Page 1

GAS OPERATED

G

MODELS:

□ M24G100A-4SP □ M24G200A-4SP

□ M36G200A-4SP □ M36G300A-4SP

DESCRIPTION:

The Market Forge CSD-1 compliant gas operated steam

boiler is mounted in a polished stainless steel cabinet

base of modular design to match other Market Forge

cooking equipment. Equipped with 6” (152mm) stain-

less steel legs, adjustable bullet feet, reinforced stain-

less steel counter top and single lift off front panel. No

connection or piping extends beyond either end of the

cabinet, and all piping is enclosed. Frame construction is

8 gauge stainless steel, type 409.

Boiler has manual drain capability as standard. Access

port for Total Concept and PM Plus delimer, descaler,

corrosion inhibitor and a single check valve to the boiler

feed are included.

The unit is automatically lled with cold water and brought

to pressure when the power and heat switches are turned

on and drained under pressure when the power switch

is turned off. A cold water condenser automatically cools

all the steam exhausted from the boiler to drain.

Note:

Boiler is suitable for operation at any pressure

from 5-15 PSI (0.4 kg/cm2). If two operating pressures

are required, such as 5 PSI to one unit and 15 PSI to

another specify pressure reducing valve to provide 5 PSI

(0.4 kg/cm2) operation.

The only available space to supply utilities to the boiler

is the 6” (152mm) space between the oor and the cabinet.

OPERATION SHALL BE BY:

A.S.M.E. constructed and National Board Registered,

gas red boiler rated at:

STEAM BOILER

□ 100,000 BTU - M24G

□ 200,000 BTU - M24G or M36G

□ 300,000 BTU - M36G

Boiler shall be equipped for operation with:

□ Natural Gas □ LP Gas

Boiler shall be operated at a MAWP of:

● 15 PSI (1kg/cm2)

Manifold gas pressure shall be 4” W.C. (102mm) for nat-

ural gas and 10” W.C. (254mm) for LP Gas. Incoming

pressure must not exceed 14” W.C. (357mm).

The manufacturer reserves the right to modify materials and specications without notice.

JOB NAME: ________________________

ITEM NO.: _________________________

NO. REQUIRED: ____________________

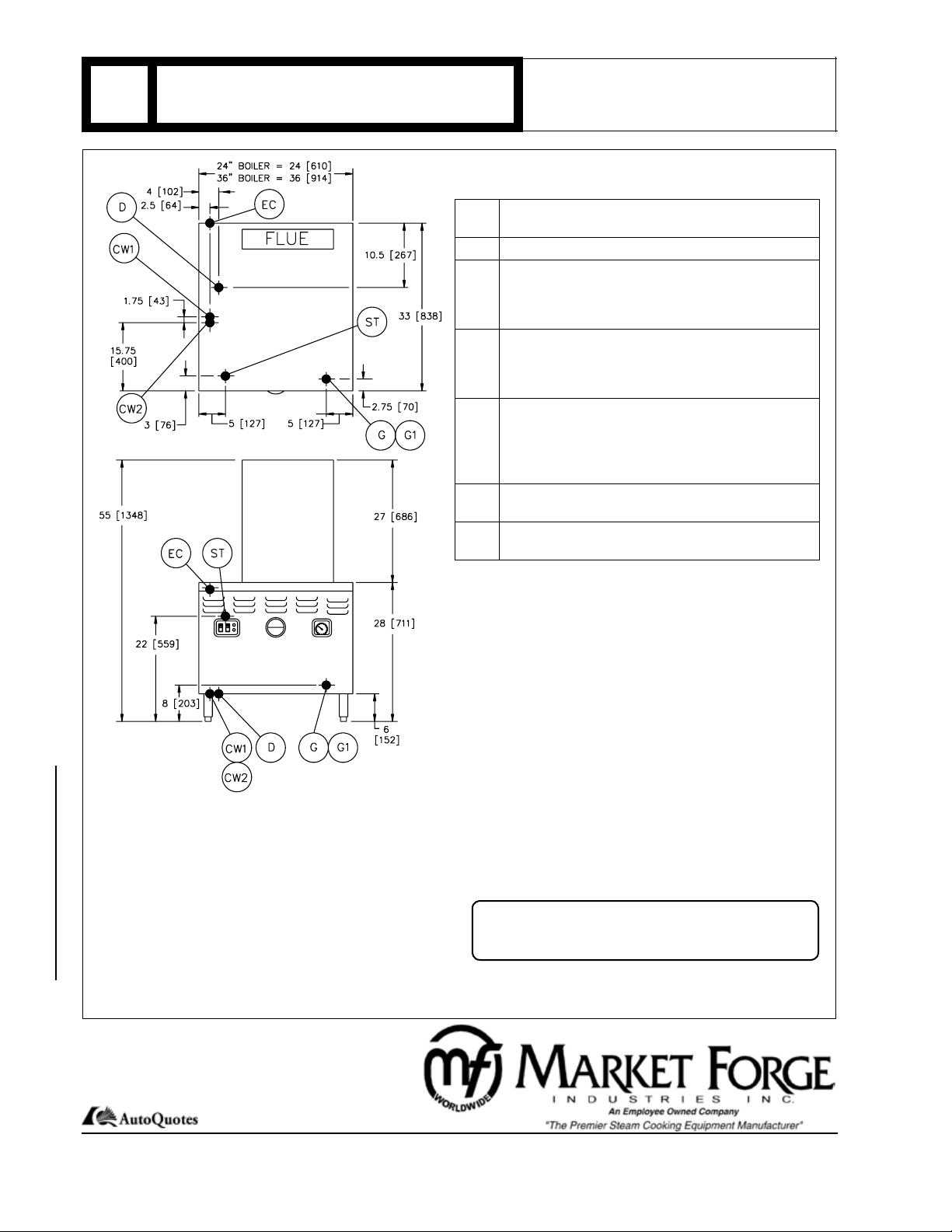

100 & 200 BTU

24” Cabinet Base

Steam Boiler Shown

with Flue Riser

300 BTU, 36” Cabinet

Base Steam Boiler

Shown with Flue Riser

STANDARD FEATURES:

● CSD-1 Compliant. ● Pressure Gauge.

● Cold Water Condenser. ● Water Strainer.

● Automatic Water Level Control. ● Air Vent.

● One Power Supply. ● Low Water Cut-off.

● Water Gauge Glass.

● Operating and High Limit Pressure Controls.

● Safety Relief Valve and Cathodic Descaler.

● Boiler is Insulated as Standard.

● Totally Serviceable from the Front.

● 9 foot Power Cord/NEMA 5-15.

● Intermittent Spark Pilot ignition.

● Boiler is Suitable for Combustible oors.

OPTIONAL AT EXTRA COST:

□ KleenSteam Filter System. □ Prison Package.

□ Flanged Feet. □ Twin Check Valve.

□ Steam Take Off Kit.

□ Pressure Reducing Valve.

□ One case of Total Concept (delimer).

□ One case of PM Plus (corrosion inhibitor).

□ Casters (Must be ordered with Strain Relief ).

□ Quick Disconnect Gas Hose with Strain Relief - 48”.

□ Quick Disconnect Gas Hose with Strain Relief - 60”.

SPEC SHEET: S-4888

07/11

FOOD SERVICE EQUIPMENT

Gas Boiler

35 Garvey Street • Everett • MA • 02149

Printed in U.S.A.

Tel: (617) 387-4100, (866) 698-3188 • Fax: (800) 227-2659, (617) 387-4456

custserv@mi.com • w w w . m f i i . c o m

Page 2

SPEC SHEET: S-4888

07/11

G

GAS OPERATED

STEAM BOILER

JOB NAME: ________________________

ITEM NO.: _________________________

NO. REQUIRED: ____________________

SERVICE CONNECTIONS

Electrically Operated:

G Gas Connection - 3/4” (19mm) NPT 100,000 and

200,000 BTU.

G1 Gas Connection - 1” (25mm) NPT, 300,000 BTU.

CW1 Cold Water - 3/8” (10mm) NPT for cold water to

boiler. Cold water lines will have a maximum of

50 PSI (3.5kg/cw2) and a minimum of 25 PSI (1.8

kg/cw2) water pressure (Water may be ltered).

CW2 Cold Water - 3/8” (10mm) NPT for cold water to

condenser. Cold water lines will have a maximum

of 50 PSI (3.5kg/cw2) and a minimum of 25 PSI

(1.8 kg/cw2) water pressure.

D Drain - Pipe full 2” (50mm) I.P.S. to ush oor

drain capable of receiving water owing at a maximum rate of 5 gallons (19 liters) per minute. DO

NOT MAKE SOLID CONNECTION TO FLOOR

DRAIN.

EC Electrical Connection - 120 Volts AC, 60 Hz, single

phase, and a 9 foot Power Cord/NEMA 5-15.

ST Steam Take-off - Connection for operation of adja-

cent steam powered equipment.

DRAIN LINE INSTALLATION:

is marked with a colored tag and is located at the lower

rear left side of the boiler as viewed from the front. This

exhaust line may be left open if the boiler has to be

situated in a tiled oor depression or a tiled curb sec-

Gas Boiler

tion that is equipped with drain facilities. If this is not

the case, then a 2” (51mm) NPT drain line must be

connected to divert the exhaust to the oor drain. If it is

necessary to use more than three elbows, increase the

FOOD SERVICE EQUIPMENT

size of the waste line accordingly.

It is our policy to build equipment which is design certied by N.S.F., N.E.M.A. and C.S.A. However, a continuing program of product improvement

makes it necessary to submit new models to the agencies as they are developed and consequently not all models bear the appropriate agency labels.

The drain port of the unit

Notes: If equipment is installed where elevation exceeds

2,000 feet (609.6 meters) above sea level, specify installa-

tion altitude so that proper gas orices can be provided.

The only available space to supply utilities to the gas boiler

is the 6” (152mm) space between the oor and the cabinet.

Allow 3” (76mm) space from side wall and 6” (152mm)

from real wall if adjoining walls are combustible.

PVC & CPVC PIPE ARE NOT ACCEPTABLE MATERIALS FOR DRAINS.

CAUTION: Before connecting water to this unit, water supply should be analyzed to make sure hardness is no greater than 2.0 grains and pH level is within the range of 7.0-

8.5. Water which fails to meet these standards should be

treated by installation of water conditioner. EQUIPMENT

FAILURE CAUSED BY INADEQUATE WATER QUALITY

IS NOT COVERED UNDER WARRANTY.

WARNING: DO NOT UNDER ANY CIRCUMSTANCE

CONNECT THE EXHAUST DRAIN LINE DIRECTLY TO

A SEWER LINE.

35 Garvey Street • Everett • MA • 02149

Tel: (617) 387-4100, (866) 698-3188 • Fax: (800) 227-2659, (617) 387-4456

custserv@mi.com • w w w . m f i i . c o m

Loading...

Loading...