Page 1

FULL JACKETED TILTING

G

MODEL: □ FT-40GLF 40 Gallon (152 liters)

DESCRIPTION: The kettle has double-wall construc-

tion of 300 series stainless steel forming a full steam

jacket around the kettle. The jacket enclosure con-

tains factory sealed water and antifreeze. The kettle

exterior is fully insulated. The bottom of the kettle is

a hemispherical design for superior heat circulation.

The recessed control panel is located on the front

right side of the unit in full view of the operator. Standard controls include direct immersion thermostat,

water sight glass, cooking light, pressure gauge and

electronic ignition with ignition indicator light. Safety

features include low water cutoff with indicator light,

pressure switch, pressure relief valve and a 100%

safety gas shut off valve.

SELF-CONTAINED GAS FIRED

STEAM JACKETED KETTLE

JOB NAME: ___________________________

ITEM NO.: ____________________________

NO. REQUIRED: _______________________

SPEC SHEET: S-6007

02/10

The kettle pivots on trunnions connected to the gear

and control consoles. The worm and gear tilting

mechanism allows the kettle to tilt forward to a full

90° for complete draining. The tilt mechanism is self

locking for positive stop action. The consoles are drip

proof, stainless steel clad and are supported on all

welded 1 5/8” (41mm) diameter stainless steel legs

with anged feet.

The kettle construction is stainless steel throughout

and built in accordance with the ASME code.

Input

MODEL

FT-40GLF 120,000 75% Minimum

OPERATION WILL BE BY: Natural or L.P. gas utilizing a high efciency power burner system. The steam

kettle is A.S.M.E. code stamped for operation to 50

PSI. Temperature range from 150° F to 285°F.

The controls shall be equipped for operation on:

BTU/Hour

Combustion

Efciency

□ 120 VAC, 1pH, 50/60 Hz.

The manufacturer reserves the right to modify materials and specications without notice.

FT-40GLF Shown with Optional 2” Draw-Off Valve

ELECTRICAL OPTIONS:

□ 220V, 50Hz, 1pH or for sure on 220 to 240V supply

unit. Total Max Amps: 1.0

OPTIONAL AT EXTRA COST:

□ Spring assist cover, HSC.

□ 2” tangent draw off, FDOR-2 with strainer.

□ 3” tangent draw off, FDOR-3 with strainer.

□ Tri-Basket assembly.

□ Single pantry faucet with swing spout, SP-12.

□ Double pantry faucet with swing spout, DP-12.

□ Graduated measuring strip, MS-1.

□ Solid disk strainer DOS-2.

□ 316 stainless steel liner for high acid content

products.

□ Etched Gallon Markings.

FOOD SERVICE EQUIPMENT

Full Jacketed Tilting Gas Kettle

PRINTED IN U. S. A. 35 Garvey Street • Everett • MA • 02149

Tel: (617) 387-47100 • Toll Free: (866) 698-3188 • Fax: (617) 387-4456 • Outside MA Fax: (800) 227-2659

E-Mail: custserv@mi.com • Website: w w w . m f i i . c o m

Page 2

SPEC SHEET: S-6007

02/10

G

FULL JACKETED TILTING

SELF-CONTAINED GAS FIRED

STEAM JACKETED KETTLE

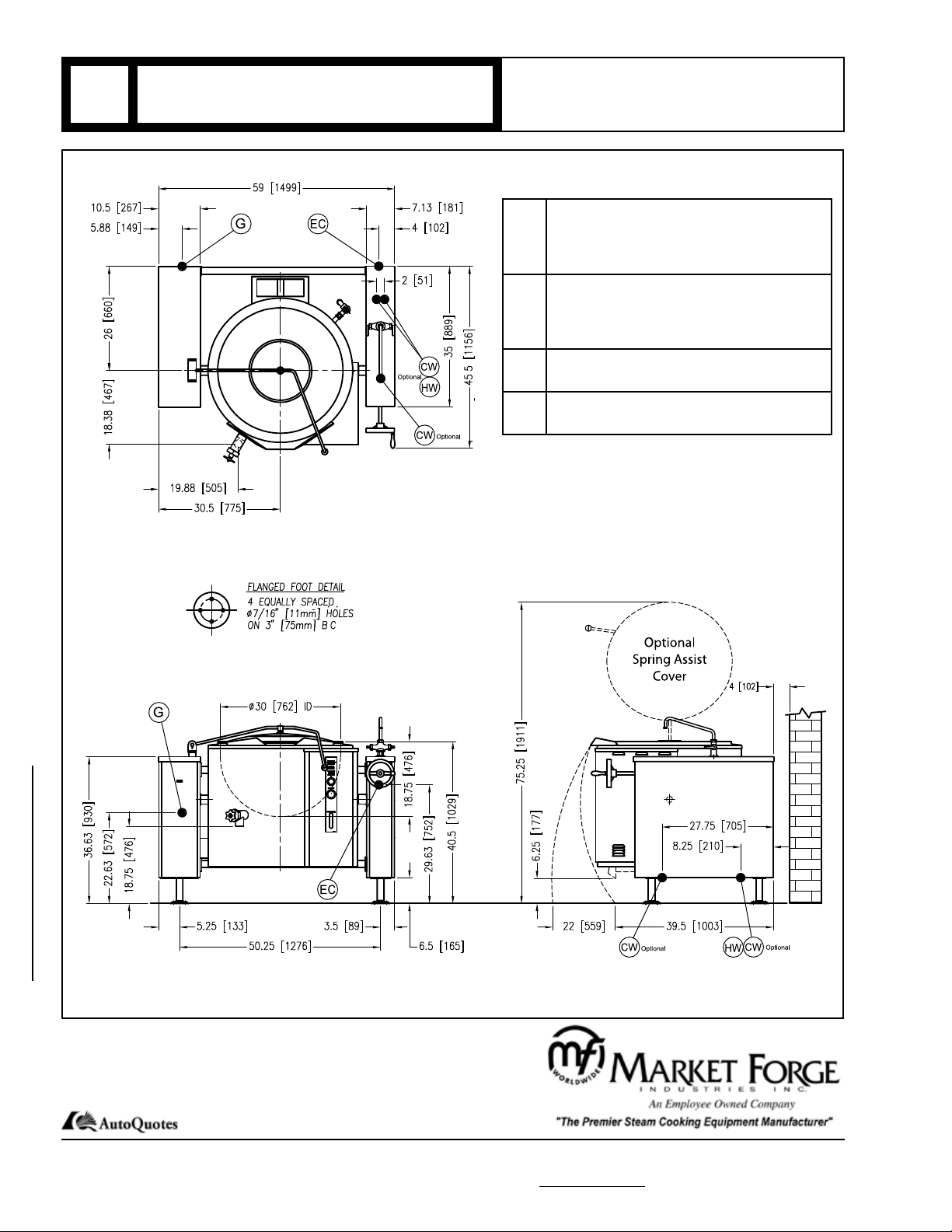

DETAILS & DIMENSION

SERVICE CONNECTIONS

Gas Operated

EC Electrical Connection - 120V, 60Hz,

1pH with grounding wire, unless other

wise specied. Includes a 6 foot and 3

prong plug. Total Max Amps: 4.0

G Gas Connection - 3/4” (19mm) N.P.T. a

gas shut-off valve must be installed in

supply piping convenient and adjacent

to unit.

CW Cold Water - 3/8” (10mm) O.D. tubing

to optional faucet.

HW Hot Water - 3/8” (10mm) O.D. tubing to

optional faucet.

▪ BTU/Hour: 120,000

▪ kW/Hour: 35.2

▪ Gas Supply (Supply Pipe Pressure W.C.)

- Natural 6”-14” (152-356mm)

- Propane 11”-14” (279-356mm)

▪ Minumum Clearance (Sides & Back) :

- 4” (102mm)

Full Jacketed Tilting Gas Kettle

FOOD SERVICE EQUIPMENT

It is our policy to build equipment which is design certied by U.L., E.T.L., A.S.M.E., N.S.F. and C.S.A. However, a continuing program of product improvement

makes it necessary to submit new models to the agencies as they are developed and consequently not all models bear the appropriate agency labels at all times.

Tel: (617) 387-47100 • Toll Free: (866) 698-3188 • Fax: (617) 387-4456 • Outside MA Fax: (800) 227-2659

35 Garvey Street • Everett • MA • 02149

E-Mail: custserv@mi.com • Website: w w w . m f i i . c o m

Loading...

Loading...