Market Forge EJ-7E Installation Manual

INSTALLATION AND OPERATION

MANUAL AND PARTS LIST

ELECTRIC CONVECTION STEAMER

MODELS: EJ-7E

EJ-10E

PRINTED IN CANADA

PART NUMBER 10223R1 1 2010-06-24

INSTALLATION AND OPERATION MANUAL AND PARTS LIST,

ELECTRIC CONVECTION STEAMER, MODELS EJ-7E, EJ-10E

IMPORTANT NOTES FOR INSTALLATION AND OPERATION

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

WARNING: Improper installation, operation, adjustment, alteration,

service or maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions

thoroughly before installing, operating or servicing this equipment.

This manual should be retained for future reference.

Intended for commercial use only. Not for household use.

Adequate clearances must be maintained for safe and proper operation.

PART NUMBER 10223R1 2 2010-06-24

INSTALLATION AND OPERATION MANUAL AND PARTS LIST,

ELECTRIC CONVECTION STEAMER, MODELS EJ-7E, EJ-10E

TABLE OF CONTENTS

DESCRIPTION PAGE

Important Notes for Installation and Operation ....................................2

1.0 Service Connections ....................................................4

2.0 Installation Instructions ...................................................5

3.0 Operation ............................................................10

4.0 Cleaning .............................................................16

5.0 Maintenance .........................................................18

6.0 Troubleshooting .......................................................19

7.0 Service ..............................................................20

8.0 Parts List ............................................................22

PART NUMBER 10223R1 3 2010-06-24

INSTALLATION AND OPERATION MANUAL AND PARTS LIST,

ELECTRIC CONVECTION STEAMER, MODELS EJ-7E, EJ-10E

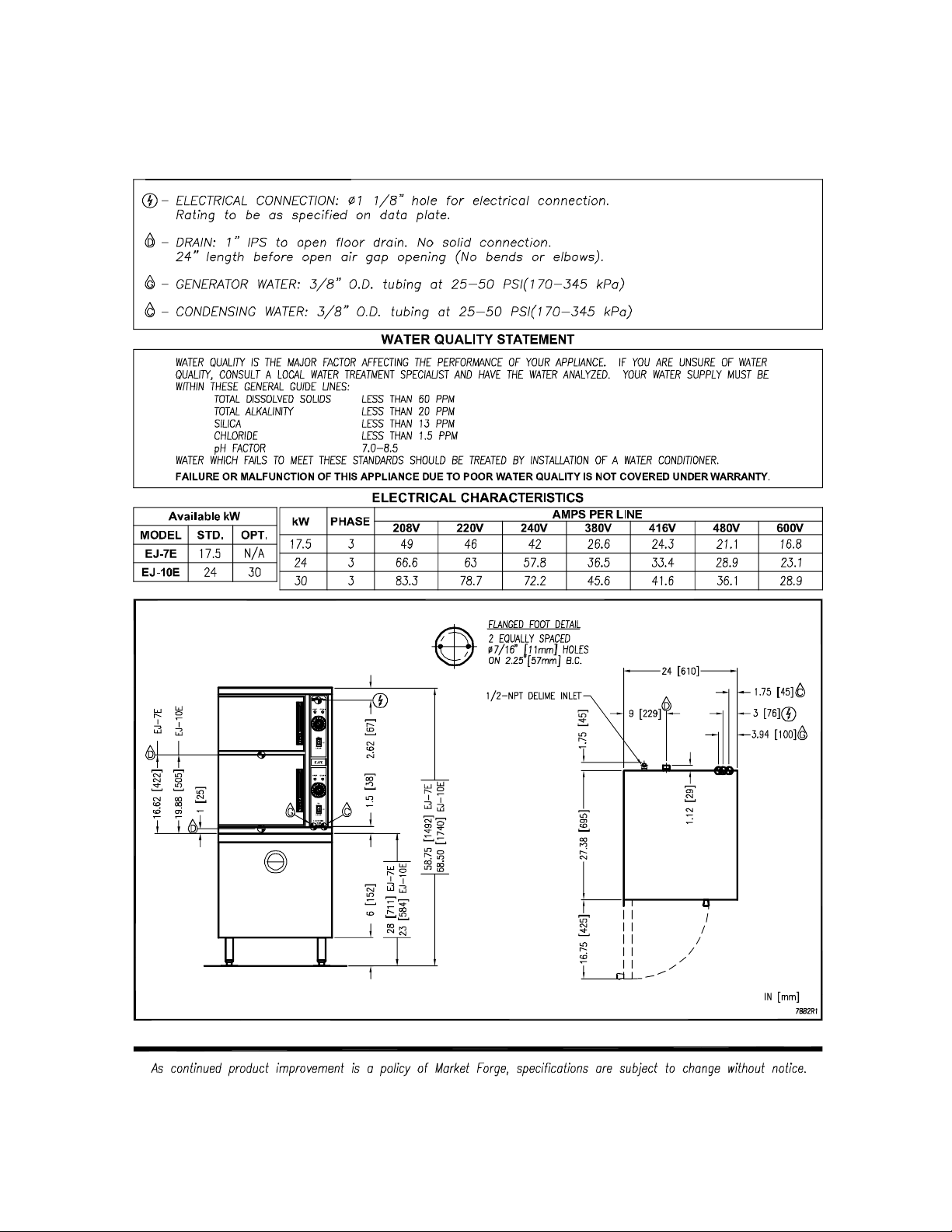

1.0 SERVICE CONNECTIONS

PART NUMBER 10223R1 4 2010-06-24

INSTALLATION AND OPERATION MANUAL AND PARTS LIST,

ELECTRIC CONVECTION STEAMER, MODELS EJ-7E, EJ-10E

2.0 INSTALLATION INSTRUCTIONS

This steamer was inspected before leaving the factory. The transportation company assumes

full responsibility for safe delivery upon acceptance of the shipment. Immediately after

unpacking the steamer, check for possible damage. If the steamer is found to be damaged

after unpacking, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, verify that the electrical service agrees with the specifications on the

machine data plate which is located on the left side panel.

LOCATION

Allow space for plumbing and electrical connections. Allow adequate access for operating and

servicing the steamer, 36" (915 mm) at the front of the steamer and 15" (381 mm) above the

steamer.

LEVELLING AND ANCHORING

Using a spirit level or pan of water in the bottom of the steamer, adjust the levelling feet to level

the steamer front-to-back and side-to-side.

Mark hole locations on the floor through the anchoring holes provided in the flanged adjustable

feet. Remove the steamer and drill holes at marked locations on the floor. Insert proper

anchoring devices.

Set steamer back in proper position.

Install bolts through anchoring holes and into anchors to secure the steamer to the floor. Seal

bolts and flanged feet with Silastic.

After the drain is connected, check for level by pouring water onto the floor of the compartment.

All water should drain through the opening at the back of the compartment cavity.

ELECTRICAL CONNECTION

WARNING: Electrical and grounding connections must comply with

applicable portions of the national electrical code and/or other local

electrical codes.

PART NUMBER 10223R1 5 2010-06-24

INSTALLATION AND OPERATION MANUAL AND PARTS LIST,

ELECTRIC CONVECTION STEAMER, MODELS EJ-7E, EJ-10E

INSTALLATION INSTRUCTIONS (Continued)

WARNING: Disconnect the power supply to the appliance before

cleaning or servicing.

Make electrical connection through the 1-1/8" (29 mm) diameter hole provided using 3/4" (19

mm) trade size conduit. Refer to the wiring diagram located inside the right side panel. Use

90°C minimum insulated wire.

PLUMBING CONNECTIONS

WARNING: Plumbing connections must comply with applicable

sanitary, safety, and plumbing codes.

The water supply inlets are provided with 3/8" (10 mm) compression fittings for 3/8" O.D.

copper tubing. The water supply line pressure should be 25 - 50 psi (170 - 345 kPa) for each

line. The water supply to the generator tank is separate from the water supply to the cooling

system where steam is condensed before entering the drain line.

Install line strainers (not provided). A manual shutoff valve for each supply line must be

provided convenient to the steamer.

We recommend treated water feeding the boiler inlet supply, and untreated water feeding the

cooling system inlet. Hook-ups are labelled on the back of the steamer.

ADJUSTMENT FOR HIGH ALTITUDE LOCATIONS

The steamer has been factory set so that when it is ON, and during the READY phase, it will

maintain water temperature in the steam generator tank at approximately 205°F (96°C) (just

below water boiling point). However, for high altitude locations, an authorized service agency

must adjust the steamer to achieve this temperature.

ADJUSTMENT FOR DRAIN WATER TEMPERATURE

Cooling solenoid valves have been adjusted to yield drain temperatures of 140°F. This will vary

depending on install location water supply temperature and pressure. A qualified service

person should adjust the cooling solenoid valves should the drain temperature be other than

desired. Refer to Section 7.0 Service on page 20 for adjustment instructions.

PART NUMBER 10223R1 6 2010-06-24

INSTALLATION AND OPERATION MANUAL AND PARTS LIST,

ELECTRIC CONVECTION STEAMER, MODELS EJ-7E, EJ-10E

DRAIN CONNECTIONS

The drain connection must be 1" (25 mm)

IPS down, preferably with one or two

elbows only, maximum length 6 feet (1830

mm) and piped to an open gap type drain

(Figure 1). Drain pipe should be either iron

or copper. DO NOT use PVC pipe – PVC

pipe may lose its rigidity or glue may fail.

CAUTION: To avoid

injury or damage to the

steamer, do not connect

solidly to any drain

connection.

FIGURE 1

WATER QUALITY

The water supply connected to the steam generator should meet the following guidelines:

Failure to comply with water quality statement on page 4 may void the warranty.

Water supplies vary from one location to another. Other factors affecting steam generation are

iron content, chlorides, and dissolved gasses. A local water treatment specialist should be

consulted before installing any steam generating equipment.

Untreated water contains scale producing minerals which can precipitate onto the surfaces in

the boiler. Due to the temperatures in the boiler, the minerals can bake onto the surfaces and

components. This can result in early component failure and reduced product life.

Mineral scale on components causes several problems:

1. The surfaces of the heating devices become coated with scale, reducing the heat transfer

efficiency. This can produce hot spots on the heating elements and result in premature

failure.

PART NUMBER 10223R1 7 2010-06-24

INSTALLATION AND OPERATION MANUAL AND PARTS LIST,

ELECTRIC CONVECTION STEAMER, MODELS EJ-7E, EJ-10E

WATER QUALITY (Continued)

2. The water level probes become coated with scale. Scale will bridge across the probe

insulator from the metal extension which senses the water level in the boiler shell. Once

this scale becomes wet, the water level control is unable to maintain the proper water level

in the boiler. This situation may cause an electric heating element to fail if the element is

not adequately covered by water.

Strainers and filters will not remove minerals from the water.

Refer to REMOVAL OF LIME SCALE DEPOSITS, page 18.

VENT HOOD

Some local codes may require the steamer to be located under an exhaust hood. Information

on the construction and installation of ventilating hoods may be obtained from NFPA Standard

No. 96, Vapor Removal from Cooking Equipment, (latest edition).

PART NUMBER 10223R1 8 2010-06-24

INSTALLATION AND OPERATION MANUAL AND PARTS LIST,

ELECTRIC CONVECTION STEAMER, MODELS EJ-7E, EJ-10E

START-UP TEST

WARNING: The steamer and its parts are hot. Use care when

operating, cleaning or servicing the steamer. The cooking

compartment contains live steam. Stay clear while opening the

door.

Once the steamer is installed and all mechanical connections have been made, thoroughly test

the steamer before operation.

1. Check that proper water, drain, and electrical connections have been made.

2. Turn main power switch ON. After approximately 15 minutes, the READY light should come

on, indicating that the water temperature is 205°F (96°C).

3. When the READY light comes on, set the timer at 5 minutes. With door open, observe that

no steam is entering the compartment and the COOKING light is OFF.

4. Close compartment door. The COOKING light should now be lit and steam should be

heard entering the compartment after about 45 seconds (5 minutes if boiler is empty).

5. Check drain line to ensure that water from the cold water condenser is flowing through the

drain line.

6. Open compartment door and observe that steam supply to the chamber is cut off (READY

light should again come on and COOKING light goes off).

7. Close compartment door and let cooking cycle finish. When the timer returns to the “O”

position, a buzzer will sound, signalling the end of the cooking cycle. To silence the buzzer,

turn the dial timer to OFF.

8. Complete the above steps for each cooking compartment.

9. To shut the steamer down, turn the main power switch OFF and leave the compartment

doors slightly open to allow the inside to dry out.

PART NUMBER 10223R1 9 2010-06-24

INSTALLATION AND OPERATION MANUAL AND PARTS LIST,

ELECTRIC CONVECTION STEAMER, MODELS EJ-7E, EJ-10E

3.0 OPERATION INSTRUCTIONS

WARNING: An obstructed drain can cause personal injury or

property damage.

1. Ready Plot Light When lit, indicates steam generator

2. Cooking Pilot Light When lit, indicates that a cooking

3. Timed Cooking/Constant Cooking Mode Set the cooking time (0 to 60

4. Main Power Switch

ON The steam generator will

OFF The steam generator will drain. No

DELIME Closes the drain valve while CLR

has reached 200º Fahrenheit (93º

Celsius) and is ready for the cooking

cycle.

cycle is in progress.

minutes) - steam cooking will begin

after the door is closed. The

cooking cycle will be interrupted if

the door is opened during the

cooking cycle; resume cooking by

closing the door. Select “Constant

Steam” for continuous cooking.

automatically fill and begin heating

to the pre-set temperature for

standby. Red light will illuminate on

the main power switch.

lights.

liquid is being poured into the steam

generator during the Delime

procedure. Amber light will

illuminate on the main power switch.

5. Buzzer Signals end of cooking period (not

shown).

PART NUMBER 10223R1 10 2010-06-24

INSTALLATION AND OPERATION MANUAL AND PARTS LIST,

ELECTRIC CONVECTION STEAMER, MODELS EJ-7E, EJ-10E

3.0 OPERATION INSTRUCTIONS (Continued)

BEFORE FIRST USE

Clean the protective oils from all surfaces of the steamer. Use a non-corrosive, grease

dissolving commercial cleaner, following manufacturer’s directions. Rinse thoroughly and wipe

dry with a soft clean cloth.

PREHEAT

Turn the main power switch ON. When the READY light comes on, set the timer to 1 minute to

preheat the compartment. This should be done when the steamer is first used for the day or

whenever the chamber is cold. The door should be closed during the preheat cycle. The

COOKING light will be lit. When the buzzer sounds, set the timer to the OFF position. The

steamer is now ready to cook.

COOK

With compartment preheated and READY light ON, place pans of food into the compartment

and close the door.

Set timer to desired cooking time. (The cooking cycle may be interrupted at any time by

opening the door. To resume operation, close the door.) Steam will flow into the compartment

and the COOKING light will be lit.

At the end of the cooking cycle, the buzzer will sound, the COOKING light will go off and steam

supply to the compartment will cease. Turn the timer to the OFF position to silence the buzzer.

CONSTANT STEAM COOKING - This mode will give continuous steam to the cooking

chamber until the operator turns power OFF to the steamer. .

When cooking is complete, or not in use, the constant steam cooking feature should be shut

off. This prevents the boiler from running unnecessarily. This will help conserve water, and will

reduce boiler maintenance.

SHUTDOWN

Turn main power switch OFF. The boiler will automatically blow down. Leave the compartment

door open to allow the inside to dry out. For an extended shutdown, turn the main power switch

OFF; turn power and water supply OFF.

Drain the boiler after each day’s use to flush out minerals and minimize scale build-up. The

boiler drains automatically for approximately 4 - 6 minutes after the main power switch is turned

off.

PART NUMBER 10223R1 11 2010-06-24

INSTALLATION AND OPERATION MANUAL AND PARTS LIST,

ELECTRIC CONVECTION STEAMER, MODELS EJ-7E, EJ-10E

COOKING HINTS

Your steamer efficiently cooks vegetables or other foods for immediate serving. Steam cooking

should be carefully time controlled. Keep hot food holding-time to a minimum to produce the

most appetizing results. Prepare small batches, cook only enough to start serving, then cook

additional amounts to meet demand.

Preparation

Prepare vegetables, fruits, meats, seafood, and poultry normally by cleaning, separating,

cutting, removing stems, etc. Cook root vegetables in a perforated pan. Other vegetables may

be cooked in a perforated pan unless juices are being saved. Liquids can be collected in a

solid pan placed under a perforated pan.

Perforated pans are used for frankfurters, wieners, and similar items when juices do not need to

be preserved. Solid pans are good for cooking puddings, rice and hot breakfast cereals.

Vegetables and fruits are cooked in solid pans in their own juice. Meats and poultry are cooked

in solid pans to preserve their juice or return broth.

Canned foods can be heated in their opened cans (cans placed in solid pans), or the contents

may be poured into solid pans. DO NOT place unopened cans in the steamer.

Frozen Food Items

Separate frozen foods into smaller pieces to allow more efficient cooking.

Use a pan cover for precooked frozen dishes that cannot be cooked in the covered containers

in which they are packed if they require more than 15 minutes of cooking time. When a cover

is used, approximately one-third additional cooking time is necessary. Cooking time for frozen

foods depends on the amount of defrosting required. If time permits, allow frozen foods to

partially thaw overnight in a refrigerator. This will reduce their cooking time.

PART NUMBER 10223R1 12 2010-06-24

Loading...

Loading...