Market Forge M24E User Manual

ELECTRICALLY OPERATED

E

MODELS

M24E - 24” wide, 24 kW electric boiler

M36E - 36” wide, 24 kW electric boiler

DESCRIPTION

The Market Forge CSD-1 compliant electrically operated steam boiler is mounted in a polished stainless steel cabinet base of modular

design to match other Market Forge cooking equipment. Equipped

with 6” (152mm) stainless steel legs, adjustable bullet feet, stainless steel counter top and single lift off front panel. No connection

or piping extends beyond either end of the cabinet, and all piping is

enclosed. Frame construction is 8 gauge stainless steel, type 409.

Unit is automatically filled with cold water and brought to pressure

when the power and heat switches are turned on and automatically

drained, under pressure, when the power switch is turned off. A cold

water condenser automatically cools all the steam and hot water

exhausted from the boiler to drain at 140°F (60°C).

Boiler has automatic drain capability as standard. Access port for

Total Concept and PM Plus delimer, descaler and corrosion inhibitor

and a single ASSE approved, check valve/backflow preventer to the

boiler feed are included.

Note: Boiler is suitable for operation at any pressure from 5-15 PSI

(0.4 kg/cm2). If two operating pressures are required, such as 5 PSI

to one unit and 15 PSI to another specify pressure reducing valve to

Electric Steam Boiler

provide 5 PSI (0.4 kg/cm2) operation.

The only available space to supply utilities to the boiler is the 6”

FOOD SERVICE EQUIPMENT

(152mm) space between the floor and the cabinet.

OPERATION SHALL BE BY:

Electrically powered, A.S.M.E. constructed and National Board

Registered, MAWP 15 PSI (1kg/cm2) boiler equipped for operation

with:

M24E - 24 kW (36, 42, 48 kW option available)

M36E - 24 kW (36, 42, 48 kW option available)

SHIPPING WEIGHT

M24E - 330 lbs (150 kg)

M36E - 530 lbs (240 kg)

STEAM BOILER

JOB NAME: ___________________________

ITEM NO.: ____________________________

NO. REQUIRED: _______________________

M24E M36E

STANDARD FEATURES:

CSD-1 Compliant

Nickel Plated

ASSE Approved backflow preventer

Pressure Gauge

Cold Water Condenser

Water Strainer

Automatic Water Level Control

Air Vent

One Power Supply

Low Water Cut-off

Water Gauge Glass

Operating and High Limit Pressure Controls

Safety Relief Valve and Cathodic Descaler

Boiler is Insulated as Standard

Totally Serviceable from the Front

OPTIONS & ACCESSORIES

(at additional charge)

Quick disconnect water lines (2) required

Casters

KleenSteam Filter System

6” Flanged Feet

Twin Check Valve

Steam Take-Off Kit

Pressure Reducing Valve

Prison package, includes lockable stainless steel hinged

control cover, tamper proof screws, (4) 6” adjustable

flanged feet

44 Lakeside Avenue, Burlington, VT 05401 USA • Tel: (802) 658-6600 • Fax: (802) 864-0183

www.mfii.com

E

ELECTRICALLY OPERATED

STEAM BOILER

DETAILS & DIMENSIONS

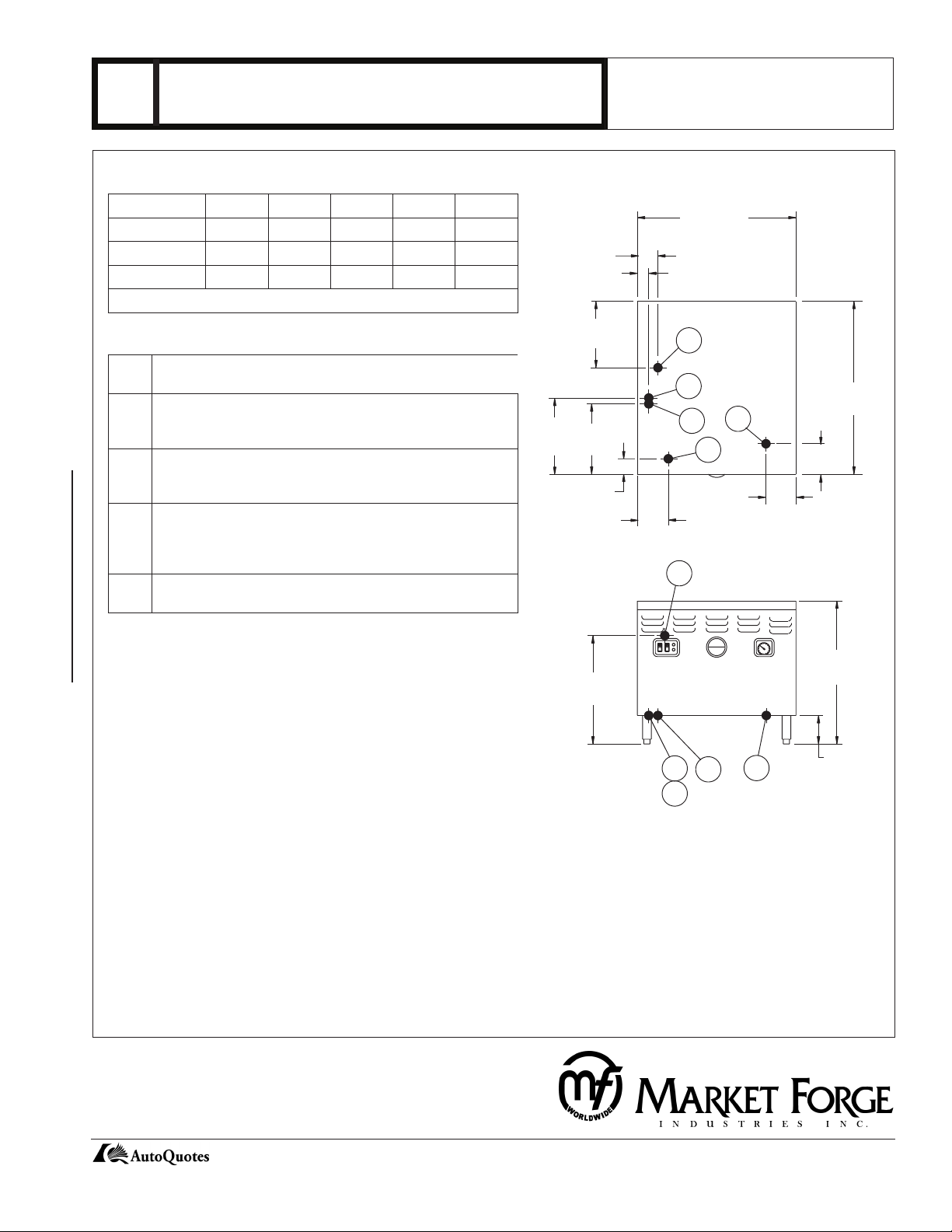

ELECTRICAL REQUIRMENTS

Volts Phase 24kW 36kW 42kW 48kW

208 (197-219) 3 66 100 117 -

240 (220-240) 3 58 87 - 116

480 (360-500) 3 29 44 - 58

Details of other electrical systems available upon request.

SERVICE CONNECTIONS

EP Power Supply - Use wire suitable for at least 90°C. Nominal

amp per line wire.

CW1 Cold Water - 3/8” (10mm) NPT for cold water to boiler. Cold

water lines will have a maximum of 50 PSI (3.5kg/cw2) and a

minimum of 25 PSI (1.8 kg/cw2) water pressure

CW2 Cold Water - 3/8” (10mm) NPT for cold water to condenser.

Cold water lines will have a maximum of 50 PSI (3.5kg/cw2)

and a minimum of 25 PSI (1.8 kg/cw2) water pressure.

D Drain - Pipe full 2” (50mm) NPT to flush floor drain capable

of receiving water flowing at a maximum rate of 5 gallons (19

liters) per minute. DO NOT MAKE SOLID CONNECTION TO

FLOOR DRAIN.

ST Steam Take-off - Connection for operation of adjacent steam

powered equipment.

The only available space to supply utilities to the electric boiler is the 6”

Electric Steam Boiler

(152mm) space between the floor and the cabinet.

PVC & CPVC PIPE ARE NOT ACCEPTABLE MATERIALS FOR

FOOD SERVICE EQUIPMENT

DRAINS.

WARNING: DO NOT UNDER ANY CIRCUMSTANCE CONNECT THE

EXHAUST DRAIN LINE DIRECTLY TO A SEWER LINE.

CAUTION: REMOTE KETTLE OPERATION If this boiler is feeding a

remote kettle that will be more than 5 feet (1.5 meters) away, consult

factory before ordering.

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water quality

must be within the following general guidelines.

TDS: 40-125 ppm Hardness: 35-100 ppm Chlorine: <0.2 ppm

Silica: <13 ppm Chlorides: <25 ppm

Chloramine: <0.2 ppm pH: 7.0 - 8.5

DIMENSIONS ARE IN INCHES [MM]

24 [610] M24E

36 [914] M36E

4 [102]

2.5 [64]

12.5

[318]

10.5

[267]

10.5

[267]

3 [76]

5 [127]

22

[559]

D

CW1

CW2

ST

CW1

CW2

ST

D

EP

6 [152]

EP

33

[838]

6 [152]

28

[711]

6 [152]

The best defense against poor water quality is a water treatment system

designed to meet your water quality conditions.

The manufacturer reserves the right to modify materials and specifications without notice.

PRINTED IN U. S. A.

SPEC SHEET: 14-0112 Rev F (10/16)

44 Lakeside Avenue, Burlington, VT 05401 USA • Tel: (802) 658-6600 • Fax: (802) 864-0183

www.mfii.com

Loading...

Loading...