Page 1

ECO-JET ELECTRIC TWIN GENERATOR

E

MODELS

EJ-10E - (2) five pan steamers with two electric steam

generators

DESCRIPTION

Shall be a Market Forge Model EJ-10E, two compartment convection

steam cooker with individual steam generators and controls mounted

on a stainless steel cabinet base.

Industry First: The Eco-Jet Series is the only atmospheric twin generator electric steamer that comes complete with a self contained

water filter system. The built-in system eliminates the hassle of where

to put the filter.

The steamer will be of double-wall construction with 1-1/2” (38mm)

thick insulation between cooking compartment and exterior walls, and

will have two type 316 stainless steel welded cooking compartments

with coved internal corners, and a 16 gauge stainless steel back.

Each cooking compartment on the steamer has a heavy duty door

with an inner liner of stainless steel with a full perimeter gasket seal

and outer liner of one piece all welded stainless steel with positive

lock and seal mechanism and spring release. Steam generation to

the compartment shall be interrupted when the door is opened and

reactivated when the door is closed.

Each compartment will be equipped with two steam inlets positioned

precisely to ensure even steam cooking across all food products.

Two Compartment Steamer

Controls for each compartment will include a 60-minute timer with

load compensation and constant steam position, illuminated ON/

FOOD SERVICE EQUIPMENT

OFF/DELIME power switch, pilot READY light, pilot COOKING light,

cold water steam condenser system, and removable stainless steel

pan supports. An integrally connected stainless steel drip trough to

collect condensate when the doors are opened shall be provided.

Each compartment will be independently controlled by setting the

cooking time on the 60-minute timer. At the end of the cooking cycle,

the pilot cooking light will turn off and a continuous signal will sound.

Signal is silenced by returning the timer to the OFF position.

Each compartment will have an independent steam generator and

controls that will be automatically filled with water and brought to a

ready temperature when the power switch is turned ON and automatically drained when the power switch is turned OFF, low water cut-off

safety control, and delime port access located at the rear of unit for

Total Concept delime/descaler. For ease of serviceability, generator

controls are conveniently located on the right side of the steamer

enclosure.

CAPACITY

1” 2-1/2” 4” 6”

20 10 6 4

CONVECTION STEAMER

PAN DEPTH

JOB NAME: ___________________________

ITEM NO.: ____________________________

NO. REQUIRED: _______________________

STANDARD FEATURES:

Four Flanged Feet

Automatic Blow Down

Removable Stainless Steel Pan Supports

External Delime Ports for each Generator

Heavy Duty all Welded “Slammable” Doors

SHIPPING WEIGHT

350 lbs (159 kg)

OPTIONS & ACCESSORIES (at additional charge)

Pans & Covers

12” x 20” pan cover

12” x 20” x 1” solid pan

12” x 20” x 1” perforated pan

12” x 20” x 2-1/2” solid pan

12” x 20” x 2-1/2” perforated pan

12” x 20” x 4” solid pan

12” x 20” x 4” perforated pan

12” x 20” x 6” solid pan

12” x 20” x 6” perforated pan

Voltage options

220 VAC, 3 Phase, 50/60 Hz

380 VAC, 3 Phase, 50/60 Hz

415 VAC, 3 Phase, 50/60 Hz

480 VAC, 3 Phase, 50/60 Hz

220/380 VAC, 3 Phase, 4 wire, 50/60 Hz

240/415 VAC, 3 Phase, 4 wire, 50/60 Hz

Replacement filter kit (set of 2)

Prison package, includes lockable stainless steel hinged

control cover, tamper proof screws, (4) 6” adjustable

flanged feet

44 Lakeside Avenue, Burlington, VT 05401 USA • Tel: (802) 658-6600 • Fax: (802) 864-0183

www.mfii.com

Page 2

ECO-JET ELECTRIC TWIN GENERATOR

E

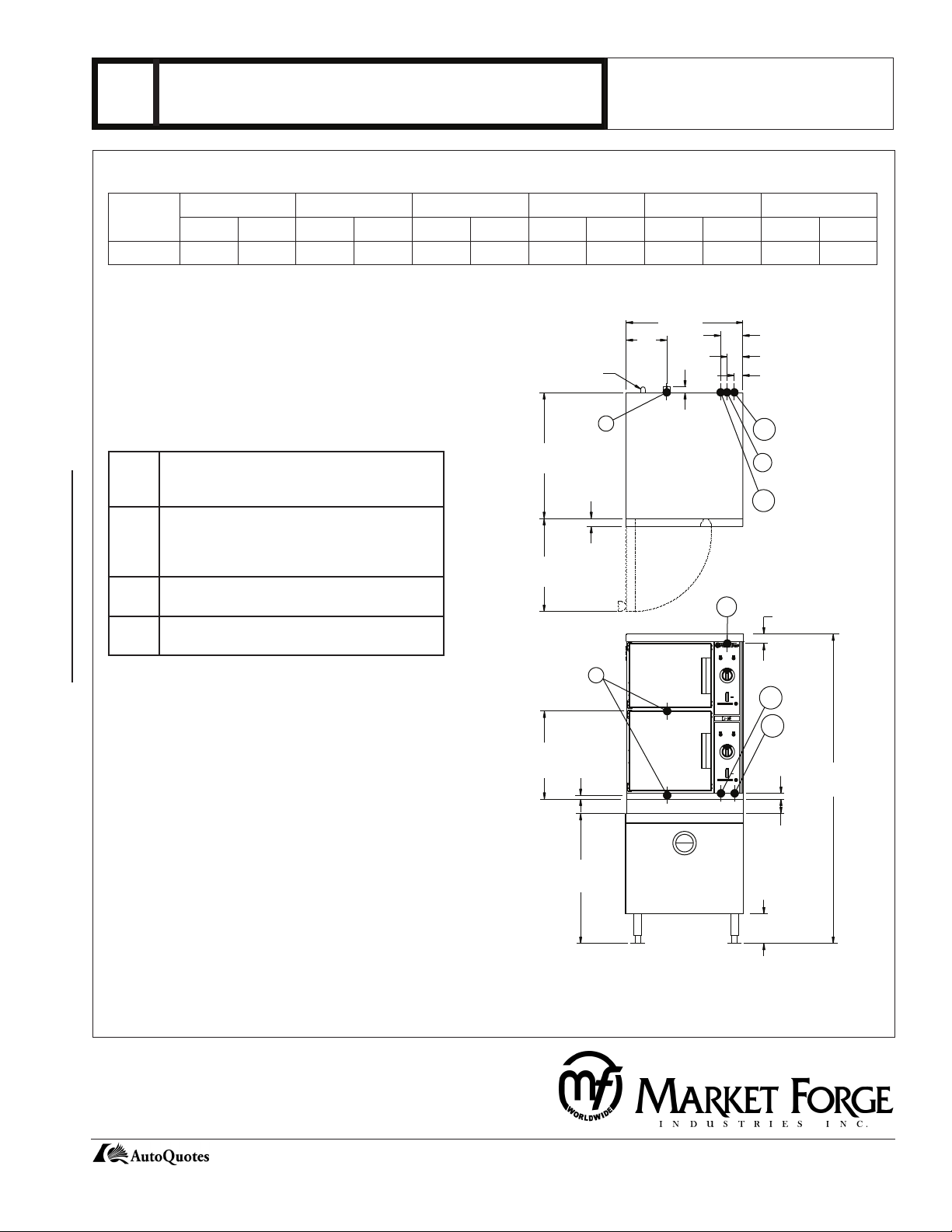

ELECTRICAL REQUIREMENTS

CONVECTION STEAMER

DETAILS & DIMENSIONS

PHASE

208V 220V 240V 380V 416V 480V

kW AMP kW AMP kW AMP kW AMP kW AMP kW AMP

3 30.0 83.3 30.0 78.7 30.0 72.2 30.0 45.6 30.0 41.6 30.0 36.1

Electrically heated steam generator operating at 0 PSI (0kg/

cm2) with field replaceable elements rated at: 15kW per

generator, 30kW total. The generator shall be equipped for

operation on:

208 VAC, 3 Phase, 60 Hz

240 VAC, 3 Phase, 60 Hz

Additional voltages available as an option.

SERVICE CONNECTIONS

EC Electrical Connection - ø1-1/8” (29mm)

Connection for incoming power supply wire on

terminal block.

D Drain Connection - 1”ø (25mm) NPT to open

floor drain. NO SOLID CONNECTION! 24”

length before open air gap opening. NO BENDS

OR ELBOWS!

CW1 Cold Generator Water - 3/8” (10mm) tubing at

25-50 PSI.

CW2 Cold Condensing Water - 3/8” (10mm) tubing

Two Compartment Steamer

DRAIN LINE INSTALLATION:

FOOD SERVICE EQUIPMENT

The drain ports of the unit are marked with a colored tag

and are located at the lower rear left side of the boiler as

viewed from the front. Two 1” (25mm) NPT drain lines must

be connected to divert the exhaust to the floor drain. If it is

necessary to use more than three elbows, increase the size

of the waste line accordingly.

CAUTION: Before connecting water to this unit, water supply should be analyzed to make sure hardness is no greater

than 2.0 grains and pH level is within the range of 7.0-8.5.

Water which fails to meet these standards should be treated

by installing a filter or conditioner. EQUIPMENT FAILURE

CAUSED BY INADEQUATE WATER QUALITY IS NOT

COVERED UNDER WARRANTY.

at 25-50 PSI.

DIMENSIONS ARE IN INCHES [MM]

9

[229]

1/2” NPT Delime Inlet

D

33

[838]

16.75

[425]

19.88

[505]

1.38

[35]

D

1

[25]

28

[711]

24 [610]

1.12

[29]

EC

3.94 [100]

3 [76]

1.75 [45]

CW2

EC

CW1

CW1

CW2

6 [152]

2.62 [67]

1.5

[38]

5

[127]

68.5

[1740]

PRINTED IN U. S. A.

SPEC SHEET: 14-0102 Rev B (3/15)

The manufacturer reserves the right to modify materials and specifications without notice.

44 Lakeside Avenue, Burlington, VT 05401 USA • Tel: (802) 658-6600 • Fax: (802) 864-0183

www.mfii.com

Loading...

Loading...