illustrated to cover all boiler equipment that uses a steam coil as a source of power other than

those which have been custom designed under special order.

1.1 HOW TO USE THIS MANUAL

The illustrations of components are aids to the

identification, disassembly and assembly of parts.

The part listings provide information necessary for

the ordering of replacement parts (proper part

names and part numbers). When requesting parts or

service, always furnish the model and serial number

of your complete unit, which will indicate to Market

Forge Service Division the type of boiler with which

you are equipped. This information can be found on

the nameplate attached to the boiler frame.

1.2 OPERATING INSTRUCTIONS FOR STEAM

COIL BOILERS

Explanation of how the control system works on

automatic steam coil boilers. With the boiler filled

with water to its proper level and the heat switch

turned to its on position the solenoid steam valve will

be activated allowing outside steam to flow to the

boiler steam coil. When the boiler builds up its set

pressure, the pressure switch on the left side of the

control box opens. This will open up the circuit to the

solenoid coil in the steam valve

which in turn will stop the flow of outside steam to

the boiler. As the pressure in the boiler drops off

the pressure control switch will again come into

operation and complete the circuit and build the

boiler back up to its set pressure. When the

operator wishes to stop all steam generation, he

need only place the heat switch to the off position.

1.3 SERVICE

Should repairs be required, a network of authorized

service agencies is available to assist with prompt

service. A current Directory of Authorized Service

Agencies and service assistance may be obtained

by contacting:

Product Service Department

Market Forge Company 35

Garvey Street Everett, MA 02149

Telephone: (617) 387-4100

The model and serial numbers must be referenced

when corresponding with Market Forge.

1-1

Modular Steam Coil Steam Supply Generators

SECTION 2 INSTALLATION INSTRUCTIONS

WARNING:

Read before opening the shipping

containers. Do not at any time lay the

equipment down on its back, side, top or

front. To do so may damage the equipment

and invalidate the warranty.

2.1 RECEIVING INSTRUCTIONS

Inspect the equipment before signing the bill of

lading. The equipment supplied was tested and

inspected before shipment. The carrier

accepted it as complete and without damage.

This merchandise became your property when it

was accepted by the carrier at the factory.

Market Forge cannot assume responsibility for

loss or damage during transit.

For this reason, you should immediately inspect

for visible and concealed damage or shortages

before signing for shipment as follows:

1. Count the number of cartons and packages

received to be sure they coincide with the bill

of lading.

2. Visually check all cartons for external

damage.

3. Remove all cartons from their skids to

examine equipment for concealed damage.

The carton is nailed and strapped to the skid.

It will be necessary to cut the straps and pry

off the container.

4. After inspection, replace the cartons over the

equipment on the skids to protect and secure

the equipment until it is ready for installation.

5. Sign for shipment if all is in order. Note

shortages, external and concealed damage, if

any, on the bill of lading before accepting a

partial or damaged shipment.

6. If necessary, contact the carrier immediately

to file a claim. All claims must be filed by the

receiver.

7. Do not remove the cartons or the skids from

the cooking equipment until the unit has been

transported through the building to the actual

set-up location. The cartons should remain on

the equipment as protection against dents

and scratches.

2.2 SETTING IN PLACE

2.2.1 Installing legs

Some models are shipped without legs. A

separate carton will contain the legs. If your

model is received this way be sure to follow the

installation instruction sheet packed with the

legs.

2.2.2 Leveling

In order for the boiler to drain correctly it is

important to use a level on cabinet top, both

left and right and front-to-back. If not level

adjust feet. On compartment cookers check

interior shelves to be level.

2.2.3 Panels and Doors

Panels and doors for the cabinet may be

shipped separate. Refer to installation

instructions enclosed with panels and doors

for method of attaching. It is recommended

that panels and doors be installed after

mechanical connections are made to avoid

damage.

2.3 IMPORTANT INFORMATION ON

STEAM COIL STEAM GENERATORS TO

STEAM FITTER

The use of steam coil operated equipment is

increasing, and it is important that you are

aware of both the advantages and the

limitations of this equipment.

A steam coil generator assures a supply of

clean steam, and is generally recommended

when steam is available but not considered

clean enough to come in contact with food.

Toxic steam generator cleaning compounds

are often used to clean steam generators,

and this is usually the reason for not

recommending direct -connected cookers.

It is very important that a minimum of 15 PSI

be available in the incoming steam line if a

steam coil steam generator is to be installed

for use with a 5 PSI compartment cooker. If

the equipment connected to the steam

generator operates at 15 PSI, minimum

incoming pressure must be 30 PSI, except in

the case of a single Steam-It, which can be

operated on an incoming pressure of 20 PSI.

Maximum recommended incoming steam

pressure is 50 PSI.

(Table 2-1) shows Boiler Horse Powe r (BHP)

generated by our steam coil boilers at various

incoming pressures. One (1) BHP is required

for each cooking compartment in "A" and "W"

models. A jet cooker requires 3 BHP and a

Steam-It 1/2 BHP. It is not necessary to

include steam requirements for kettles, as

kettles may be direct connected since the

steam does not come into contact with the

food.

2-1

Section

2

Installation

Pressure maintained

Steam generator Steam generator

PSI

20 PSI

PSI

.8

3.4

4.0

of Incoming Pressure)

Steam Flow in

Lbs. Steam per

1/

2

on Incoming Steam

Line

15

BHP OUTPUT

set at 15 PSI set at 5 PSI

------

3.5

15 PSI. This is because the greater the

temperature differential between the steam

on the incoming line and the steam

generated in the steam generator, the

greater the BHP available. For proper

30

35 PSI

4.0

Table 2-1

Please note that a steam coil boiler set at 5 PSI

(Maximum BHP

available regardless

cooking results you must have sufficient

steam flow. Both pressure and volume are

important.

This relates to pipe size and steam supply to

the steam coil steam generator.

will generate more boiler horsepower than one

set at

2.4 BOILER HORSEPOWER AND STEAM FLOW INFORMATION

Recommended boiler horsepower and steam flow in pounds per hour. (NOTE: 1 Boiler Horsepower 34.5 Ibs. of

steam per hour. Do not confuse steam PRESSURE with steam FLOW.)

Delivered

Boiler H.P.

Hour

Compartment steam cookers (Per compartment) 1 34.5

Steam-jacketed kettles (Per 20 gals.) 1 34.5

Direct connected Steam-It

Direct connected Jet Cooker

2 1/2

17.25

86.25

Coffee Urn (Per 10 gals.) 1/10 3.4

Steam Table (Per square ft.)

1/20

1.7

Bain Marie (Per square ft.) 1/10 3.4

Warming Oven (Per square ft.) 1/20 1.7

Table 2-2

Flow of Steam in pipe, in pounds of steam per hour.

Line pressure in lbs. per square inch (PSI) Pipe size in inches:

5 10

15 20

25 30

40 50

60 70

1/2 3/4 1 1 1/4 1 1/2 2

60

70

75

80

85

90

100

108 114

120

110 125

135 145

155 165

185 200

214 226

200 220

240 255

270 285

320 345

368 390

390 430

470 505

530 565

615 680

730 770

550 610

665 715

740 800

885 965

1030

1095

970

1075

1170

1255

1300

1400

1550

1680

1800

1910

Table 2-3

2-2

Modular Steam Coil Steam Supply Generators

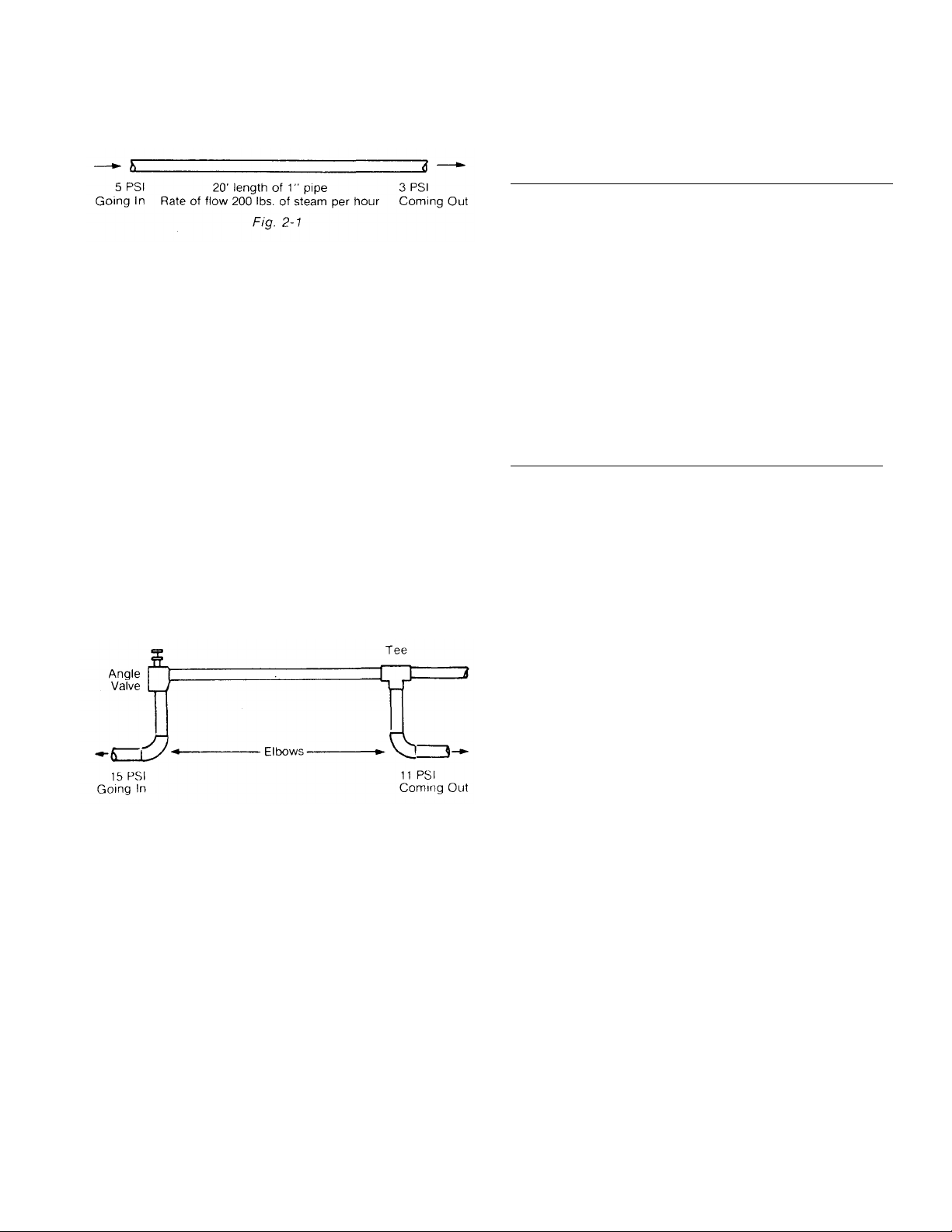

Capacities are based on allowing a pressure drop of 2

245

Actual run

20'.

Equivalent run

41.4'.

Rate of

PSI in a length of pipe equal to 240 diameters of the

pipe. For ex ample, (Fig. 2-1) in one-inch pipe, at the

steam flows shown, there would be a pressure drop of

2 PSI in 240 inches, (20 feet) of straight run.

If the rate of flow is increased, the pressure drop will

be greater. If the rate of flow is decreased, the

pressure drop will be less.

Elbows, valves, and other fittings cause greater

pressure drop. (See next section)

In determining proper pipe size at a given line

pressure to deliver the desired rate of steam flow and

pressure at the steam cooker, it is necessary to know

not only the actual length of the pipe run, but also the

equivalent length of run. Each fitting or value causes

resistance equal to a certain length of straight pipe.

This equivalent length must be added to the actual

length in order to determine the equivalent length of

run. For example, (Fig. 2-2) assume an actual length

of 20' of 20" pipe with two elbows, an angle valve, and

a side outlet tee. Table 2-4 shows that to determine

the equivalent length of run we must add 2.2' for each

of the elbows , 12' for the angle valve, and 5' for the

side outlet tee, giving us an equivalent length of run of

41.4' of straight pipe.

Resistance of fittings expressed in terms of equivalent length of straight pipe. (Measurements are in

feet)

Pipe

Standard

Size

Elbow

1.3' 3' .3' 14' 7'

1/2"

3/4" 1.8' 4' .4' 18' 10'

1" 2.2' 5' .5' 23' 12'

1

3.0' 6' .6' 29' 15'

1

3.5' 7' .8' 34' 18'

2" 4.3' 8' 1' 46' 22'

Side

Outlet

Tee

Gate

Valve

Globe

Valve

Table 2-5

Temperature (degrees F) of steam at various

altitudes and pressures.

Altitude 5 PSI 10 PSI 15 PSI

Sea level

2000 feet

5000 feet

10,000 feet

227

224

220

213

240

237

234

228

Table 2-4

Rule-of-thumb Conversion Information

• 1 BHP —approximately 10 KW

• 1 BHP —approximately 34,000 BTU

These conversions are easily-remembered

approximations. In making conversions, the

efficiency of the steam generator must be

considered. A gas steam generator with an input of

34,000 BTU and operating at 50% efficiency, will

deliver 1/2 BHP.

Angle

Valve

250

248

240

Flow: 240 Ibs. of steam per hour.

Fig. 2-2

2-3

2.5 STEAM FITTER AND PLUMBER

2.5.1 Steam Connection

It is recommended that, whenever possible, the

steam input to the steam generator be a separate

line from the source of supply. If the steam

generator must be piped to a line which also

supplies other steam consuming devices, the pipe

sizes and pressures will have to be verified as to

capacity.

Section

2

Installation

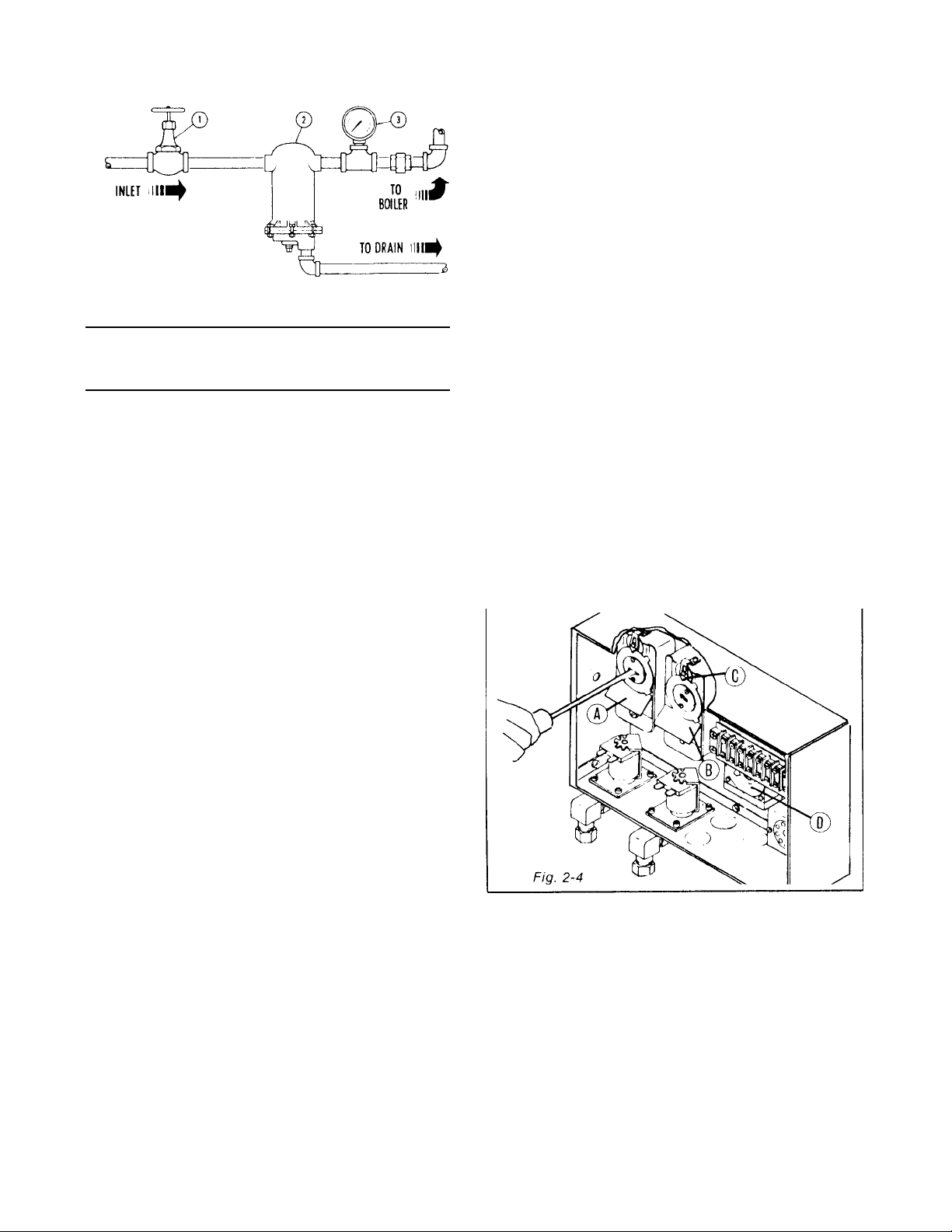

SUGGESTED STEAM CONNECTIONS:

ITEM

1

2

3

Fig. 2-3

(Fig. 2-3) shows a recommended system of the

installation which includes the following equipment: A

globe valve for shut off, a ball float trap which assures

that the steam supply is clean and dry, a pressure

gauge to measure inlet pressures from the source of

supply.

DESCRIPTION

3/4" Globe Valve

Ball Float Trap

Pressure Gauge

PART NO.

10-2821

10-5336

NOTE: If steam supply line has an extremely high

excess amount of condensate, it may be neces sary to

install 2 ball float traps.

10% of recommended operating pressure, the

pressure control switches are adjusted properly and

the unit is operating satisfactorily.

4. Steam generator pressure switches are factory set

and should not be adjusted unless absolutely

necessary. If pressure is found to be other than

above, proceed as follows:

a. Remove front cover from modular control

box.

b. With screwdriver adjust pressure switches (A) and

(B). Steam coil steam generators used to

generated steam for a Steam-It, Jet Steam

Cooker or Kettle which operate at 15 PSI should

be set as follows: Switch (A) should be set at 12

PSI and Switch (B) at 20 PSI. If 15 Ib. steam

generator is used for 5 Ib. operation, follow

above instructions and then refer to "adjusting

watts 3/4" pressure reducing valve".

c. Steam coil steam generators used to generate

steam for a compartment type steam cooker

which operates at 5 PSI should be set as follows:

Switch (A) should be set at 5 PSI and Switch (B)

at 10 PSI. d. Dial C is the differential dial and

should always be set at 1 PSI on both Switch (A)

and (B).

e. The cold water condenser thermostat (Dial D) is

provided as standard equipment with all

automatic drain steam generators. This

thermostat is preset at the factory for 140°F and

should not be re-adjusted in the field.

IMPORTANT

Before making final connection, blow out the steam

line to remove all dirt, scale, packing, etc., that may

be accumulated during pipe fittings.

If condensate coming out of the coil is to be returned

to the customer's steam generator, disconnect the

condensate tubing from the main drain and connect it

to the optional condensate return fitting. See page 2-8

for location of this connection.

2.6 SETTING OF STEAM GENERATOR PRESSURE CONTROL SWITCHES (On models

before 1979) (Fig. 2-4)

To be sure steam generator pressure control

switches are set properly, use the following

procedure:

1. Start steam generator and allow it to build up to

pressure- 5 Ibs. or 15 Ibs.

2. Release pressure into cooking chamber by turning

on unit- Jet, Compartment Cooker, Steam-It.

3. Shut off cooking unit and let steam generator build

back up to pressure. Check the steam generator

pressure gauge. If pressure is within

2-4

NOTE: On earlier model steam generators,

adjustments of the pressure control switches may be

done with a screwdriver as shown. Later model steam

generators require the use of a special wrench, which

may be obtained from Market Forge.

Modular Steam Coil Steam Supply Generators

2.7 PRESSURE CONTROL SWITCH ADJUSTMENT (On models after 1979) (Fig. 2-5) If

generator fails to maintain steam pressure in

operating range, pressure control switch may

require adjustment.

1. Start generator and allow pressure to build up

to operating level -15 PSI 1 kg/cm2.

2. Check generator pressure gauge. If gauge

indicates 12 to 14 PSI, pressure control

switches are properly adjusted.

3. If generator does not come on when pressure

gauge reads 12 PSI and does not go off when

pressure gauge reads 14 PSI, proceed as

follows:

a. Remove screws and lift front cover off

control box.

Warning: Because power must be on to

adjust pressure switches, be sure to

protect against electrical shock.

b. Hand adjust operating pressure control

switch (A) and high limit pressure control

switch (B) by turning adjusting nut (Knurled

knob) clockwise to raise and counter-

Fig. 2-5

clockwise to lower actuation point. Switch

(A) should be set so that generator comes

on when generator pressure gauge reads

12 PSI and goes off when gauge reads 14

PSI. Switch (B) should be set so that

generator will shut off if pressure reaches

15 PSI. If 15 Ib. steam generator is used for

5 Ib. operation, follow above instructions

and then refer to "adjusting watts 3/4"

pressure reducing valve".

c. The actuation value (differential) is factory

set and cannot be changed.

d. The cold water condenser thermostat is

pre-set at factory at 130°F 54° C and

should not be reset.

e. Repeat steps 1, 2, and 3. If 12 to 14 PSI

generator pressure gauge reading is

obtained during generator operation,

adjustment is correct. If proper adjustment

cannot be made, consult Trouble-Shooting

Guide in Section 4, in this manual.

f. After making adjustments, replace cover on

control box.

2-5

Section

2

Installation

2.8 WATER LEVEL CONTROL (On models

before Feb. 1984)

The Water Level Control used by Market Forge is a

float type switch with a float ball inside the boiler. The

water level control is equipped with two microswitches

which turn the water supply on and off and the power

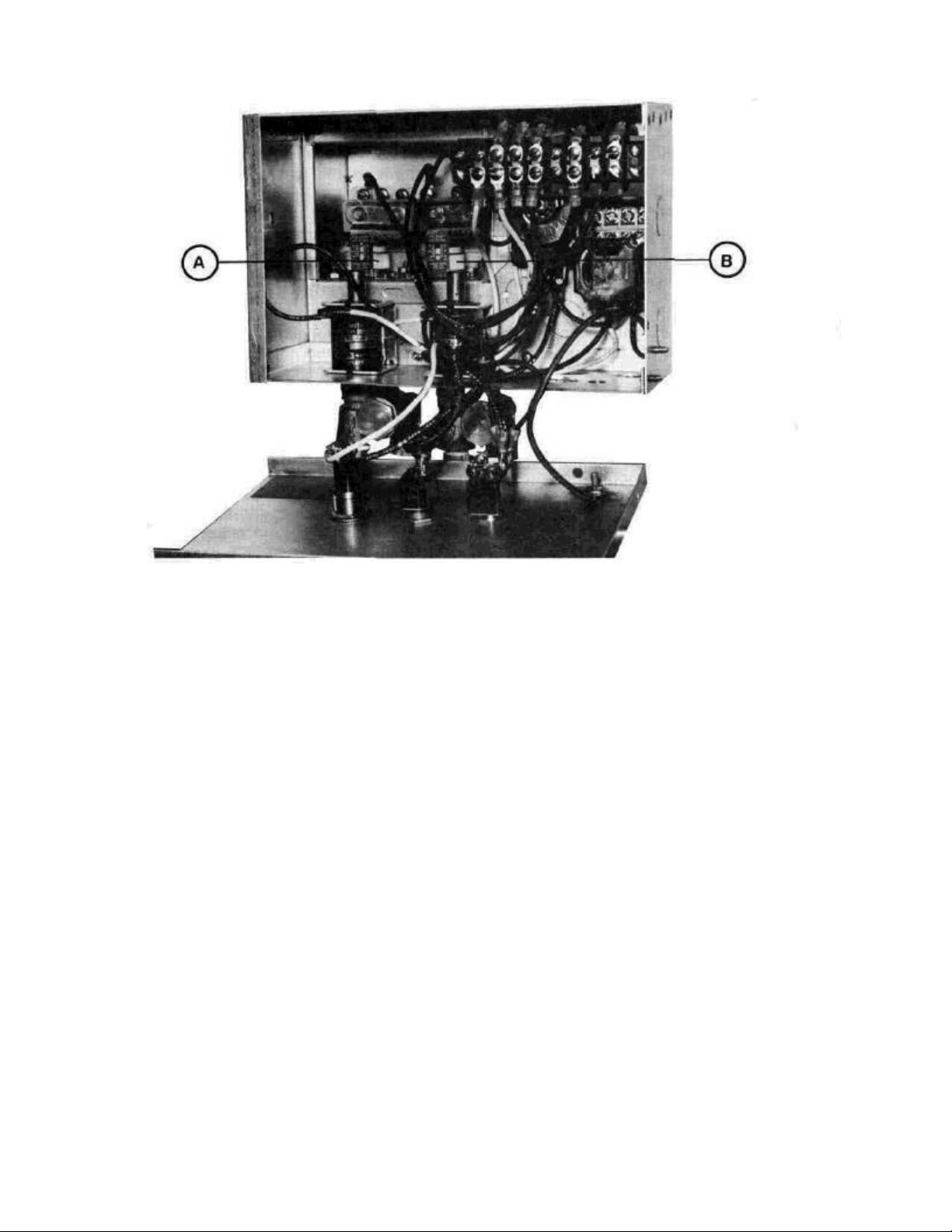

supply on and off. (Fig. 2-6)

Microswitch (A) prevents the source of power from

coming on until there is an adequate supply of water

in the boiler.

Microswitch (B) shuts off water supply when the water

level has reac hed 2/3 full as viewed in the gauge

glass.

CAUTION:

Before removing cover disconnect 115V power

supply. When the boiler is full, water level should

reach 2/3 full in gauge glass and the water feed

should shut off. If this is not correct, remove cover to

water level control and adjust Microswitch (B). To

adjust, loosen lock nut and turn screw clockwise to

raise level and counterclockwise to lower level.

If no water is visible in gauge glass and power comes

on when water switch is reset, this indicates that:

1. Microswitch (A) is out adjustment and must be

readjusted. To adjust, remove cover to water level

control, loosen lock nut and turn adjusting screw in

a clockwise direction. Continue this adjustment so

that heat does not come on until the gauge glass is

2/3 filled with water.

2. Use Ohmmeter across to check for proper

continuity through microswitches.

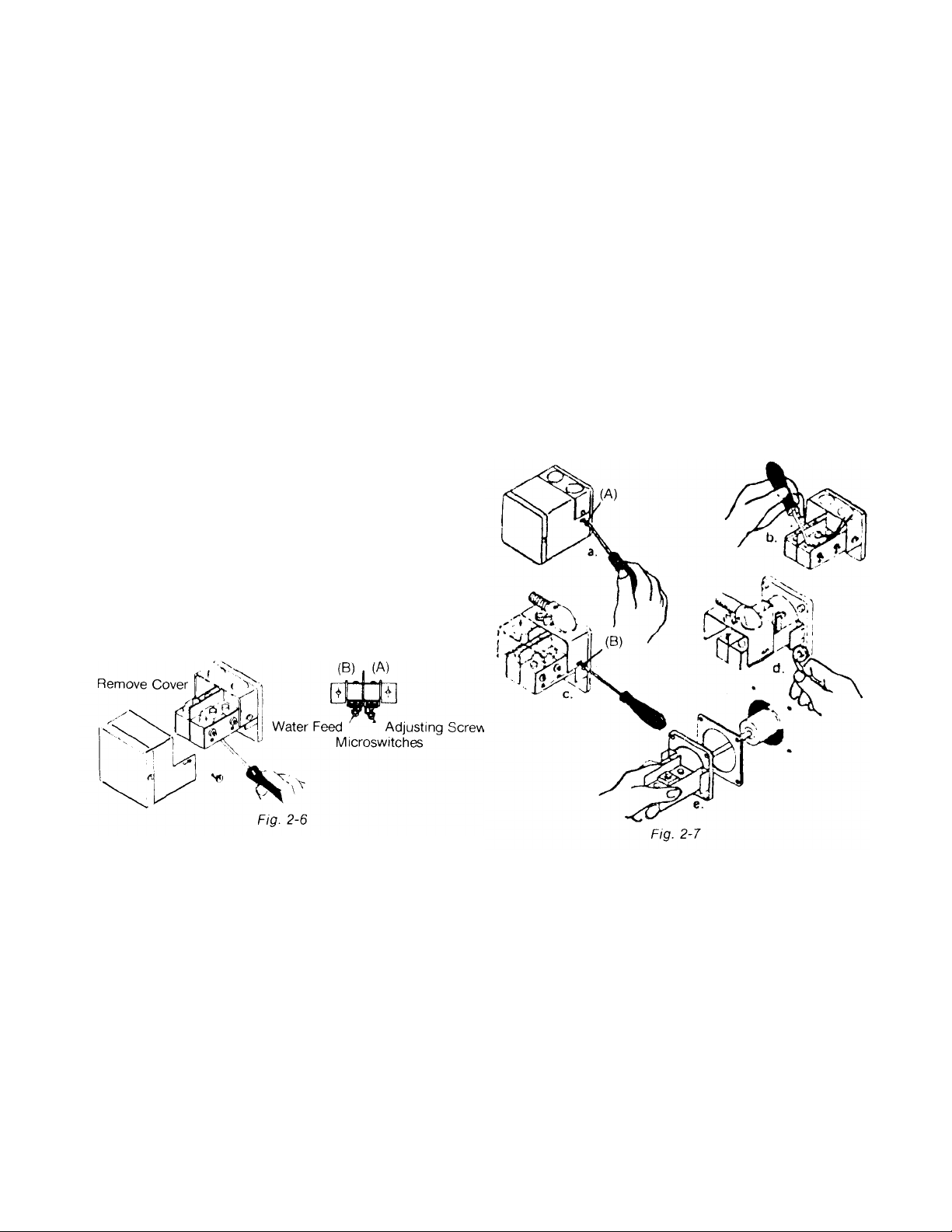

c. Remove the two screws (B) on either side of

housing. The housing, with all external wiring still

attached, may then be removed to one side.

d. With an Alien set screw wrench remove the set

screws at the four corners of the mounting plate.

e. Pull ouy and remove the complete float assembly

and gasket from the boiler.

f. Clean the internal boiler parts of the water level

control. Use a tooth brush to clean the bellows. If

the deposits are excessive, a flat blade putty knife

may be used to clear accumilations from between

the bellows fins. However, care should be used

not to rupture them or twist bellows out of

alignment. When satisfied that the complete float

switch assembly is clean, and that the bellows are

free to operate properly, reinstall assembly into the

boiler using a new gasket to establish a firm seal.

First, be sure that surfaces contacting the gasket

are completely clean. Reverse the disassembly

steps to reinstall into the boiler.

g. CAUTION: Be sure to check adjustments as shown.

2.8.1 Disassembly Instructions

Remove water level control as follows: (Fig. 2-7)

a. Remove the two screws (A) on either side and

remove the cover.

b. Disconnect the 4 intial wires from their

terminals. Mark all wires and terminal posts to

simplify reassembly.

2-6

2.9 WATER LEVEL CONTROL (On models

after Feb. 1984)

CAUTION:

Before removing cover, disconnect power

supply.

The McDonnell-Miller Water Level Control is not

adjustable. If not functioning properly, entire water

level control must be replaced.

Loading...

Loading...