Market Forge ETP-5E Installation Manual

INSTALLATION AND OPERATION

MANUAL AND PARTS LIST

ELECTRIC CONVECTION STEAMER

MODELS: ETP-5E

ETP-10E

___________________________________________________________________________

S-6505 35 Garvey Street, Everett, MA 02149-4403

Rev. B 08/08 Tel: (617) 387-4100, (866) 698-3188

Fax: (617) 387-4456, (800) 227-2659

custserv@ mfii.com, www.mfii.com

IMPORTANT NOTES FOR INSTALLATION AND OPERATION

Retain this manual for f uture reference.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

WARNING: Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death. Read the

installation, operating and maintenance instructions thoroughly

before installing, servicing or operating this equipment.

IMPORTANT

Do not attempt to operate this unit in the event of power failure.

Adequate clearances must be maintained for safe and proper operation.

Contact the factory, the factory representative or a local service company to

perform maintenance and repairs should the appliance malfunction. Refer to

warranty terms.

Intended for commercial use only. Not for household use.

2

SUMMARY

3

TABLE OF CONTENTS

SUMMARY......................................................................................................................................................3

1.0 SERVICE CONNECTIONS

ETP-5E............................................................................................................................................................5

ETP-10E..........................................................................................................................................................6

2.0 INTRODUCTION

DESCRIPTION................................................................................................................................................7

BASIC FUNCTIONING....................................................................................................................................7

3.0 INSTALLATION

LOCATION......................................................................................................................................................8

MECHANICAL CONNECTIONS......................................................................................................................8

INSTALLATION CODES AND STANDARDS..................................................................................................8

TO INSTALL....................................................................................................................................................8

PLUMBING CONNECTIONS ..........................................................................................................................9

DRAIN CONNECTIONS................................................................................................................................10

INSTALLING DRAIN ADAPTER....................................................................................................................10

WATER CONDITIONING ..............................................................................................................................10

INSTALLING YOUR AQUA-PURE COMMERCIAL SERIES WATER

FILTRATION SYSTEM..................................................................................................................................11

4.0 PERFORNANCE CHECK

TESTING UNIT..............................................................................................................................................12

BEFORE FIRST USE....................................................................................................................................12

5.0 OPERATING INSTRUCTIONS

PREHEATING...............................................................................................................................................13

COOKING.....................................................................................................................................................13

SHUT-DOWN PROCEDURE ........................................................................................................................14

COMPLETE SHUT-DOWN.............................................................................................................14

CLEANING....................................................................................................................................................15

DRAINAGE....................................................................................................................................................15

COOKING COMPARTMENT DRAINAGE....................................................................................15

DRIP/SPILL TROUGH DRAINAGE ..............................................................................................15

CONTROLS..................................................................................................................................................16

TEST KITCHEN BULLETIN...........................................................................................................................17

COOKING GUIDE.........................................................................................................................................18

STEAM COOKING ........................................................................................................................................20

PREPARATION............................................................................................................................................. 20

PAN...............................................................................................................................................................20

6.0 PREVENTIVE MAINTENANCE

INTRODUCTION...........................................................................................................................................21

CLEANING (DAILY) ......................................................................................................................................21

CLEANING (WEEKLY)..................................................................................................................................22

DELIMING PROCEDUES..............................................................................................................................23

STAINLESS STEEL ......................................................................................................................................24

TO REMOVE HEAT TINT..............................................................................................................................24

7.0 TROUBLESHOOTING

GENERAL TROUBLESHOOTING GUIDE ....................................................................................................25

ELECTRICAL FAULT ISOLATION GUIDE....................................................................................................26

TIMER MOTOR.............................................................................................................................................26

DOOR INTERLOCK SWITCH .......................................................................................................................27

INDICATOR LIGHTS.....................................................................................................................................27

BUZZER........................................................................................................................................................27

WIRING.........................................................................................................................................................27

8.0 ADJUSTMENTS

ADJUSTMENTS FOR HIGH ALTITUDE LOCATIONS..................................................................................28

DOOR GASKET REPLACEMENT.................................................................................................................28

EXTERIOR PANEL REMOVAL.....................................................................................................................28

9.0 PARTS

10.0 WIRING

IMPORTANT NOTES FOR INSTALLATION AND OPERATION.....................................................................2

........................................................................................................................................................................29-36

....................................................................................................................................................................37-42

4

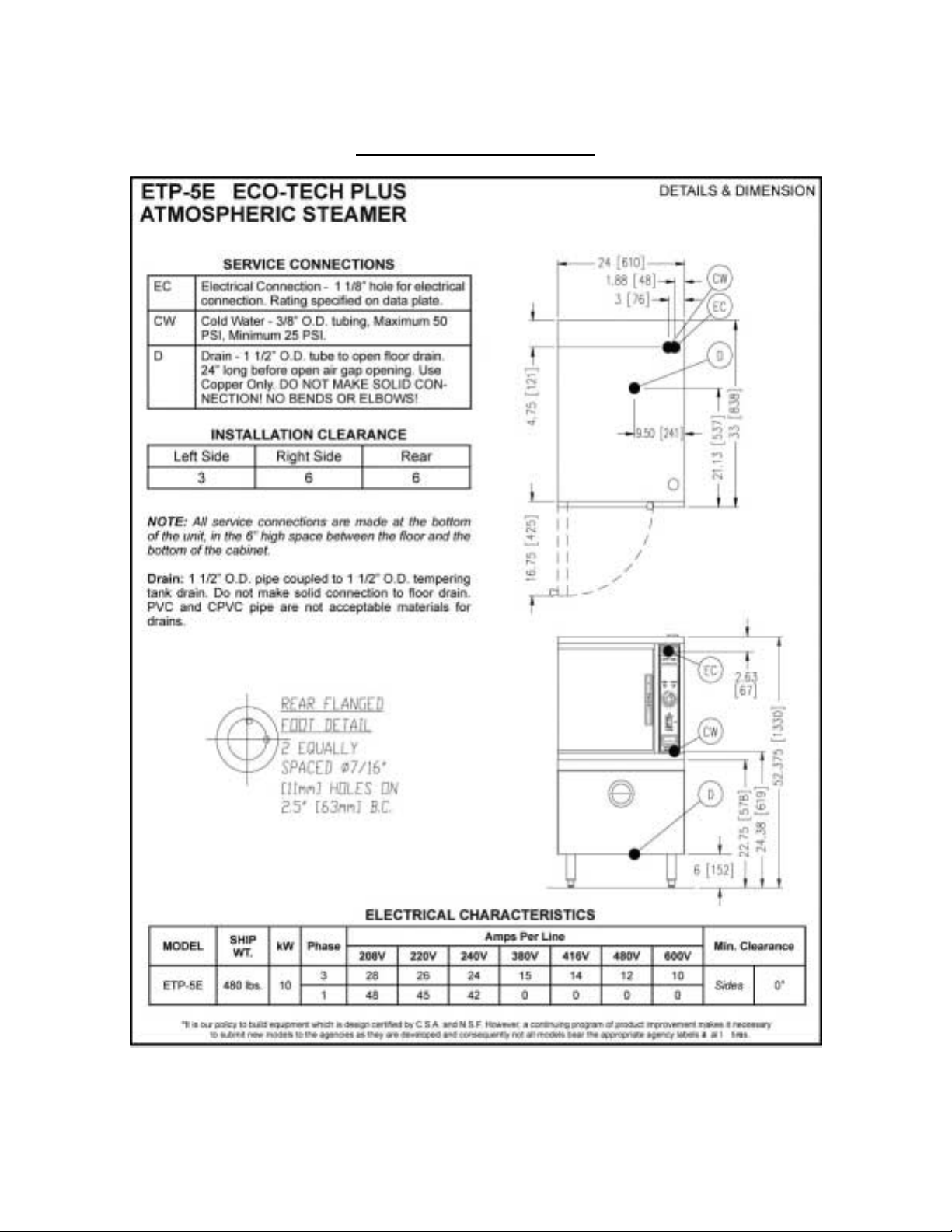

1.0 SERVICE CONNECTIONS

5

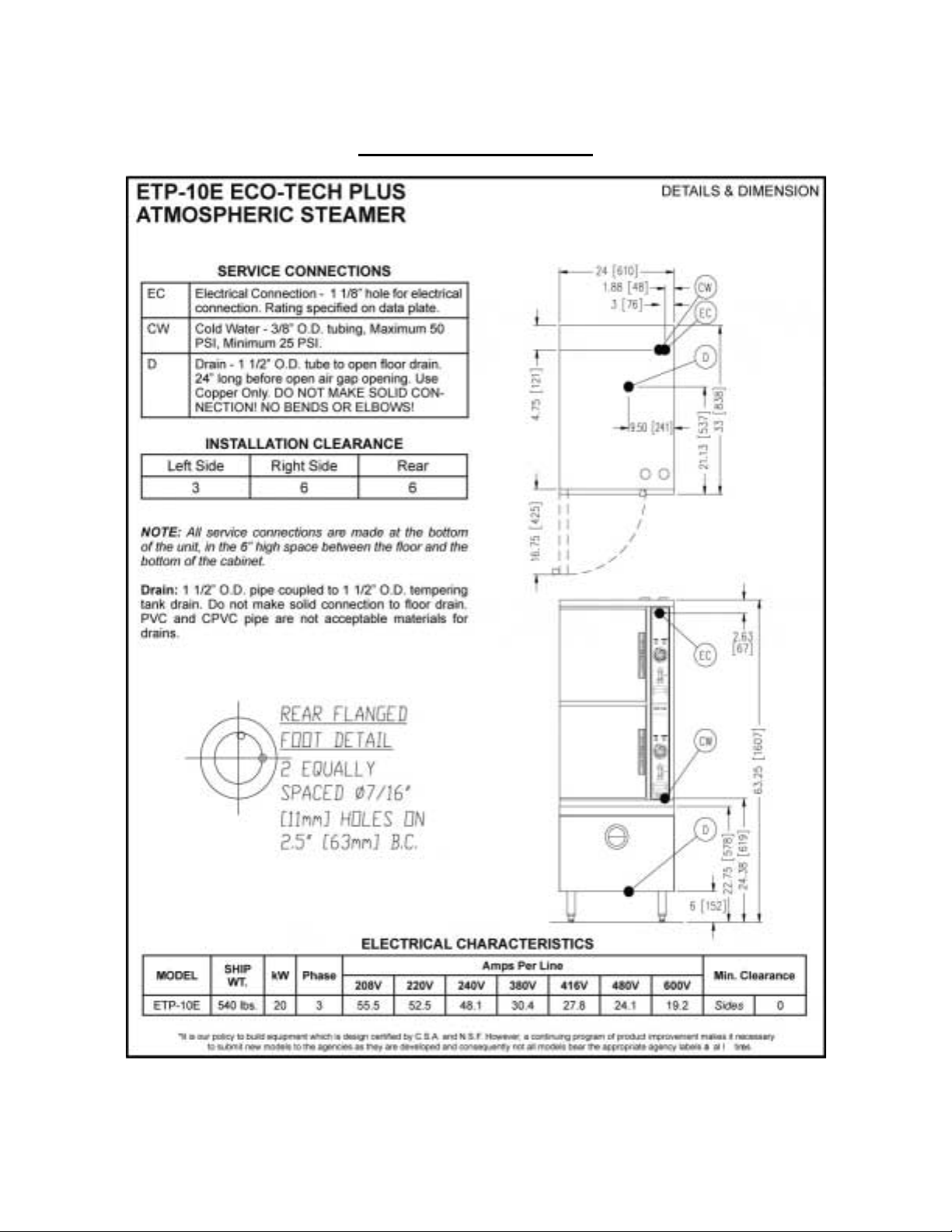

1.0 SERVICE CONNECTIONS

6

2.0 INTRODUCTION

DESCRIPTION

The ETP-5E and ETP-10E are electric fired pressureless steam cookers. The cooking

compartments are equipped with a three-piece door with inner gasket plate isolated from the

exterior surface. Door latch operat es by slam action for positive sealing of the door. O perating

controls are displayed on a front-mounted panel and include indicator lights for ready and

cooking modes, a timer to set cook t imes and a selectable hold cycle to keep food warm once

cooked, a temperature display to monitor cavity temperature, and an illuminated

ON/OFF/DELIME switch.

BASIC FUNCTIONING

The cooker is ready for operat ion when the READY lig ht comes on.

At the end of the set interval, t imer contacts switch to shut of f the cook ing operation and sound

a signal buzzer. The buzzer is silenced by returning the timer dial t o the OFF position. In the

Ο

‘HOLD’ mode, the cooker will maintain a safe food holding temperature at or above 150

F.

Steam emitted f rom the compartment along with liquid cooking drainage is directed through a

removable drain screen inside t he compartment. Drainage from the compartment as well as

from the steam generators, after the appliance is shut-off, is directed to the drain box in the

cabinet base. The drain box condenses the steam prior to dischar ge into the drain.

7

3.0 INSTALLATION

LOCATION

Allow space for plumbing and electrical connections. Minimum clearances are 3" (74mm) on

the sides and 6" (152mm) on the back for proper air circulation. Allow adequate access for

operating and servicing the steamer, 36" (915mm) at the f ront of the steamer and 15" (381mm)

above the steamer.

MECHANICAL CONNECTIONS

All electrical and plumbing connections are located on the rear panel of the unit. See ‘SERVICE

CONNECTIONS’ on pages 5 and 6 for location of mechanical connections.

WARNING: These procedures must be followed by qualified

personnel or warranty will be voided. An open gap floor drain is

required immediately below the appliance drain.

INSTALLATION CODES AND STANDARDS

Electrical grounding must be provided in accordance with local codes, or in t he absence of local

codes, with the National Electrical Code ANSI /NFPA 70, or the Canadian Electrical Code, CSA

C22.2 as applicable.

Ventilation must be provided in accordance with local codes, or in the absence of local codes,

with ANSI/NFPA 96 Standard for Ventilation and Fire Protection of Commercial Cooking

Operations.

WIRI NG DIAGRAM FOR APPLI ANCE IS LOCATED ON RIGHT HAND SI DE PANEL OF THE

COOKER CABINET.

TO INSTALL:

1. Uncrat e car efully. Report any freight dam age to the freight com pany imm ediat ely.

2. Set t he unit in place. Be certain to maintain the minimum clearances from combustibles and

non-combustibles.

3. Using a spirit level or pan of water in the bott om of the steamer, adjust the levelling feet t o

level the steamer front-to-back and side to side.

4. Mark hole locations on the floor through the anchoring holes provided in the flanged

adjustable feet. Remove the steamer and drill holes at marked locations on the floor. I nsert

proper anchoring devices.

5. Set steamer back in proper posit ion.

8

3.0 INSTALLATION (Continued)

6. Install bolts through anchoring holes and into anchors to secure the steamer to the floor.

Seal bolts and flanged feet with Silastic or equivalent.

7. After the dr ain is connected, check for level by pouring water onto the floor of the compartment.

All water should drain through the opening at t he back of the compartment cavity.

WARNING: Disconnect the power supply to the appliance before

cleaning or servicing.

Make electrical connection through the 1- 1/8" ( 29mm) diameter hole provided using 3/4" (19mm)

trade size conduit. Refer to the wiring diag ram located inside the right side panel. Use 90

minimum insulated wire.

PLUMBING CONNECTIONS

Ο

C

NOTICE: Equipment not installed in accordance with these

guidelines may void the warranty.

CAUTION: An obstructed drain can cause personal injury or

property damage.

WARNING: Plumbing connections must comply with applicable

sanitary, safety, and plumbing codes.

The water supply inlets are provided with 3/8" (10mm) compression fittings f or 3/8" O.D. copper

tubing. The water supply line pressure should be 25-50 PSI ( 1.8-3.5 kg/cm

water supply to the generator tank is separat e from the water supply to the cooling system where

steam is condensed before entering the drain line.

Install line strainers (not provided). A m anual shutoff valve for each supply line must be provided

convenient to the steamer.

We recommend treated water feeding the boiler inlet supply, and untreated water feeding the

cooling system inlet. Hook-ups are labelled on the back of the steamer

9

2

) for each line. The

3.0 INSTALLATION (Continued)

DRAIN CONNECTIONS:

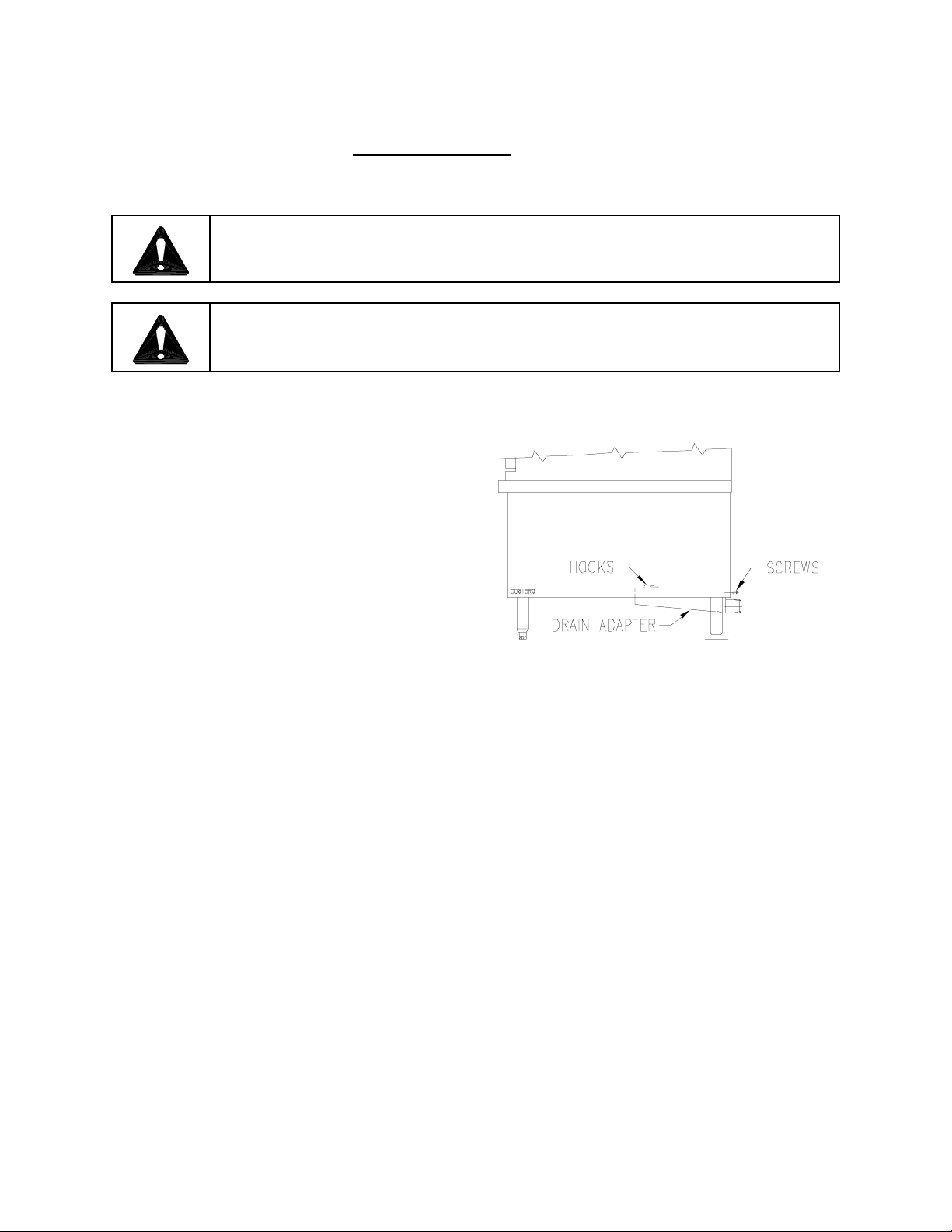

WARNING: An open gap floor drain is required immediately below

the appliance drain.

CAUTION: PVC OR CPVC are not acceptable materials for drains.

INSTALLING THE DRAIN ADAPTER

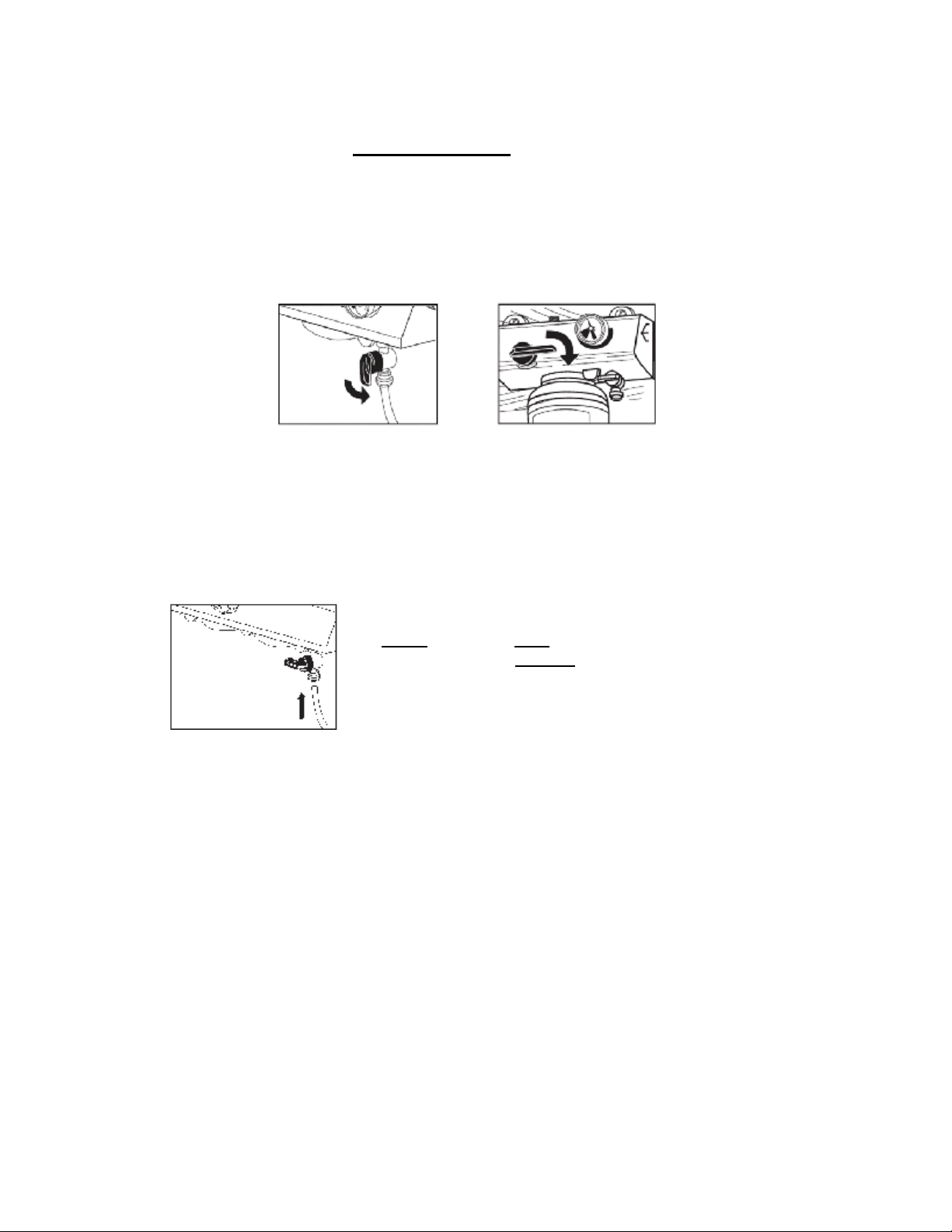

From the rear of the unit, position the drain

adapter hooks through the slot s in the floor of

the cabinet to and align with the holes at the

rear and fasten in place with provided screws.

When m aking the dr ain connection to the 1½”

NPT male thread of the drain adapter, use a

pipe wrench to firmly support the drain

adapter nipple to prevent damage to the

assembly.Once this scale becomes wet, the

water level control is unable to maintain the

proper water level in the steam generator.

STRAINERS and FILTERS will NOT remo ve all miner als from the water.

WATER CONDITIONING:

Untreated water contains scale-producing minerals which can precipitat e ont o the surfaces in the

steam generator. Due to the t emperatures in the steam generat or, the minerals can bake onto

the surfaces and components. This can result in early component f ailure and reduced product

life. W at er level probes become coat ed with scale. Scale may bridge acr oss the pr obe insulator

from the m etal extension, which senses the water level in the steam g enerator shell. O nce this

scale becomes wet, the water level control is unable to maintain the proper water level in the

steam generator.

STRAINERS and FILTERS will NOT treat equipment for scale reduction.

This equipment is furnished with an Aq ua- Pur e® Commercial Series water filtration system. An

initial flushing procedure f or the filter system must be performed before using t his equipment.

10

3.0 INSTALLATION (Continued)

INITIALISING YOUR AQUA-PURE® COMMERCIAL SERIES WATER FILTRATION SYSTEM

1. From the front of the unit, open the cabinet base door to access the f ilter system.

2. Turn on the water to the filt er system .

3. To remove the short tube from the flush valve, press the retaining collar in t oward the

valve and remove the tube. Insert the 1/4" tube pr ovided by firmly inserting it into the

fitting. Run the tubing to the drain.

4. Turn flush valve “ON” and flush the cartridge to remove any entrapped air and carbon

fines. The time to flush is two minutes. Turn FLUSH VALVE to “OFF”. The system is

now ready for use.

Filter Status Indicators: Three LEDs, green to indicate

“Active

exhausted”, and “Change

filter is exhausted or 6 months have passed.

”, yellow “Alert” to indicate that the filter is “80%

” red LED alerts that 100% of the

11

4.0 PERFORMANCE CHECK

WARNING: The steamer and its parts are hot. Use care when

operating, cleaning or servicing the steamer. The cooking

compartment contains live steam. Stay clear while opening door.

TESTING UNIT

Once the steamer is installed and all mechanical connections have been made, thoroug hly test

the steamer before operation.

1. Check that proper water, drain and electrical connections have been made.

2. Turn main power switch ON. After approximately 10 minutes, the “READY” light should

come on, indicating that the water tem per ature is approximately 200

3. When the “READY” lig ht comes on, set timer to t he “5 minute” position. With door open,

observe that no steam is entering the compar tment and that the “COOKING” light is OFF.

4. Close compar tm ent door. T he CO OKING light should now be illuminated and steam should

be heard entering the compartment after about 45 seconds.

5. T he tempering tank does not discharge to drain until the water in the top of the tank reaches

Ο

F or the unit is shut off and t he generators are allowed to drain.

130

6. Open compartment door and observe that steam supply to chamber is cut off. “READY”

light should again come on as “COOKING ” light goes “OFF”.

7. Close compartment door and let cooking cycle finish. When the timer returns to “0" position,

a buzzer will sound signaling the end of t he cooking cycle. Buzzer must be m anually turned

off by setting the t im er t o its “OFF” position.

8. Complete the above steps for each cooking compar tment.

9. To shut the steamer down, turn the main power switch OFF and leave the compartment

doors slightly open to allow the inside to dry out.

BEFORE FIRST USE

Clean the protective oils from all surfaces of the steamer. Use a non-cor r osive, grease

dissolving commercial cleaner, following manufacturer’s directions. Rinse thoroughly and wipe

dry with a soft clean cloth.

12

Ο

F (93ΟC).

5.0 OPERATION INSTRUCTIONS

CAUTION: Live steam and accumulated hot water in the

compartment may be released when the door is opened.

CAUTION: An obstructed drain can cause personal injury or

property damage.

PREHEATING

Before each initial operation of the cooker, and at any other time when the cooking

compartment is cold, a one- minute preheating period is required. To preheat t he cooker, put

steam source into operation and proceed as follows:

1. Close cooking compartment door .

2. Set 60-Minute Timer Dial to “1-minut e” setting.

3. Turn off buzzer, which sounds to indicate cooking is complete, by setting the Timer Dial

to OFF position.

4. The steamer is now ready to cook.

COOKING

CAUTION: Live steam and accumulated hot water in the

compartment may be released when the door is opened.

Before loading the cooker, be sure compartment is hot (See preheat ing inst ructions above).

1. Slide pans of food into cook ing compartment pan supports.

2. Close cooking compartment door .

3. Set timer cooking time:

a. HO LD - for holding cooked f oods in a warm state. Will maintain the cooking cavity at

or above 150

b. 60- MINUTE TIMER - for timed cooking. Set timer to the required cooking time (see

Cooking Guide on page 0).

Ο

F (65ΟC).

13

Loading...

Loading...