Page 1

1

TM

UNITY 2

Air Server Series 2 Operators

Manual

Version 1.0

February 2008

1. Introduction to the Air Server Accessory for UNITY 2 ............................................................2

1.1. Summary of Operation ...............................................................................................2

2. Developing a UNITY 2-Air Server method for whole air / gas analysis .....................................3

2.1. UNITY 2-Air Server method ........................................................................................3

2.2. Setting the carrier gas type ........................................................................................3

2.3. Parameters for on-line mode methods .........................................................................4

2.4. On-line methods .......................................................................................................6

3. Automatic sequencing of whole-air / gas analyses ................................................................7

3.1. Performing analyses ..................................................................................................7

3.2. Using the sequence builder and creating sequences of runs ............................................7

3.3. Setting up your first sequence ....................................................................................8

3.3.1. Editing individual lines in a sequence ....................................................................9

3.3.2. Recycling sequences ......................................................................................... 10

3.4. Running the sequence..............................................................................................10

3.5. Starting at a predefined date and time .......................................................................11

3.6. Stopping a sequence................................................................................................ 12

Air Server Series 2 Operators Manual

Page 2

2

1. Introduction to the Air Server Accessory for UNITY 2

The UNITY 2 Thermal Desorber normally requires sample introduction by means of a standard

sample tube. This could be a sorbent tube (used for diffusive or pumped sampling) or an empty tube

into which solid or liquid samples are weighed for direct desorption. The Air Server accessory

connects to UNITY 2 and extends the compatible sample range to include whole air / gas samples

e.g. continuous monitoring of air / gas streams or samples collected in whole-air containers such as

canisters or Tedlar bags. Tubes can still be desorbed using a UNITY 2 configured with the Air Server

accessory.

The Air Server contains appropriate inert switching valves and link tubing to interface the accessory

to UNITY 2. The Air Server is controlled via the UNITY 2 software. It features selection between three

(or eight) inlet ports as standard, using inert, PTFE-body solenoids, and is compatible with gas-phase

samples ranging in pressure from sub-atmospheric to 50 psig. Three ports are commonly used for

sample, calibrant and zero gas streams, but could just as easily be used for three (eight) different

samples.

1.1. Summary of Operation

The gas stream selected is directed out of the Air Server accessory (via the dryer - if one is fitted)

and into the UNITY 2 cold trap via the Link tube. During this ‘sampling phase’, UNITY 2’s cold trap is

electrically cooled and volatiles from acetylene to n-C14 can be quantitatively sampled and retained.

The sample / standard gas, once stripped of its target VOCs, exits through the desorb flow vent and

is directed to the ‘flow in’ port of the electronic mass flow controller on UNITY 2. It is not possible to

split during sampling. Set and actual sampling flows are displayed via the UNITY 2 software.

If the sample / standard gas is pressurised (>10 psi), the flow through the entire UNITY 2-Air Server

system is driven by this pressure. However if the sample is at low (<10 psi), atmospheric or just

below atmospheric pressure, a pump (

through the system.

Note: the flow controller and the optional pump are located downstream of the cold trap and thus

do not come into contact with the sample prior to trapping.

At the end of sampling and after a purge of carrier gas to eliminate air from the trap, the UNITY 2

focusing trap heats in the normal way, transferring compounds of interest to the analytical system

and triggering the measurement cycle. The outlet split at this point may be entered in the software

and is controlled by the mass flow controller. Collection of the next sample can begin, if required, as

soon as the cold trap has re-equilibrated at its trapping temperature.

The UNITY 2-Air Server sequence of operation is as follows:

1. Standby

2. Leak test (optional)

3. Pressure release

4. Pre-purge

5. Sampling

6. Line purge

7. Trap purge

8. Trap fire

U-ASPM1 / U-ASPM2

) is required to ‘pull’ the gas-phase sample

Air Server Series 2 Operators Manual

Page 3

3

Key Air Server applications include: -

Continuous on-line measurement of C2 to C10 hydrocarbons in ambient air using UNITY 2-Air

Server with GC-FID

Process monitoring of trace level volatiles in CO2 using UNITY 2-Air Server with process MS

Process monitoring of aroma during food and beverage production using UNITY 2 Air Server

combined with electronic nose technology

2. Developing a UNITY 2-Air Server method for whole air /

gas analysis

2.1. UNITY 2-Air Server method

Once the software has been downloaded to the Air Server, the only operating mode available will be

On Line Air and an on-line sampling method is displayed. The system is now ready for use with

whole-air samples or for continuous on-line monitoring of air or gas streams.

2.2. Setting the carrier gas type

Under the ‘View’ menu select ‘Options’ and then ‘Gas’.

Access the carrier gas selection by clicking on the box with the small arrow to the right of the

gas type.

The three carrier gas options - He, H2 and N2 - will then be displayed.

Air Server Series 2 Operators Manual

Page 4

4

Click on the desired gas and then click on the ‘OK’ button to select and set the carrier gas

type.

2.3. Parameters for on-line mode methods

All on-line method parameters (except Sample Gas and Sample Channel) are accessed and

changed in the same way as tube desorption method parameters in other method modes - see the

UNITY 2 operators manual.

This section of the manual only covers those parameters which differ from those used in standard

tube desorption methods. For common parameters, such as the flow path temperature, reference is

made to the relevant sections of the main UNITY 2 operators manual.

Split on in standby: This is the same parameter used in tube desorption methods (see the UNITY 2

operators manual) except that, in on-line mode the flow through the split in standby is controlled by

the electronic mass flow controller. The flow range is from 5-100 ml/min and may be set as required.

Leak test: Given that UNITY 2-Air Server systems are commonly used in a continuous or semicontinuous sequence by recycling or linking methods and given that there is no need to break into

the sample flow path by using the lever mechanism to change a tube between samples, the leak test

is optional in on-line mode.

However, if a sequence of air analyses is to be run in on-line mode and with the leak test deselected, it is recommended that an initial leak test be carried out to check system integrity before

initiating the series of runs.

To do this, first set up the run with ‘leak test’ selected - i.e. check the appropriate box.

Ensure that the UNITY 2 to Air Server Link tube is properly located in the desorption oven

with the lever mechanism fully down.

Initiate the run using the ‘Start run’ command. Watch as the instrument performs the

complete leak test. If the leak test is successful, stop the run immediately as described in the

main UNITY 2 operators manual.

The on-line mode method can then be modified to de-select the leak test before running the

sequence of samples. Save the method at this stage.

If the leak test is not successful, re-check the seal of the UASL link tube and all the

connections between UNITY 2 and the Air Server.

Pressure release: The Air Server can be used to sample using a pump or directly from a

pressurised container. In standby, the UNITY 2 trap and internal flow path is at the pressure of the

column. In the case of a pressurised source, if the carrier gas pressure is greater then the pressure

of the sample, then carrier gas will flow into the container when the sequence enters pre -purge. In

order to avoid dilution of the sample with carrier gas the pressure of the UNITY 2 flow path is first

reduced by venting carrier gas through the split line prior to opening any sampling valves. The

duration of this vent is set in the View >Options>Sequence section of the UNITY 2 software

Air Server Series 2 Operators Manual

Page 5

5

Note: The default value is 0.3, values greater than this may be required particularly if sampling from

very low-pressure source such as tedlar bags.

Prepurge time: Range 0.0 to 99.9 minutes selectable in 0.1 minute increments.

This ensures that the UNITY-Air Server flow path and individual sample lines leading up to the Air

Server are swept with the current sample before sample collection. This allows accurate metering of

a volume of sample during the sample collection phase without either contamination from previous

samples or dilution by carrier gas. The mass flow controller controls the pre-sample purge flow to

that set for sampling. The pre-sample purge flow is all directed down the split line. None of the gas is

allowed to pass into the cold trap.

Trap purge time: Range 0.2 to 99.9 minutes selectable in 0.1 minute increments.

This relates to the post sampling purge of the sampling lines and cold trap with carrier gas before the

trap is desorbed. It is analogous to the ambient temperature purge of the tube before desorption

(see the UNITY 2 operators manual). The Air Server and UNITY 2 sweep the internal sample flow

path (including the dryer, if fitted) out of the split, for the first 80% of the trap purge time, thus

ensuring that the metered volume of sample collected on the cold trap is not added to. During the

remaining 20%, the carrier gas is switched to flow entirely through the cold trap and eliminate air

before the trap is heated.

Note: By careful adjustment of the cold trap sorbents, purge volume and cold trap temperature it is

also often possible to use the trap purge to selectively eliminate water and / or solvents without

losing compounds of interest.

Air Server Series 2 Operators Manual

Page 6

6

Trap purge flow: Range 5-100 ml/min.

This determines the flow rate of carrier gas during the trap purge procedure above.

Check boxes for dryer: If a dryer is installed on the back of the Air Server, ‘Dryer On’ must be

selected in the method by checking the appropriate box.

Note: Failure to do this will lead to sample passing into the membrane dryer without the counter

flow of dry air / nitrogen being actuated. This can cause contamination of the dryer.

The dryer will not function without the appropriate hardware being installed.

Sample time: Range 0.0 to 999.9 minutes selectable in 0.1 increments. After the leak test (if

selected) and after the pre-sample purge, the flow of sample air / gas is directed to the electricallycooled trap of UNITY 2 for the time set as ‘sample time’.

Flow rate: Range 5-100 ml/min. This determines the flow of sample air / gas into the cold trap for

the sampling time. It is controlled by the mass flow controller on UNITY 2 and is independent of the

pressure of the sample. During sampling the actual flow will be displayed in the System Status box

of UNITY 2 software.

GC Cycle time: Entry of GC cycle time allows collection of the next sample to overlap the analysis of

the previous sample. The cycle time should equal the sum of times of all the different phases of

analyser operation – for example GC run time, cool down and equilibration. In the case of on-line

mode operation, UNITY 2 software uses the cycle time parameter to calculate when collection of the

next sample can begin such that the cold trap will be ready to desorb just after the analyser is ready

for the next injection.

Note: If sampling delays and intervals are set in the “Automation Window” then the GC cycle

time should be set to 0.1 minutes to avoid any interference with automated sampling times.

Further Notes:

• Splitting is not available during the on-line sampling phase.

• As with tube desorption methods, the status of the flow path in on-line mode can be displayed

schematically on the PC screen at all times. This facility is accessed as described in the UNITY 2

users manual.

Split flow during trap heat: Range 5-100 ml/min. It is possible to split the sample as it desorbs

during trap heat. In this case, the carrier gas head pressure drives the flow of carrier gas through

the hot trap and determines the flow to the analyser(s). The flow to the split vent and, consequently

the split ratio, is determined by the split flow setting and is controlled by the mass flow controller.

Note: Other cold trap parameters are as described for tube desorption methods - see the UNITY 2

operators manual.

2.4. On-line methods

Once an on-line mode method has been generated it is treated in the same way as one of the tube

desorption methods with respect to ‘controlling’ system operation, storage, recall and method linking

- see the UNITY 2 operators manual.

Air Server Series 2 Operators Manual

Page 7

7

3. Automatic sequencing of whole-air / gas analyses

3.1. Performing analyses

The UNITY 2-Air Server system runs in a fashion analogous to that of the automated UNITY 2-U

system, in that the Automation Window provides the top level control for running the instrument.

The Automation Window allows the user the freedom to run a single method or a complex sequence

of timed analyses with minimal effort.

3.2. Using the sequence builder and creating sequences of runs

Sequences are made up of sets with each set being a series of analyses. When a set is first created it

is a rapid and convenient tool for associating a defined number of analyses with a specific method

and sample channel. However, once created, sets may be modified to contain any combination of

methods and / or sample channels. Sequences containing complex sets may be saved for use at a

later date.

Sequences and sets are created and / or amended via the Automation Window which appears by

default in Air Server mode. When the software is set up to run in Air Server mode for the first time, a

default sequence with one set of ten runs is created. Right clicking with the mouse anywhere within

the "Sequence Builder" section of the Automation Window will bring up the contextual menu for

the sequence builder.

LTR

A

Note: These options can also be accessed by selecting the ‘Automation’ menu.

The contextual menu contains six items:

New Sequence Creates a new blank sequence in a new Automation

Window.

Open Sequence Opens the File Open dialogue to allow a previously saved

sequence to be opened in a new Automation Window.

Add Sequence Opens the File Open dialogue to allow a previously saved

sequence to be appended to the end of the current

sequence.

Add New Set Opens the Add New Set dialogue (see Section 3.3) and once

the new set has been defined it is appended to the next

available row in the sequence.

Add Sample Adds a single sample to a set within a sequence (only

available once a Set has been expanded by clicking on the

plus (+) sign located to the left of the Set name).

Delete Item Deletes the selected row - this may also be performed by

pressing the Delete button on your keyboard.

Air Server Series 2 Operators Manual

Page 8

8

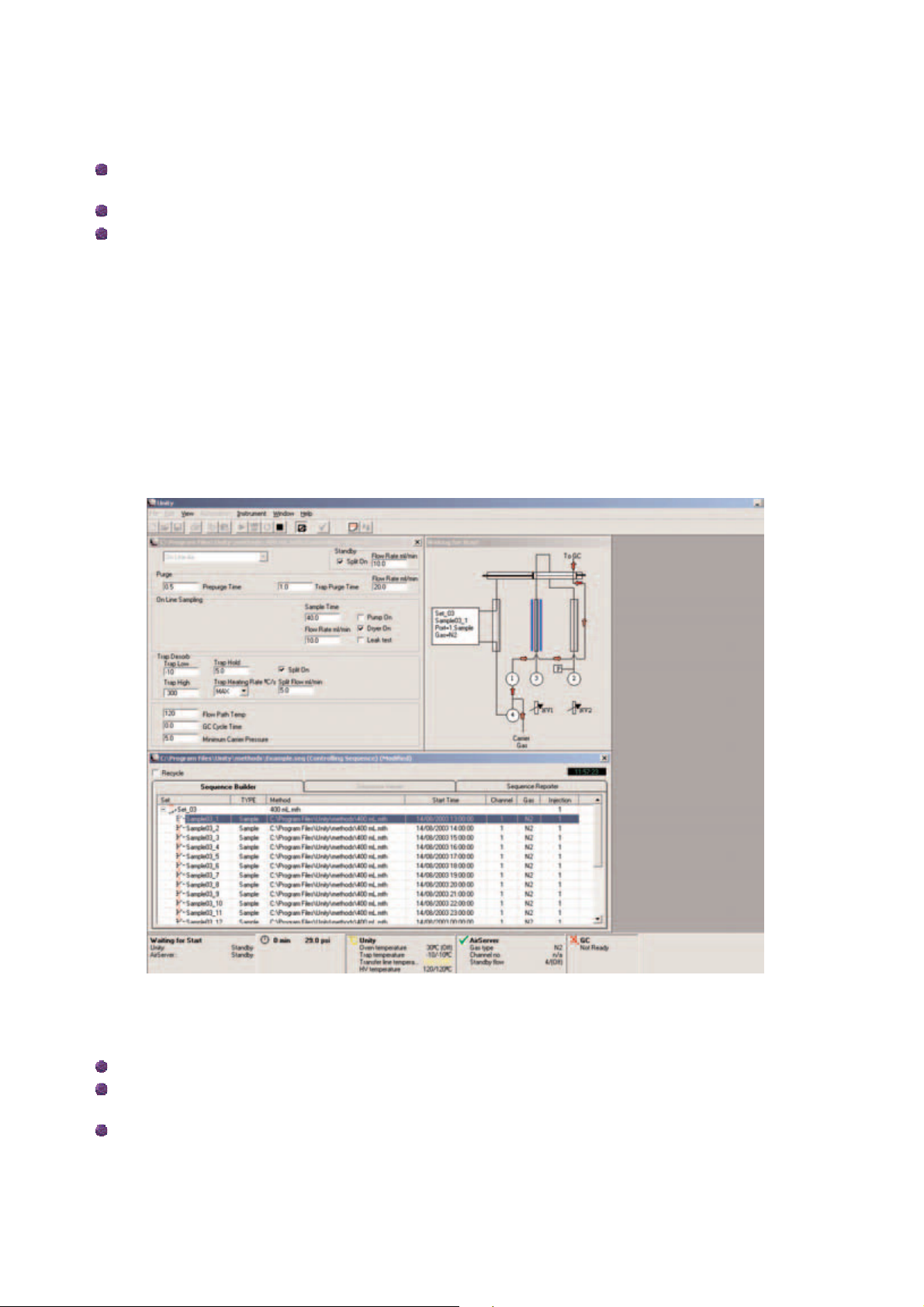

3.3. Setting up your first sequence

The first stage to setting up a single analysis or series of analyses is to edit and save an Air Server

method with convenient parameters. In the example shown below a method has been set up to take

400 ml of sample in 10 minutes and saved under the name "400 ml.mth".

Once you have created your new Air Server method and saved it you are ready to create your first

sequence.

Right click in the sequence builder and select ‘New Sequence’ and a new empty Automation

Window will appear.

It is good practice at this point to save this new sequence under a suitable file name (in the

example below the name chosen was "Example.seq") - to do this, use the "File - Save As"

function in the main software window.

Having saved your new sequence the next step is to create your first set. As before right click to

bring up the contextual menu and select "Add OLA Set". This will bring up the “Select Method to

be used with Sample or Set” dialogue which allows you to select the saved method you wish to

use.

Once the method has been selected the "Add New Set" dialogue box will appear with the selected

method entered in the Method box.

Air Server Series 2 Operators Manual

Page 9

9

The parameters within the "Add New Set" dialogue are the following:

Set Name Alphanumeric name given to a set to describe its contents – it is the only

name that will be visible when a set is collapsed

Method The UNITY 2-(Air Server) method that will initially be attributed to all the

members of this set. By default the software automatically inserts here the

most recently modified method. Alternatively, double-clicking in this box with

the left-hand mouse button opens the ‘File Open’ dialogue allowing

selection of an existing UNITY 2 method.

Channel The channel that will initially be attributed to all the members of this set (1 =

Sample channel, 2 = Blank channel, 3 = Reference channel). The channel

number set here corresponds to the numbers shown on Air Server.

Samples The number of separate sample rows to be included within a set.

Injections The number of times each sample row will be repeated.

Recollect When an optional re-collection ULTRA is installed it is possible to re-collect

up to 99 on-line air samples automatically onto tubes for sample archiving

and method validation purposes.

1st When re-collect is available, see above, this defines the first tube onto which

sample will be recollected.

Gas Sets the sample gas type so that the correct calibration factor is applied to

the mass flow controller. Available options are: N2, CO2, Air, He or H2.

Sample

base name

Sample

Interval

Set delay Allows an inter-set delay to be set between the last sample of a

The base name given to all the samples within a set to which an

automatically incremented number is appended.

Allows a timed interval to be specified between consecutive samples (0-9

days : 00-23 hours : 00-59 minutes).

Note: If the sum of the times set within a given method (leak test, pressure

release, prepurge, sample, trap purge and trap fire time) exceeds the

interval specified here, then the interval will not be taken into account. In

this case consecutive runs will take place one after another at a frequency

determined by the overall method duration.

given set and the first sample of the next set. The total delay will be equal to

the delay time plus the sample interval time, therefore if the sample interval

is set to 20 minutes and the set delay is set to 40 minutes then the total

delay will be 60 minutes between the last sample of a given set and the first

sample of the subsequent set.

3.3.1. Editing individual lines in a sequence

In a true air monitoring scenario, it would be convenient to include in this set a run of zero gas to

check the instrument blank and a run of calibration gas to check retention times and response

factors.

This can be done quite simply by double clicking on any of the parameters to change them – such as

changing the gas type for the blank and calibration from Air to Nitrogen.

Air Server Series 2 Operators Manual

Page 10

10

3.3.2. Recycling sequences

It will also be common in an Air monitoring scenario to want to run the same set of runs again and

again. This may be achieved simply by clicking the recycle check box (top left in the automation

window) where you will be prompted to define a number of re-cycles. e.g. If Stop after 1 re-cycle is

selected, then the sequence is run through twice. If nothing is entered then this set of runs will run

indefinitely.

3.4. Running the sequence

Before starting the run you will need to make the sequence you have created into the controlling

sequence. This is easily achieved by clicking the icon on the menu bar. The next step is to set

the sequence going by clicking on the "Run" button in the UNITY 2 Toolbar

Once "Run" is clicked then you will be prompted to start immediately:

• "Yes" triggers the UNITY 2 Air Server system to start straight away

• "No" opens the "Start Time Dialogue" box (see below)

• "Cancel" takes the system back into standby to allow further editing of the newly created sequence

If the sequence is set to run immediately then the start time column in the sequence builder will be

filled with the relevant start times for each of the samples.

Note: if recycle is chosen then only the start times for the first run through the set are shown these start times are updated each time a full cycle is completed.

Once running, progress through the sequence may be monitored via the sequence reporter tab in the

Automation Window.

The parameters reported in the sequence reporter may be changed by going to “View” then

selecting “Options” and then selecting the “Reporting” Tab.

Air Server Series 2 Operators Manual

Page 11

11

Click on the parameters that you wish to view in the Sequence Report.

Note: a spreadsheet view of this Sequence Report (.csv file) can be created from this Reporting Tab

by clicking “Create Report File” and saving the file.

3.5. Starting at a predefined date and time

If the start of the sequence needs to be delayed until a very specific date and time then clicking

"No", when prompted to start immediately, will bring up the "Start Time" dialogue box. Here it is

possible to define the start date and time down to the nearest minute and as far in advance as

wished.

Air Server Series 2 Operators Manual

Page 12

12

3.6. Stopping a sequence

A Sequence may be stopped at any time using the ‘Stop’ icon on the main toolbar. Clicking the icon

brings up the ‘Stop Link’ dialogue box.

This instructs UNITY 2 and Air Server to stop the Sequence and return to Standby. A number of

options are available according to whether you wish to stop immediately or at the end of a

designated cycle, injection, tube etc.

Continue Running - this will allow you to continue uninterrupted if you have clicked stop by

accident.

Stop after next injection of this sample - this will stop the sequence after it has finished

sampling and injected the sample (row) that is currently running.

Stop after all injections of this sample - this will stop the sequence after it has finished all of

the sampling steps and injections defined in the current sample (row).

Stop at the end of this set - will stop when the current set has completed.

Stop at the end of this cycle - will complete all the sets in a sequence and then stop (this is

useful for interrupting a sequence when cycle indefinitely has been chosen)

Stop immediate - this will stop the UNITY 2-Air Server immediately even if it is half way

through a sampling step - using stop immediate could mean that the cold trap is loaded with

sample when you come to start the next sequence

Air Server Series 2 Operators Manual

Loading...

Loading...