Market Forge M24E Service Manual

M24E & M36E

ELECTRICALLY OPERATED BOILERS

PARTS AND SERVICE MANUAL

EFFECTIVE SEPTEMBER 2, 2014

The Company reserves the right to make substitution in the event that items specied are not available.

ERRORS: Descriptive and/or typographic errors are subject to correction.

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone: (802) 658-6600 Fax: (802) 860-3732

Superseding All Previous Parts Lists.

MARKET FORGE INDUSTRIES

www.mi.com

P/N 14-0310 Rev A (9/14)

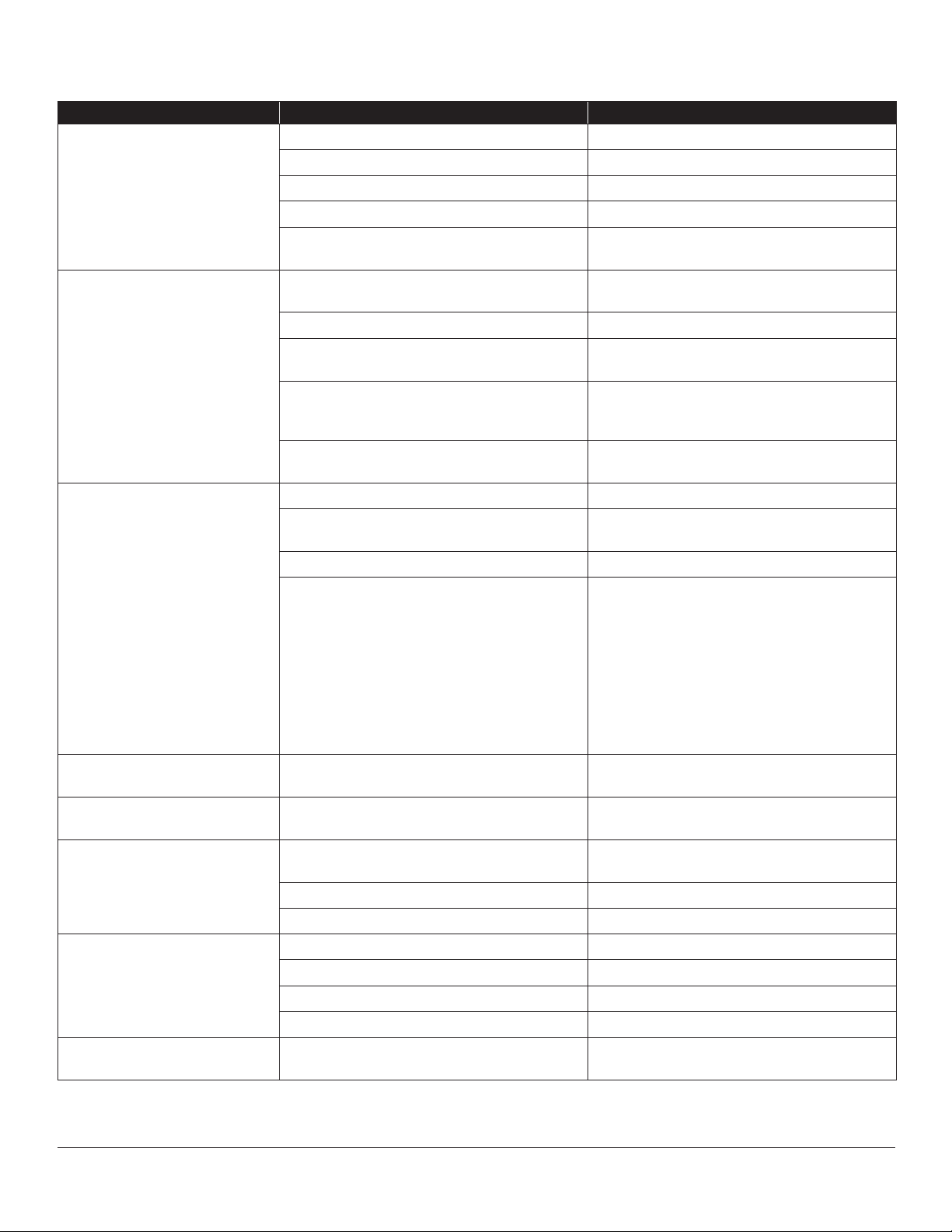

TABLE OF CONTENTS

GENERAL TROUBLESHOOTING .......................................................3

PRESSURE ADJUSTMENT .............................................................5

WATER CONTROL BOARD TESTING PROCEDURE .....................................6

WIRING DIAGRAMS

NEW GENERATION ELECTRIC BOILERS ...............................................8

18 KW, 24 KW ....................................................................... 10

36 KW, 42 KW, 48 KW ................................................................ 12

36 KW, 48 KW ....................................................................... 13

ILLUSTRATED PARTS LIST

24" BOILER BASE ................................................................... 14

PRESSURE SWITCH BOX, WITHOUT COVER......................................... 15

CONTROL BOX ASEMBLY, WITH & WITHOUT COVER ................................. 16

ELECTRIC BOILER, LEFT SIDE VIEW – 36” ........................................... 17

ELECTRIC BOILER, FRONT VIEW – 36” ............................................... 18

ELECTRIC BOILER, CONTACTOR BOX ............................................... 19

ELECTRIC BOILER, ELEMENTS ...................................................... 20

SEPTEMBER 2, 2014 2 M24E & M36E ELECTRIC BOILERS

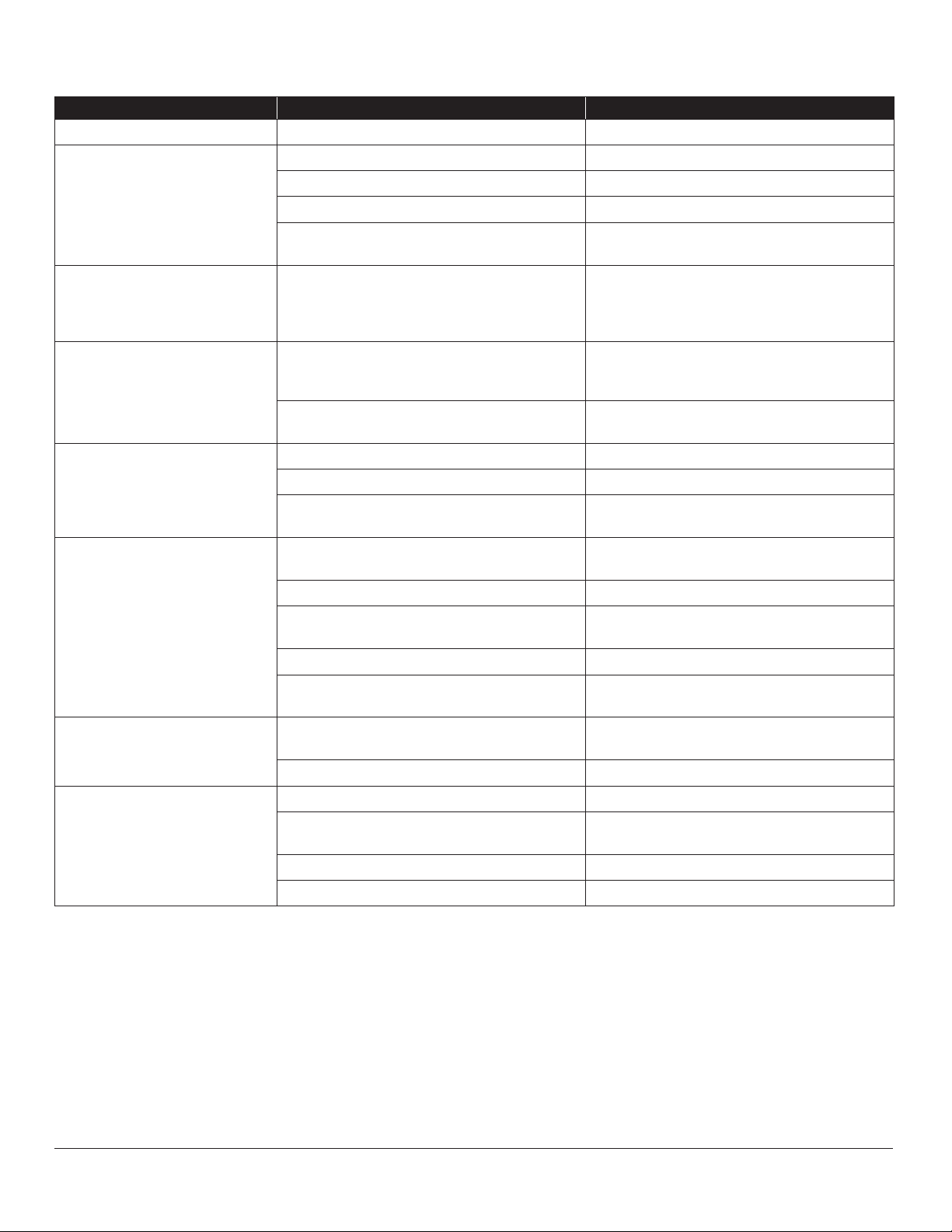

GENERAL TROUBLESHOOTING

TROUBLE POSSIBLE CAUSE REMEDY

Water does not enter the boiler. Water main shut-off Turn on

Power not reaching unit Check main fuse or circuit

Probes dirty Remove and clean

Water level control board defective Refer to test procedure in this manual

Solenoid valve defective If 120V is veried at solenoid coil, but fails to

open, replace solenoid

Boiler fails to build up pressure

when water level is proper and

fuel switch is turned on.

Boiler fails to reach full operating

pressure of 5 lbs. or 15 lbs.

Water enters boiler very slowly. Dirty Strainer screen in solenoid valve. Clean or replace strainer screen, part no. 08-

Water level in gauge glass uctuates up and down.

Contactor chatters Incorrect supply voltage. Check to see that it matches it with coil contac-

15 lbs. safety valve blows off prematurely

Boiler build up to pressure, shuts

down and fails to come on

Check to see that circuit breaker in main is

turned on

Check to see that contactors are pulling in Check continuity of coil, if open replace

Current ow is broken at water level control (ascertain with continuity check)

Current ow is broken at pressure control or

high limit control switches due to maladjustment

or defect (ascertain with continuity check)

Heating elements are defective Replace if continuity check through the circuit of

Pressure gauge reads inaccurately Replace

Pressure control and high limit control switches

are out of adjustment

Safety valve not seating properly Clean or replace

Contactor coils (one or both) not energizing and

closing circuit to the heating elements

Top shut off on water gauge is closed. Open

Dirty or worn contactor points. Clean or replace contactor

Weak coil Replace with correct voltage coil

Pressure set too high Readjust

Pressure gauge reads incorrectly Replace

Mineral build-up or dirt on seat of valve Clean

Weak spring valve Replace valve

High limit switch set too low or operating pressure control switch set too high

Check for voltage at terminal block

Check for voltage at L1 and L2, replace if defective

Readjust - to proper setting - refer to instructions for readjustment, replace if defective

each element shows defective

Follow instructions for readjusting or replace if

defective

Check - replace either contactor coils or complete contactor – if found defective. Measure

amperage at terminal block check to be sure

there is an even draw on all three phases - see

wiring diagrams for correct AMP draw. If uneven

or zero amperage draw is found on one of the

three phases, check for blown fuse. If fuse is

OK, shut off power, remove wires from heating

elements and run continuity check - replace if

defective.

4871.

tors

Follow instructions in this document for readjusting, or replace if defective

SEPTEMBER 2, 2014 3 M24E & M36E ELECTRIC BOILERS

GENERAL TROUBLESHOOTING

TROUBLE POSSIBLE CAUSE REMEDY

Air vent leaking Not closing Replace

Cold water condenser does not

function

Product in cooker does not cook

properly on rst cycle, but cooks

alright after rst cycle is exhaust-

ed

Contactor chatters Low voltage Check voltage condition. Check momentary

Welding or freezing Abnormal spike in current Check for grounds or shorts in system

Short contact button life and / or

overheating of contacts

Open circuit Mechanical damage Handle and store carefully. Do not handle coils

Overheated Coil Over-voltage or high ambient temperature Check application and circuit

Main water line shut off Turn on

Thermostat defective Replace if defective

Tighten coil nut Tighten coil nut

Check solenoid coil for continuity, if open replace

Air vent is closing Replace

Defective or incorrect coil Replace coil, rating of coil must match the line

Low voltage preventing magnet from sealing Correct voltage condition

Short circuit Remove short fault and check to be sure fuse or

Filling or dressing Do not le silver tips. Rough spots or discolor-

Interrupting excessively high current Check for grounds, shorts or excessive current

Discolored contacts caused by insufcient contact pressure, loose connection, etc.

Dirt or foreign matter on contact surface Clean with Acetone

Short circuit Remove fault and check to be sure fuse or

Burnt-out coil due to overvoltage or defect Replace coil

Wrong coil Check rating (voltage and frequency) if incor-

Shorted turns caused Replace coil

Under voltage, failure of magnet to seal in Correct system voltage. Install new coil

Check coil for continuity, if open replace

voltage dip during starting. Low voltage prevents magnet sealing. Check coil voltage rating

voltage

breaker size is correct

ation will not harm tips or impair their efciency

Check contact carrier for deformation or damage, clean and tighten connections

breaker size is correct

by the leads

rect, replace with proper coil

SEPTEMBER 2, 2014 4 M24E & M36E ELECTRIC BOILERS

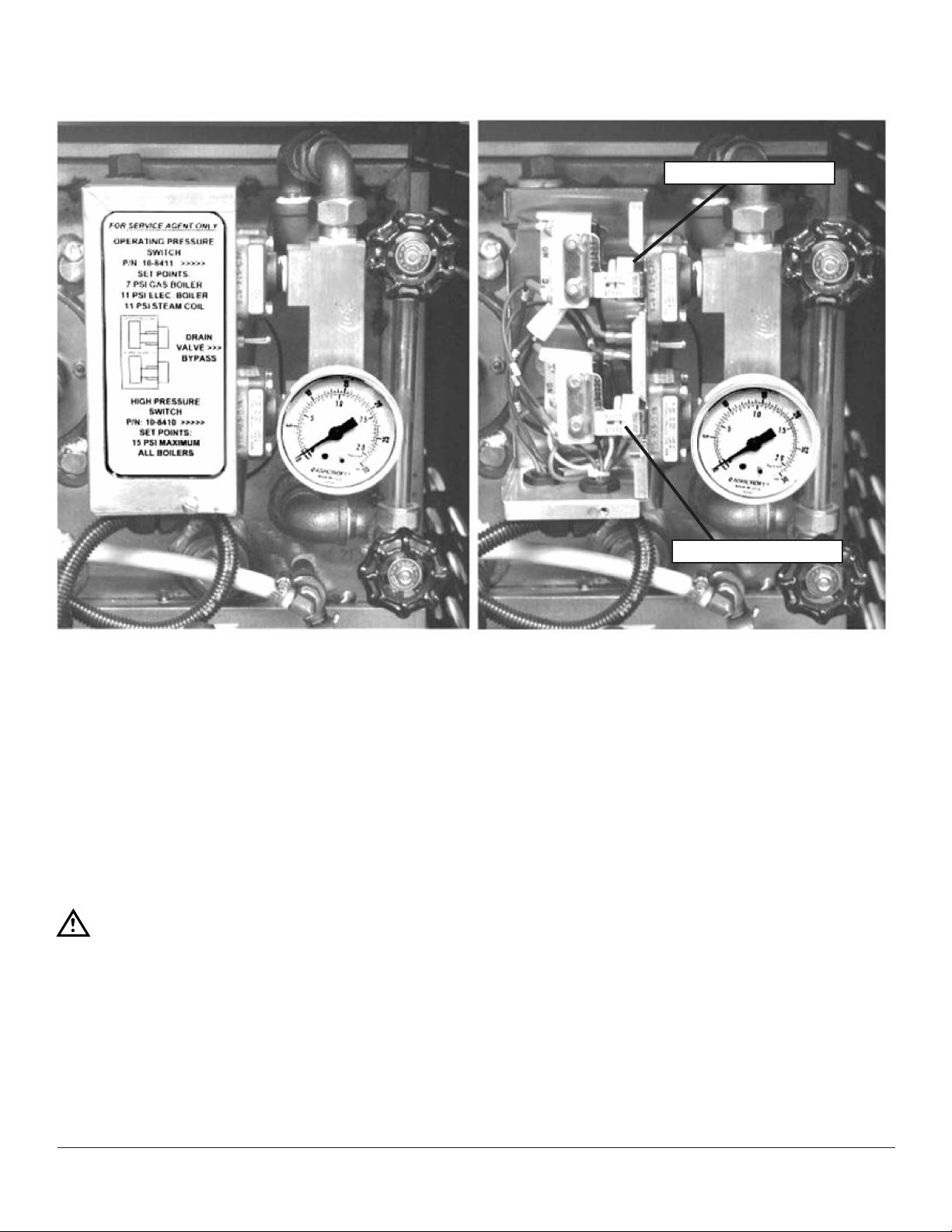

PRESSURE ADJUSTMENT

OPERATING SWITCH

If boiler fails to maintain steam pressure in operating

range, pressure control switch may require adjustment.

1. Start boiler and allow pressure to build up to operating level - 15 PSI (1kg/cm²).

2. Check boiler pressure gauge. If gauge indicates 12

to 14 PSI, pressure control switches are properly adjusted.

3. If boiler does not come on when pressure gauge

reads 7 PSI and does not go off when pressure gauge

reads 14 PSI, proceed as follows:

Pressure Switch Adjustment

WARNING

Because power must be on to adjust pressure

switches, be sure to protect against electrical

shock.

1. Remove screw and lift front cover off control box.

HI LIMIT SWITCH

ter clockwise to lower actuation point. Switch should

be set so that boiler comes on when boiler pressure

gauge reads 12 PSI and goes off when gauge reads

14 PSI. Hi limit switch should be set so that boiler will

shut off if pressure reaches 15 PSI.

3. The actuation value (differential) is factory set and

cannot be changed.

4. The cold water condenser thermostat is preset at factory.

5. Repeat steps, 1, 2, and 3. If 12 to 14 PSI boiler pressure gauge reading is obtained during boiler operation, adjustment is correct. If proper adjustment cannot be made consult Trouble-Shooting Guide in this

manual.

6. After making adjustments, replace cover on pressure

switch box and screw.

2. Hand adjust operating pressure control switch and

high limit pressure control switch by turning adjusting nut (Knurled knob) clockwise to raise and coun-

SEPTEMBER 2, 2014 5 M24E & M36E ELECTRIC BOILERS

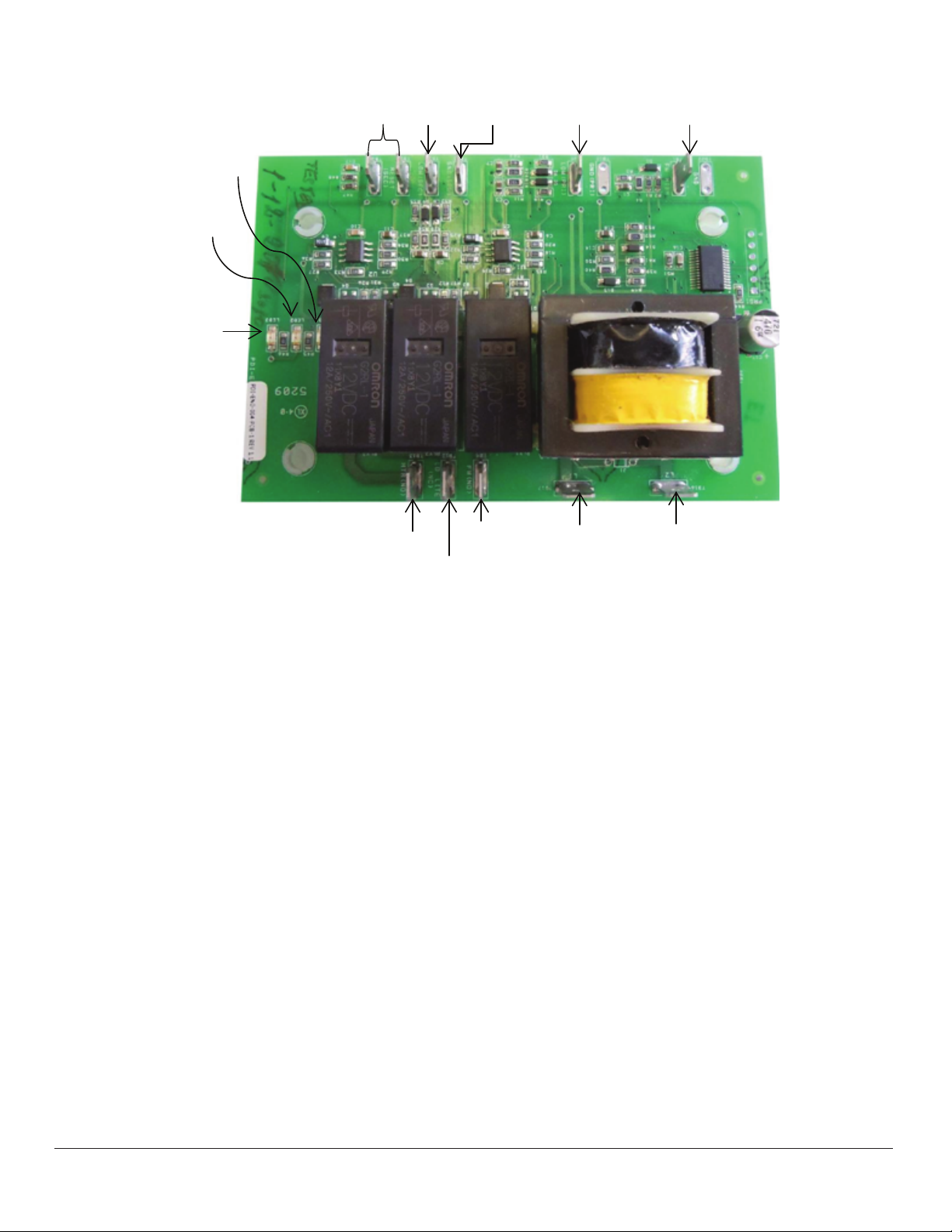

WATER CONTROL BOARD TESTING PROCEDURE

LED 1

LED 2

LED 3

RESET

LW2

GND

LW1

FW - HIGH

HTA NO

LO LITE (NC)

FW (NO)

L1

L2

This test procedure is to be used to determine if the control is working properly. It is not intended to determine why

the control may have failed.

If testing shows that the control is operating properly,

check all probe and solenoid wiring and the condition of

the electrodes in the steam chamber.

Contact the factory if the boiler still does not operate properly after completing the testing.

Tools Needed:

• Digital or Analog V-O-M meter.

• Alligator clip type test jumpers (2 sets min.).

Turn Off Power to Control:

• Use V-O-M to verify there is no power at terminals L

1 & L2.

• Use V-O-M to verify that there is no power at terminals ‘FW(NO)’, ‘LO LlTE(NC)’ & ‘HTR(NO)’. If there

is power at any of these terminals, you will need to

nd the source and turn it off.

Remove Wires from Probe and Relay Switch Terminals:

• DO NOT remove wires from L 1 & L2 terminals.

• Tag wires and remove from probe and relay contact

terminals including ‘GND’ terminal.

• Tag and remove wires from ‘RESET’ terminals.

• Connect jumper wire to both ’RESET’ terminals.

Turn Power On to Terminals L 1 & L2:

• ‘LED l’ should turn on.

• ‘LED 2’ should be off.

• ‘LED 3’ should be off.

• Use V-O-M to verify that there is power at ‘FW(NO)’

& ‘LO LlTE(NC)’ terminals and no power ‘HTR(NO)’

terminals

Test Feedwater Function:

• Connect jumper wire to ‘FW HIGH and ‘GND’ terminals.

• ‘LED l’ should turn off after a 10 second delay.

• Use V-O-M to verify that there is no power at the

‘FW (NO)’ terminal.

• Remove jumper from ‘FW HIGH’ and ‘GND’ terminals. . ‘LED l’ should turn on.

• Use V-O-M to verify that there is power at the

‘FW(NO)’ terminal.

SEPTEMBER 2, 2014 6 M24E & M36E ELECTRIC BOILERS

Loading...

Loading...