Page 1

DIRECT STEAM TILTING

D

MODELS: □ FT-6

STEAM JACKETED KETTLE

“DROP-IN”

□ FT-10

□ FT-12

□ FT-20

DESCRIPTION:

Will be a Market Forge Direct Steam, Tilting Countertop,

“Drop-In” Steam Jacketed Kettles, models:

MODEL CAPACITY SHIP WT.

□ FT-6

□ FT-10

□ FT-12

□ FT-20

Kettle will be constructed of welded satin nish, stainless steel type 304. A double wall kettle interior will form

a steam jacket around the lower 2/3 of the kettle. Kettle

bottom will be of elliptical design for improved heat cir-

culation. Type 316 stainless steel liner for high acid con-

tent products. Tubular stainless steel mounting frame will

have steam supply and condensate return pipes com-

pletely concealed within frame members.

Sealed stainless steel tilt mechanism bearings will permit the kettle to tilt forward 90o for complete emptying. A

removable operating handle with heat-proof knob can be

mounted on the left or right side of each kettle. Kettle will

be built to A.S.M,E. code and will be N.S.F. approved.

OPERATION WILL BE BY:

Direct steam at a minimum of 5 PSI (0.4 kg/cm2) and a

maximum of 50 PSI (3.4 kg/cm2).

6-Gallon

10-Gallon

12-Gallon

20-Gallon

(23 liter)

(38 liter)

(46 liter)

(76 liter)

44 lbs.

61 lbs.

70 lbs.

95 lbs.

JOB NAME: ________________________

ITEM NO.: _________________________

NO. REQUIRED: ____________________

FT-6

OPTIONAL:

□ One-piece lift-off stainless steel cover.

□ Stainless steel wire basket.

□ Double Pantry Faucet with Swing Spout and

Mounting Bracket.

□ Single Pantry Faucet with Swing Spout and Mounting

Bracket.

□ 1/2” (13mm) Leg-Mounted Steam Control Valve .

□ 1-1/2” (38mm) Draw-Off Valve with Strainer.

□ Steam Trap.

□ 18” High Floor Stand with Sliding Drain Pan.

□ 28” High Stainless Steel Cabinet Base with Hot and

Cold Water Fill Faucets, Depressed Area and Drains

Clean-Up Pan with Removable Splash Guard, and

Steam Control Valve on Stainless Steel Marine

Edged Countertop.

□ Check Valve.

□ 22” High Stainless Steel Cabinet Base with Hot and

Cold Water Fill Faucets, Depressed Area and Drains,

Clean-Up Pan with Removable Splash Guard, and

Steam Control.

SPEC SHEET: S-2189G

01/13

Countertop Direct Steam Kettle

FOOD SERVICE EQUIPMENT

The manufacturer reserves the right to modify materials and specications without notice.

35 Garvey Street • Everett • MA • 02149-4403

Tel: (617) 387-4100 • Toll Free: (866) 698-3188

Fax: (617) 387-4456 (MA and Overseas) • Fax: (800) 227-2659 (Ex. MA)

E-mail: custserv@mi.com • www.mi.com

Page 2

DIRECT STEAM TILTING

CR

S

D

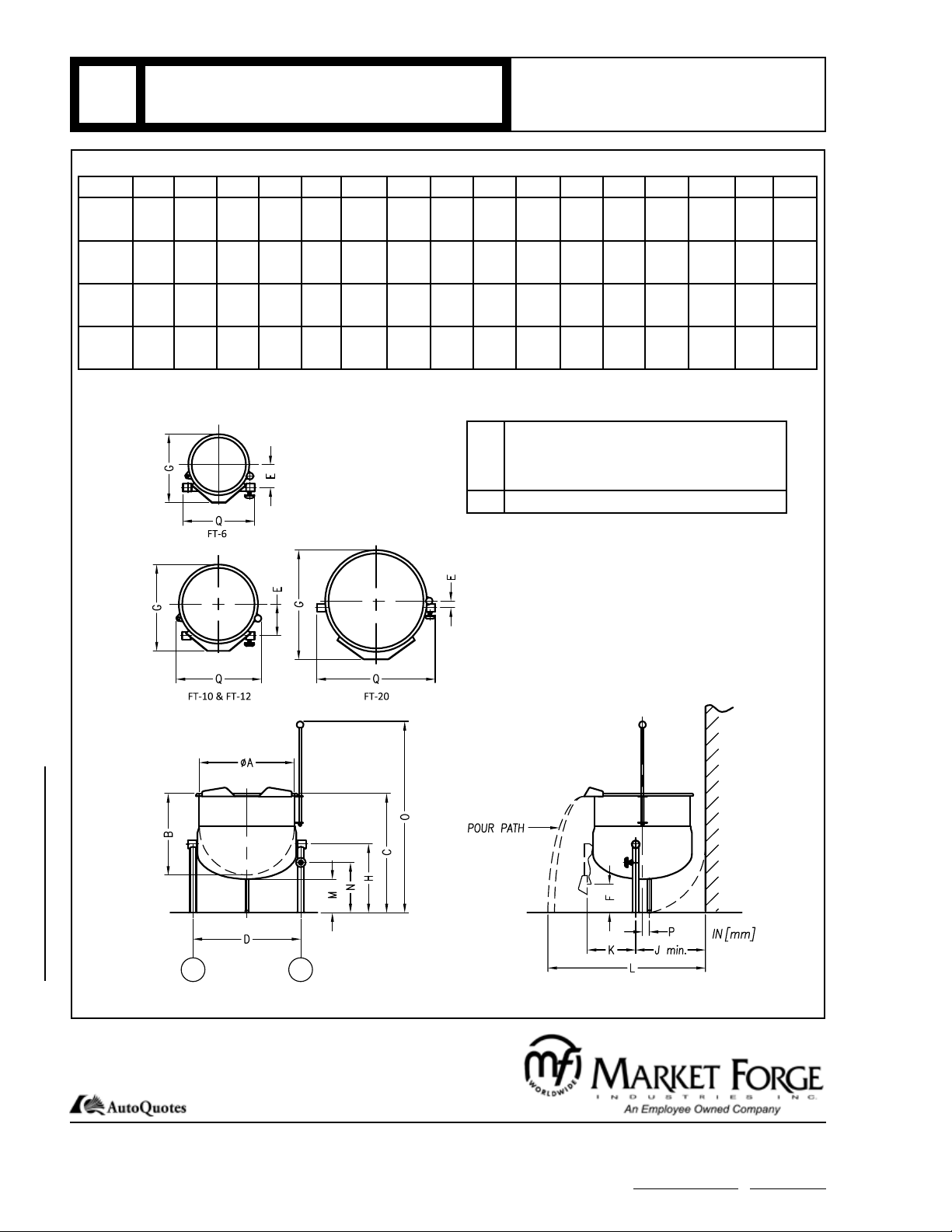

MODEL

FT-6 12 14.5 19.5 13.75 5 7.5 15.12 8.5 12.25 10.38 30.25 4 4.38 34.12 0 16

FT-10 16 15 18.5 13.75 7 7.75 19.12 9 13.25 8.88 32.25 2.38 4.88 33.12 0 19.25

FT-12 16 17 20.5 13.75 7 7.75 19.12 9 16.25 10.88 39.5 2.38 4.88 35.12 0 19.25

FT-20 21 18 26.5 23.5 1.5 6.25 24.12 15.25 15.75 10.5 40.5 7.5 11.12 42.38 1.5 26

STEAM JACKETED KETTLE

A B C D E F G H J K L M N O P Q

305 368 495 349 127 191 384 216 311 264 768 102 111 867 0 406

406 381 470 349 178 197 486 229 413 225 819 60 124 841 0 489

406 432 521 349 178 197 486 229 413 276 1003 60 124 892 0 489

533 457 673 597 38 159 613 387 400 267 1029 191 283 1076 38 660

“DROP-IN”

DIMENSIONS

SERVICE CONNECTIONS

Direct Connected

S Steam Supply - 1/2” (13mm) IPS, 15-50

PSI (1.0-305 kg/cm2). Pressure

reducing valve is required if incoming

pressure exceeds 50 PSI (3.5 kg/cm2)

CR Condensate Return - 1/2” (13mm) IPS.

DETAILS & DIMENSION

SPEC SHEET: S-2189G

01/13

FOOD SERVICE EQUIPMENT

Countertop Direct Steam Kettle

It is our policy to build equipment which is design certied by U.L., A.S.M.E, N.S.F. and C.S.A. However, a continuing program of product improvement makes

it necessary to submit new models to the agencies as they are developed and consequently not all models bear the appropriate agency labels at all times.

Installation Clearance: When installing kettles

against combustible/non-combustable surfaces (rear

walls) 1” (25mm) minimum clearance is required and

(side walls) 3” (76mm) minimum clearance is required.

NOTE: If steam generator to which kettle is to be

connected does not provide for condensate return,

a 1/2” (13mm) steam trap must not be installed. If

steam generator does not provide for condensate return, both a 1/2” (13mm) steam trap and 1/2” (13mm)

check valve must be installed.

PRINTED IN U. S. A. 35 Garvey Street • Everett • MA • 02149-4403

Tel: (617) 387-4100 • Toll Free: (866) 698-3188

Fax: (617) 387-4456 (MA and Overseas) • Fax: (800) 227-2659 (Ex. MA)

E-mail: custserv@mi.com • www.mi.com

Loading...

Loading...