OWNER’S MANUAL

ECO-TECH PLUS ATMOSPHERiC STEAMER

WARNiNG:

iMPROPER iNSTALLATiON, ADJUSTMENT, ALTERATiON, SERViCE OR MAiNTENANCE CAN CAUSE

PROPERTY DAMAGE, iNJURY OR DEATH. READ

THiS MANUAL THOROUGHLY BEFORE iNSTALLiNG,

SERViCiNG OR OPERATiNG THiS EQUiPMENT.

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLiNE OR OTHER

FLAMMABLE VAPORS AND LiQUiDS iN THE ViCiNiTY OF THiS OR ANY OTHER UNiT.

CAUTiON:

iN THE EVEN THAT THE OPERATOR SMELLS GAS

PROPER iNSTRUCTiONS MUST BE POSTED iN A

PROMiNENT LOCATiON. THiS iNFORMATiON SHALL

BE OBTAiNED BY CONSULTiNG YOUR LOCAL GAS

SUPPLiER.

MODEL: ETP-10G

iMPORTANT:

DO NOT ATTEMPT TO OPERATE THiS UNiT iN THE

EVENT OF A POWER FAiLURE.

ADEQUATE CLEARANCES MUST BE MAiNTAiNED

FOR SAFE AND PROPER OPERATiON.

THE UNiT AREA MUST BE KEPT FREE AND CLEAR

OF COMBUSTiBLES.

DO NOT OBSTRUCT THE FLOW OF COMBUSTiON

AND VENTiLATiON AiR.

CONTACT THE FACTORY, THE FACTORY REPRESENTATiVE OR LOCAL SERViCE COMPANY TO PREFORM MAiNTENANCE AND REPAiRS SHOULD THE

UNiT MALFUNCTiON.

35 Garvey Street • Everett • MA • 02149-4403

S-6501 Rev. A 05/07

Fax: (617) 387-4456 (MA and Overseas) • Fax: (800) 227-2659 (Ex. MA)

Tel: (617) 387-4100 • Toll Free: (866) 698-3188

E-mail: custserv@mi.com • www.mi.com

It is our policy to build equipment which is design certied by A.G.A./C.G.A. and N.S.F. However, a continuing program of product improvement makes it necessary to submit new models to the

agencies as they are developed and consequently not all models bear the appropriate agency labels at all times.

TABLE OF CONTENTS

INTRODUCTION ................................................... i

INSTALLATION ......................................................1

OPERATION ..........................................................3

MAINTENANCE .....................................................7

TROUBLE-SHOOTING ..........................................9

ILLUSTRATED PARTS LIST ..................................13

iNTRODUCTiON

PERFORMANCE CHECK:

WARNiNG: THE STEAMER AND iTS PARTS ARE

HOT. USE CARE WHEN OPERATiNG, CLEANiNG

OR SERViCiNG THE STEAMER. THE COOKiNG

COMPARTMENT CONTAiNS LiVE STEAM. STAY

CLEAR WHiLE OPENiNG DOOR.

Once the steamer is installed and all mechanical

connections have been made, thoroughly test the

steamer before operation.

Check that proper water, drain and electrical

1.

and gas connections have been made.

Turn main power switch ON. After approximate-

2.

ly 10 minutes, the “READY” light should come

on, indicating that the water temperature is approximately 200° Fahrenheit (93° Celsius).

Check that “Ignition” light comes on when the

3.

burner pilot is ON.

When the “READY” light comes on, set timer

4.

to the “5 minute” position. With door open, ob-

serve that no steam is entering the compart-

ment and that the “COOKING” light is OFF.

Close compartment door. The COOKING light

5.

should now be illuminated and steam should be

heard entering the compartment after about 45

seconds.

The tempering tank does not discharge to drain

6.

until the water in the top of the tank reaches

130°F or the unit is shut off and the generators

are allowed to drain.

7.

Open compartment door and observe that

steam supply to chamber is cut off. “READY”

light should again come on as “COOKING” light

goes “OFF”.

Close compartment door and let cooking cycle

8.

nish. When the timer returns to “0”

i

iNTRODUCTiON

DESCRiPTiON:

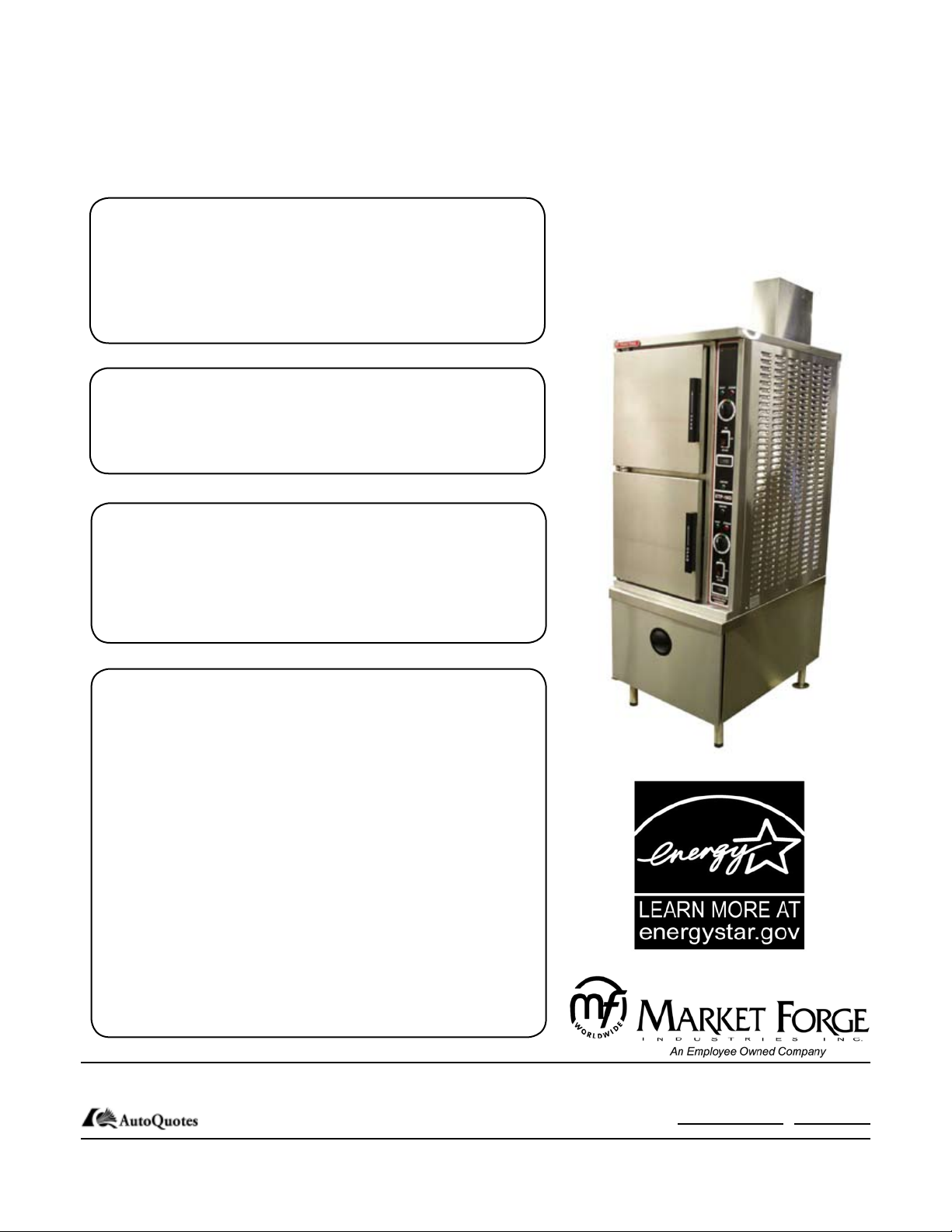

The Eco-Tech Plus Atmospheric Steamer from

Market Forge Industries is a stainless steel

atmospheric steamer with two cooking compartments, each with an independent closecoupled atmospheric 42,000 BTU gas steam

generator.

Benets: The Eco-Tech Plus incorporates a

water management system that reduces the

amount of water used to condense generated

steam, resulting in substantial savings on energy-related costs.

Industry First!: The ETP-10G is the only Atmospheric Twin Generator Steamer that comes

complete with a self contained water lter system. The built-in system eliminates the hassle

of where to put the lter and also provides a

warning indicator when it is time to change the

cartridges.

The Energy Star rating may qualify for rebates

in your state. Consult your local utility company

for details.

Construction: Eco-Tech Plus cooking com-

partments and cabinet are stainless steel with

unitized body construction. Cooking compartments have removable left, right, and rear body

panels. Each cooking compartment has a positive, fully insulated, slam-action door constructed of Type 300 stainless steel. Door gasket is a

one-piece, NSF Approved silicone rubber gasket mounted on the inside of the door. Compartments are equipped with door interlock

switches that automatically cut off power to the

gas valve when the doors are opened.

TECHNiCAL SPECiFiCATiONS:

Cooking Compartment: Each compartment is

provided with stainless steel pan support racks

and a stainless steel liner. The front edge of the

bottom compartment contains a condensate

drip trough that drains automatically to a water

management tempering tank.

Controls: Each compartment is individually

controlled by an on/off power switch and 60minute electromechanical timer. At the end of

the cooking time, a continuous signal will sound

which can be silenced by returning the timer

to the off position. An exclusive mode selector gives the operator the option of using each

cooking cavity as a holding cabinet.

Operation: Each compartment utilizes a pow-

erful close-coupled 42,000 BTU steam generator that supplies steam to the cooking compartments. Generators are held in the “ready” mode

for quick response for heavy-demand situations. Each generator is rated at 42,000 BTU.

Generator chambers are mounted at the rear

of the steamer cavity and close-coupled to the

steam compartment. Generators include as

standard a pilotless ignition system, automatic water level control, low-water cutoff, safety

relief valve, and preheat thermostat (190°F)

and high limit. Each generator includes an access port for Total Concept delimer/descaler.

DiMENSiONS AND CAPACiTY:

Internal Dimensions of cooking compartments:

14.5” Wide x 10.75” High x 23” Front-To-Back.

(368 mm Wide x 273 mm High x 584 mm FrontTo-Back) Allow 6” 152 mm of space on the right

side if height of adjoining wall or equipment exceeds 29” 737 mm.

Capacity:

Each cooking compartment will accommodate

(9) 12” x 20” x 1” deep pans

(5) 12” x 20” x 21/2” deep pans

(3) 12” x 20” x 4” deep pans

OPTiONAL:

● 12” x 20” x 1” perforated stainless steel pans.

● 12” x 20” x 2 1/2” perforated stainless steel pans.

● 12” x 20” x 2 1/2” solid stainless steel pans.

● 12” x 20” x 4” perforated stainless steel pans.

● 12” x 20” x 4” solid stainless steel pans.

● Total Concept Descaler (case of 4 gallons).

● Casters with Strain Relief.

● P.M. Plus.

ii

iNTRODUCTiON

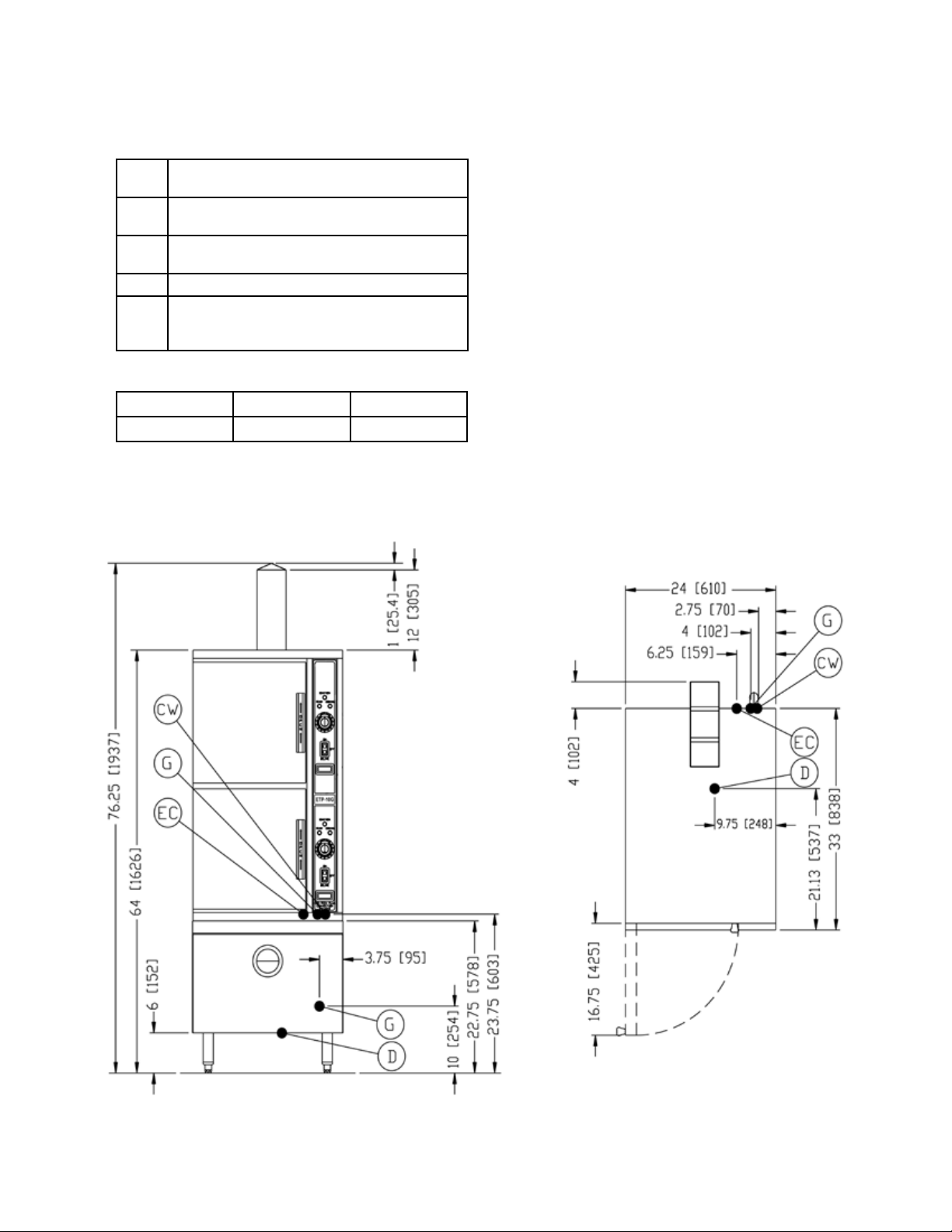

SERViCE CONNECTiONS

G Gas Connection - 3/4” NPT (Male) 84,000

BTU’s.

CW1 Cold Water - Generator - 3/8” O.D. tubing,

Maximum 50 PSI, Minimum 25 PSI.

CW2 Cold Water - Condenser - 3/8” O.D. tubing,

Maximum 50 PSI, Minimum 25 PSI.

D Drain - 1/2” O.D. tube to open oor drain.

EC Electrical Connection - 120 Volts AC, 60 Hz,

single phase, comes with 6 foot cord. NEMA

5-15.

iNSTALLATiON CLEARANCE*

Left Side Right Side Rear

3 8 6

* Use on non-combustible oors only.

Gas Connection: 1/2” NPT female 3 1/2” W.C. natural

10” W.C. propane

NOTES: If the equipment is to be installed where the el-

evation exceeds 2,000 ft. (609.6 meters) above sea level,

specify installation altitudes so that the proper gas orices

can be provided. Rated Input: 42,000 BTU per compartment.

All service connections are made at the bottom of the unit,

in the 6” high space between the oor and the bottom of

the cabinet.

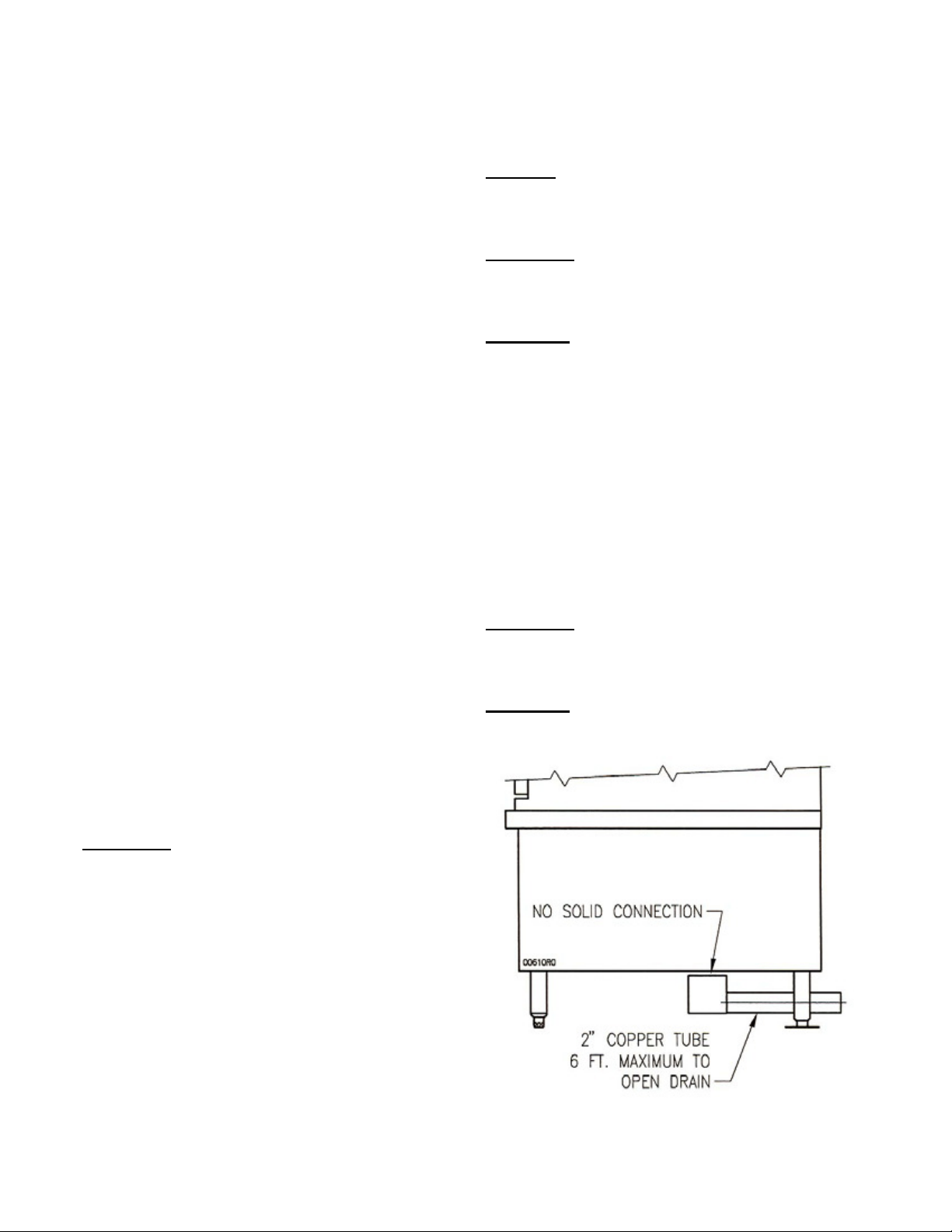

Drain: 1 1/2” O.D. pipe coupled to 1 1/2” O.D. tempering

tank drain. Do not make solid connection to oor drain.

PVC and CPVC pipe are not acceptable materials for

drains. Before connecting water to this unit, have water

supply analyzed to make sure that hardness is no greater

than 2.0 grains per gallon and a pH level is within the

range of 7.0–8.5. Water that fails to meet these standards

should be treated by the installation of a water conditioner. Equipment failure caused by inadequate water quality

is not covered under warranty.

iii

iNSTALLATiON

SETTiNG iN PLACE:

The location of installation must be under an exhaust hood, which will remove water vapor emitted when the cooker door is opened, and exhaust

combustion fumes. Level the unit in nal location by

turning the adjustable feet. Using the cabinet top as

a reference, obtain level adjustment left-to-right and

front-to-back.

MECHANiCAL CONNECTiONS:

All electrical and plumbing connections are located

on the rear panel of the unit. See ‘SERVICE CONNECTIONS’ on page 4 for location of mechanical

connections.

iNSTALLATiON CODES AND STANDARDS:

Installation must conform with local codes, or in absence of local codes, with the National Fuel Gas

Code - ANSI Z223.1/NFPA 54, or the Natural Gas

and Propane Installation Code, CSAB149.1 as applicable.

The appliance and its individual shut off valve

1.

must be disconnected from the gas supply piping system during any pressure testing of that

system at pressures in excess of ½ psi.

The appliance must be isolated from the gas

2.

supply piping system by closing its individual

manual shut off valve during any pressure testing of the gas supply piping system at test pressures equal to or less than ½ psi.

Electrical grounding must be provided in accor

dance with local codes, or in the absence of local

codes, with the National Electrical Code ANSI/NFPA

70, or the Canadian Electrical Code, CSA C22.2 as

applicable.

Ventilation must be provided in accordance with local codes, or in the absence of local codes, with

ANSI/NFPA 96 Standard for Ventilation and Fire

Protection of Commercial Cooking Operations.

WARNiNG: Electrical grounding instructions Units come equipped with a three-prong

(grounding) plug for your protection against

shock hazard and should be plugged directly

into a properly grounded three-prong receptacle. Do not cut or remove the grounding prong

from this plug. (120 VOLT UNITS ONLY).

WiRiNG DiAGRAM FOR APPLiANCE iS LOCATED ON RiGHT HAND SiDE PANEL OF THE

COOKER CABiNET.

EXHAUST FANS AND CANOPiES:

Canopies are set over ranges, ovens, kettles, etc.,

for ventilation purposes. It is recommended that a

canopy extend 6” past the appliance and be located

6’ 6” from the oor. Filters should be installed at an

angle of 45 degrees or more with the horizontal. This

position prevents dripping of grease and facilitates

collecting the run-off grease in a drip pan, usually

installed with the lter. A strong exhaust fan tends to

create a vacuum in the room and may interfere with

burner performance or may extinguish pilot ames.

Makeup air openings approximately equal to the

fan area will relieve such vacuum. In case of unsatisfactory performance on any appliance, check with

the exhaust fan in the “OFF” position.

WALL EXHAUST FAN:

Exhaust fans should be installed at least two feet

above the vent opening at the top of the unit.

CLEARANCES:

Adequate clearance must be provided in aisle and

at the side and back. Adequate clearances for air

openings into the combustion chamber must be

provided, as well as for serviceability. Use appliance on noncombustible surface only. Minimum

clearance from combustible and noncombustible

construction, 3” on left side, 8” on right side and 6”

-

from back.

WARNiNG: THESE PROCEDURES MUST BE

FOLLOWED BY QUALiFiED PERSONNEL OR

WARRANTY WiLL BE VOiDED. AN OPEN GAP

FLOOR DRAiN iS REQUiRED iMMEDiATELY BELOW THE APPLiANCE DRAiN.

TO iNSTALL:

Un-crate carefully. Report any freight damage

1.

to the freight company immediately.

Set the unit in place. Be certain to maintain the

2.

minimum clearances from combustibles and

non-combustibles.

Level the appliance using a spirit level.

3.

1

iNSTALLATiON

Be certain to leave adequate clearances for

4.

cleaning, maintenance and service.

GAS CONNECTiON:

1.

The Serial and Rating Plate on the unit indicates

the type of gas your unit is equipped to burn.

DO NOT connect to any other gas type.

A ¾” NPT line is provided at rear for the con-

2.

nection. Each compartment is equipped with an

internal pressure regulator which is set at 3.5”

W.C. manifold pressure for natural gas and 10”

W.C. for propane gas. Use c” pipe tap on the

burner manifold for checking pressure.

An adequate gas supply is imperative. Undersized

or low pressure lines will restrict the volume of gas

required for satisfactory performance. A steady

supply pressure, between 6” W.C. and 14” W.C.

for natural gas and 11” W.C. and 14” W.C. for propane gas is recommended. With all units operating

simultaneously, the manifold pressure on all units

should not show any appreciable drop. Fluctuations of more that 25% on natural gas and 10% on

propane gas will create problems, affecting burner

operation. Contact your gas company for correct

supply line sizes.

PLUMBiNG CONNECTiONS:

NOTiCE: EQUiPMENT NOT iNSTALLED iN ACCORDANCE TO THESE GUiDE LiNES MAY VOiD

THE WARRANTY.

WARNiNG: PLUMBiNG CONNECTiONS MUST

COMPLY WiTH APPLiCABLE SANiTARY, SAFETY AND PLUMBiNG CODES.

CAUTiON: AN OBSTRUCTED DRAiN CAN

CAUSE PERSONAL iNJURY OR PROPERTY

DAMAGE.

Two water lines are provided. Connect water supply lines to the 3/8” copper tubes at the rear of the

steamer.

One line is for supply of water to the generator and

one for cold condensate water to condense live

steam entering the drain line.

DRAiN CONNECTiONS:

WARNiNG: AN OPEN GAP FLOOR DRAiN iS

REQUiRED iMMEDiATELY BELOW THE APPLiANCE DRAiN.

Purge the supply line to clean out any dust, dirt or

other foreign matter before connecting the line to

the unit. Use pipe joint compound which is suitable

for use with LP on all threaded connections.

Test pipe connections thoroughly for gas leaks.

WARNiNG: NEVER USE AN OPEN FLAME TO

CHECK FOR GAS LEAKS. CHECK ALL CONNECTiONS FOR LEAKS USiNG SOAPY WATER

BEFORE USE.

ELECTRiCAL CONNECTiON:

120 VAC-60 Hz - Single Phase. Units with this electrical rating are factory supplied with a three-wire

cord and three-prong plug which ts any standard

120V, three-prong grounded receptacle. A separate

15 amp supply is needed for each unit.

CAUTiON: PVC OR CPVC ARE NOT ACCEPTABLE MATERiALS FOR DRAiNS.

2

iNSTALLATiON

WATER CONDiTiONiNG:

It is important that the water supplied to the gen-

erator be softened to no more than 2.0 grains of

hardness and have a pH of 7.0 to 8.5. This degree

of hardness can be easily obtained with the use of

a properly maintained water softener. The use of a

water meter will determine the water consumption

and when the water softener needs regeneration or

recharging. Failure to comply with these water condition standards may void the warranty.

Untreated water contains scale producing minerals which can precipitate onto the surfaces in the

OPERATiON

WARNiNG: iN THE EVENT OF MAiN BURNER iGNiTiON FAiLURE, A 5 MiNUTE PURGE PERiOD

MUST BE OBSERVED PRiOR TO RE-ESTABLiSHiNG iGNiTiON SOURCE. iF SO EQUiPPED,

SOME UNiTS WiLL AUTOMATiCALLY RE-ATTEMPT iGNiTiON.

WARNiNG: iN THE EVENT A GAS ODOR iS DETECTED, SHUT DOWN EQUiPMENT AT THE

MAiN SHUT OFF VALVE AND CONTACT THE

LOCAL GAS COMPANY OR GAS SUPPLiER

FOR SERViCE.

LiGHTiNG:

Ensure power, gas and water supply is on.

1.

Turn power switch “ON”.

2.

Generator tank will begin lling with water.

3.

Once water level has been reached, the ignition

4.

light will come on and remain on throughout the

operation of the appliance.

When the READY light comes on the steamer

5.

is ready for use.

SHUTDOWN STAND-BY:

Set timer to “OFF” position and leave door slightly

open.

COMPLETE SHUTDOWN:

Set timer to “OFF” and turn power switch “OFF”.

1.

Generator will drain automatically.

steam generator. Due to the temperatures in the

steam generator, the minerals can bake onto the

surfaces and components. This can result in early

component failure and reduced product life. Water

level probes become coated with scale. Scale may

bridge across the probe insulator from the metal ex-

tension which senses the water level in the steam

generator shell. Once this scale becomes wet, the

water level control is unable to maintain the proper

water level in the steam generator. STRAINERS

and FILTERS will NOT remove all minerals from

the water.

Turn water supply “OFF”.

2.

Turn gas supply “OFF”

3.

Disconnect power supply.

4.

PREHEATiNG:

Before each initial operation of the cooker, and at

any other time when the cooking compartment is

cold, a 5-minute preheating period is required. To

preheat the cooker, put steam source into operation

and proceed as follows:

Close cooking compartment door.

1.

Set 60-Minute Timer Dial to “5-minute” setting.

2.

Turn off buzzer, which sounds to indicate cook-

3.

ing is complete, by setting the Timer Dial to OFF

position.

COOKiNG:

CAUTiON: LiVE STEAM AND ACCUMULATED

HOT WATER iN THE COMPARTMENT MAY BE

RELEASED WHEN THE DOOR iS OPENED.

Before loading the cooker, be sure compartment is

hot. See preheating instructions.

Slide pans of food into cooking compartment

1.

pan supports.

Close cooking compartment door.

2.

3

OPERATiON

3. Set timer cooking time:

3.

a. HOLD - for holding cooked foods in a warm

state. Will maintain the cooking cavity at or

above 150°F (65°C).

b. 60-MINUTE TIMER - for timed cooking.

Set timer to the required cooking time (see

4.

Cooking Guidelines).

Turn off buzzer, which sounds to indicate cook-

5.

ing is complete, by setting timer dial to the OFF

position.

Open door slightly at rst letting most of the

6.

steam out of the compartment and then fully

open the door.

7.

Unload by sliding pans of food from pan supports.

CAUTiON: AN OBSTRUCTED DRAiN CAN

CAUSE PERSONAL iNJURY OR PROPERTY

DAMAGE.

Frequently check that the compartment drain and

plumbing is free of all obstructions. Never place

food containers, food or food portion bags in the

cooking compartment in such a way that the compartment drain becomes obstructed.

Each compartment is equipped with a removable

drain screen. Frequently check the drain screen for

accumulation of food particles. Should food particles accumulate against, or clog the drain screen,

remove it, clean it thoroughly and then replace it in

its original position.

SHUT-DOWN PROCEDURE:

No shut-down procedure is required for the cooker

except to check that both timer dials are in the OFF

position and that both compartment doors are open.

When all cooking has been completed for the day,

the steam source must be shut off.

COMPLETE SHUTDOWN:

Set timer to “OFF” and turn power switch “OFF”.

1.

Steam generators will drain automatically.

Turn water supply “OFF”.

2.

Close manual gas shut off valve.

3.

4.

Disconnect power supply.

CAUTiON: WHEN THE UNiT iS NOT iN USE,

LEAVE THE COOKiNG COMPARTMENT DOORS

UNLATCHED TO PROLONG THE LiFE OF THE

DOOR GASKET.

CLEANiNG:

1.

After each period of daily operation (more frequently as required to maintain cleanliness), the

cooker should be thoroughly cleaned by completing the following steps:

2.

Remove left and right side pan supports by lifting up and off mounting studs. Remove the drain

screen in the rear of the compartment. Wash

with a mild detergent. Rinse and set aside for

reassembly.

3.

Wash cooking compartment interior using a mild

detergent and water. Rinse and dry thoroughly.

4.

Replace pan supports and drain screen in com

partment and leave door open.

COOKiNG COMPARTMENT DRAiNAGE:

The bottom of the cooking compartment is angled

slightly toward the rear of the unit. This assures that

any condensate build-up or spills will be directed

toward the drain, which is located at the rear bottom center of the cooking compartment. Any liquid

exiting the cooking compartment runs down the

cooking compartment drain tube and into the condensate tank.

DRiP/SPiLL TROUGH DRAiNAGE:

The Pressureless Steam Cooker has a drip/spill

trough below the cooking compartment door. It will

catch any condensate gathering on the front of the

unit when the door is opened.

WARNiNG: THE STEAMER AND iTS PARTS ARE

HOT. USE CARE WHEN OPERATiNG, CLEANiNG

OR SERViCiNG THE STEAMER. THE COOKiNG

COMPARTMENT CONTAiNS LiVE STEAM. STAY

CLEAR WHEN OPENiNG DOOR.

CAUTiON: AN OBSTRUCTED DRAiN CAN

CAUSE PERSONAL iNJURY OR PROPERTY

DAMAGE.

-

4

Loading...

Loading...