Market Forge F-25PE Service Manual

F-PE, F-LE AND FT-LE SERIES

2/3 JACKETED ELECTRIC STATIONARY & TILTING KETTLES

PARTS AND SERVICE MANUAL

EFFECTIVE APRIL 6, 2016

The Company reserves the right to make substitution in the event that items specied are not available.

ERRORS: Descriptive and/or typographic errors are subject to correction.

Telephone: (802) 658-6600 Fax: (802) 860-3732 www.marketforge.com

Superseding All Previous Parts Lists.

MARKET FORGE

P/N 14-0358 Rev B

TABLE OF CONTENTS

MAINTENANCE ........................................................................3

TROUBLESHOOTING ..................................................................4

REPAIR AND REPLACEMENT ..........................................................5

ILLUSTRATED PARTS LIST

KETTLE ...............................................................................6

TILT CONSOLE ...................................................................... 10

CONTROL BOX ...................................................................... 12

HINGE ASSEMBLY ................................................................... 13

SPRING ASSIST HINGE ASSEMBLY .................................................. 14

SPRING ASSIST COVER ASSEMBLY

FOR FIELD INSTALLATION ON FT-LE MODELS ....................................... 15

DRAW-OFF VALVE ................................................................... 16

WIRING DIAGRAMS

F-20LE / F-20PE ..................................................................... 18

F-30LE / F-30PE ..................................................................... 23

F-40LE, F-60LE, F-80LE & F-100LE /

F-40PE, F-60PE, F-80PE & F-100PE .................................................. 28

FT-20LE ............................................................................. 33

FT-30LE ............................................................................. 38

FT-40LE, FT-60LE, FT-80LE & FT-100LE ............................................... 43

FT-40LE, FT-60LE, FT-80LE & FT-100LE

OPTIONAL 33 KW ................................................................... 48

APRIL 6, 2016 2 F-PE, F-LE & FT-LE SERIES ELECTRIC KETTLES

MAINTENANCE

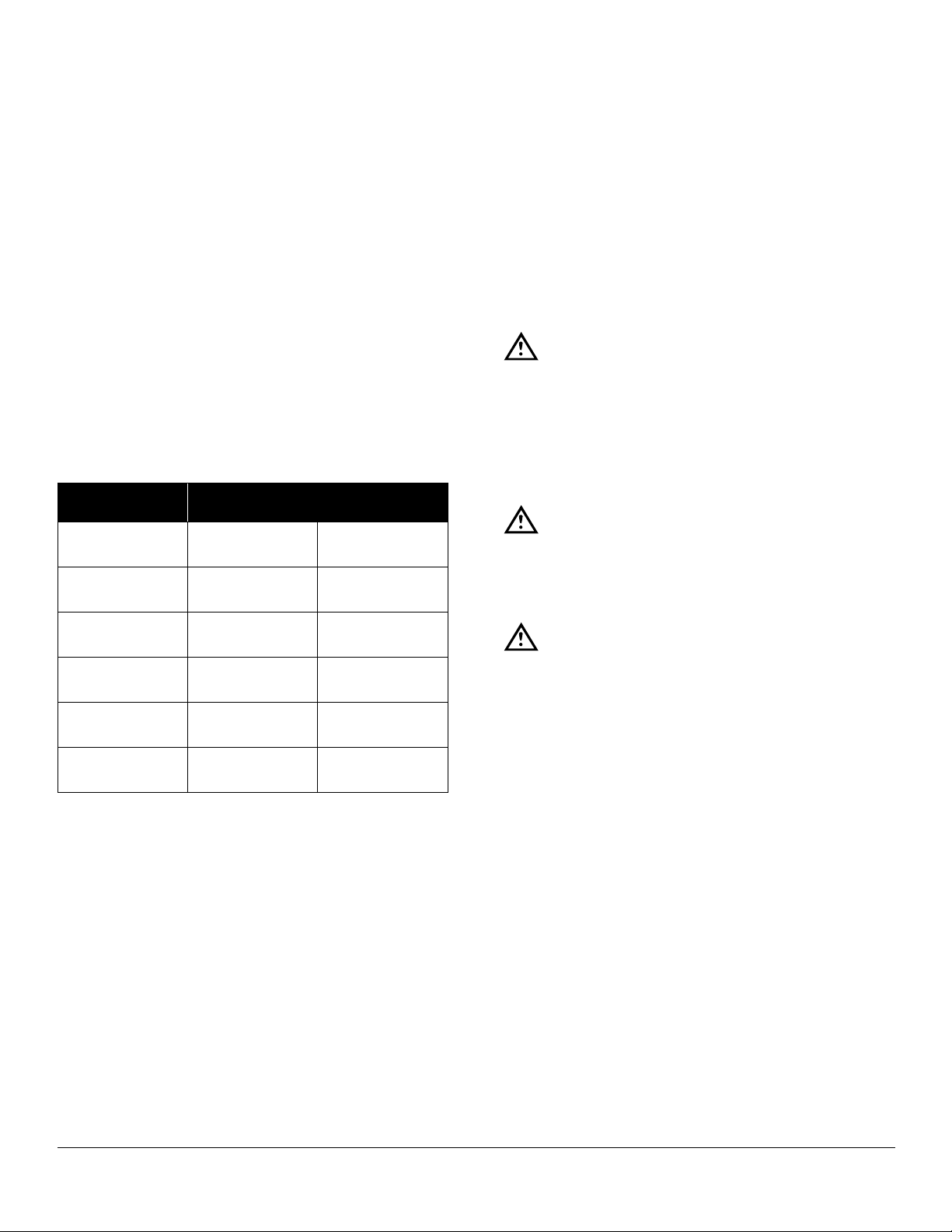

LOW WATER LEVEL

Proper water level must be maintained within the jacket

for the kettle to operate. Depletion of water may occur

from excessive opening of, or leakage through the safety

relief valve.

If water is below required operating level, either initially

at start-up or during use, the kettle will automatically shut

off, refuse to operate and the LOW WATER signal light

will come on.

In order for the kettle to operate, the following procedure

must be followed:

1. Trip the safety relief valve lever to relieve all pressure

from the kettle jacket.

2. At exterior rear of kettle jacket remove nut from Air

Vent.

3. Insert funnel into Air Vent opening and slowly add the

indicated amount of clean water for:

MODELS ADD

20 & 25 gallon

30 gallon

40 gallon

60 gallon

80 gallon

100 gallon

140 ounces

(4.14 litres)

150 ounces

(4.44 litres)

220 ounces

(6.50 litres)

250 ounces

(7.39 litres)

330 ounces

(10.05 litres)

420 ounces

(12.42 litres)

IF COMPLETELY

EMPTY, ADD:

376 ounces

(11.12 litres)

504 ounces

(14.90 litres)

548 ounces

(16.20 litres)

586 ounces

(17.33 litres)

850 ounces

(25.12 litres)

1088 ounces

(32.17 litres)

4. Replace Air Vent nut.

5. Follow Air Venting Instructions below.

6. Continue normal Operating Procedure of kettle.

AIR VENTING INSTRUCTIONS

Periodically check Pressure Gauge when the kettle is

cold. Reading should be in (green) VACUUM zone between 20 to 25, otherwise air is present and efcient heating will not occur.

To remove air, set Thermostat Knob at 8 and heat empty

kettle until TEMPERATURE pilot light goes off.

Open Air Vent nut one full turn for 10 seconds to exhaust

air from kettle jacket. Close Air Vent nut.

SAFETY VALVE MAINTENANCE AND TESTING

CAUTION

Under normal operating conditions a “try lever

test” should be performed every two months.

Under severe service conditions, or if corrosion and/or deposits are noticed within the

valve body, testing must be performed more

often. A “try lever test” should also be performed at the end of any non-service period.

CAUTION

Hot, high pressure uid may be discharged

from body drain and vent during “try lever”

test. Care must be taken to avoid any bodily

contact.

CAUTION

High sound levels may be experienced during

“try lever” test. Wear proper safety equipment

and exercise extreme care! Test at, or near,

half of the operating pressure by holding the

test lever fully open for at least two seconds

to ush the valve seat free of sediment and

debris. Then release lever and permit the

valve to snap shut.

If lift lever does not activate, or there is no

evidence of discharge, turn off equipment immediately and contact a licensed contractor or

qualied service personnel.

APRIL 6, 2016 3 F-PE, F-LE & FT-LE SERIES ELECTRIC KETTLES

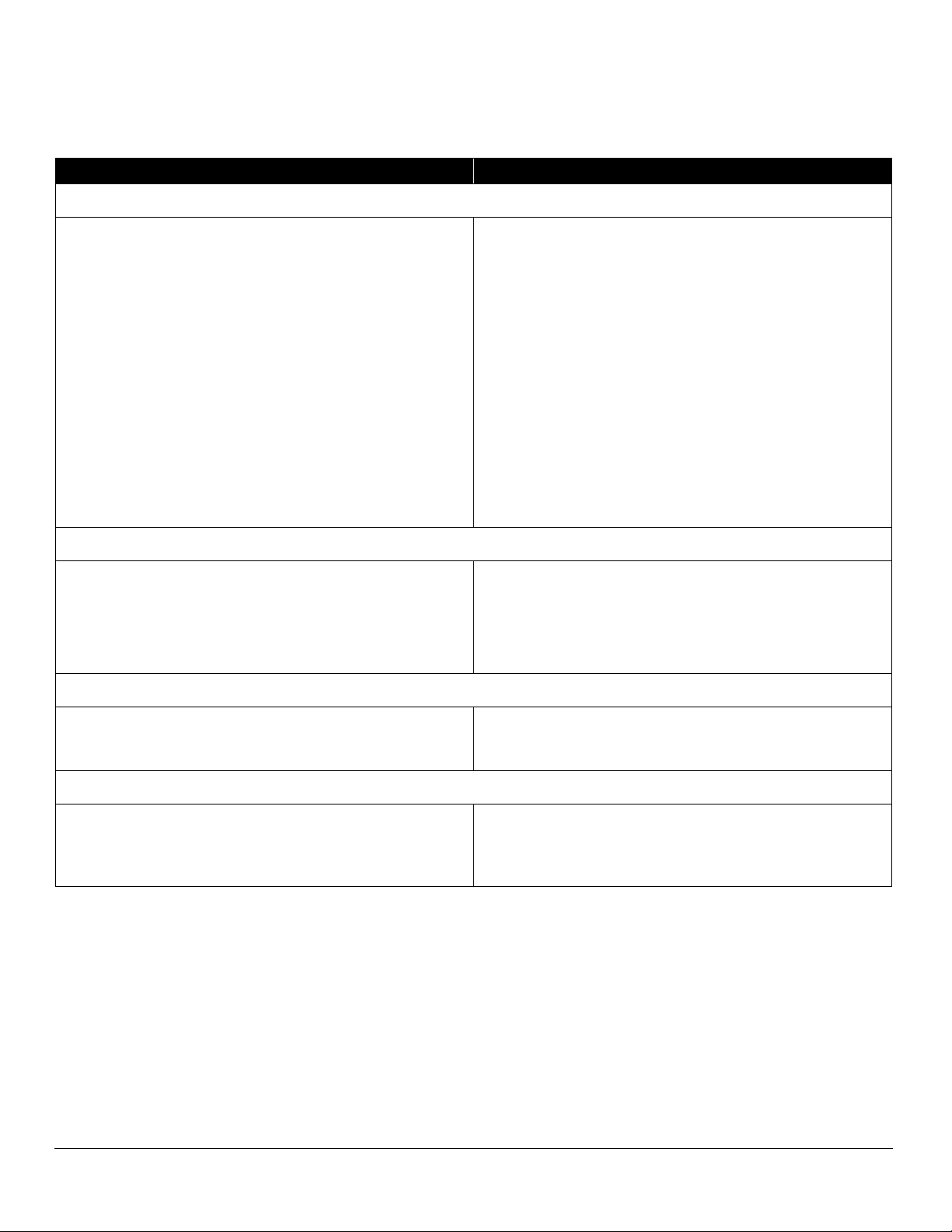

TROUBLESHOOTING

The table below gives information to assist service personnel in locating the general source of the problems, which occur

with the self-contained kettles. Before attempting to locate the source of difculty described, the technician should be familiar with basic functioning described in basic functioning under the introduction section.

PROBLEM (PROBABLE CAUSE) REMEDY

1. Indicator light fails to light with switch in ON position and thermostat dial set.

a. Power to kettle is OFF.

b. Kettle tilted (FT__LE Only).

c. Low water level in steam jacket, low water light on.

d. Indicator light burned out.

e. Faulty power switch.

f. Faulty thermostat.

g. Faulty tilt interlock switch of time delay (FT__LE Only).

h. Faulty level control.

i. Faulty wiring.

2. Kettle not hot enough to boil water with thermostat dial set at “10”.

a. Air in kettle jacket.

b. Faulty relief valve.

c. Burned out heating element.

a. Locate external circuit breaker shut-off for incoming

power and place in ON position.

b. Return to full vertical position.

c. Fill jacket.

d. Replace light.

e. Replace switch.

f. Replace thermostat.

g. Replace as required.

h. Replace control.

i. Inspect condition of wire and tightness of all connec-

tors. Correct as required.

a. Open bleed vent one full turn for 10 seconds and

close.

b. Replace valve.

c. Refer to #4. Heating Element Replacement.

3. Low water light on.

a. Low water level in jacket.

b. Defective level control.

4. Kettle hard to tilt (FT__LE models only).

a. Gears dry.

b. Worn trunnion bearings.

a. Fill jacket (refer to operating instructions).

b. Replace control.

a. Apply high quality bearing grease inside console.

b. Disassemble left and right side bearings and replace

as required.

APRIL 6, 2016 4 F-PE, F-LE & FT-LE SERIES ELECTRIC KETTLES

REPAIR AND REPLACEMENT

#1 GENERAL

In the parts section of this manual contains a listing of

alI replaceable parts and associated illustrations of the

kettle. Disassembly procedures will be obvious from the

illustrations, When replacing probes or gauges in the

steam jacket, it is essential to install replacements so as

to obtain a pressure tight seal. Tape sealant should be

used.

#2 MODEL SERIES FT__LE DISASSEMBLY

All controls are accessed by lowering the kettle to the full

tilt position and removing screw and bottom cover. The

tilting gear mechanism is contained inside the console.

Removal of screw and console cover permits access to

gears for service and periodic application of gear grease.

#3 MODEL SERIES F-__PE DISASSEMBLY

To access controls, screw is removed and bottom cover

F-__PE

1. Lay kettle on cover hinge.

2. Remove screws from both

halves of bottom cover.

3. Remove each cover half

separately,

4. Remove nuts from element

5. Remove element.

6. Install new element.

7. Reverse steps 1-4.

F-__LE

1. Lay kettle on cover hinge.

2. Remove anged foot from each leg.

3. Remove screws from bottom cover.

4. Remove cover.

5. Remove, nuts from element.

6. Remove element.

7. Install new element.

8. Reverse steps 1-5.

is slid down to the oor, Repair and testing of contactors

and water level contactors assisted by loosening the separate mounting plate for these components. For all other

controls, it is necessary to reach up inside the kettle.

NOTE: For more extensive repair, it is possible to disas-

semble the pedestal mounting and lift the kettle

off the base plate. After repairs are completed,

the base plate cover must be resealed to the oor

and the pedestal using Silicone sealant.

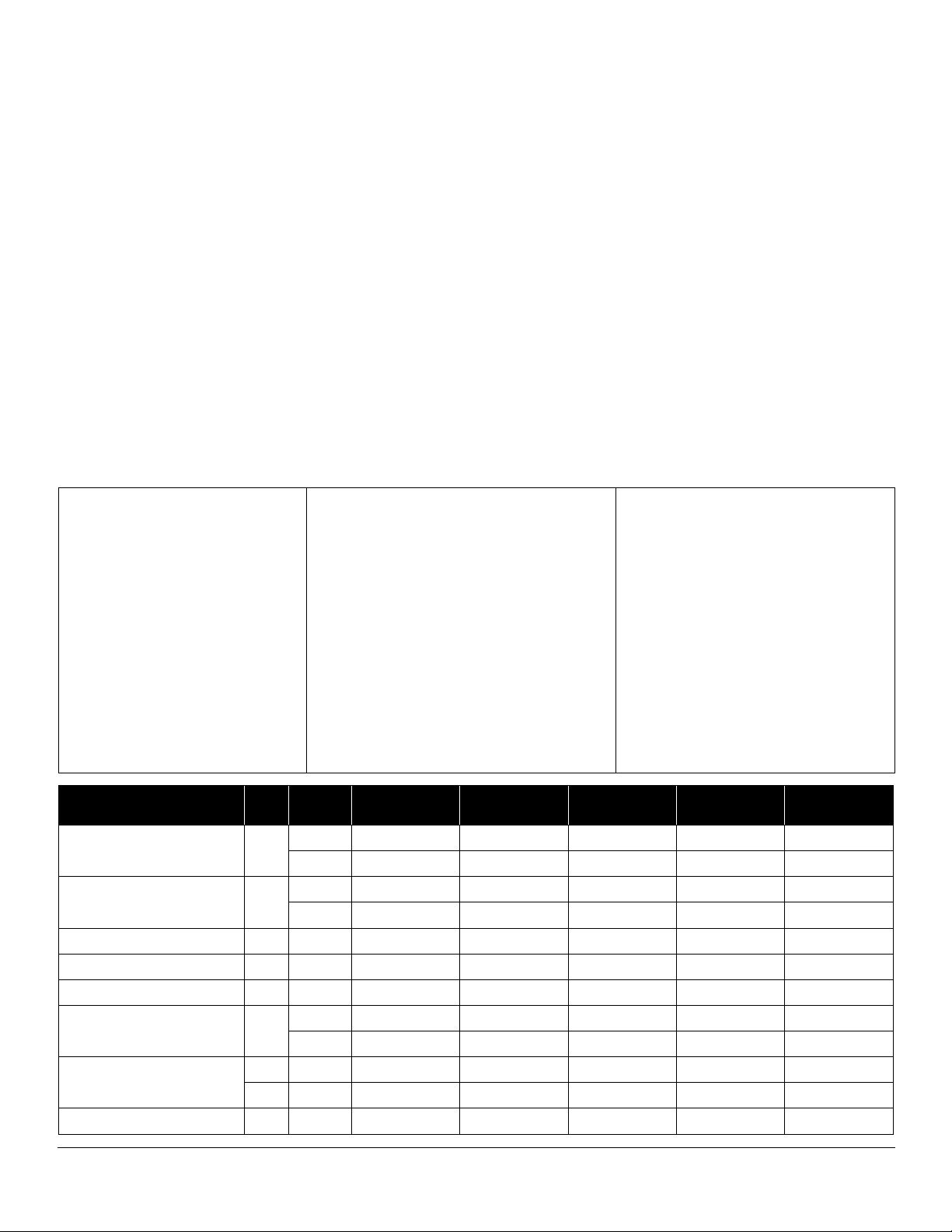

#4 HEATING ELEMENT REPLACEMENT

Heating elements are replaceable. The kettle is equipped

with three separate protective features – a low water level

control, a tilt shut-off switch and a thermostat control.

Defective elements are isolated by testing each element

with an ohmmeter. If a zero ohm reading cannot be obtained for any element, it is defective.

To replace defective element, proceed as follows:

FT__LE

1. Lay kettle on cover hinge (if so

equipped) or on rear of kettle.

2. Remove screws from bottom

cover.

3. Remove cover.

4. Remove nuts from element.

5. Remove element.

6. Install new element.

7. Reverse steps 1-4.

MODELS KW PHASE

20 gallon kettles 12

30 gallon kettles 15

40 gallon kettles 24 3 67 58 29 63 58

60 gallon kettles 24 3 67 58 29 63 58

80 gallon kettles 24 3 67 58 29 63 58

F-100PE 24

FT-100LE

Optional

F-100LE 24 3 67 58 29 63 58

24 3 67 58 29 63 58

33 3 91.6 79.4 39.7 50.1 45.9

1 57 50 25 - -

3 34 29 15 32 29

1 73 63 32 - -

3 42 37 18 40 37

1 115 100 50 - -

3 67 58 29 63 58

280VAC

AMP

240VAC

AMP

480VAC

AMP

220/380VAC

AMP

240/415VAC

AMP

APRIL 6, 2016 5 F-PE, F-LE & FT-LE SERIES ELECTRIC KETTLES

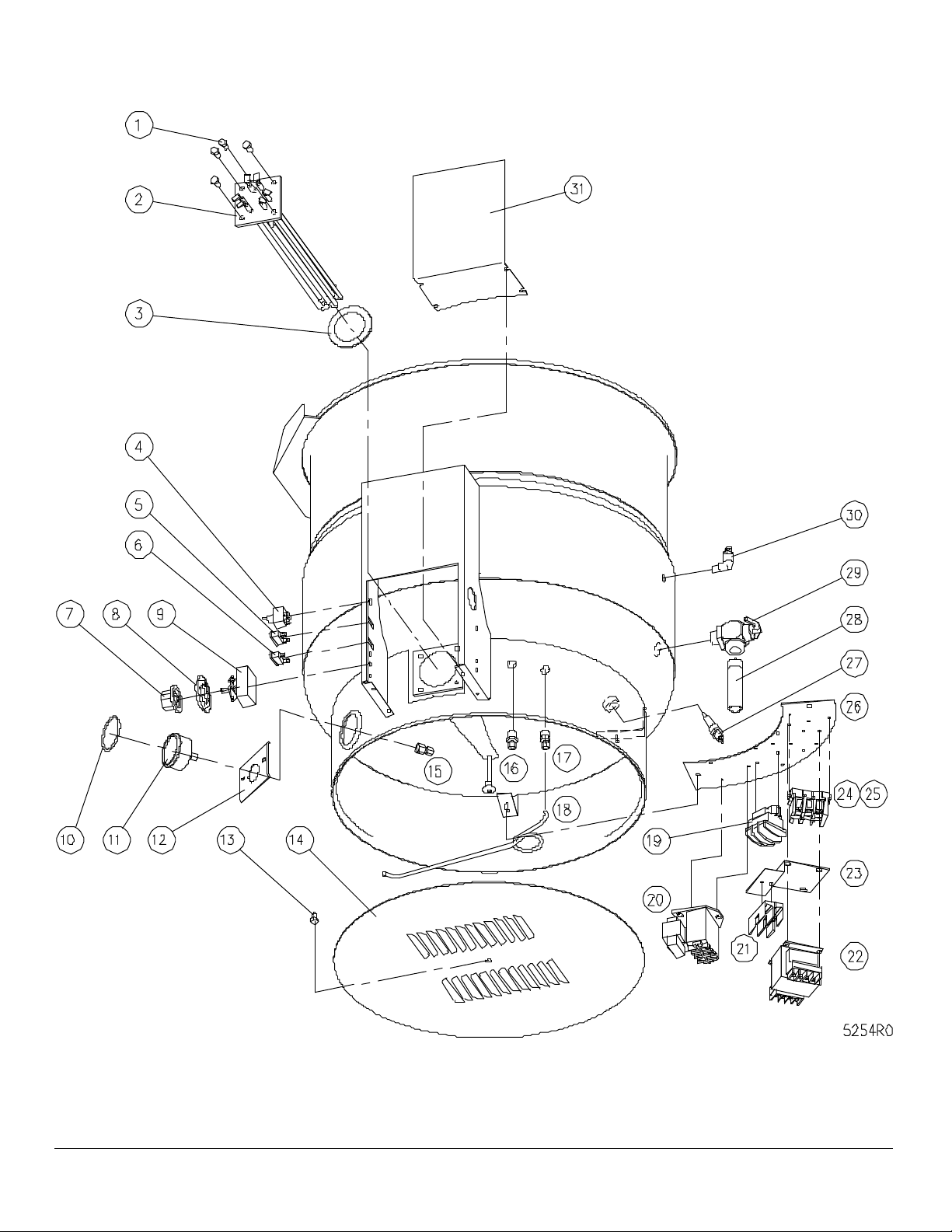

KETTLE

APRIL 6, 2016 6 F-PE, F-LE & FT-LE SERIES ELECTRIC KETTLES

KETTLE

ITEM PART NO. DESCRIPTION

20 30 40 60/80 100

1 97-6392 Hex Bolt, 5/16 - 18 x 3/4" 4 4 4 4 4

**2 97-5019 Element Assembly, 208V, 12 kW 1

97-5020 Element Assembly, 220/380V, 12 kW 1

97-5021 Element Assembly, 240/416V, 12 kW 1

97-5022 Element Assembly, 480V, 12 kW 1

-- Element Assembly, 600V, 12 kW 1

97-5033 Element Assembly, 208V, 15 kW 1

97-5034 Element Assembly, 220/380V, 15 kW 1

97-5035 Element Assembly, 240/416V, 15 kW 1

97-5036 Element Assembly, 480V, 15 kW 1

-- Element Assembly, 600V, 15 kW 1

97-5037 Element Assembly, 208V, 18 kW 1 1

97-5038 Element Assembly, 220/380V, 18 kW 1 1

97-5039 Element Assembly, 240/416V, 18 kW 1 1

97-5040 Element Assembly, 480V, 18 kW 1 1

-- Element Assembly, 600V, 18 kW 1 1

97-5127 Element Assembly, 208V, 24 kW 1 1

-- Element Assembly, 220/380V, 24 kW 1 1 1

97-5128 Element Assembly, 240/416V, 24 kW 1 1 1

97-5130 Element Assembly, 480V, 24 kW 1 1 1

-- Element Assembly, 600V, 24 kW 1 1 1

97-5893 Element Assembly, 208V, 33 kW 1 1 1

-- Element Assembly, 220/380V, 33 kW 1 1 1

-- Element Assembly, 240/416V, 33 kW 1 1 1

97-5876 Element Assembly, 480V, 33 kW 1 1 1

-- Element Assembly, 600V, 33 kW 1 1 1

** SELECT AS REQUIRED

QUANTITY

ITEM PART NO. DESCRIPTION QTY

3 97-5025 Element Gasket

4 97-6513 Power Switch

5 -- Pilot Light - Low Water

6 -- Pilot Light - Temperature 1

7 97-5339 Dial 1

8 97-5012 Bezel 1

9 -- Thermostat 1

10 97-5620 “O” Ring 1

11 97-5002 Pressure Gauge 1

APRIL 6, 2016 7 F-PE, F-LE & FT-LE SERIES ELECTRIC KETTLES

KETTLE

ITEM PART NO. DESCRIPTION QTY

12 97-5147 Pressure Gauge Mounting Plate 1

13 -- Hex Bolt, 5/16 - 18 x 1/2" 1

**14 97-5051 Bottom Cover, (3041-7), FT-20LE 1

-- Bottom Cover, (3041-8), FT-30LE 1

-- Bottom Cover, (3041-9), FT-40LE 1

-- Bottom Cover, (3041-10), FT-60LE 1

-- Bottom Cover, (3041-11), FT-80LE 1

-- Bottom Cover, (3041-12), FT-100LE 1

-- Bottom Cover, (3041-1), F-20LE 1

-- Bottom Cover, (3041-2), F-30LE 1

-- Bottom Cover, (3041-3), F-40LE 1

-- Bottom Cover, (3041-4), F-60LE 1

97-5088 Bottom Cover, (3041-5), F-80LE 1

-- Bottom Cover, (3041-6), F-100LE 1

97-5080 Bottom Cover, F-20PE 1

-- Bottom Cover, F-30PE 1

-- Bottom Cover, F-40PE 1

97-5714 Bottom Cover, F-60PE 1

-- Bottom Cover, F-80PE 1

-- Bottom Cover, F-100PE 1

15 97-5046 Connector, 1/4 cc x 1/4 FPT 1

16 97-5619 Connector, Thermostat 1

17 97-5000 Connector, 1/4 cc x 3/8 MPT 1

18 -- Copper Tube 1/4 x 26", 20 Gallon 1

97-6382 Copper Tube, 1/4 x 28", 30, 40 Gallon 1

-- Copper Tube, 1/4 x 29", 60 Gallon 1

-- Copper Tube, 1/4 x 33", 80 Gallon 1

-- Copper Tube, 1/4 x 35", 100 Gallon 1

**19 97-5609 Contactor, 208, 220, 240V - 12, 15, 18 kW 2

97-5609 Contactor, 380, 220/380, 416, 240/416, 480, 600V, -12, 15, 18 kW 1

97-5610 Contactor, 208, 220, 240V- 24 kW 2

97-5610 Contactor, 480, 600V, 24 kW 1

97-5611 Contactor, 208, 220, 240V - 33 kW 2

97-5611 Contactor, 480, 600V -33 kW 1

20 97-6527 Level Control 1

**21 98-6187 Fuse Block, 600V (380V - 600V) 2

98-6188 Fuse, 1/2 Amp., 600V (380V-600V) 2

97-5476 Fuse, 250V, 3A (208-240V) 2

APRIL 6, 2016 8 F-PE, F-LE & FT-LE SERIES ELECTRIC KETTLES

KETTLE

ITEM PART NO. DESCRIPTION QTY

97-5864 Fuse Holder, (208-240V) 2

97-5476 Fuse, 250V, 3A, (220/380V and 240/415V) 1

97-5864 Fuse Holder (220/380V and 240/415V) 1

**22 97-5616 Transformer, 380-220, 50/60 Hz, 100VA 1

97-5616 Transformer, 415-220, 50/60 Hz, 100VA 1

97-5613 Transformer, 480-240, 60 Hz, 100VA 1

98-6191 Transformer, 600-240, 60 Hz, 100VA 1

23 97-6376 Transformer Fuse Block Mounting Bracket 1

24 98-6186 End Section 1

25 98-6185 Terminal Block Section 3

* 97-6586 Rail 1

**26 -- Component Mounting Plate (2781-1), 20 Gallon 1

-- Component Mounting Plate (2783-1), 30 Gallon 1

-- Component Mounting Plate (2782-1), 40 Gallon 1

-- Component Mounting Plate (2784-1), 60 Gallon 1

-- Component Mounting Plate (2785-1), 80, 100 Gallon 1

27 97-5425 Probe 1

28 97-6368 Down Tube 1

29 97-5009 Relief Valve 1

30 97-5415 Air Vent Assembly 1

**31 97-5658 Control Box Cover (6880-1), 20 Gallon 1

-- Control Box Cover (6880-2), 30 Gallon 1

-- Control Box Cover (6880-3), 40 Gallon 1

-- Control Box Cover (6880-4), 60 Gallon 1

-- Control Box Cover (6880-5), 80 Gallon 1

-- Control Box Cover (6880-6), 100 Gallon 1

*32 97-5647 Control Panel Decal, 30 Gal. 1

-- Control Panel Decal, 40 Gal.

-- Control Panel Decal, 60 Gal.

-- Control Panel Decal, 80 Gal.

-- Control Panel Decal, 100 Gal.

97-5646 Decal (20 Gallon) 1

* NOT SHOWN.

** SELECT AS REQUIRED.

APRIL 6, 2016 9 F-PE, F-LE & FT-LE SERIES ELECTRIC KETTLES

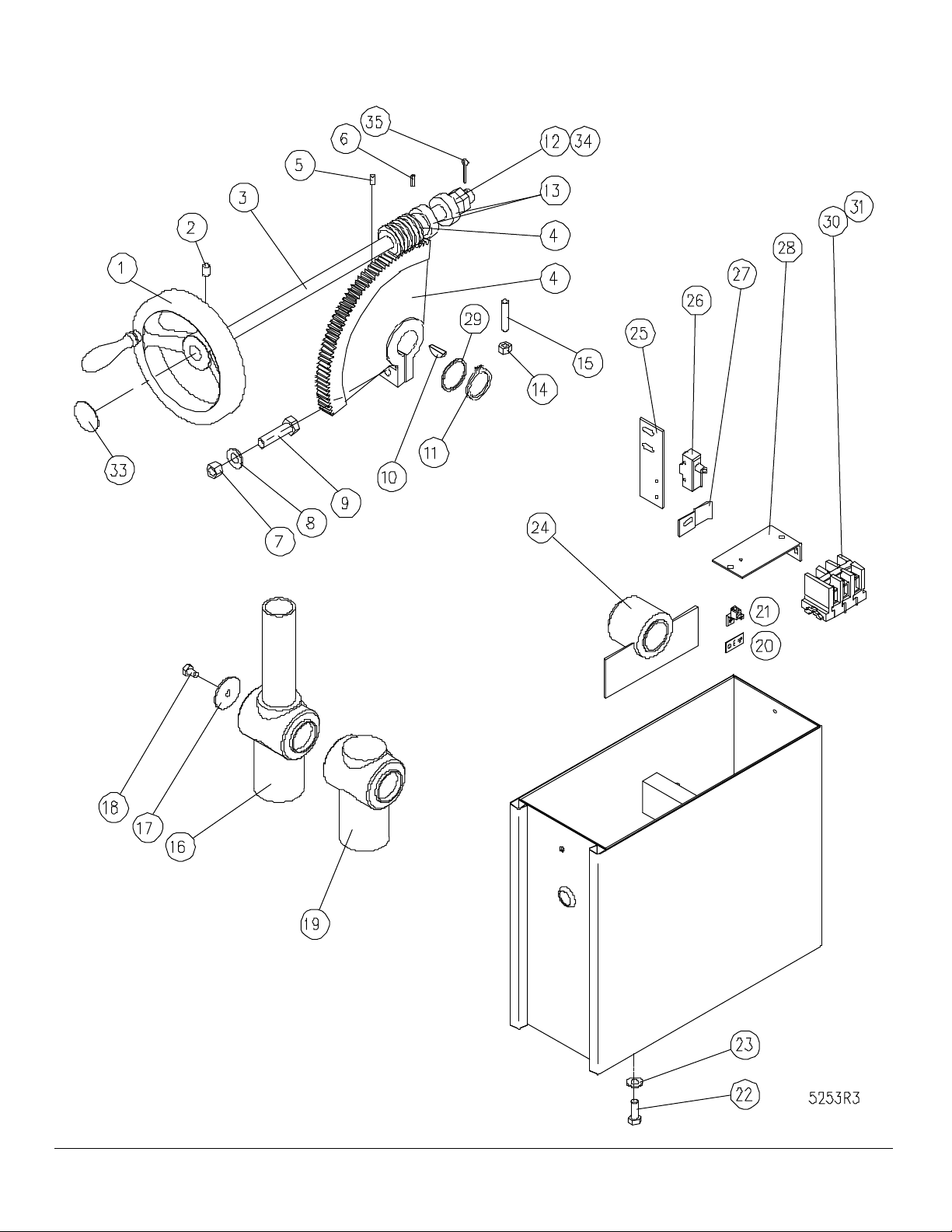

TILT CONSOLE

APRIL 6, 2016 10 F-PE, F-LE & FT-LE SERIES ELECTRIC KETTLES

TILT CONSOLE

ITEM PART NO. DESCRIPTION QTY

1 97-5090 Hand Wheel 1

2 97-5091 Set Screw 3/8 -16 x 1/2" 1

3 -- Tilt Shaft 1

4 97-5822 Segment Gear & Worm Gear Kit (Includes 5 to 11)

5 97-5416 Set Screw, 1/4 - 20 x 1/2 1

6 97-5093 Tension Pin, 3/16 Diameter x 1-1/4" L 1

7 -- Nut 1/2 - 13 1

8 -- Lock Washer, 1/2" 1

9 -- Bolt 1/2 - 13 x 2" 1

10 97-5652 Key Woodruff 1

11 97-5546 Retaining Ring 1

12 97-5096 Jam Nut 2

13 97-5909 Thrust Bearing 2

14 97-5584 Nut, 3/8 - 16 1

15 97-5365 Set Screw, 3/8 - 16 x 1 3/4" 1

16 97-5670

17 97-5368 Stainless Steel Washer 1

18 97-5883 Bolt 1

19 97-5669 Out bore Bearing 1

20 -- Ground ID Tag 1

21 97-5052 Ground Lug 1

22 -- Bolt 3/8-16 x 1" 4

23 -- Lock Washer 3/8" 4

24 97-5547 Block Bearing 1

25. -- Micro Switch Bracket 1

26 97-5414 Micro Switch 1

27 -- Micro Switch Activator Bracket 1

28 -- Terminal Block Bracket 1

29 -- Spacer, 1/16" Thick As Required

30 98-6185 Terminal Block 3

31 98-6186 End Section 1

* 97-6586 Rail 1

* 32. -- Screw, Console Cover, 10 - 32 x 1/2" 1

33 -- Decal - Tilt 1

34 97-5820 Washer, 3/4 ID x 1-1/4" OD 1

35 97-5821 Cotter Pin S.S. 3/16" x 1" L. 1

* NOT SHOWN

Out bore Bearing complete with extension - used on spring assist covers only specify model.

1

APRIL 6, 2016 11 F-PE, F-LE & FT-LE SERIES ELECTRIC KETTLES

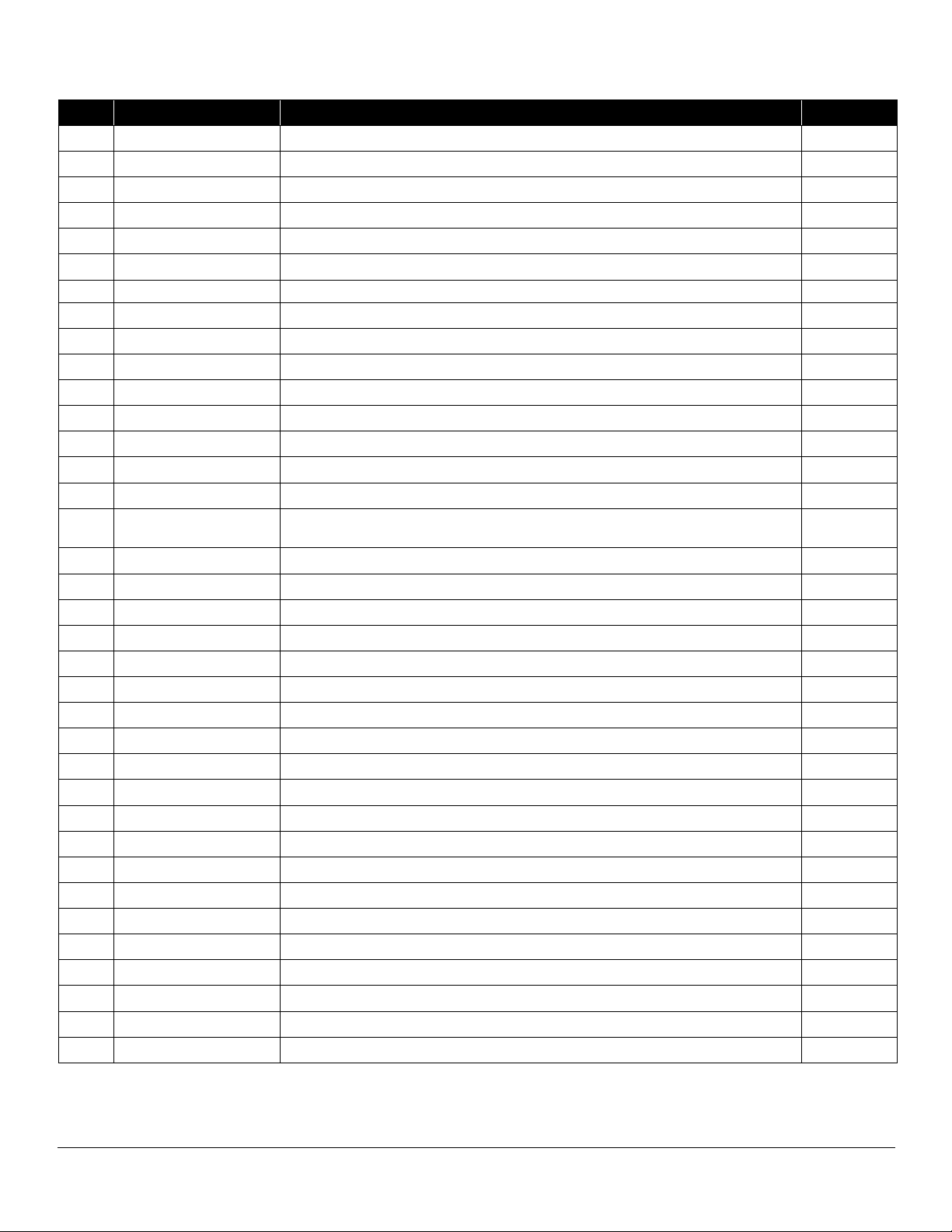

CONTROL BOX

ITEM PART NO. DESCRIPTION QTY

1 97-5032 Adjustable Flanged Foot 3

2 -- Console Box 1

3 -- Console Cover 1

4 -- Screw 10 - 32 x 1/2" 1

APRIL 6, 2016 12 F-PE, F-LE & FT-LE SERIES ELECTRIC KETTLES

HINGE ASSEMBLY

ITEM PART NO. DESCRIPTION QTY

1 97-5008 Knob 1

** 2 97-5596 Handle Assembly, 20 Gallon Kettle 1

97-5597 Handle Assembly, 30 Gallon Kettle 1

97-5598 Handle Assembly, 40 Gallon Kettle 1

3 97-5200 Bolt 2

4 97-5579 Fiber Washer 4

5 97-5601 Nut 2

6 97-5471 Cover, 20 Gallon Kettle 1

97-5723 Cover, 30 Gallon Kettle 1

97-5053 Cover, 40 Gallon Kettle 1

97-5054 Cover, 60 Gallon Kettle 1

97-5594 Cover, 80 Gallon Kettle 1

97-5595 Cover, 100 Gallon Kettle 1

* * SELECT AS REQUIRED

APRIL 6, 2016 13 F-PE, F-LE & FT-LE SERIES ELECTRIC KETTLES

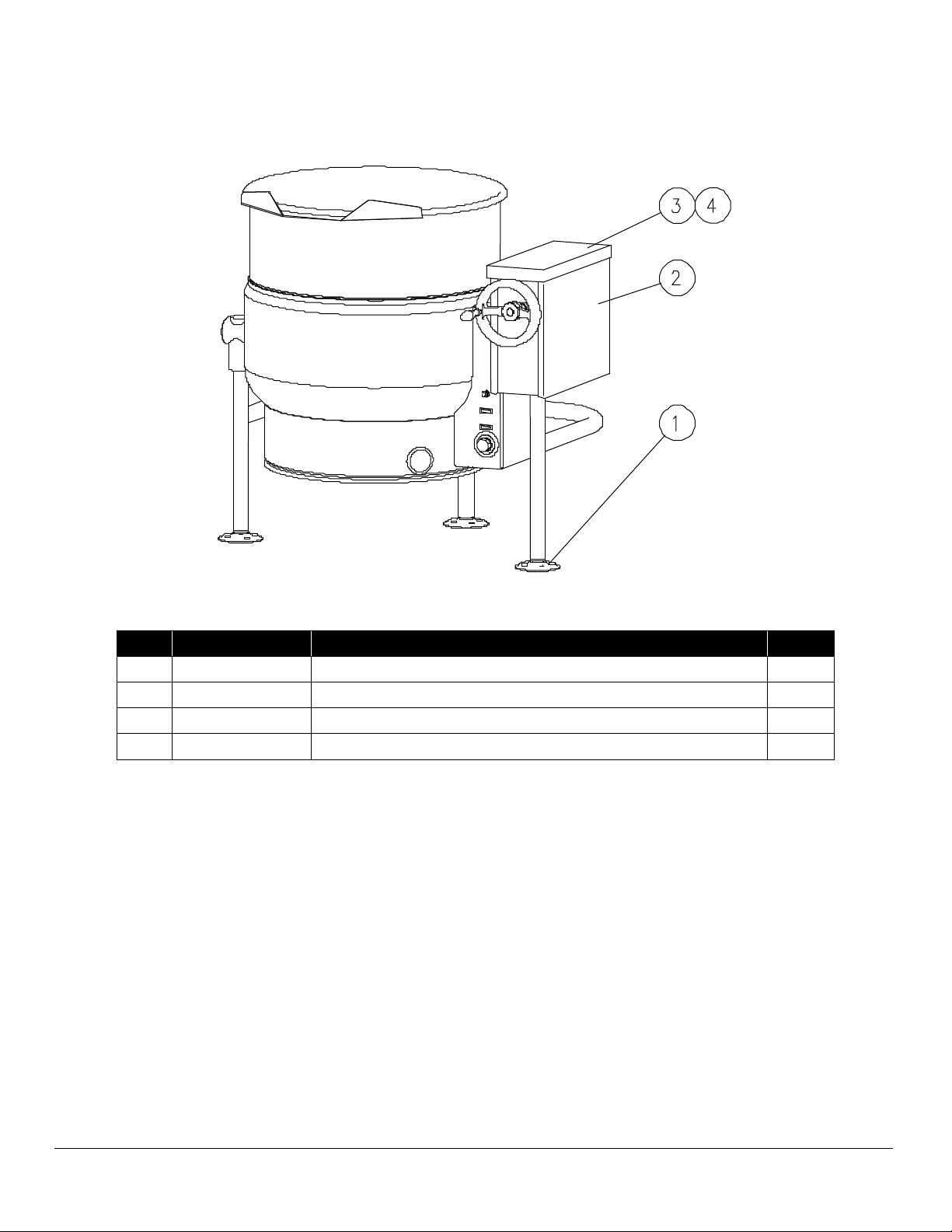

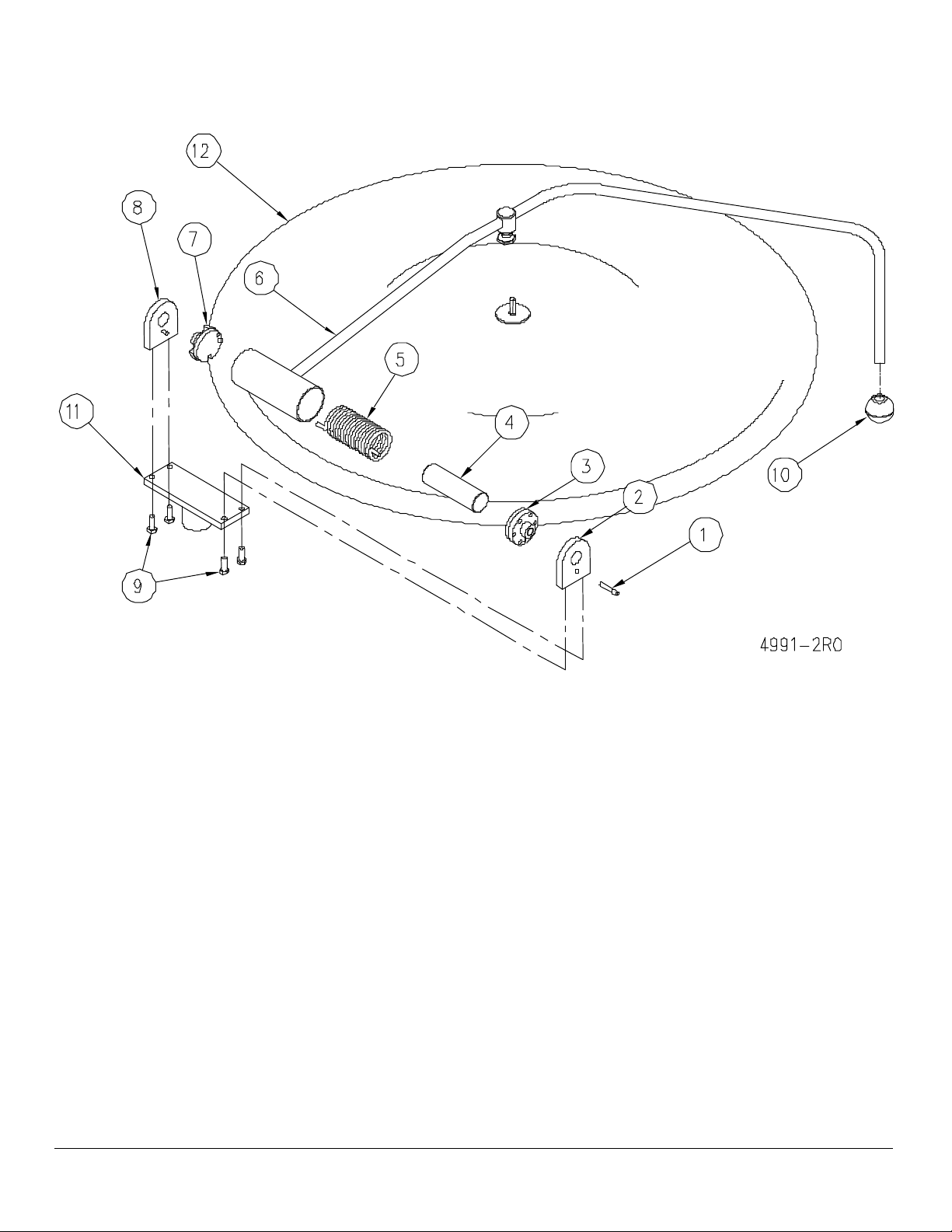

SPRING ASSIST HINGE ASSEMBLY

APRIL 6, 2016 14 F-PE, F-LE & FT-LE SERIES ELECTRIC KETTLES

SPRING ASSIST HINGE ASSEMBLY

ITEM PART NO. DESCRIPTION QTY

97-5464 HINGE ASSEMBLY

1. 97-5352 Lock Pin 1

2. 97-5343 End Lock Plate 1

3. 98-5354 Stationary Disc 1

4. 98-6074 Core 1

5. 97-5160 Spring 1

** 6. 97-5585 Handle Assembly, 20 Gallon Kettle 1

97-5586 Handle Assembly, 30 Gallon Kettle 1

97-6388 Handle Assembly, 40 Gallon Kettle 1

97-5059 Handle Assembly, 60 Gallon Kettle 1

97-5587 Handle Assembly, 80 Gallon Kettle 1

97-5588 Handle Assembly, 100 Gallon Kettle 1

7. 97-6391 Rotary Disc 1

8. 97-5356 End Stop Plate 1

9. 97-6392 Cap Screws 4

10. 97-5008 Knob 1

11. 97-6393 Mounting Plate Assembly - Tilting Models Only 1

** 12. 97-5471 Covers, 20 Gallon Kettle 1

97-5723 Covers, 30 Gallon Kettle 1

97-5053 Covers, 40 Gallon Kettle 1

97-5054 Covers, 60 Gallon Kettle 1

97-5594 Covers, 80 Gallon Kettle 1

97-5595 Covers, 100 Gallon Kettle 1

** SELECT AS REQUIRED.

SPRING ASSIST COVER ASSEMBLY

FOR FIELD INSTALLATION ON FT-LE MODELS

PART NO. DESCRIPTION

4225-1 FT-20LE

4225-2 FT-30LE

97-6733 FT-40LE

97-5581 FT-60LE

4225-5 FT-80LE

4225-6 FT-100LE

ITEMS NOT SHOWN

APRIL 6, 2016 15 F-PE, F-LE & FT-LE SERIES ELECTRIC KETTLES

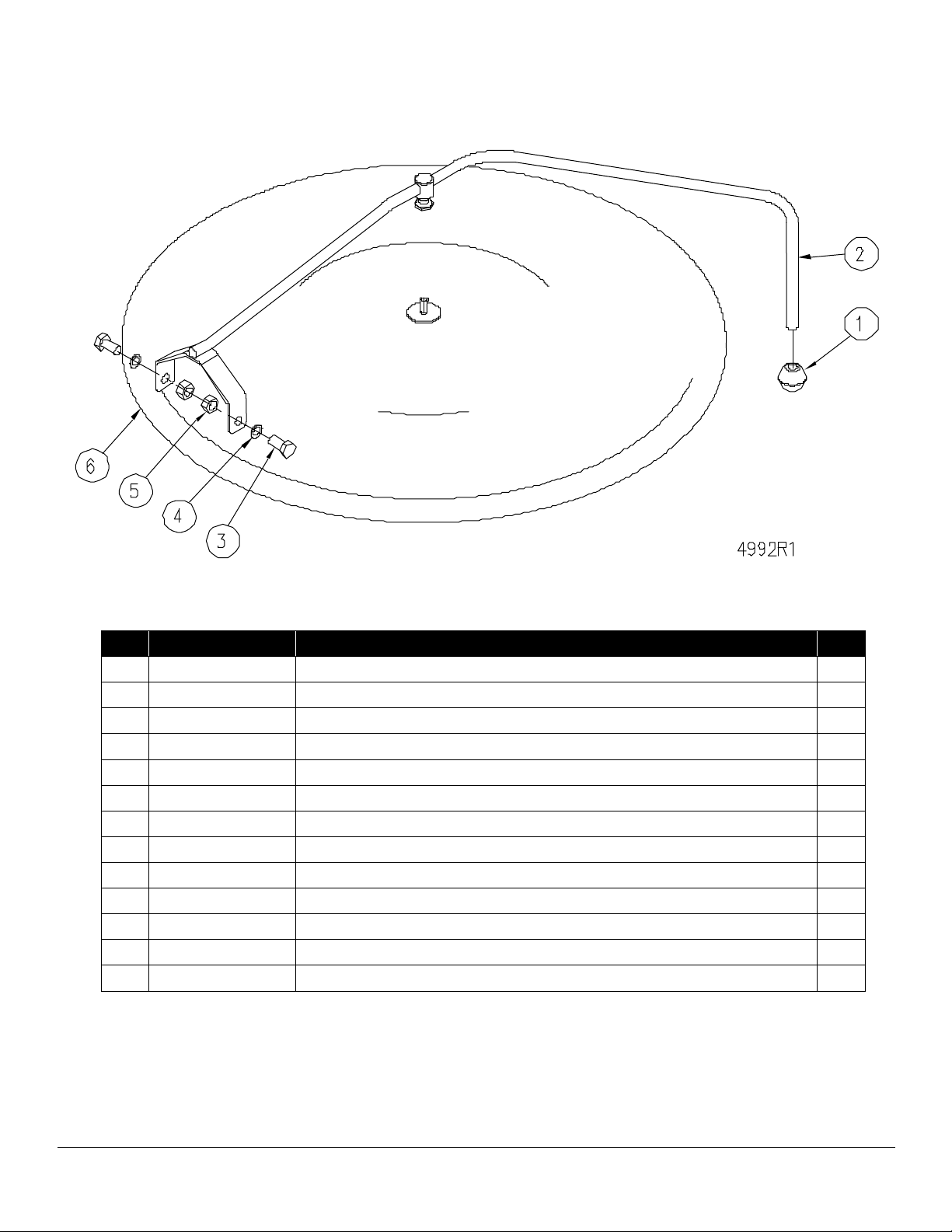

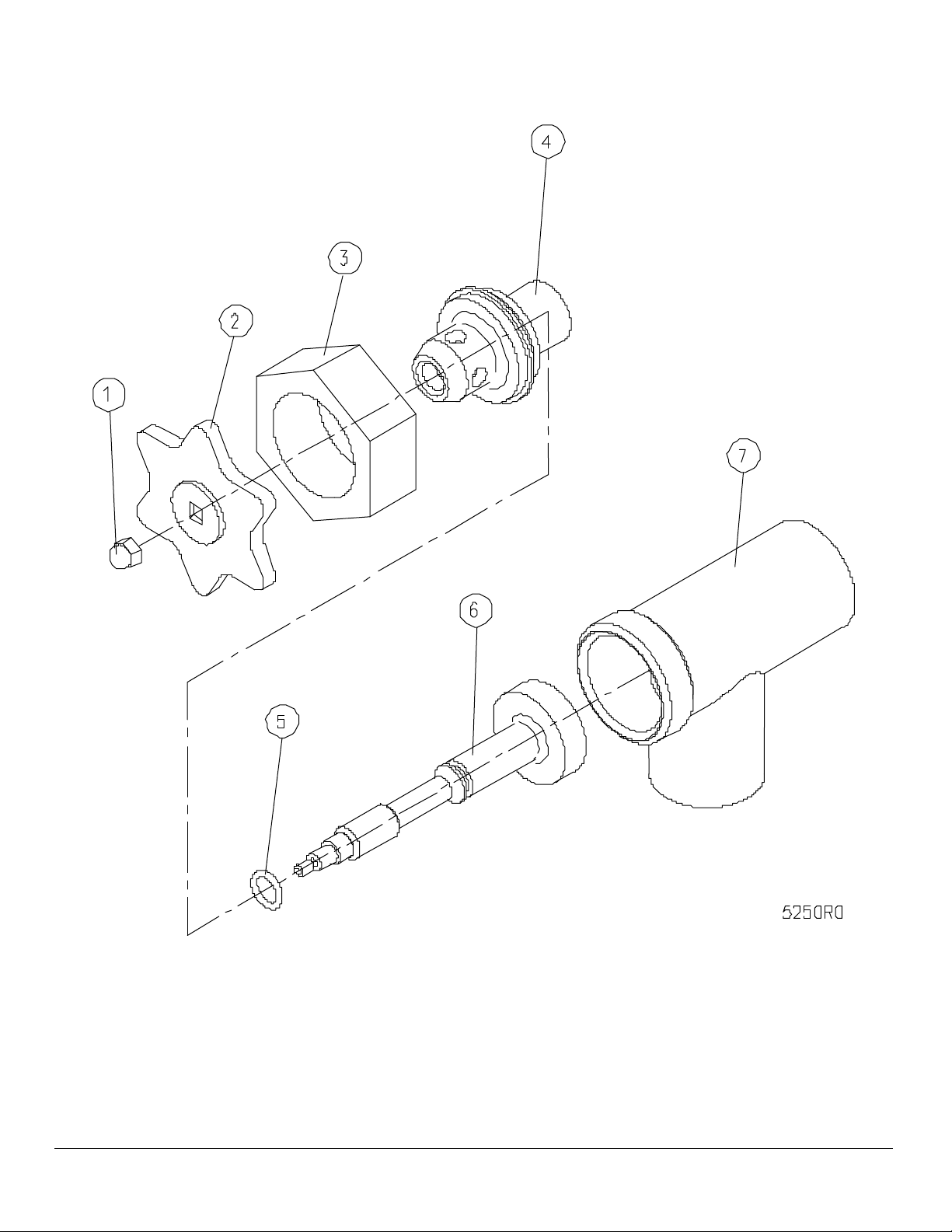

DRAW-OFF VALVE

APRIL 6, 2016 16 F-PE, F-LE & FT-LE SERIES ELECTRIC KETTLES

Loading...

Loading...