Market Forge ETP-10E Installation Manual

ECO-TECH® PLUS

ELECTRIC CONVECTION STEAMER

INSTALLATION - OPERATION - MAINTENANCE

MODEL

ETP-10E

44 Lakeside Avenue, Burlington, Vermont 05401 USA

Telephone: (802) 658-6600 Fax: (802)864-0183

www.mi.com PN 14-0269 Rev B (7/16)

© 2016 - Market Forge Industries Inc.

Your Service Agency’s Address:

Model

Serial number

Steamer installed by

Installation checked by

IMPORTANT

WARNING: Improper installation, adjustment, alternation,

service or maintenance can

cause property damage, injury or death. Read the installation, operation and maintenance instructions thoroughly

before installing or servicing

this equipment.

FOR YOUR SAFETY

Do not store or use gasoline or

other ammable vapors or liquids in the vicinity of this or any

other appliance.

Do not attempt to operate this

unit in the event of power failure.

Adequate clearances must be

maintained for safe and proper

operation.

The information contained in this

manual is important for the proper installation, use, and maintenance of this steamer. Adherence to these procedures and

instructions will result in years

of trouble-free service. Please

read this manual carefully and

retain it for future reference.

TABLE OF CONTENTS

INSTALLATION

Service Connections ..................................................... 2

Introduction .............................................................. 3

Installation............................................................... 4

Location ............................................................. 4

Mechanical Connections .............................................. 4

Installation Codes and Standards ...................................... 4

Installation Procedures ............................................... 4

Installating the Drain Adapter .......................................... 4

Water Conditioning ................................................... 5

Filter System Installation Set-Up ....................................... 5

Filter Change Procedure .............................................. 6

OPERATION

Operating Instructions .................................................... 8

Cooking ............................................................. 8

Cleaning ............................................................ 9

Drainage ............................................................ 9

Adjustment for High Altitude Locations ................................. 9

Control Panel ........................................................... 10

Test Kitchen Bulletin ..................................................... 11

Cooking Guide .......................................................... 12

Steam Cooking ......................................................... 15

MAINTENANCE

Cleaning & Deliming ..................................................... 16

Daily Cleaning ...................................................... 16

Weekly Cleaning .................................................... 16

Deliming ............................................................ 17

Stainless Steel ...................................................... 17

To Remove Heat Tint ................................................ 17

ERRORS: Descriptive, typographic or pictorial errors are

subject to correction. Specications are subject to change

without notice.

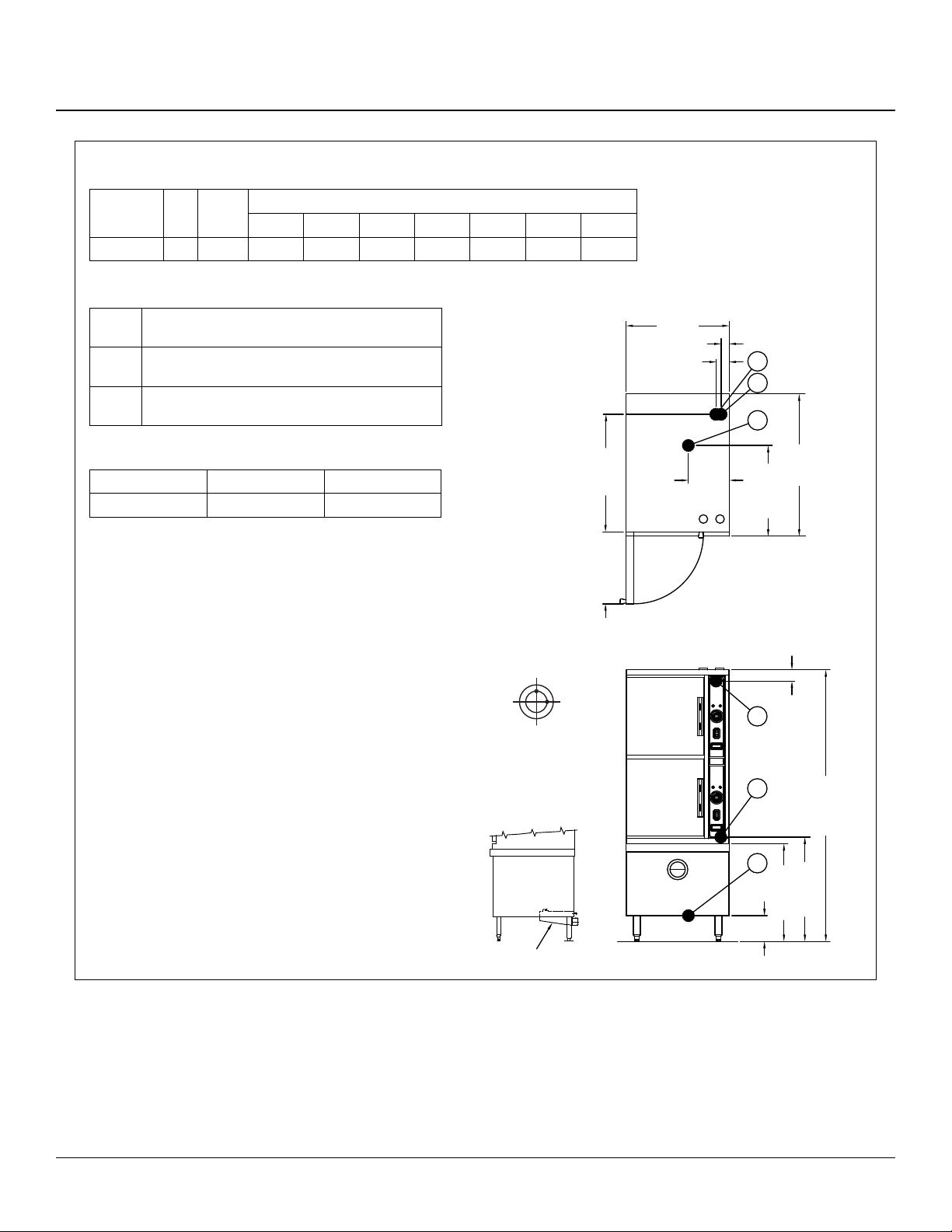

Service Connections

DRAIN ADAPTER

ELECTRICAL CHARACTERISTICS

MODEL kW Phase

208V 220V 240V 380V 416V 480V 600V

Amps Per Line

ETP-10E 20 3 55.5 52.5 48.1 30.4 27.8 24.1 19.2

SERVICE CONNECTIONS

DIMENSIONS ARE IN INCHES [MM]

EC Electrical Connection - 1 1/8” hole for electrical

connection. Rating specified on data plate.

CW1 Cold Water - 3/8” (10mm) NPT, Maximum 50

PSI, Minimum 25 PSI.

D Drain - 1-1/2” NPT male from the drain adapter

(see illustration)

INSTALLATION CLEARANCE

Left Side Right Side Rear

3 6 6

NOTE: Allow 6” 152 mm of space on the right side if height of

adjoining wall or equipment exceeds 29” 737 mm.

NOTE: All service connections are made at the rear of the unit.

NOTE: PVC and CPVC pipe are not acceptable materials for

drains.

4.75 [121]

16.75 [425]

24 [610]

1.88 [48]

3 [76]

9.50

[241]

CW

EC

D

33 [838]

21.13 [537]

2.63

[67]

WATER SUPPLY

Good quality water feed is the responsibility of the owner.

Water quality must be within the following general guidelines.

TDS: 40-125 ppm Chlorides: <25 ppm

Silica: <13 ppm pH: 7.0 - 8.5

Chloramine: <0.2 ppm Chlorine: <0.2 ppm

Hardness: 35-100 ppm

The best defense against poor water quality is a water treatment system designed to meet your water quality conditions.

Appliance to be installed with backflow protection according to

federal, state or local codes.

REAR FLANGED

FOOT DETAIL

2 EQUALLY SPACED

Ø7/16” [11] HOLES

ON 2.5 [63] B.C.

Figure 1

READY COOKING

O

5

F

F

O

10

O

15

65

P

60

20

E

25

55

EC

50

30

N

45

35

40

ON

OFF

DELIME

ETP-10E

READY COOKING

O

5

F

CW

F

O

10

O

15

65

P

60

20

E

25

55

50

30

N

45

35

40

ON

OFF

ECO-TECH PLUS

CONVECTION

DELIME

STEAMER

63.25 [1607]

D

24.38 [619]

22.75 [578]

INSTALLATION

2

DESCRIPTION

The ETP-10E is an electric powered pressureless steam

cooker. The cooking compartments are equipped with

a three-piece door with inner gasket plate isolated from

the exterior surface. Door latch operates by slam action

for positive sealing of the door. Operating controls are

displayed on a front-mounted panel and include indicator

lights for ready and cooking modes, a timer to set cook

times and a selectable hold cycle to keep food warm once

cooked, a temperature display to monitor cavity temperature, and an illuminated ON/OFF/DELIME switch.

BASIC FUNCTIONING

The cooker is ready for operation when the READY light

comes on.

At the end of the set interval, timer contacts switch to shut

off the cooking operation and sound a signal buzzer. The

buzzer is silenced by returning the timer dial to the OFF

position. In the ‘HOLD’ mode, the cooker will maintain a

safe food holding temperature at or above 150°F.

Steam emitted from the compartment along with liquid

cooking drainage is directed through a removable drain

screen inside the compartment. Drainage from the compartment as well as from the steam generators, after the

appliance is shut-off, is directed to the drain box in the

cabinet base.

Introduction

3

INSTALLATION

Installation

LOCATION

Allow space for plumbing and electrical connections.

Minimum clearances are 3” (74mm) on the sides and 6”

(152mm) on the back for proper air circulation. Allow ad-

equate access for operating and servicing the steamer,

36” (915mm) at the front of the steamer and 15” (381mm)

above the steamer.

MECHANICAL CONNECTIONS

All electrical and plumbing connections are located on the

rear panel of the unit. See ‘SERVICE CONNECTIONS’

for location of mechanical connections.

WARNING

These procedures must be followed by quali-

ed personnel or warranty will be voided. An

open gap oor drain is required immediately

below the appliance drain.

INSTALLATION CODES AND STANDARDS

Electrical grounding must be provided in accordance with

local codes, or in the absence of local codes, with the

National Electrical Code ANSI/NFPA 70, or the Canadian

Electrical Code, CSA C22.2 as applicable.

Ventilation must be provided in accordance with local

codes, or in the absence of local codes, with ANSI/NFPA

96 Standard for Ventilation and Fire Protection of Commercial Cooking Operations.

WIRING DIAGRAM FOR APPLIANCE IS LOCATED ON

RIGHT HAND SIDE PANEL OF THE COOKER CABINET.

6. Install bolts through anchoring holes and into anchors

to secure the steamer to the oor. Seal bolts and

anged feet with Silastic or equivalent.

7. After the drain is connected, check for level by pour-

ing water onto the oor of the compartment. All water

should drain through the opening at the back of the

compartment cavity.

WARNING

An open gap oor drain is required immediately below the appliance drain.

CAUTION

PVC OR CPVC are not acceptable materials

for drains.

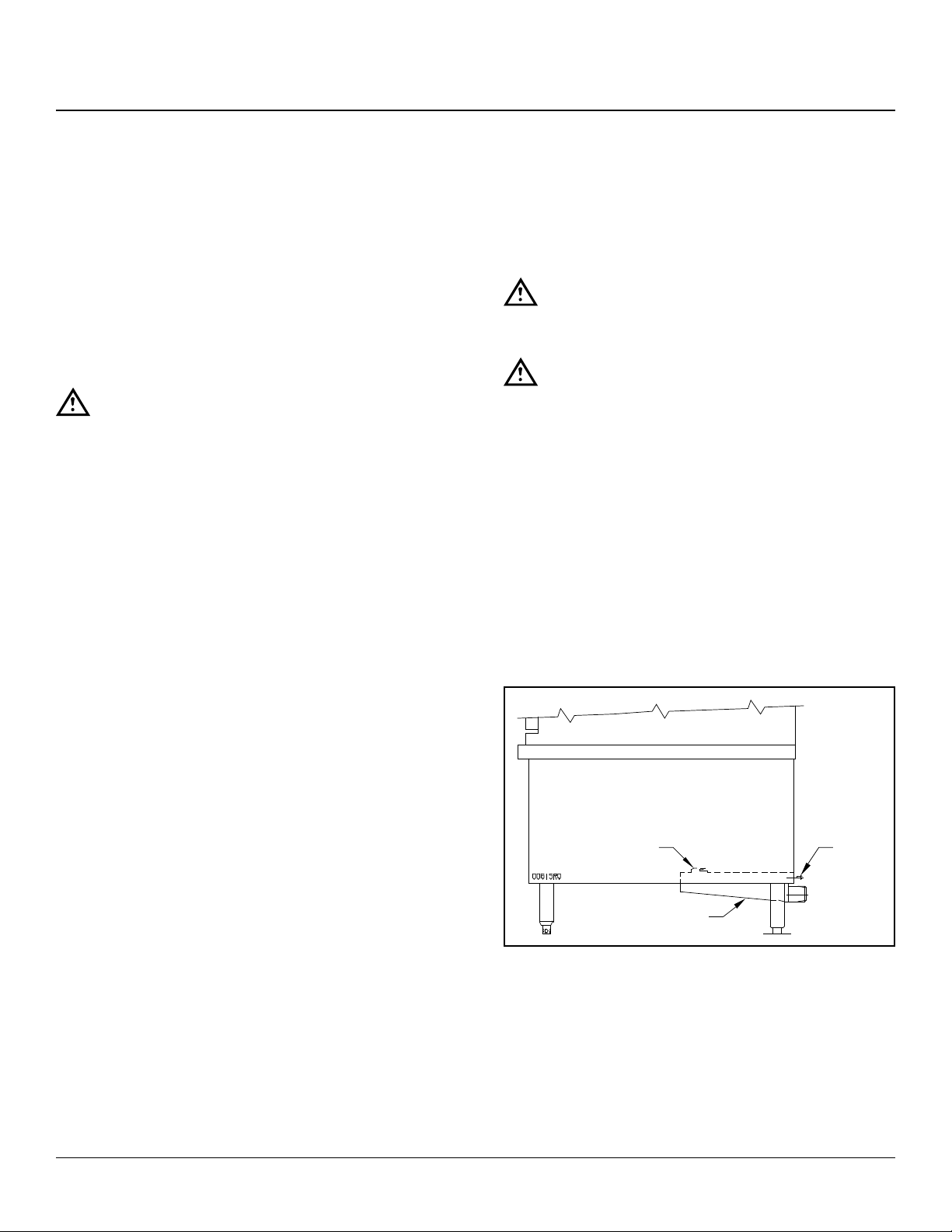

INSTALLATING THE DRAIN ADAPTER

From the rear of the unit, position the drain adapter hooks

through the slots in the oor of the cabinet base and align

with the holes at the rear and fasten in place with provided

screws.

When making the drain connection to the 1½” NPT male

thread of the drain adapter, use a pipe wrench to rmly

support the drain adapter nipple to prevent damage to the

assembly.

STRAINERS and FILTERS will NOT remove all minerals

from the water.

INSTALLATION PROCEDURES

1. Uncrate carefully. Report any freight damage to the

freight company immediately.

2. Set the unit in place. Be certain to maintain the minimum clearances from combustibles and non-combustibles.

3. Using a spirit level or pan of water in the bottom of the

steamer, adjust the levelling feet to level the steamer

front-to-back and side to side.

4. Mark hole locations on the oor through the anchoring holes provided in the anged adjustable feet. Remove the steamer and drill holes at marked locations

on the oor. Insert proper anchoring devices.

5. Set steamer back in proper position.

INSTALLATION

HOOKS SCREWS

DRAIN ADAPTER

Figure 2

4

Loading...

Loading...