Page 1

Series 2

UNITY

Thermal desorber

A universal TD platform for tagged and

untagged tubes

Page 2

Series 2

UNITY

Thermal Desorption – GC(MS)

Thermal desorption (TD) is a highly versatile, sensitive

and labour-saving sample preparation technique for the

measurement of volatile and semi-volatile organic

compounds (VOC and SVOC) in air and materials. It

provides the ultimate sample introduction technology

for GC/GCMS combining selective concentration

enhancement with direct extraction into the carrier gas

and efficient transfer/injection all in one fully

automated and labour saving package.

TD is applicable to GC-compatible organics ranging in

volatility from acetylene and freons to high boilers such

as n-C

40

, phthalate plasticisers and benzo-α-pyrene. It

also offers quantitative concentration for some

inorganic gases including; nitrous oxide, SF6, CS2and

H2S. Key applications include:

• Environmental and workplace air monitoring

• Civil defence and forensic analysis

• Materials and materials emissions testing

• Food, flavour and fragrance profiling

Many material samples, such as polymers, paints,

drugs, foods, textiles, etc. can be directly thermally

desorbed. Weighed samples are heated in a stream of

carrier gas allowing volatiles to be extracted into the

gas flow, refocused and injected into the GC(MS)

analyser as a discreet, concentrated band of vapour.

Alternatively, vapours in gas or air can be concentrated

on- or off-line onto sorbent traps/tubes before TDGCMS analysis. Several hundred litres of air or gas can

be sampled and the vapours transferred/injected into

the analyser in as little as 200 µl of carrier gas.

Concentration factors as high as 10

6

can be obtained.

Thermal desorption is now recognised as the technique

of choice for air monitoring (workplace and

environmental) and is the subject of many

international standard methods. Key examples include:

EN ISO 16017, ISO 16000-6, EN 14662 (parts 1 & 4),

ASTM D6196, US EPA TO-15 (canisters) & TO-17

(tubes), NIOSH 2549, UK Environment Agency

guidance on landfill gas (LFGH 04) and US EPA

guidance for on-line ozone precursor monitoring.

Markes TD systems offer full compliance with all these

standards.

Thermal desorption offers significant advantages

versus solvent extraction (SE). Key benefits include:

Typically 1000-fold enhancement in sensitivity, greatly

enhanced recovery (>95% vs. 30-80 % with SE), reusable sample tubes, no toxic solvent required and

reduced analytical interference.

Page 3

UNITY 2 Main Features

• Provides a single platform for all TD applications - labile species, semi-volatiles (up to n-C40), ultravolatiles (including C2H2and freons), trace levels (ppt) and high concentrations (ppm/%).

• R

epeat analysis

via SecureTD-Q

™:

Overcomes the one shot limitation of conventional TD systems.

• Cryogen-free operation: Electrically-cooled, sorbent trapping to -30°C eliminates ice plug formation and

reduces running costs.

• Compatible with 3.5-inch x ¼-inch OD sample tubes, with or without electronic tags. UNITY 2 allows an

individual TubeTAG™ to remain with a specific sample tube throughout its life, recording tube history and

facilitating sample tracking between field and laboratory.

• Fully method compliant including stringent leak testing without heat or gas flow applied.

• Fully upgradeable to multi-tube, multi-canister and/or on-line automation. Can also be coupled with

headspace for even greater sample flexibility.

• Time saving ov

erlap mode allows desorption of a subsequent sample to begin while GC analysis of a

previous sample continues.

• Plug-and-play TD: UNITY 2 adds to any commercial GC(MS) and is designed for easy maintenance.

utomated internal standard introduction onto

Thermal Desorption (TD)

• A

blank as well as sampled tubes.

Innovators

• Electrically-cooled sorbent trapping with uniquely-

For over a decade Markes International has pioneered

and commercialised enhancements to analytical

thermal desorption instrumentation and associated

sampling apparatus. The following examples of key

technical advances have all been introduced by Markes

since 1997 and now set the standard for TD

instrumentation:

• SecureTD-Q (quantitative re-collection of split

flow for repeat analysis), which overcomes the

historical one-shot limitation of TD methods and

1

simplifies method/data validation

• Electronic tube tagging (TubeTAG)

.

2

.

• Diffusion locking3(DiffLok™) for enhanced

sample integrity and robust (mechanically simple)

automation.

4

• Patented inert valving

for compatibility with

every TD application on a single analytical

platform – ultra-volatiles, semi-volatiles (up to

n-C40) plus reactive species - mercaptans, CS

gas, etc. – all on one TD system.

fast trap heating rates for splitless capillary GC

operation and optimum sensitivity without risk of

ice formation.

• Off-line conditioning for multiple tubes without

the need to blank-off unused tube connections.

• On-line desorbers with twin, electrically-cooled,

reciprocally-operated focusing traps for truly

continuous air monitoring (TT24-7™).

• Specialist sorbent tubes: Certified reference

standards, SafeLok™ tubes

3

, Silcosteel™ tubes.

• A range of unique sampling tools, several of them

5

patented

, for measuring volatile and semivolatile organics in challenging matrices:

liquids/solids/emulsions, breath, in-situ soil,

polymers, natural products, construction

products, etc.

1. Patent# GB 2395785 (Automated re-collection using a single TD autosampler), 2. Patent# US 6,446,515 B2, 3. Patent# GB 2337513 US 6,564656 B1

4. Patent# GB 2336649, 5. UK patent application reference 0501928.6 (µ-CTE)

Page 4

Introducing the UNITY 2

Thermal Desorber

UNITY 2, Markes’ next generation thermal desorption

platform, harnesses this pedigree. It incorporates every

feature required for TD method compliance, every

system innovation of the last ten years and the fieldproven reliability characteristic of all Markes TD

instrumentation. Its introduction to the market place

offers a state-of-the-art yet robust range of thermal

desorbers with systems available at prices to suit every

budget.

Building on the field-proven strengths of UNITY,

UNITY 2 combines tube desorption with cryogen-free

analyte re-focusing and efficient back-flush desorption

of the focusing trap. Trap desorption injects analytes

(split or splitless) into the GC capillary column in a

narrow, focused band of vapour and triggers the

GC(MS) run.

The patented, inert heated valve integrated into UNITY

2 facilitates the ambient temperature zero flow leak

testing specified by standard methods and allows

simultaneous analysis of volatile and semi-volatile

compounds. The short, narrow-bore sample flow path

is uniformly heated and optimizes analyte recovery.

SecureTD-Q™ (re-collection of tube and/or trap

desorption split flow) offers quantitative repeat analysis

and is available as standard on every UNITY 2.

SecureTD-Q overcomes the one-shot limitation of older

thermal desorbers.

UNITY 2 provides a method-compliant TD platform that

is ideally suited to meet the ever more stringent

demands of laboratory accreditation, data/method

validation and good laboratory practice. It is operated

using intuitive software loaded onto the same PC as

ChemStation™.

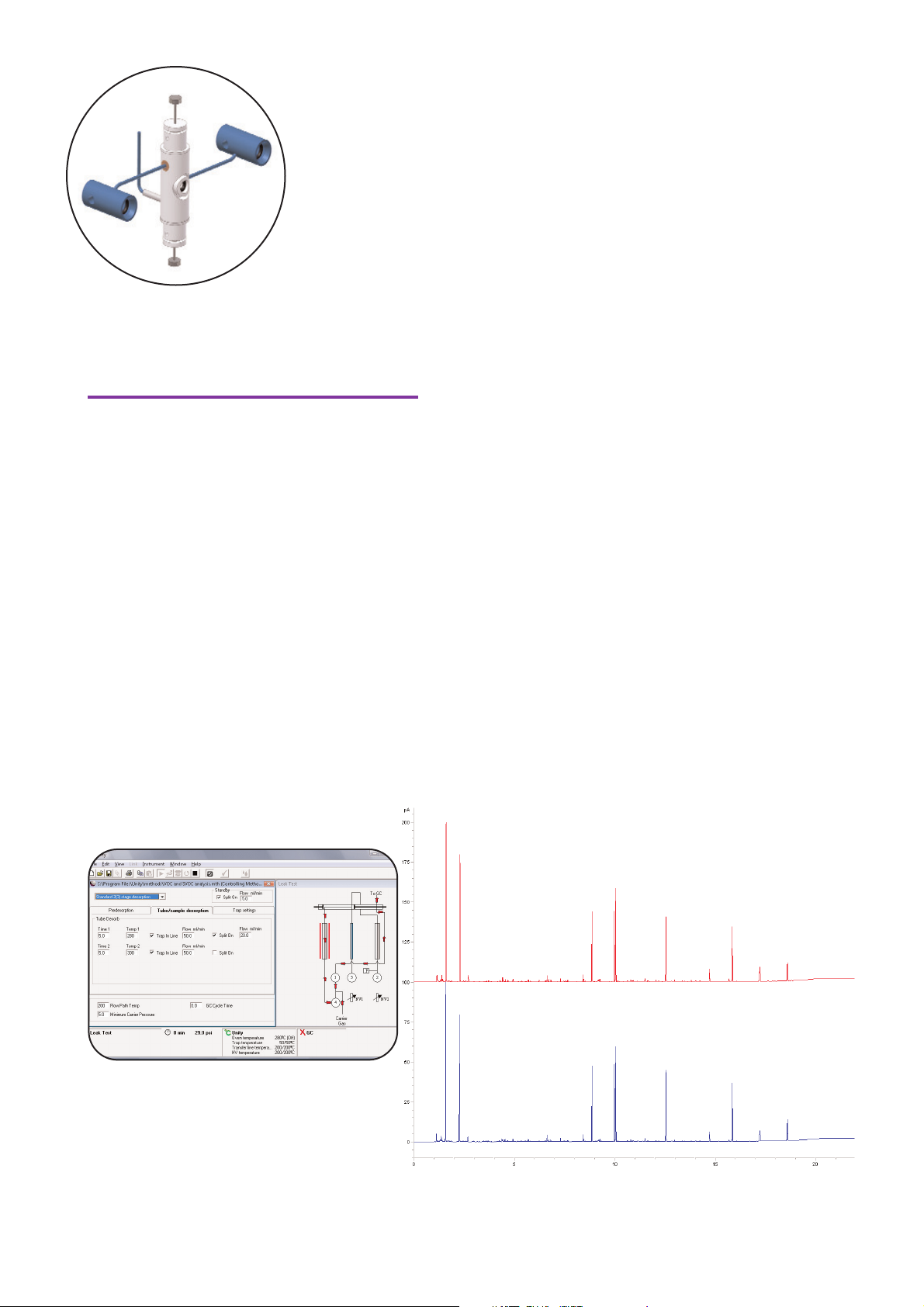

Chromatogram showing simultaneous analysis

of VOC and SVOC with Secure TD-Q repeat

analysis validating recovery across the range

Benzene

Toluene

Dimethyl phthalate

Diethyl phthalate

Hexadecane

Dibutyl phthalate

Diethyl-hexyl phthalate

Di-n-decyl phthalate

Sample

Re-collection &

repeat analysis

Page 5

One TD platform...

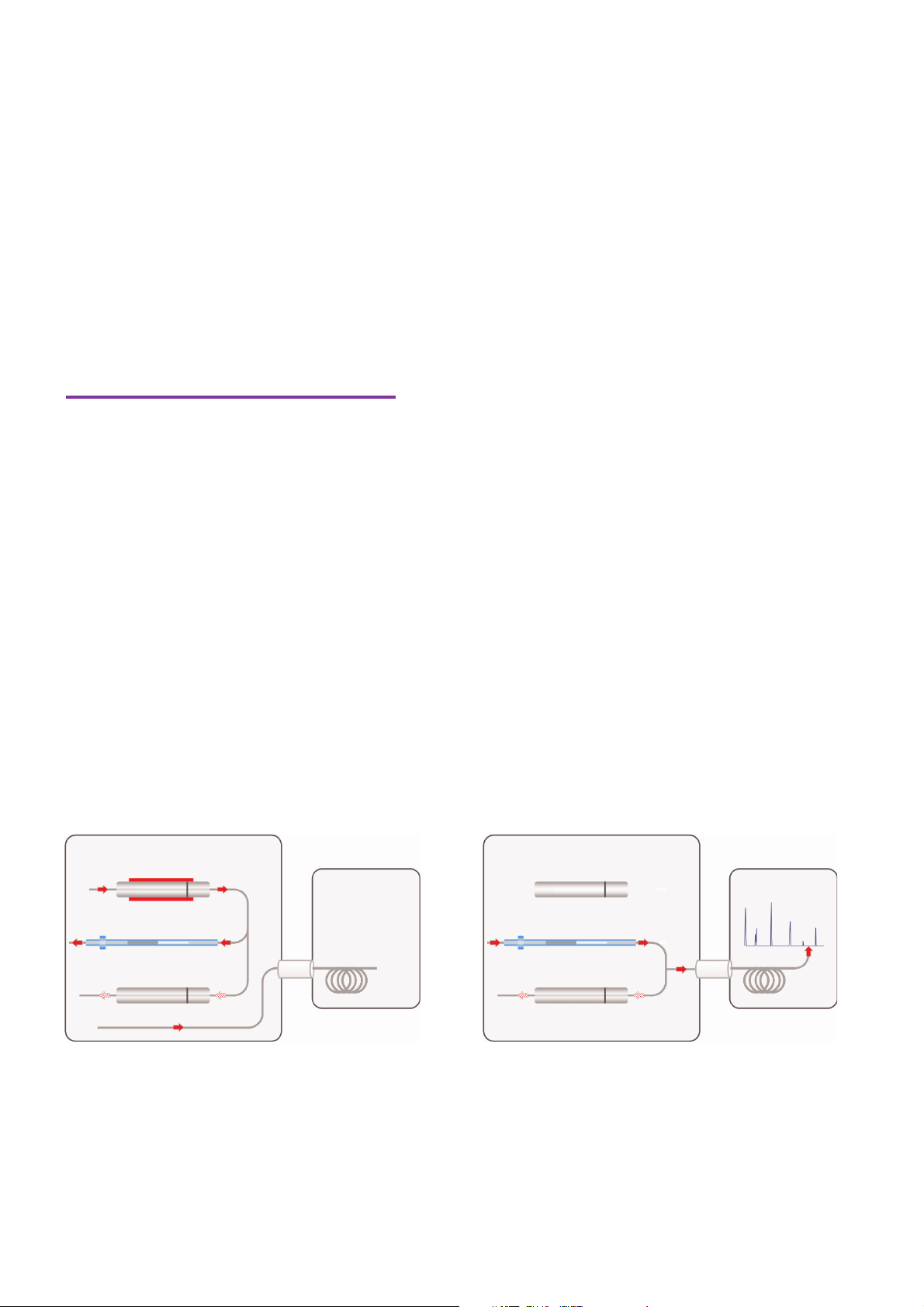

Schematics depicting the flow path of gas during tube desorption (left) and focusing trap desorption (right)

UNITY 2

GC(MS)

UNITY 2

GC(MS)

Trap desorption

Tube desorption

Sample tube

Sample tube

Cold trap Cold trap

Optional split

Optional split

Bypass line

Universal TD platform for all

applications

UNITY is renowned for its application versatility and

UNITY 2 takes this flexibility to another level. With

extended electrical cooling of the entire 60 mm sorbent

bed, the UNITY 2 focusing trap offers quantitative,

cryogen-free retention of ultra volatiles such as freons

and acetylene from larger volumes of air/gas. Markes

offers a range of off-the-shelf pre-packed UNITY 2

traps, each containing up to 4 sorbents. Some of these

are almost universally applicable, others are optimized

for the retention of ultra-volatiles/volatiles (e.g. C

hydrocarbons/freons to n-C12) and still others offer

quantitative retention of target analytes with selective

purging of water or solvents prior to analysis.

2

Tube desorption is now possible at temperatures above

400ºC. Critical sections of the internal flow path have

also been optimized, both for enhanced recovery of

higher boiling ‘sticky’ compounds and quantitative

analysis of reactive components. Example analytes

include: 5/6-ring PAHs, phthalates, PCBs, hydrocarbons

to n-C40, mercaptans, explosives and chemical warfare

agents.

The patented heated valve built into UNITY 2 is

specifically designed for analytical TD. It can be

operated at the low temperatures that are required for

enhanced recovery of labile components and also

allows quantitative recovery of high boilers such as

n-C

.

40

Page 6

...every application

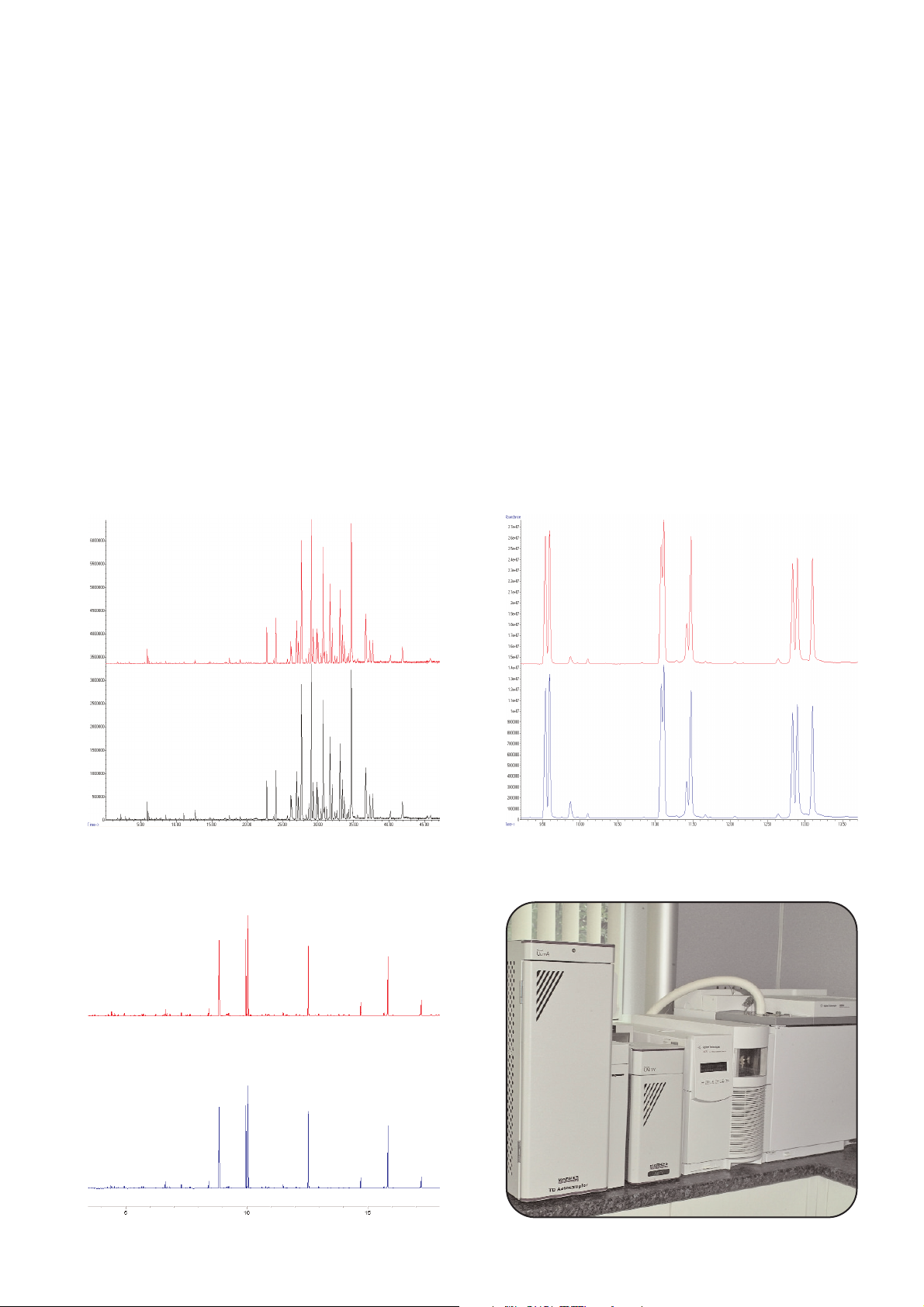

Quantitative recovery of high boilers (e.g. PCBs, phthalates and PAHs)

Dimethyl phthalate

Diethyl phthalate

Hexadecane

Dibutyl phthalate

Diethyl-hexyl phthalate

Di-n-decyl phthalate

Sample

Re-collection &

repeat analysis

Benzo(a)anthracene

Chrysene

Benzo(b)fluoranthracene

Benzo(k)fluoranthracene

Benzo(a)pyrene

Indeno(1,2,3-cd)pyrene

Dibenzo(a,h)anthracene

Benzo(g,h,i)perylene

Sample

Re-collection &

repeat analysis

Sample

Re-collection &

repeat analysis

PCB standard mixture

(Aroclor 1260)

Phthalate standard mixture

with internal standard

PAH standard mixture

“60 mm sorbent trap length, combined with -30°C cooling, uniquely fast trap

heating and patented TD valving ensure UNITY 2 offers optimum performance

for the widest possible TD application range”

Page 7

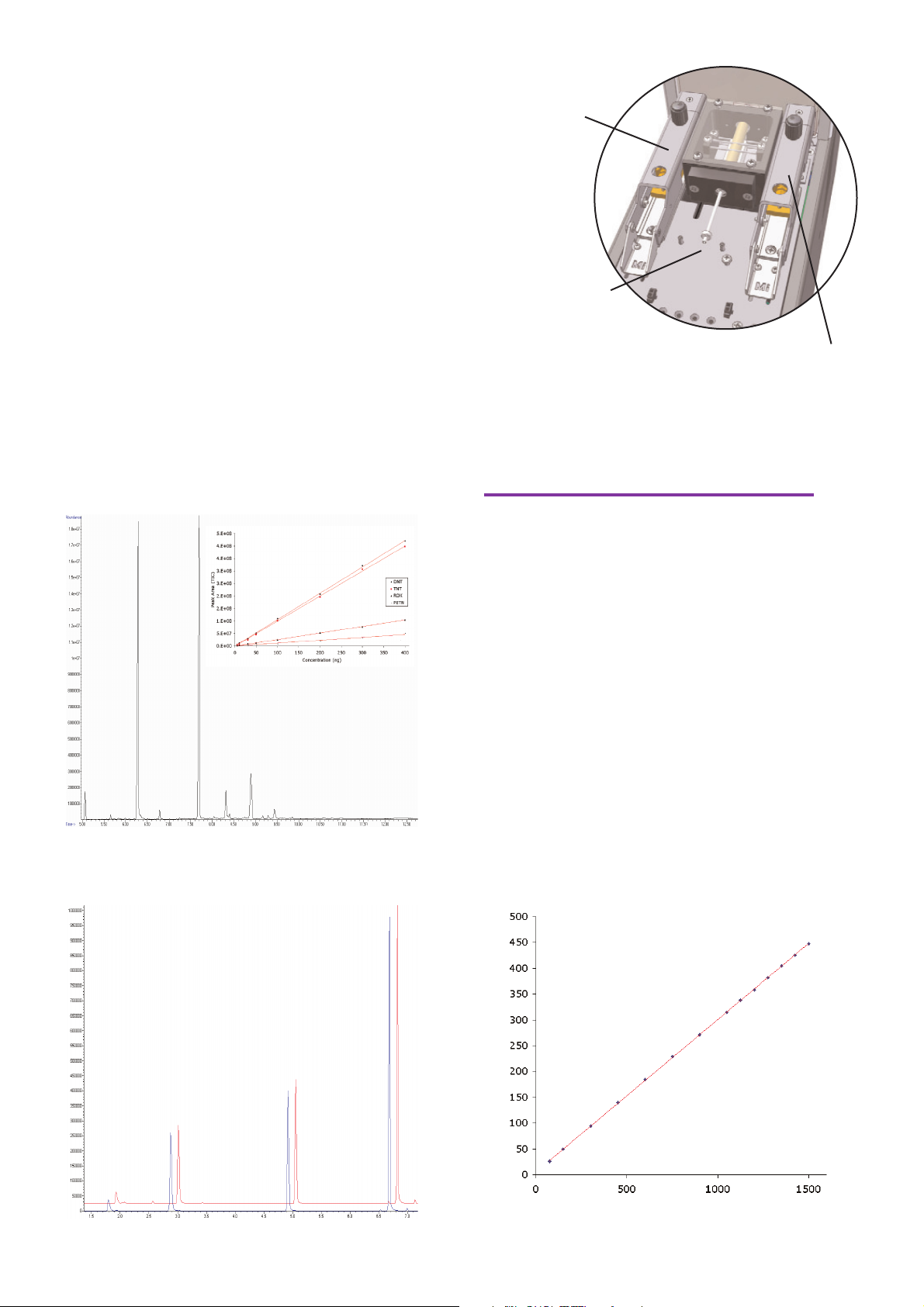

Sample tube desorption

Easy-change focusing trap

Split filter/re-collection tube

Enhanced user accessibility

Simplifying routine maintenance operations has been a

key focus during UNITY 2 development. Changing the

focusing trap, for example, is a simple user-enabled

process. No tightening or loosening of fittings is

required and a new easy-grip collar at the nonsampling end of each trap makes it very easy to

withdraw and replace. Other relevant features include

simple user access to split filters and transfer line

connections. Sealing o-rings have also been selected

both for extended life (typically at least 12 months)

and negligible artifact formation.

Compatible with labile analytes (e.g. explosives,

mercaptans)

DNT

TNT

PETN

RDX

R2 = 0.9997

R

2

= 0.9991

R

2

= 0.9996

R

2

= 0.9769

Ethyl

mercaptan

Benzene

Toluene

Xylene

Mixture of four explosives

Recovery of ethyl mercaptan with flow path at

80°C, re-collection and subsequent re-analysis

Cryogen-free retention of ultra-volatile analytes from

large volumes of air/gas

Sample Volume (mL)

Acetylene Peak Area

y = 0.2953x + 5.2249

R

2 = 0.9999

Page 8

Sample tracking with

(1) Tag permanently attached to tube &

programmed with tube-related

information using TAG

SCRIBE

(2) Tagged tube sent to field. Sample

start & end information written

to tag via TAG

SCRIBE

(3) Tagged tube returned to lab & data

retrieved using TAG

SCRIBE

. Tagged tube

desorbed using UNITY 2

(4) Tagged tube

ready for re-use

TubeTAG

Error-free tube and sample

tracking

Electronic tube tagging and tracking allows individual

TD sample tubes to be tracked from laboratory to field

and within a laboratory. RFID tags can be programmed

with tube- and sample-specific data such as tube ID

number, type and date of packing, number of thermal

cycles, sampling times/flows and customer reference

number. (More information is given in the TubeTAG

brochure.)

TubeTAG is being heralded as a future standard

requirement for large scale environmental monitoring

projects, industrial hygiene applications, civil defence,

etc. and is particularly important whenever monitoring

data is being linked to human health/comfort or public

safety. UNITY 2 can be used to analyse tagged tubes

(tags do not have to be removed) thus simplifying the

process of tracking tube history and performance.

With TubeTAG compatibility as standard, UNITY 2

ensures a future-proof analytical platform.

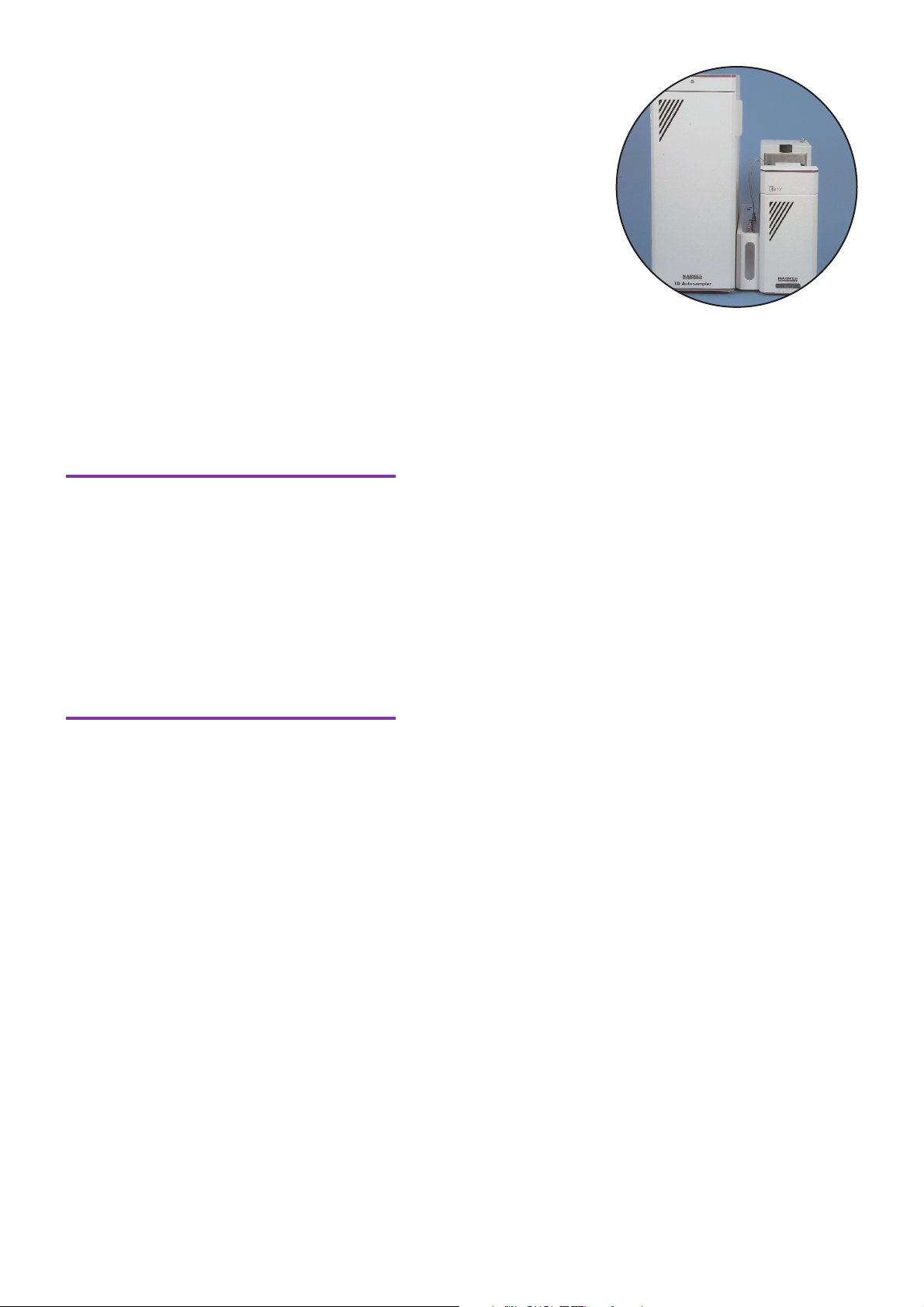

Page 9

UNITY 2 configured for both tube and

Fully upgradeable...fully flexible

Unattended operation for

extended periods

Featuring cryogen-free operation and lower

consumption of supply gases than other brands of TD,

UNITY 2 offers long-term unattended operation. It

needs only 40 ml/min dry gas flow, which equates to

>4 months continuous operation on a standard

cylinder, making it ideal for continuous field

monitoring, for example at remote environmental

stations.

Fully upgradeable: Tubes,

canisters & on-line gas streams

The UNITY 2 series TD range now includes options for

automated sequencing of up to 100 tubes and up to 8

on-line air/gas streams or canister/bags. A single

UNITY 2 platform desorber can be simultaneously

configured for both on-line/canister sequencing and

ULTRA 2 automation for up to 100 sample tubes.

UNITY 2 upgrade options include:

• The Universal Heated Inlet for interfacing

headspace vapours from custom sample

vessels directly to the UNITY 2 focusing trap.

• On-line/canister sequencing. Including 3- or

8-channel options for compliance with key

methods such as continuous monitoring of tracelevel ozone precursors (C

2-C10

hy

drocarbons) and

US EPA Method TO-14/15 “Air Toxics”.

• Series 2 U

LTRA 100-tube automation. The

ULTRA is available with built in options for

everything from internal standard addition to

automated sample re-collection.

• Headspace (HS)-TD: connection kits are now

available for connecting UNITY 2 to the Agilent

G1888 automated HS sampler. Combined systems

offer automated HS-trap, full functionality TD

and conventional equilibrium headspace all on

one analytical system.

Simple connectivity

100-tube ULTRA and multi-channel canister/on-line

options are now even easier to connect and disconnect

from UNITY 2 as requirements change; UNITY 2

provides plug-and-play TD.

Please see relevant brochures for further information

on all of these upgrade options.

canister/on-line automation

Page 10

Productivity & flexibilty

Retention time locking for GC(MS)

Accurate automatic control over split and desorb flows

with MFC options

Rapid cooling of UNITY 2 trap

Time (mins)

Temperature °C

Enhanced electronic control of

gas flows

Optimised productivity

UNITY 2 trap cooling times have been reduced to

minimize cycle times and complement the system’s

expanded automation capabilities. This feature coupled

with overlap mode (whereby a subsequent sample tube

is desorbed while GC analysis of the previous sample is

still ongoing) make UNITY 2 highly time efficient

thereby optimising productivity.

UNITY 2 is compatible with the back pressure regulated

electronic pneumatic control (EPC™) of Agilent

GCs. EPC offers precise control of carrier gas

flow/pressure through the entire TD-GC(MS) system as

part of the GC(MS) programme. This stabilizes

retention times independent of TD analytical conditions

(split flows, sorbents, desorption temperatures, etc.)

ultimately aiding analyte identification. EPC also allows

accurate monitoring and closed-loop control of the

column head pressure, whatever the stage of thermal

desorption operation and whatever the required flow.

Multiple splitting options

Building on UNITY’s compatibility with analyte levels

from sub-ppt to percent, every UNITY 2 offers

unsurpassed split versatility. Users can select from

splitless operation, single split (split open during either

tube or trap desorption) or double split (split open

during both tube and trap desorption.)

Every UNITY 2 features SecureTD-Q quantitative recollection of all split flow, for repeat analysis and

method/data validation (see overleaf and separate

brochure.)

Page 11

C

14

C

16

C

18

C

20

C

24

C

28

C

32

C

36

C

40

99% recovery of C40validated using SecureTD-Q

Negligible carry-over (0.03%)

following analysis of 1.3 mg toluene

Automatic control over split flows

Standard UNITY 2 systems feature the full range of

split options (splitless, single split and double split),

but with manually controlled flow rates. Electronic

control of split and desorb flows is offered by 1 or 2

optional mass flow controllers (MFC) integrated

into UNITY 2. These provide versatile electronic

control of both split and desorption flows, featuring

flexible split flow rate selection combined with precise

control at low flows. The UNITY 2 MFC modules also

facilitate flow rate recall during an automated sequence

with multiple TD methods.

Negligible carryover

With less than 0.01% carryover, UNITY 2 facilitates

automated multi-method analysis. High level samples,

such as stack gases or residual solvents, can be

included in the same automated sequence as sub-ppb

environmental air monitoring samples if required.

Building on the strengths of

UNITY

In addition to the enhancements described above,

UNITY 2 has drawn key strengths from its eminent

predecessor. Key features pioneered on UNITY and now

available on UNITY 2 include:

SecureTD-Q

• Repeat analysis: SecureTD-Q (i.e. quantitative

re-collection of any and all split flow during both

tube and trap desorption) was pioneered by

Markes International in 1998. Each sample is recollected on a conditioned tube (tagged or

untagged) and may be used for repeat analysis,

method/data validation or archiving of

critical samples. SecureTD-Q is available as

standard on every UNITY 2 and overcomes the

one-shot limitation of traditional TD systems

and methods. (For more information see separate

brochure.) No other single tube desorber offers

quantitative recovery of all split flow for repeat

analysis.

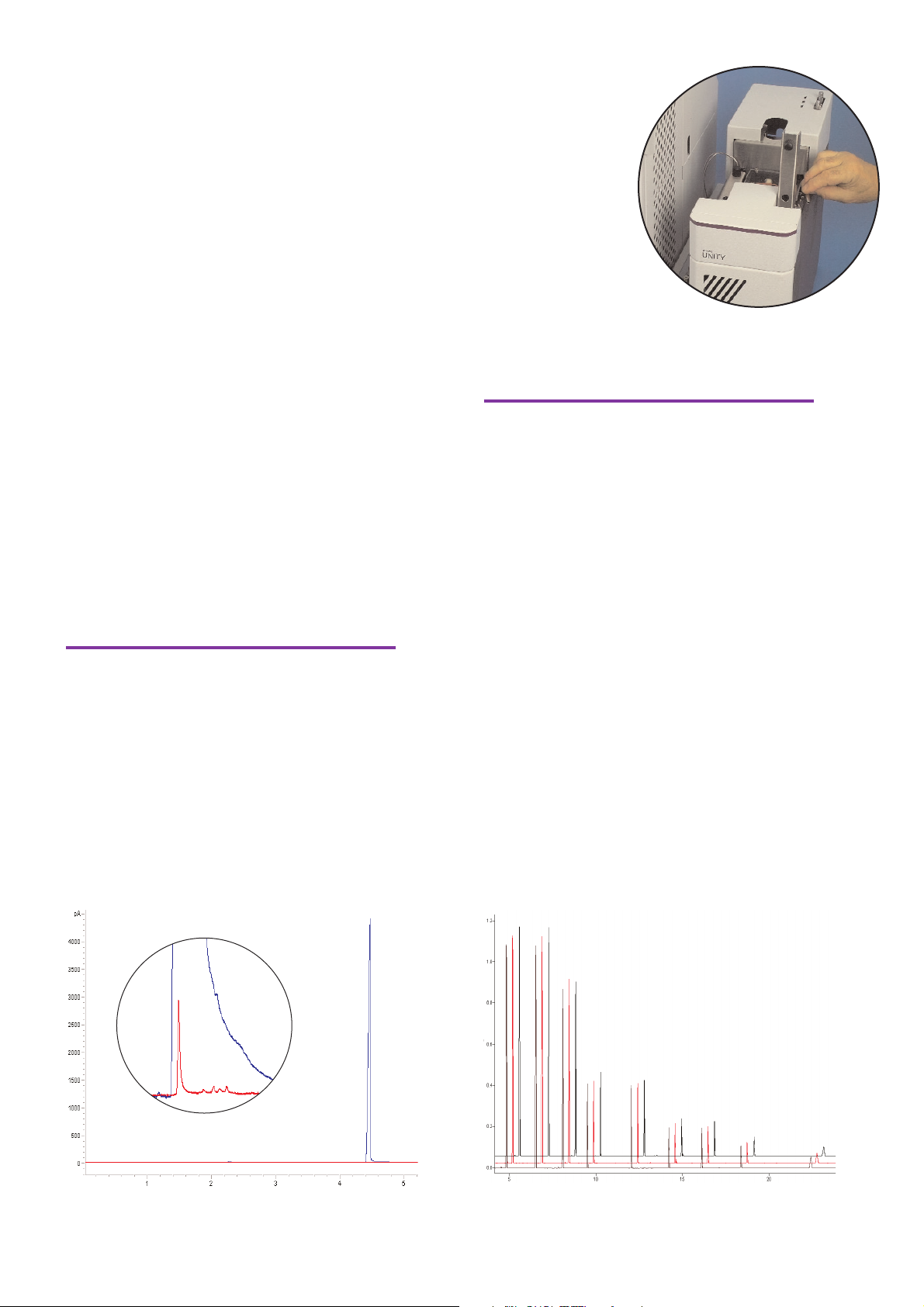

Page 12

Example of splitless desorption of indoor air contaminated with low levels of toluene and benzene

Insert showing good shape for toluene peak

Repeat analysis as standard

Benzene

Toluene

7.2 7.3

GC column: HP5 MS (30m,

0.25mm diameter, 250 µm phase)

Peerless analytical performance

• UNITY 2 provides a universal TD platform for very

volatile, high boiling and reactive compounds at

high and low concentrations.

• Unsurpassed trap heating rates (100°C/sec) and

unique trap heater design offer optimum

desorption efficiency even under low flow (<2

ml/min) splitless conditions. This ensures best

possible detection limits for trace level

compounds.

• Pre-purge of air to vent and flexible water

management options prevent risk of

sorbent/analyte oxidation and minimise

analytical interference.

Ease of use

• Cryogen-free operation for minimal running

costs, optimum up-time and no risk of ice

formation blocking the flow path during

desorption of humid samples.

• Small footprint. At only 16 cm (6-inches) wide,

UNITY 2 occupies minimal bench space.

• Intuitive user interface. Every TD method

parameter is displayed on one easy-tounderstand screen minimizing the operator

learning curve.

<3 secs at

half height

Page 13

Method compliance and system

validation

• Full compliance with key international

standard methods such as EN ISO 16017, ISO

16000-6, ASTM D6196-03, US EPA Method TO17, NIOSH 2549 and other similar standards.

• Stringent no-flow, ambient temperature leak test

to ensure data integrity. Failed tubes are

preserved intact for operator intervention. Fully

interlinked ready/start signals ensure that trap

desorption only occurs when the rest of the

analytical system is ready for analysis.

UNITY 2 leak test and logged as a sample failure.

In the case of tagged tubes, back-pressure can

be manually recorded on the tag and stored as

part of tube history if required.

Productivity and versatility

• UNITY 2 can be upgraded to automatic tube

desorption and/or automated canister/on-line

analysis and/or headspace-trap.

• Time saving overlap mode: When one sample

is being analysed via GC(MS) another can be leak

tested and desorbed.

• Validation of desorption efficiency/analyte

recovery is simplified using SecureTD-Q (see

above). Use of repeat analysis for TD

method/data validation is described in standard

TD methods such as ASTM D6196.

• Continuous monitoring of carrier gas pressure,

downstream of the sorbent tube and focusing

trap. This pressure reading may be logged for

every sample and for all stages of TD operation

allowing tubes with anomalously high back

pressures to be identified. Moreover, if a tube

is completely blocked this is detected by the

Example international standard methods for

thermal desorption

US EPA Method TO-17: Pumped monitoring of ambient air

EN ISO 16017: Pumped or diffusive sampling of ambient,

indoor and workplace air, plus materials emissions

ASTM D6196: Pumped or diffusive sampling of ambient,

indoor and workplace air plus materials emissions

ISO 16000-6: TD-GCMS/FID analysis of materials emissions

collected using emission test cells or chambers

ASTM F1982: TD-GCMS analysis of compounds of interest for

semi-conductor applications

EN 14662: Benzene in ambient air

Various occupational hygiene-related national standards,

including NIOSH 2549 (US) and MDHS 72/80 (UK)

• System versatility. UNITY 2 is compatible with

any commercial GC(MS). The selective

concentration offered by UNITY 2 allows target

analytes to be quantitatively retained while

unwanted interferents (water, solvents,

etc.) are

purged to vent.

Automated TD requirements for compliance with

standard methods

No flow, ambient temperature leak test

Dry purge/internal standard addition in sampling direction

Pre-purge of air to vent to prevent interference

Inert flow path for compatibility with reactive compounds

like mercaptans

Cryogen-free focusing trap desorbed rapidly in backflush

mode for simultaneous compatibility with very volatile and

semi-volatile analytes

Tubes sealed throughout autosampler operation

Quantitative repeat analysis for method and data

validation (ASTM D6196-03)

Page 14

Markes International...

Calibration accessory for

TD tubes

Bio-VOC sampler for

collecting alveolar breath

samples & transferring

them to sorbent tubes

TC-20 multi-tube

conditioning/dry purge unit

for up to 20 tubes

Micro-Chamber/Thermal

Extractor (µ-CTE) for measuring

emissions from materials &

consumer products

MTS-32 sequential pumped

sampling onto multiple

tubes

Canisters and related

accessories

Wide range of empty and

prepacked TD sample tubes

TubeTAG RFID tag system

for sorbent tube informatics

VOC-Mole soil probes for

in situ monitoring of

contaminated land

Markes International: Everything for thermal

desorption

UNITY 2 is complemented by the comprehensive portfolio of thermal desorption

instrumentation and associated sampling equipment provided by Markes International.

Many of the innovative and labour-saving accessories available are unique to Markes

including specialist low flow sample tubes, multi-sample test equipment for materials

emissions screening, calibration accessories, breath samplers, soil probes, etc.

Page 15

TD application guides

A series of TD application guides is available from

Markes International. Titles include:

• Environmental Air Monitoring and Occupational

Health & Safety

• Residual Volatiles & Materials Emissions Testing

• Defence and Forensic

• Food, Flavour, Fragrance & Odour Profiling

Each 16-32 page guide features example TD

applications with key analytical conditions.

Trademarks

SafeLok, DiffLok, TT24-7, SecureTD-Q and TubeTAG are

all trademarks of Markes International Ltd.

EPC and ChemStation are all trademarks of Agilent

Technologies.

Silcosteel is a trademark of Restek Inc., USA

...experts in thermal desorption

Page 16

Markes International Ltd.

Gwaun Elai Medi Science Campus

T: +44 (0)1443 230935 F: +44 (0)1443 231531

E: enquiries@markes.com W: www.markes.com

Llantrisant

RCT

CF72 8XL

United Kingdom

Loading...

Loading...