Page 1

OWNER’S MANUAL

Tilting Self-Contained

Gas Steam Jacketed Kettles

MODELS:

• FT-20GL • FT-40GL • FT-60GL • FT-80GL • FT-100GL

An Employee Owned Company

35 Garvey Street ● Everett ● MA ● 02149-4403 Form No. S-1922A

Tel: (617) 387-4100 ● Fax: (617) 387-4456 (MA)

Toll Free: (866) 698-3188 ● Outside MA Fax: (800) 227-2659

Customer Service: custserv@mi.com ● Visit Us At: www.mi.com

●

02/08

Page 2

TABLE OF CONTENTS

INSTALLATION ...............................................................................1-2

OPERATION ...................................................................................3

MAINTENANCE ..............................................................................4

TROUBLE-SHOOTING ..................................................................5

ILLUSTRA

WIRING ...........................................................................................13-14

TED PARTS LIST ...........................................................5-12

i

Page 3

INSTALLATION

Uncrate carefully. Report any hidden freight damage to

the freight company immediately.

Set unit in place. Be certain to maintain the following

minimum clearances to combustible construction. Side

“0” inches, back “4” inches at ue box. Level the unit

using a spirit level in all directions on the top of the kettle (lid up). Adjust the bottom foot on each leg to over-

come an uneven oor. Be certain to leave adequate

clearances for cleaning, maintenance and service. If

unit is also equipped with an optional water ll valve

it too must be connected with a exible water supply

tube, quick disconnect and strain relief.

Appliance location should have an exhaust system

provided directly above the appliance to exhaust

combustion generated by the gas burner. For use on

noncombustible oors. Minimum clearance from combustible and noncombustible constructions, sides “0”

inches, back “4” inches at ue box.

Clearance must be adequate in aisle and at the side

and back. Adequate clearances for air openings into

combustion chamber must be provided, as well as for

serviceability. All units must be installed in such a man-

ner that the ow of combustion and ventilation are not

obstructed. Provisions for an adequate air supply must

also be provided. Do not obstruct the lower front or left

side of the unit, as combustive air enters through these

areas.

DESCRIPTION: The kettle has double-wall construction of 300 series stainless steel forming a steam jacket

around the lower 2/3 of the kettle. The jacket enclosure

contains factory sealed water and antifreeze. The kettle

exterior is fully insulated. The bottom of the kettle is a

hemispherical design for superior heat circulation. The

recessed control panel is located on the front right side

of the unit in full view of the operator. Standard controls

include direct immersion thermostat, water sight glass,

cooking light, pressure gauge and electronic ignition

with ignition indicator light. Safety features include low

water cutoff with indicator light, pressure switch, pressure relief valve and a 100% safety gas shut off valve.

The kettle pivots on trunnions connected to the gear

and control consoles. The worm and gear tilting mechanism allows the kettle to tilt forward to a full 90° for

complete draining. The tilt mechanism is self locking

for positive stop action. The consoles are drip proof,

stainless steel clad and are supported on all welded 1

5/8” (41mm) diameter stainless steel legs with anged

feet.

kettle is A.S.M.E. code stamped for operation to 50

PSI. Temperature range from 150° F to 285° F.

120 VAC, 1pH, 50/60 Hz

OPTIONAL AT EXTRA COST:

Spring assist cover, HSC

2” tangent draw off, FDOR-2

3” tangent draw off, FDOR-3

Tri-Basket assembly

Single pantry faucet with swing spout, SP-12

Double pantry faucet with swing spout, DP-12

Graduated measuring strip, MS-1

Perforated strainer

Solid disk strainer DOS-2

316 stainless steel liner for high acid content

SERVICE CONNECTIONS: GAS INSTALLATION TO

CONFORM TO LOCAL CODES OR IN THE ABSENCE OF

LOCAL CODES TO NATIONAL FUEL GAS’ CODE - ANSI

Z223.l.- LATEST EDITION IN CANADA INSTALLATION IN

ACCORDANCE WITH CAN/CGA-B149.1 OR 0.2 OR CUR-

RENT CODE

The appliance and it’s individual shut-off valve

1.

.

must be disconnected from the gas supply piping

system during any pressure testing of that system at .test pressures in excess of 1/2 PSI (0.1

kg/cm2).

The appliance must be isolated from’ the gas sup-

2.

ply piping system by closing it’s individual manual

shut-off valve during any pressure testing of the

gas supply piping system at test pressures equal

to or less than 1/2 PSI (0.1 kg/cm2).

ELECTRICAL GROUNDING MUST BE PROVIDED IN ACCORDANCE WITH LOCAL CODES, OR IN THE ABSENCE

OF LOCAL CODES, WITH THE NATIONAL ELECTRIC

CODE, ANSI/NFPA 70 - LATEST EDITION’ IN CANADA

INSTALLATION IN ACCORDANCE WITH C.S.A. C22.1 CANADIAN ELECTRIC CODE PART 1.

WARNING: ELECTRICAL GROUNDING INSTRUCTIONS

UNITS EQUIPPED WITH A THREE-PRONG (GROUNDING) PLUG FOR YOUR PROTECTION AGAINST SHOCK

HAZARD AND SHOULD BE PLUGGED DIRECTLY INTO A

PROPERLY GROUNDED THREE-PRONG RECEPTACLE.

DO NOT CUT OR REMOVE THE GROUNDING PRONG

FROM THIS PLUG. (120 VOLT UNITS ONLY).

Units with these electrical rating are factory equipped

with a transformer.. To connect supply wire remove

top right cover and route supply wires and ground wire

through the hole in the back of console with strain relief

tting supplied. Connect wires to terminal block and

ground lug. Replace cover.

OPERATION SHALL BE BY: Natural or L.P. gas utiliz-

ing a high efciency power burner system. The steam

Wiring diagram for unit is located in side panel of the

left hand console facing the front of the unit..

1

Page 4

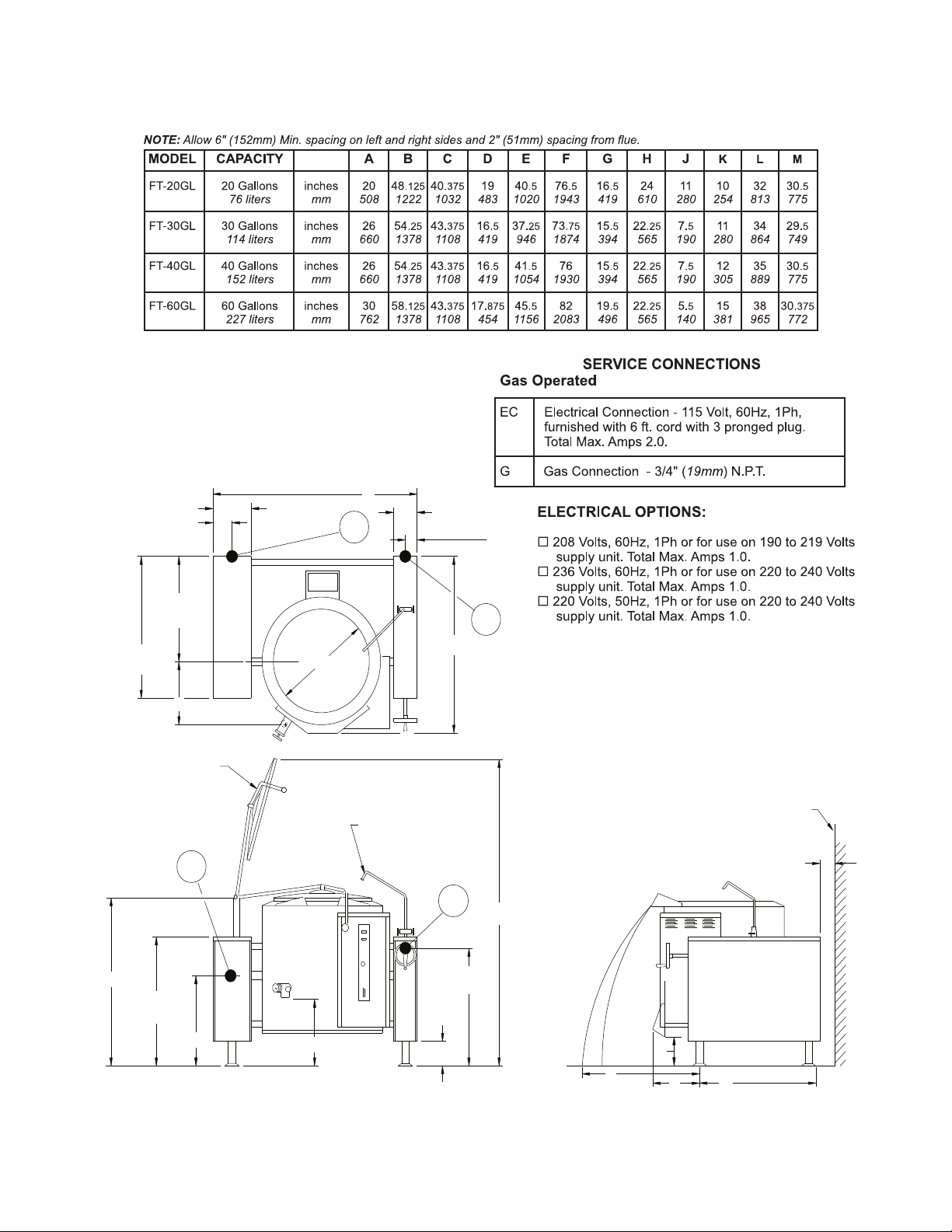

INSTALLATION

26�

660mm

35�

889mm

G

Optional Spring

Assist Cover

G

E

36 1/4�

921mm

H

D

EC

29�

736mm

6�

152mm

F

Optional Faucet

C

EC

6 1/4�

159mm

3 1/8�

79mm

10 1/4�

260mm

B

G

A

5 1/8�

130mm

Wall

4 Min.

102mm

J

K

M

L

Page 5

OPERATION

IMPORTANT NOTE: Unit is shipped with gas combi-

nation valve turned “ON”

OPEN MANUAL GAS SHUT OFF VALVE.

1.

WITH THERMOSTAT SET AT OFF.

2.

TURN POWER SWITCH ON.

3.

SET THERMOSTAT TO MAXIMUM, INITIATING

4.

A 30 SECOND PRE-PURGE.

NOTE: If after 36 seconds the burner fails to ig-

nite or burner lights then goes out the system goes

into safety lockout; de-energize the system by setting the thermostat to OFF for 5 minutes and try

again.

SET THERMOSTAT TO DESIRED TEMPERA-

5.

TURE SETTING.

DAILY SHUTDOWN

TURN POWER SWITCH OFF.

1.

TURN THERMOSTAT OFF.

2.

THERMOSTAT - The thermostat selects are de-

4.

sired internal kettle operating temperatures.

PRESSURE GAUGE - The pressure gauge indi-

5.

cates that internal operating pressure of the kettle. When cold, the gauge should indicate 25 to

30 inches mercury column vacuum. If it does not,

refer to “Re-establishing Vacuum” above this section. Under normal operation with the kettle empty

(thermostat set at 285oF) the pressure shall reach

38 PSI. When loaded the pressure may be considerably less.

SIGHT GLASS - The sight glass indicates the min-

6.

imum and maximum water level within the kettle.

If water level falls below minimum level more distilled water should be added. See “Adding Water”

section.

PRESSURE RELIEF VALVE - A safety device

7.

which prevents the internal kettle pressure from

ever exceeding 50 PSI. If should never be tampered with.

LOW WATER LIGHT COMES ON - ADD WATER

COMPLETE SHUTDOWN

TURN POWER SWITCH OFF.

1.

TURN THERMOSTAT OFF.

2.

TURN POWER SUPPLY TO UNIT OFF.

3.

REMOVE FRONT ACCESS PANEL ON LEFT

4.

SIDE AND TURN DIAL ON COMBINATION VALVE

TO OFF.

CLOSE MANUAL GAS SHUT OFF VALVE.

5.

FRONT PANEL CONTROLS

POWER SWITCH - This switch turns the main

1.

power to the unit on and off. If must be turned on to

heat the kettle. It should be turned of when kettle

will not be in use for long periods of time.

(RED) COOKING LIGHT - This light is on when-

2.

ever the main burner gas is on.

(AMBER) LOW WATER LIGHT - All kettles are

3.

supplied with sufcient distilled water in pressurized jacket. If at any time the water level falls be-

low that required for proper operation, the kettle

will not heat and this light will come on. See “Adding Water” Section.

Unit should be completely cold and off.

1.

Lift handle of pressure relief valve to release vac-

2.

uum in kettle.

Remove relief valve and attach a 3/4” NPT elbow

3.

pointing upward.

Using pure distilled water only, pour the water into

4.

the open end of the elbow (a funnel will be helpful).

Water will enter kettle slowly, as air must escape

through the same hole. Water should be added until water level is at the sight glass half way between

the minimum and maximum levels.

When sufcient water has been added, remove

5.

elbow and replace pressure relief for steam at 50

PSI.

Vacuum must be re-established.

6.

The total amount of distilled water in each kettle is:

FT-20GL - 6 Gallons of water

•

FT-30GL - 9 Gallons of water

•

FT-40GL - 9 Gallons of water

•

FT-60GL - 12 Gallons of water

•

3

Page 6

MAINTENANCE

PERIODIC MAINTENANCE

NOTICE: As a safety precaution, disconnect the power

supply during cleaning or servicing.

CLEANING

For easier cleaning add cold water to the kettle immediately after removing contents and let soak.

Wash exposed cleanable areas daily. To remove normal dirt, grease or product residue from stainless steel,

use ordinary soap and water applied with a sponge

or cloth. Dry thoroughly with a clean cloth. Never use

vinegar or any corrosion cleaner. Never, use ordinary

steel wool, wire brush or steel scouring pads. Never

use cleaning solvents with a hydrocarbon base on

control panel. Blower wheel inlet screen and motor air

vent should be cleansed if an accumulation of dust or

lint is obvious.

At least twice a year the unit venting system should be

examined and cleaned. At least twice a year have an

authorized Service Person clean and adjust the unit for

maximum performance.

RE-ESTABLISHING VACUUM

With the kettle completely cold a vacuum of 25 to 30

inches mercury column should be maintained as indicated by the pressure gauge on the front control

panel. If at any time the vacuum is less than 25 inches

M.C. the vacuum should be re-established. With the

kettle empty turn the thermostat knob to the highest

temperature. When the pressure gauge reaches 2.0

PSI turn thermostat off, open the pressure relief valve

until manometer reads 1 PSI then sharply release it.

This should remove the air and any loss in performance should return. Should the kettle fail to maintain

a vacuum after repeated attempts to establish it further

checks should be made to see if the pressure relief

valve is leaking or if there are any leaks in the pressure

relief valve piping, copper lines going to the pressure

switch, pressure gauge or thermostat tting.

ADJUSTMENTS

THERMOSTAT: The thermostat adjustment should not

be changed. Check the following before changing the

thermostat.

With kettle cold, the pressure on the pressure

1.

gauge should read 25 to 30 inches mercury column vacuum. If not, see “Re-establishing Vacuum”

above.

The pressure switch is .not set too high or too

2.

low and causing the out of adjustment condition.

A voltmeter should be used by a properly trained

servicemen to determine if the pressure switch or

thermostat is actually cycling the burners. If the

pressure switch is found to be the problem. See

“Pressure Switch” below.

PRESSURE SWITCH: The pressure switch should not

be adjusted until it is determined to be the cause of an

operating pressure difculty. See “thermostat” section

to determine if the source of difculty is the pressure

switch or thermostat, The major difculties caused by

pressure switch miss-adjustment are:

Pressure relief valve opening, especially on pre-

1.

heat from a cold start to 285oF (pressure switch

set too high).

Pressure in kettle is to low and burners are being

2.

shut down by pressure switch (not thermostat).

The pressure switch is preset for proper operation

from the factory. It is adjusted to the maximum pressure which will prevent the pressure relief valve from

opening. This setting will be slightly different on different kettles due to variations in the pressure relief

valves. During preheat to the maximum thermostat

setting (285oF), from either a cold condition or a lower

temperature setting, the temperature may overshoot

the thermostat setting and be shut down by the pressure switch. This is normal, however, after the kettle

has cycled several times (empty) the thermostat will

begin cycling the unit. .

TO ADJUST PRESSURE SWITCH:

With the kettle empty and completely cold, turn

1.

kettle on and set thermostat to maximum setting

(285oF).

Pressure in kettle (read pressure gauge on front

2.

panel) should reach a maximum pressure of 40

PSI and pressure relief valve should not open.

Kettle pressure may rise 3 or 4 PSI even afterburners shut down.

Relief valve should not open when kettle pressure

3.

is 40 PSI pressure switch setting is satisfactory.

If relief valve opens, reduce setting on pressure

4.

switch, cool kettle completely by running cold water through it and repeat this procedure.

If pressure in kettle is below 40 psi increase set-

5.

ting of pressure switch, cool kettle completely by

running cold water through it and repeat this procedure.

To obtain access to the pressure switch the front

6.

panel must be removed. Remove the screws on

either side of the panel. Be sure to support the

panel to avoid excessive strain on the wiring.

To increase the pressure switch setting turn the

7.

white ribbed knob clockwise; to decrease turn it

counterclockwise. Use the centre of the black ring

as an indicator.

4

Page 7

TROUBLE-SHOOTING

MOTOR WILL NOT RUN!

1. No Current.

2. Defective Thermostat.

3. Defective Motor.

4. Motor Overload Out.

5. Blown Fuse.

MOTOR RUNS, SPARK PRESENT

ON GAS IGNITION!

1. Manual Main Valve Off.

2. Miss-located Spark or Ground Rods.

3. Defective Valve.

4. Defective Primary Safety Control.

5. Air Shutter Open Too Far.

MOTOR RUNS, NO SPARK!

1. Defective Transformer.

2. Defective Spark Ignition.

3. Defective Spark Electrode (Cracked

Insulator).

4. Defective High Tension Wire.

5. Defective Centrifugal Switch on Motor.

FLAME BURNS ONLY ABOUT 6

SECONDS & SHUTS OFF!

1. Flame Rod or Flame Ground Misslocated.

2. Defective Flame Rod Wire.

3. Defective Primary Control.

NOTE: Loose, broken or grounded wiring may cause many of the

symptoms listed, Check all wiring make sure it is intact.

ILLUSTRATED PARTS

FIGURE 1.

ITEM PART NO. DESCRIPTION QTY.

1

2

3

4

5

6

7

8

9

10

11

12

13

*14

*

15

16

17

18

19

20

21

22

23

* SELECT AS REQUIRED.

97-5725 PILOT LIGHT - GREEN 24V 1

97-5423 INSTRUCTION LABEL 1

97-5424 L.W. MTG. BRACKET 1

97-5554 PROBE 1

97-5426 L.W. CUT OFF 1

97-5427 THERMOSTAT 1

97-5357 POLY PANEL 1

97-5429 POWER SWITCH 1

97-5430 PILOT LIGHT - RED 1

97-5431 PILOT LIGHT - AMBER 1

97-5559 DIAL 1

97-5433 PRESSURE GAUGE BRACKET 1

97-5002 PRESSURE GAUGE 1

97-5434 MTNG. BRKT (20, 30 & 40 GALLON ONLY) 1

97-3435 MTNG. BRKT (60 GALLON ONLY) 1

97-5436 SIHT GLASS 1

97-5437 PRESSURE SWITCH 1

97-5997 RELIEF VALVE 1

97-5032 FLANGE FOOT 4

10-6963 TERMINAL BLOCK 2

10-6962 END SECTION 1

97-5414 INTERLOCK SWITCH 1

97-5441 GROUND LUG 1

97-5415 VENT 1

5

SHORT FLAME!

1. Wrong Main Orice.

2. Low Gas Pressure.

3. Air Shutter Adjustment.

4. Main Manual Valve Partially Closed.

5. Inoperative Step Regulator Portion

of Main Valve.

LONG HAZY FLAME!

1. Wrong Main Orice.

2. High Gas Pressure.

3. Dirty Blower Wheel.

4. Air Shutter Adjustment.

5. Main Regulator Adjustment.

GAS FAILS TO SHUT OFF!

1. Dirt on Valve Seat.

2. Defective Main Valve.

Page 8

FIGURE 1.

ILLUSTRATED PARTS

6

Page 9

ILLUSTRATED PARTS

FIGURE 2.

ITEM PART NO. DESCRIPTION QTY.

10

11

12

1

2

3

4

5

6

7

8

9

97-5090 HANDWHEEL

97-5091 SET SCREW

97-5092 TILT SHAFT

97-5420 BUSHING

97-5094 WORM GEAR

97-5093 TENSION PIN

97-5095 THRUST BEARING

97-5096 JAM NUT

97-5845 KEY

97-5546 RETAINING RING

97-5416 SET SCREW

97-5098 SEGMENT GEAR

1

1

1

2

1

1

2

2

1

1

1

1

7

Page 10

FIGURE 3.

ILLUSTRATED PARTS

FIGURE 3.

ITEM PART NO. DESCRIPTION QTY.

**1

2

3

4

5

*

*

97-5829

98-6196

97-5902

97-5091

97-5090

97-5814

97-5832

CONSOLE COVER

CONSOLE COVER ASSY., FAUCET MOUNT (OPTIONAL)

SPACER, FAUCET MOUNT (OPTIONAL)

SET SCREW

HAND WHEEL

FRONT BEARING

TILT SHAFT

8

1

1

1

1

1

1

1

Page 11

ILLUSTRATED PARTS

FIGURE 3.

ITEM PART NO. DESCRIPTION QTY.

6

7

8

9

10

**11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

**30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

** NOT SHOWN.

** SELECT AS REQUIRED.

97-6494 TILT LABEL

97-5712 TRUNNION HOUSING ASSEMBLY

97-5845 KEY

97-5546 RETAINING RING

97-5737 ARM

97-5868 FLAT WASHER 3/8

97-5870 HEX SOCKET CAP SCREW, 3/8 -16 x 2- 1/8

97-5869 HEX SOCKET CAP SCREW, 3/8 -16x1- 1/4

97-5818 CHAIN LINK

97-5830 SCREW JACK

97-5735 BASE ASSEMBLY

97-5831 BASE BRACKET ASSEMBLY

97-5813 BEARING

97-5032 ADJUSTABLE FOOT

97-5732 SIDE PANEL

97-5738 TRUSS HEAD SLOT SCREW, 10-32 x 1/2

10-6963 TERMINAL BLOCK SECTION

10-6962 END SECTION

97-5848 EARTH ID TAG

97-5866 FLAT WASHER #10

97-5751 TRUSS HEAD PHILLIPS DRIVE, 10-32 x 1 1/4

97-5733 RD HEAD SLOT DRIVE SCREWS 8-32 x 1/4

97-5865 EXTERNAL TOOTH WASHER #8

97-5811 PIN

97-5872 HEX SOCKET SET SCREW 1/4 -20 x 1/2

97-5871 LOCK WASHER 3/8

97-5584 HEX NUT 3/8 - 16

97-5790 GREASE NIPPLE, 1/8 NPT

97-5652 FLAT WASHER 5/16

97-5739 HEX NUT 5/16 -18

97-5833 FLEXIBLE SHAFT GUIDE

97-5819 NYLON SHAFT GUIDE

97-5873 SET SCREW 1/4 -20 x 3/8

97-5741 EXTERNAL RETAINING RING

97-5815 KEY

97-6569 SPROCKET

97-5812 OUTPUT SHAFT

97-5816 SPROCKET

97-5817 CHAIN

1

1

1

1

1

**

1

8

1

1

1

1

2

2

1

10

2

1

1

2

2

3

3

1

1

**

7

1

2

2

1

2

1

1

2

1

1

1

1

9

Page 12

FIGURE 4.

ILLUSTRATED PARTS

FIGURE 4.

ITEM PART NO. DESCRIPTION QTY.

97-5530 HINGE ASSY - 20-40 GALLON KETTLE

10

1

2

3

4

5

6

6

7

8

9

97-5352 LOCK PIN

97-5343 END LOCK PLATE

97-5344 STATIONARY DISC

97-5698 CORES

97-5699 SPRING

97-5335 HANDLE ASSY- 20 GALLON KETTLE

97-5336 HANDLE ASSY - 30/40 GALLON KETTLE

97-5347 ROTARY DISC

97-5348 END STOP PLATE

97-5349 CAP SCREW

97-5337 KNOB

1

1

1

2

1

1

1

1

1

4

1

97-5464 HINGE ASSY - 60 GALLON KETTLE

10

1

2

3

4

5

6

7

8

9

97-5352 LOCK PIN

97-5343 END LOCK PLATE

97-5354 STATIONARY DISC

97-5345 CORES

97-5160 SPRING

97-5842 HANDLE ASSY

97-5352 ROTARY DISC

97-5356 END STOP PLATE

97-5545 CAP SCREWS

97-5337 KNOB

1

1

1

2

1

1

1

1

4

1

10

Page 13

ILLUSTRATED PARTS

FIGURE 5.

FIGURE 6.

FIGURE 6.

ITEM PART NO. DESCRIPTION QTY.

1.5”

VALVE

1

98-6155 98-6155 98-6155 NUT

2

3

4

5

6

7

-- -- -- HANDLE

97-5068 97-5069 97-5070 HEX ASSY NUT

97-5074 97-5072 97-5073 BONNET

97-5074 97-5074 97-5074 DISC & STEM ASSY

97-5077 97-5078 97-5079 O-RING

97-6496 97-6159 97-6497 VALVE BODY

2”

VALVE

3”

VALVE

1

1

1

1

1

1

1

11

Page 14

FIGURE 7.

ILLUSTRATED PARTS

12

Page 15

FIGURE 8.

WIRING

13

Page 16

FIGURE 9.

WIRING

14

Page 17

Loading...

Loading...