Page 1

TWIN MIXING KETTLES

D

MODELS: * FTM(2)-40L

SIZE: 102"-121" wide* by 38.25" front-to back

DESCRIPTION:

Market Forge Model __________ Twin, direct steam,

twin tilting kettle operating at a maximum of 35 psi.

Construction shall be welded stainless steel type 304

satin finish. A double-wall kettle interior shall form a

steam jacket around the lower 2/3 of the kettle. The

bottom of the kettle shall be of hemispheric design for

maximum heat transfer. (316 stainless steel liner is

standard on 40-gal. for high-acid content products.)

DIRECT CONNECTED

* FTM(2)-60L

* FTM(2)-80L

* FTM(2)-100L

(2591-3073 mm wide by 971 mm frontto-back)

*Depending on model

JOB NAME:

ITEM NO.:

NO. REQUIRED:

The tubular legs shall be constructed of stainless steel

pipe fitted with four-hole adjustable flanged feet for

securing to the floor. A sealed stainless steel tilt

mechanism shall permit the kettle to tilt forward a full

90° for complete emptying. The tilt mechanism shall

be self-locking for positive stop action.

The mixer is a variable-speed unit powered by a 5 hp

electric motor driving a hydraulic pump. Two agitators

shall be included: a primary stainless steel scraper/

agitator, and a secondary high-speed mixer. Both agitators shall be removable for cleaning, and no tools

will be required for removal.

The console front to have the main power switch,

mixer lift switch, and variable speed control.

The bridge is constructed of 10-gauge stainless steel

and contains two heavy-duty hydraulic motors to drive

the agitators. The bridge shall be power tilt, and swing

140° out of the way for kettle tilting or cleaning.

COOKING CAPACITIES:

* FTM(2)-40L (2) 40-gal. (152-liter)

* FTM(2)-60L (2) 60-gal. (227-liter)

* FTM(2)-80L (2) 80-gal. (303-liter)

* FTM(2)-100L (2) 100-gal. (379-liter)

Model FTM(2)-40L shown

OPERATION WILL BE BY:

Direct steam at 15 to 50 PSI (1.0 to 3.5 kg/cm2). 1/3

BHP required. Over 50 PSI (3.5 kg/cm2), a pressurereducing valve is required. Standard hydraulic power

supplies are either of the following:

* 208 Volt, 3 Phase, 60 Hz

* 240 Volt, 3 Phase, 60 Hz

OPTIONAL AT EXTRA COST:

(Indicate quantity in space provided.)

Stainless steel split lift-off cover

Swing faucet on left console

3" manual butterfly valve

2" manual butterfly valve

316 stainless steel liner for high-acid content products (standard on 40-gal.)

480 Volt, 3 Phase, 60 Hz (for motor)

Quick chill system

Steam control kit, CKT-1

High-pressure operation

Ball float trap

50 PSI operation

SPEC NO. FOOD SERVICE EQUIPMENT

S-2394B

6/02 TWIN MIXING KETTLES DIRECT CONNECTED

Printed in U.S.A.

The manufacturer reserves the right to modify materials and specifications without notice

An Employee-Owned Company

WORLD HEADQUARTERS: 35 Garvey Street, Everett, MA 02149 CUSTSERV@MFII.COM

Tel: 617-387-4100, Facsimile: 617-387-4456 or 800-227-2659 (U.S., except MA)

Page 2

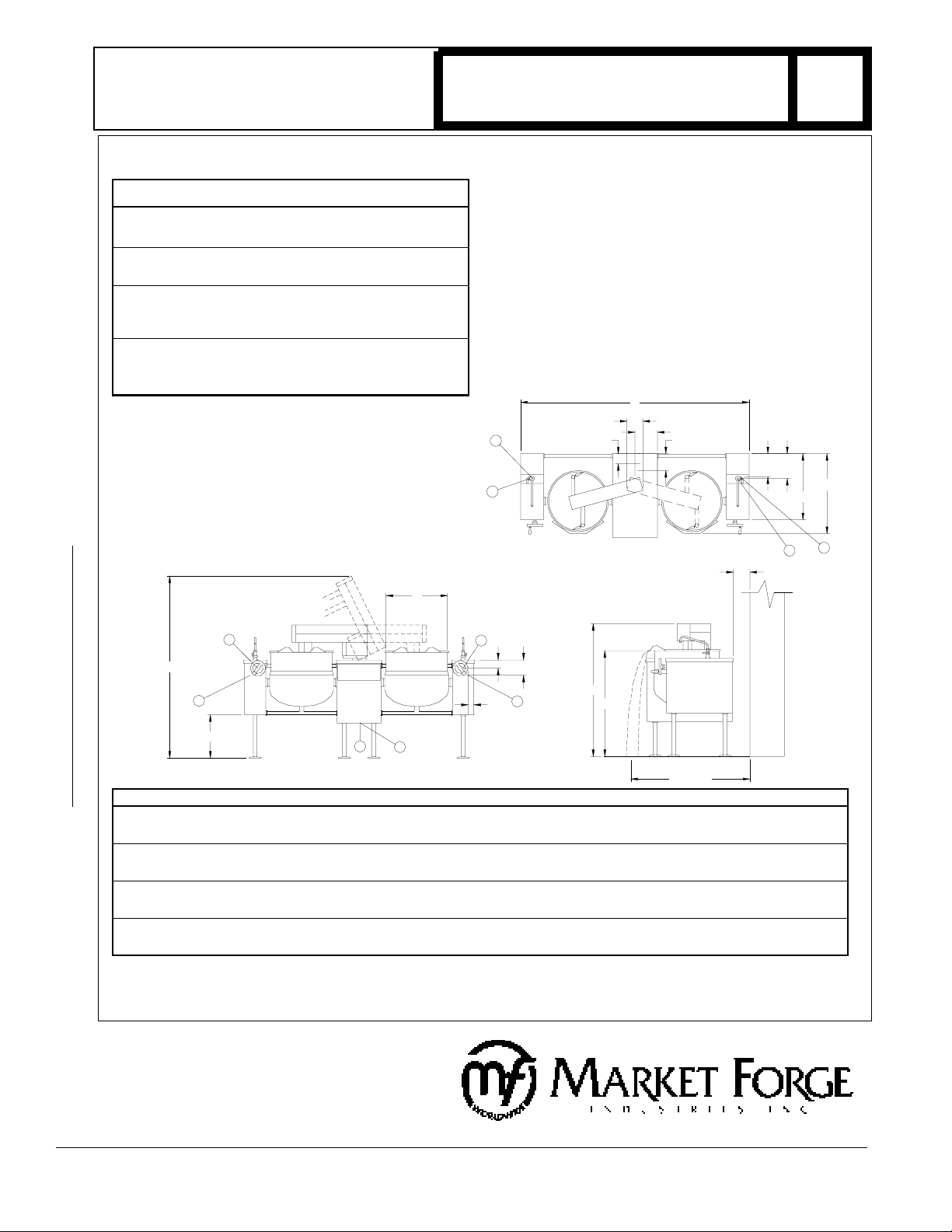

DETAILS & DIMENSIONS

SERVICE CONNECTIONS

TWIN MIXING KETTLES

DIRECT CONNECTED

D

Direct Connected

S*: Steam Supply—3/4" (19 mm) I.P.S.. for incoming

steam at 15-50 P.S.I (1.0-3.5 kg/cm2).

CW: Cold Water—1/2" (12.7 mm) nominal tubing for cold

water kettle fill faucet.

1

CR†: Condensate Return—

/2" I.P.S. (13 mm) I.P.S. condensate return from kettles may be connected to condensate return line.

EC: Electrical Connection—Mixer

Power Supply: 208-240 V 14 Amps 60 Hz

480 V 07 Amps 60 Hz

*Pressure reducing valve is required if incoming pressure exceeds 50 PSI (3.5 kg/cm2).

A

CW

E

S

†Optional

Pressure relief valve must be installed in the incom-

ing steam line if not connected to a Market Forge gas

or electric steam generator. valve is supplied on request at no extra cost.

NOTE:

PVC and CPVC pipe are not acceptable materials for

drains.

B

8[203]

CW

S

CW

3.5[89]

7[179]

S

2[51]

4[102]

D

C

10[254]

8[203]

10 1/4[260]

11[279]

30[762]

CW

4[102] MIN

38 1/4[971]

S

F

MODEL CAPACITY ABCDEFG

FTM(2)-40L 40 gallons inches 26 102 45.5 55 75.625 15.125 56

152 liters mm 660 2591 1156 1397 1921 384 1422

FTM(2)-60LE 60 gallons inches 29.5 108 49 58.5 80 19.5 58

227 liters mm 749 2743 1245 1486 2032 495 1473

FTM(2)-80LE 80 gallons inches 33 116 49 58.5 8 0 19.5 60

303 liters mm 838 2996 1245 1486 2032 495 1524

S-2394A

5/01 TWIN MIXING KETTLES DIRECT CONNECTED

FTM(2)-100LE 100 gallons inches 35.5 121 49 58.5 85 19.5 6 3

379 liters mm 121 3073 1245 1486 2159 495 1600

*It is our policy to build equipment which is design-certified by A.G.A., U.L., A.S.M.E., N.S.F., C.G.A., and C.S.A. However, a

continuing program of product improvement makes it necessary to submit new models to the agencies as they are

SPEC NO. FOOD SERVICE EQUIPMENT

Printed in U.S.A.

developed, and consequently not all models bear the appropriate agency labels at all times.

WORLD HEADQUARTERS: 35 Garvey Street, Everett, MA 02149 CUSTSERV@MFII.COM

Tel: 617-387-4100, Facsimile: 617-387-4456 or 800-227-2659 (U.S., except MA)

EC

CR

DIMENSIONS

G (APPROX)

An Employee-Owned Company

Loading...

Loading...