Page 1

F-125L, F-150L, F-125P & F-150P

STATIONARY DIRECT STEAM KETTLES

PARTS AND SERVICE MANUAL

EFFECTIVE SEPTEMBER 10 2014

The Company reserves the right to make substitution in the event that items specied are not available.

ERRORS: Descriptive and/or typographic errors are subject to correction.

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone: (802) 658-6600 Fax: (802) 860-3732

Superseding All Previous Parts Lists.

MARKET FORGE INDUSTRIES

www.mi.com

P/N 14-0345 Rev A (9/14)

Page 2

TABLE OF CONTENTS

TROUBLESHOOTING ..................................................................3

ILLUSTRATED PARTS LIST

QUAD LEG KETTLE ...................................................................4

PEDESTAL BASE KETTLE .............................................................5

SPRING ASSIST HINGE ................................................................6

DRAW OFF VALVE .....................................................................7

SEPTEMBER 10, 2014 2 F-125L & F-150L DIRECT STEAM KETTLES

Page 3

TROUBLESHOOTING

DRAW-OFF VALVE LEAKS

If a leak occurs through the valve stem, replace the “O”

ring.

If the leak can be attributed to faulty sealing occurring

between the stem disc and valve seat, then this problem

may be corrected by cleaning off the dried-on food residue with extremely ne emery cloth. If the vulcanized rubber stem piece has been damaged, it must be replaced.

NOTICE

Draw-off valve has a vulcanized rubber coated

stem for better sealing. Do not over tighten.

This may cause the rubber to pull away from

stem and permanently damage it. This is not

covered under warranty.

EXTREMELY SLOW COOKING TIME

If the cooking time is abnormally slow, this may be due

to insufcient steam pressure and/or volume. First determine that pressure on incoming steam line at kettle is

within 5 p.s.i. of rated kettle pressure. Note that pressures

approaching the rated kettle pressure are liable to set off

the safety relief valve. If required pressure is available

to kettle, then possibly volume of steam is not sufcient.

Minimum 3/4" pipe size is required to the kettle but if the

steam generating source is at a great distance from the

kettle, larger supply pipe will be required. Finally, the core

of the steam supply pipe may have debris or scalants that

impede steam ow and will require disassembly and inspection.

VENTING

It is recommended that the “optional” steam trap assembly be installed. This should be plumbed to the exit end

of the kettle. The thermostatic trap is a mechanical device that closes on high temperature and opens when the

temperature drops, allowing the water which formed from

condensate to exhaust but retain the steam under pressure.

SEPTEMBER 10, 2014 3 F-125L & F-150L DIRECT STEAM KETTLES

Page 4

QUAD LEG KETTLE

ITEM PART NO. DESCRIPTION QTY

** 1 9250-25 25 PSI Relief 1

3-SRV8-1 Relief Valve, 35 PSI (Optional) 1

2 5184-1 Down Tube for Relief Valve 1

3 9189-1 Ball Valve 1

4 8-1308 Adjustable Foot 4

* NOT SHOWN.

** SELECT AS REQUIRED.

SEPTEMBER 10, 2014 4 F-125L & F-150L DIRECT STEAM KETTLES

Page 5

PEDESTAL BASE KETTLE

ITEM PART NO. DESCRIPTION QTY

1 3-SRV8-1 Relief Valve, 35 PSI 1

3 SRV9-1 Relief Valve, 50 PSI 1

2 5184-1 Down Tube 1

3 3-TST4 Steam Trap, 1/2", Nickel Plated 1

4 8-6035 Y-Strainer, 1/2", Nickel Plated 1

5 9009-080 Nipple, 1/2" - Schedule 40 x 8" Long 1

6 9012-3 Street Elbow, 1/2", 90° 1

SEPTEMBER 10, 2014 5 F-125L & F-150L DIRECT STEAM KETTLES

Page 6

SPRING ASSIST HINGE

ITEM PART NO. DESCRIPTION QTY

1 M50X-1032-12 Hex. Bolt, #10-32 UNF x 1/2" Long 4

2 F01BR-10 Washer, 0.036 Thick x 0.200 ID x 7/16 OD 4

3 9029-32 Hex. Nut, #10-32 UNF 4

4 2-KB01 Knob 1

SEPTEMBER 10, 2014 6 F-125L & F-150L DIRECT STEAM KETTLES

Page 7

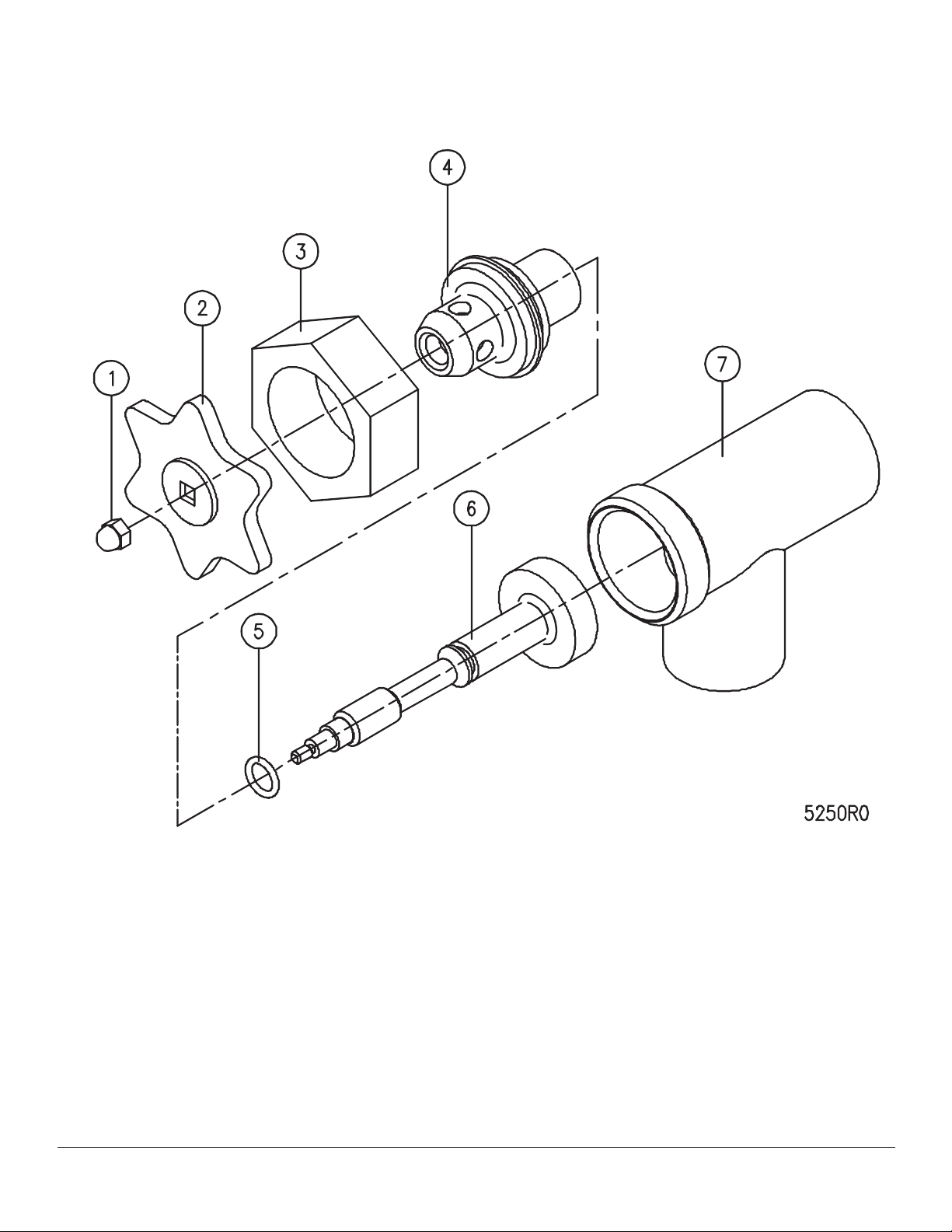

DRAW OFF VALVE

SEPTEMBER 10, 2014 7 F-125L & F-150L DIRECT STEAM KETTLES

Page 8

DRAW OFF VALVE

ITEM PART NO. DESCRIPTION QTY

3-D015 1-1/2" DRAW OFF VALVE ASSEMBLY

1 9031-3 Acorn Nut 10-24 UNC 1

2 4115-1 Handle, Stainless Steel 1

3 3-DV13 Gland Nut 1

4 3-DV14 Bonnet 1

5 3-DV16 “O” Ring 1

6 3-DV15RV Stem Assembly 1

7 3-DV17 Valve Body 1

ITEM PART NO. DESCRIPTION QTY

3-D020 2" DRAW OFF VALVE ASSEMBLY

1 9031-3 Acorn Nut 10-24 UNC 1

2 4115-1 Handle, Stainless Steel 1

3 3-DV23 Gland Nut 1

4 3-DV24 Bonnet 1

5 3-DV26 “O” Ring 1

6 3-DV25RV Stem Assembly 1

7 3-DV27 Valve Body 1

ITEM PART NO. DESCRIPTION QTY

3-D030 3" DRAW OFF VALVE ASSEMBLY

1 3-DV31 Acorn Nut, 7/16-14 UNC 1

2 3-DV32 Handle, Stainless Stee 1

3 3-DV33 Gland Nut 1

4 3-DV34 Bonnet 1

5 3-DV36 “O” Ring 1

6 3-DV35RV Stem Assembly 1

7 3-DV37 Valve Body 1

SEPTEMBER 10, 2014 8 F-125L & F-150L DIRECT STEAM KETTLES

Loading...

Loading...