Page 1

Series 2

ULTRA

Thermal Desorption

Autosampler

Multi-function TD autosampler with optional

reading/writing of electronic tube tags

Page 2

Series 2

ULTRA

1. Patent# GB 2395785 (Automated re-collection using a single TD autosampler), 2. Patent# US 6,446,515 B2, 3. Patent# GB 2337513 US 6,564656 B1

4. Patent# GB 2336649

Thermal desorption technology

Thermal desorption (TD) is a highly versatile, sensitive

and labour-saving sample preparation technique for the

measurement of volatile and semi-volatile organic

compounds (VOC and SVOC) in air and materials. It is

applicable to GC-compatible organics ranging in

volatility from acetylene to n-C40and a few inorganic

gases; including nitrous oxide, SF6, CS2and H2S. Key

applications include:

• Environmental and workplace air monitoring

• Civil defence and forensic analysis

• Materials and materials emissions testing

• Food, flavour and fragrance profiling

Many material samples such as drugs, foods, textiles,

polymers, paints, etc. can be directly thermally

desorbed by weighing them into empty TD sample

tubes.

Alternatively, vapours in gas or air can be concentrated

on- or off-line onto sorbent tubes/traps before TDGC(MS) analysis.

Page 3

ULTRA 2 Main Features

• Adds 100-tube automation to any UNITY or UNITY 2 TD platform to increase productivity.

• TubeTAG™: Reading/writing of RFID tags on sorbent tubes is now fully integrated with automated TD

operation. This revolutionizes tube and sample traceability.

• Stringent sample sealing, before and after desorption. Patented DiffLok™ caps preserve sample and blanktube integrity and ensure compliance with standard methods.

• Quantitative sample re-collection (SecureTD-Q) is offered as standard on every series 2 U

LTRA-UNITY

system for repeat analysis of critical samples and/or method validation.

• Automation of SecureTD-Q av

ailable using single or double U

LTRA configurations; totally tag-compatible for

fail-safe tracking of which sample was re-collected onto which tube.

• State-of-the-art TD analytical performance. U

LTRA 2 simply adds automatic tube processing to the

peerless thermal desorption analytical performance of UNITY 2.

• U

LTRA-reliability – field-proven,

mechanically-simple automation ensures robust operation.

• Method compliance – incorporates the ambient temperature/no-flow leak test of UNITY 2 as a guarantee of

data integrity. Option of internal standard addition to blank or sampled tubes as a further aid to analytical

quality assurance.

• Optional dry-purging of sorbent tubes (in the sampling direction) as part of the automated sequence. This

minimizes water interference and is recommended by standard methods.

• Innovative, compact design – minimizes bench space.

Innovation and excellence in

thermal desorption

Since 1997 Markes International has re-engineered

analytical thermal desorption for the 21st century.

Harnessing unparalleled technical expertise, the

company has developed a suite of ‘universal’ TD

systems and unique sampling accessories incorporating

key proprietary innovations such as:

• SecureTD-Q™ for repeat analysis and automated

re-collection using a single TD autosampler

• RFID tube tagging (TubeTAG™)

• Diffusion-locking for effective tube sealing and

robust automation

• Innovative low volume valving specifically

designed for TD

Many of these innovations now set the standard for TD

instrumentation worldwide.

3

4

2

1

Series 2 ULTRA

ULTRA 2 is an innovative, robust and method-compliant

thermal desorption (TD) autosampler for up to a

hundred industry standard (3.5-inch) sample tubes,

featuring the option of integrated reading/writing of

RFID tube tags. It adds to any series 1 or series 2

UNITY TD platform to provide unmatched TD-GC(MS)

analytical performance and extended unattended

operation e.g. through an entire weekend.

Page 4

Method-compliant automation

Series 2 ULTRA adds to any UNITY or UNITY 2 platform

desorber to offer unattended thermal desorption of up

to 100 capped tubes. The slimline design consists of

ten horizontal trays each containing up to ten tagged

or untagged tubes. Each tube in turn is loaded into

the analytical position and sealed into the carrier gas

flow path. The following analytical steps then all take

place on the U

LTRA 2 autosampler:

• Ambient temperature/no flow leak testing

• Optional dry purging and/or internal standard

addition

• Pre-purge of air from the tube

• Primary (tube) desorption

As vapours desorb from the primary sample tube in

U

LTRA 2 they are swept through the short, inert, heated

link line into the electricallycooled focusing trap of UNITY

(2) in a stream of carrier gas.

All subsequent stages of

thermal desorption (trap purge,

trap desorption, triggering of

the GC(MS) run, etc.) take

place on UNITY (2) in the

normal way.

Uncompromised TD analytical

performance

Series 2 ULTRA automates UNITY 2 without

compromising its peerless analytical performance. The

combined system provides a universal TD platform for

up to 100 3.5-inch tubes offering simultaneous

analysis of volatiles & semi-volatiles, quantitative

recovery of high boilers (including n-C40) and the

option of low flow path temperatures for compatibility

with labile analytes such as mercaptans. Systems offer

splitless capillary operation for trace level work and

single or double split methods for high concentration

samples such as stack emissions and residual solvent

in materials.

Series 2 U

LTRA-UNITY systems maintain all the

analytical advantages of UNITY 2 (as described in the

associated brochure) and offer the following additional

benefits relating to the automatic processing of TD

sample tubes.

Clean indoor air pumped onto multi-sorbent tube and analysed by TD-GCMS

1,1-difluoroethane

Ethanol

Isopentane

1,1-difluoro-1-chloroethane

Dichlorodifluoromethane

1,1,1,2-tetrafluoroethane

Hexane

Acetone

Freon 113

Propanol

Trichlorofluoromethane

Dichloromethane

Methylcyclohexane

Benzene

Tetrachloromethane

Ethyl acetate

Hexanal

Toluene

Ethyl benzene

Ethylcyclohexane

o/p xylene

Tetrachloroethane

α-pinene

Trimethylbenzene

Decane

Styrene

Limonene

Undecane

Benzyl alcohol

Nonanal

Dodecane

Tridecane

Tetradecane

Page 5

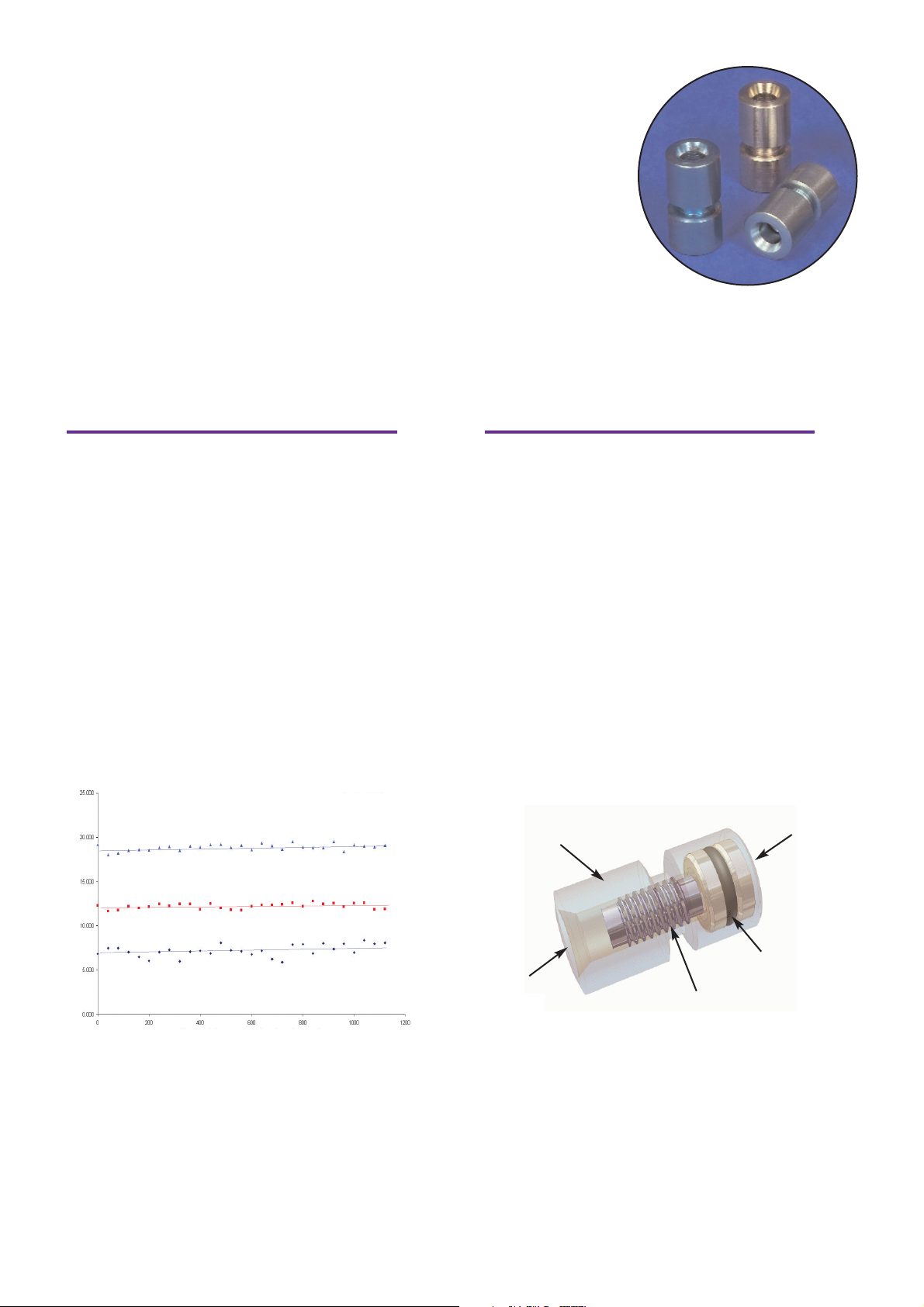

DiffLok™ caps seal tubes

No analyte losses from Tenax tubes capped with DiffLok

caps and analysed on U

LTRA over a 24 hr period

Toluene

Benzene

Time loaded tube spent on ULTRA prior to desorption (mins)

Peak area counts (x10

6

)

Xylene

effectively & simplify TD

automation

100-Tube automation optimizes

productivity

ULTRA 2 maximises the throughput and revenue

generation potential of your TD-GC(MS) system. It

offers capacity for up to 100 sample tubes together

with overlap mode. Sample overlap means that

desorption of a subsequent tube can begin while

GC(MS) analysis of a previous sample continues – thus

minimizing analytical cycle times.

With typical GC(MS) cycle times of 40 minutes, your

series 2 U

unattended processing of 100 tubes over a standard

60-hour weekend; this represents significant revenue

potential with minimal labour costs.

LTRA-UNITY TD-GC(MS) system offers

Patented tube sealing

mechanism

Tubes on series 2 ULTRA autosamplers are sealed with

Markes’ unique patented DiffLok caps. DiffLok caps

simply push on to both ends of every tube and

preserve sample integrity by preventing both analyte

loss and artifact ingress. Even volatile analytes are

confidently preserved on sorbent tubes giving identical

recovery for standards at the beginning and end of a

100-tube sequence. DiffLok caps have been field

proven to seal sampled and blank tubes much more

effectively than older push on cap designs (Ref 1).

Ref 1: Diffusive Monitor Issue 9 (Nov 1997), Losses

from ATD-400 by P. P. Ballesta

Schematic of DiffLok cap

Sample tube

pushes into cap

Inert or stainless steel outer body

(shown transparent)

here

Highly efficient tube sealing

Coned end for

Auto-alignment with

tube nozzle on ULTRA 2

(the TD autosampler)

O-ring for sealing

Threaded diffusion-locking insert

plain, cylindrical body

tube into cap

in

Page 6

ULTRA-reliable automation

TD automation with electronic

tube tracking

DiffLok caps remain on the sample tubes throughout

automated analysis, thus simplifying the mechanical

function of the instrument (no uncapping and

recapping is required) and ensuring reliable operation.

LTRA’s unsurpassed mechanical reliability has been

U

extensively field proven.

DiffLok caps are available in either stainless steel or

inert coated steel for compatibility with reactive

components.

Method compliance

Series 2 ULTRA-UNITY systems are fully compliant with

all TD standard methods and feature the mandated

ambient temperature/no-flow leak test of UNITY (2)

integrated seamlessly with the TD-GC(MS) sequence.

Data processing remains synchronized with the

analytical process at all times. Any tubes which fail the

leak test are returned intact to the sample tray

awaiting operator intervention. After a tube leak test

failure ULTRA 2 records this in the sequence reporter

and proceeds to load and leak test the next sample in

the sequence.

TubeTAG reading/writing for

enhanced tube traceability

Series 2 ULTRA autosamplers herald a revolution in

automated thermal desorption. Every ULTRA 2 offers

the option to read information from RFID tags attached

to sorbent tubes and to automatically input this

information into the sequence table. At the end of

each analysis, ULTRA 2 can also write to the tube tag

e.g. to increment the number of thermal cycles, input

any high back-pressure anomolies, change the tube

status and clear sample-specific data from the tag

ready for the next field monitoring operation.

The combination of U

major step forward in analytical quality control

for air monitoring and all TD applications.

LTRA 2 and TubeTAG offers a

Page 7

TubeTAG technology allows error-free tracking of

samples from field to laboratory & within a laboratory

(transit tagging) and logging of key tube-specific data

such as type & date of sorbent packing.

In combination with a series 2 U

LTRA-UNITY system

TubeTAG further enables:

• Automatic logging of the history of a tube

throughout its life: Number of thermal cycles,

back-pressure anomolies, number of leak test

failures, etc.

• Automatic input of sample-specific information to

the U

LTRA TD automation sequence table: Tube

number, sampled volume, diffusive sampling

time, date of sampling, etc.

U

LTRA 2 complete with the TubeTAG read/write option is

a genuine breakthrough in automated TD technology.

Imagine a future in which you can instantly identify the

sorbent(s) in each tube, when it needs to be repacked

and whether or not that tube has had a history of leaktest failures or back-pressure issues. Imagine the

benefit of error-free automatic input of key sample

data into the automation sequence. This is what U

LTRA

2 offers today.

(1) Tag permanently attached to tube

& programmed with tube-related

information usingTAG

SCRIBE

(2) Tagged tube sent to field. Sample

start & end information written

to tag via TAG

SCRIBE

(3) (a) Tagged tube returned to lab & information

automatically uploaded into U

LTRA 2 sequence table

(b) Tag updated by ULTRA 2 post-analysis

(4) Tagged tube

ready for re-use

TubeTAG: Mode of operation

Page 8

Plot showing the theoretical and measured peak areas

for repeated sample re-collection and re-desorption

Re-collections

Peak Area

DMP

DBP

Sequence of chromtagrams showing re-analysis of

re-collected phthalate mixture with internal standard

DBP

DEHP

Hexadecane

DEP

DMP

SecureTD-Q: Quantitative sample

re-collection

Every series 2 ULTRA-UNITY system features manual

re-collection of the total split flow (i.e. the split during

both tube and trap desorption) as standard. This allows

repeat analysis of critical samples and simplifies

method validation as per standard methods such as

ASTM D6196.

Automated re-collection

ULTRA 2 also offers automated sample re-collection

options using either a single ULTRA autosampler (see

ULTRA 50:50 system) or double ULTRA configuration

(see AutoSecure TD system).

Series 2 U

LTRA 50:50 systems offer automated and

quantitative re-collection of the trap desorption split

flow for 50 or 100 tubes.

Series 2 AutoSecure TD systems, incorporating two

U

LTRA 2 autosamplers, offer quantitative re-collection of

the total split flow (i.e. the split flow during both tube

and trap desorption) for all 100 tubes.

Automated re-collection now enhanced

with TubeTAG

Use of series 2 ULTRA TubeTAG read/write capability

during automated desorption/re-collection, greatly

enhances the automation and traceability of

SecureTD-Q. Automated desorption/re-collection

systems incorporating TubeTAG log the unique ID

numbers of original sample tubes and of the

corresponding re-collection tubes, both on the

respective individual tube tags and in the automation

sequence. Subsequent interrogation of an individual

tube tag can be used to confirm if that tube is either:

• A sample tube, which has now been desorbed,

with the sample re-collected on tube ID# Mi

0XXXXX, or

• A tube that now contains the re-collected sample

originally desorbed from tube ID# Mi 0YYYYY

Page 9

Flexible upgrade options

Parallel connection of automated canister analysis/on-line air monitoring also faciliated (see Air Server brochure)

Series 2 UNITY

Series 2

U

LTR

A-UNITY

Series 2

U

LTRA 50:50

system

Series 2

AutoSecure TD

system

ULTRA 2 options and accessories

The following options and accessories are available for

ULTRA 2:

Integrated TubeTAG read/write

capability

TubeTAG read/write capability is available for any series

2 ULTRA (see above) and can be factory configured or

field installed. It is compatible with all other ULTRA 2

options and accessories.

50:50 Option

LTRA 2 can be factory configured with a “

The U

option for automated sample re-collection using a

single TD autosampler. The resulting series 2 U

50:50 package is a patented, cost effective, space

saving solution for automatic thermal desorption and

re-collection of up to 100 tubes.

A standard series 2 U

LTRA-UNITY offers manual

re-collection of individual samples (see above).

Addition of a 50:50 option to the ULTRA 2 complements

this facility by offering automatic re-collection of trap

50:50”

LTRA

desorption (outlet) split flow. This means that the

outlet split flow from up to 50 samples can be recollected onto 50 fresh (conditioned) sorbent tubes.

Alternatively, the outlet split flow from up to 100

samples can be re-collected back onto the original

sorbent tubes.

The 50:50 option also facilitates automatic dry

purging of sorbent tubes in the sampling direction

prior to thermal desorption, as recommended in

standard methods such as US EPA TO-17. All other

features are the same as on standard series 2 U

LTRA-

UNITY systems.

For high throughput laboratories with a focus on data

quality, series 2 U

LTRA 50:50 offers cost-effective

automatic re-collection for any single (outlet) split

method. Sample and re-collection tubes are arranged

in colour-coded trays for operator convenience and a

clear user interface displays sequence status and the

post run sequence report.

Error-free operation of series 2 U

LTRA

50:50 is

further enhanced by using the TubeTAG read/write

option to link the identity of each desorbed tube to

that used for sample re-collection (see above)

Page 10

Automating re-collection

Schematic depicting a series 2 ULTRA (ISDP) - UNITY

system

ULTRA 2

Loop

UNITY 2

1

2

3

Sample

tube

Cold trap

Bypass line

Optional split

GC(MS)

1. Fill loop with

internal standard

2. Purge loop onto

sample tube

3. Desorb sample

for repeat analysis

Manual or automated flow control

Series 2 ULTRA systems usually harness the manual or

electronic mass flow control (MFC) incorporated into

the attached series 2 UNITY TD for control of both

desorption and split gas flows (see UNITY 2 brochure

for further details). For added versatility series 2

A

50:50 units also offer the option of 1 or 2

LTR

U

integrated electronic mass flow controllers for special

applications. These provide versatile electronic control

of both split and desorption flows during an automated

sequence with multiple TD methods.

Series 1 UNITY desorbers can also be upgraded with a

series 2 U

integrated MFCs. Configuring a series 1 UNITY with a

series 2 ULTRA 50:50 incorporating MFCs, brings both

tube automation and enhanced electronic mass flow

control of split and/or desorption flows to the original

UNITY TD platform.

LTRA 50:50 configured with one or two

Internal Standard/Dry Purge (ISDP)

option

An ULTRA 2 factory configured with an ISDP option,

incorporates all the features of the ULTRA 2

autosampler but with the added benefit of an inbuilt

internal standard (IS) addition and automatic tube dry

purging capability. When using an ULTRA 2/ISDP

system, a precise aliquot of gaseous internal standard

is transferred from a gas valve loop to the sampling

end of a sorbent tube immediately after the leak test

and before tube desorption. Addition of IS aids

analytical quality assurance and is recommended in

standard TD methods. Typical compounds used as

internal standards include toluene-d8 and

bromofluorobenzene (BFB).

Gas-phase IS can be added either to sampled or

blank tubes. When standard is added to the sampling

end of blank tubes, they are not desorbed but replaced

in the U

this case the internal standard provides a quality check

on every aspect of the monitoring process – tube

storage, transport, sampling, and analysis.

Dry purging of tubes, before analytical desorption, is

also facilitated using ISDP. Tube dry purging is carried

out in the sampling direction, with or without internal

standard addition.

Note that Markes International also offers a range of stand

alone off-line accessories for dry purging sorbent tubes and

introducing gas or liquid phase standards.

LTRA 2 tube tray ready for field monitoring. In

Page 11

ULTRA 2 with 50:50 and ISDP

Series 2 ULTRAs may be factory configured with internal

standard addition, 50:50 automated re-collection plus

dry purge capability, all on the same system.

This comprehensive U

LTRA 2 configuration is further

enhanced by the addition of TubeTAG read/write

capability for automatic logging and tracking of sample

tubes, re-collection tubes and the history of each tube.

AutoSecure TD System: The

ultimate in TD automation

Series 2 ULTRA-UNITY systems, with or without ISDP,

can be further upgraded by the addition of a second

ULTRA 2 for automated and quantitative re-collection

of total split flow, i.e. the split flow during primary

(tube) desorption (inlet split flow) as well as split flow

during secondary (trap) desorption (outlet split flow),

for all 100 tubes.

The slimline design of U

LTRA 2 lends itself to this

configuration and the total series 2 ULTRA-UNITY-ULTRA

system (AutoSecure TD) only occupies 75 cm (30inches) of benchspace. Tubes are sealed with DiffLok

caps, both on the desorption and re-collection ULTRA, to

preserve the integrity of sampled tubes, desorbed

tubes and re-collection tubes.

The user interface is very straightforward, simplifying

the sequencing process and may be further enhanced

by the addition of TubeTAG read/write capability on

both U

LTRAs to automatically log sample tubes and link

them with their associated re-collection tubes.

Trays on both autosamplers are interchangeable, so

re-collected tubes can be analysed by simply

transferring trays from one series 2 U

LTRA to the other.

ISDP reproducibility data: 24 repeats over a 24 hr period

Standard deviation: 0.13, %RSD: 1%

Page 12

Unrestricted upgrade path:

Plug-and-play TD

All series 2 ULTRA configurations may be readily

connected and disconnected to any series 1 or 2 UNITY

TD platform. ULTRA 2 can also be connected to UNITY

(2) in parallel with Air Server technology for automated

on-line air monitoring/canister analysis (see associated

brochure). In addition to this, series 2 AutoSecure TD

systems offer a unique and cost-effective route to

increasing productivity: With the addition of a second

UNITY 2, an AutoSecure TD system can be readily

transformed into two standard series 2 U

LTRA-UNITY

systems. This can be used, for example, to increase

sample throughput when demand for TD-GC(MS)

analysis is especially high.

Intuitive control software

Series 2 ULTRA control software is intuitive and

integrated with the UNITY (2) TD control software to

provide one comprehensive and easy-to-understand

user interface.

Sequence building

Automated sequences are easily constructed via the

sequence builder. Samples may be assigned individual

desorption methods and can be analysed either

sequentially or with random access. Each tube is

classified as sample, calibrant or blank and all

sequences may be stored and recalled for future

reference or repeat use.

Series 2 U

LTRA systems incorporating TubeTAG

read/write capability can be used to pre-screen tubes

loaded into the system and automatically upload any

relevant sample information (tube ID number, pumped

volume/diffusive exposure time, date of sampling, etc.)

into the automation sequence. This provides a

convenient means of cross-checking sample and tube

information before an analytical sequence is initiated.

Series 2 AutoSecure TD

sequence viewer

Page 13

Graphical sequence viewer

Optional automatic update of tube tags

The sequence viewer presents a clear graphical display

of the position, classification and operating status of

each tube. It can also serve as a template for the

operator when loading tubes.

Sequence reporting

Events associated with every analysis, such as the time

and date of each tube desorption, and deviations such

as “tube not found” or leak test failure, are all recorded

in the sequence reporter. Any tube sequence failure

triggers the GC(MS) system to start a blank run to

keep the analyser in step with the desorber.

Series 2 U

read/write capability automatically read the information

stored on the relevant tag as each tube is loaded ready

for desorption. The sequence reporter is then

automatically populated with the relevant information

for that sample tube.

LTRA systems incorporating optional TubeTAG

Tag read/write-configured series 2 ULTRA autosamplers

can also be used to automatically add or modify

relevant information on each individual tube RFID tag

post run. Options for this are fully user-selectable and

include:

• Incrementing the number of thermal cycles

• Changing the tube status from sampled to

analysed

• Inputting the ID of the tube used for re-collection

of that sample

• Clearing the sample-related information from that

tag

• Logging if that tube exhibited any back-pressure

anomolies or failed the leak test

This capability represents a revolution in quality control

and tracking of sorbent tube performance and history.

Page 14

Markes International: Everything for thermal

desorption

UNITY 2 is complemented by the comprehensive portfolio of thermal desorption

instrumentation and associated sampling equipment provided by Markes International.

Many of the innovative and labour-saving accessories available are unique to Markes

including specialist low flow sample tubes, multi-sample test equipment for materials

emissions screening, calibration accessories, breath samplers, soil probes, etc.

Markes International...

Calibration accessory for

TD tubes

Bio-VOC sampler for

collecting alveolar breath

samples & transferring

them to sorbent tubes

TC-20 multi-tube

conditioning/dry purge unit

for up to 20 tubes

Micro-Chamber/Thermal

Extractor (µ-CTE) for measuring

emissions from materials &

consumer products

MTS-32 sequential pumped

sampling onto multiple

tubes

Canisters and related

accessories

Wide range of empty and

prepacked TD sample tubes

TubeTAG RFID tag system

for sorbent tube informatics

VOC-Mole soil probes for

in situ monitoring of

contaminated land

Page 15

Summary

Trademarks

SecureTD-Q™, TubeTAG™ and DiffLok™ are all

trademarks of Markes International Ltd.

100-

tube

Choice

of tube

sizes

Effective

tube

seal

Sample

re-collection

Optional electronic

control of

split/desorb flows

Optional

automatic

reading/

writing of

RFID tags

Internal

Standard

Dry

purge

ULTRA 2 Manual of

Series 2

ULTRA 50:50

Series 2 ULTRA

with ISDP

Series 2

ULTRA 50:50

with IS

Series 2

AutoSecure TD

AutoSecure TD

with ISDP on

desorb ULTRA

both splits

As above

automatic

(outlet split

Manual of

both splits

As above

automatic

(outlet split

Automatic

(all split

Automatic

(all split

plus

only)

plus

only)

flows)

flows)

via UNITY 2

via UNITY 2

and/or

integrated MFC

options

via UNITY 2

via UNITY 2

and/or

integrated MFC

options

via UNITY 2

via UNITY 2

...experts in thermal desorption

Page 16

Markes International Ltd.

Gwaun Elai Medi Science Campus

Llantrisant

RCT

CF72 8XL

United Kingdom

T: +44 (0)1443 230935 F: +44 (0)1443 231531

E: enquiries@markes.com W: www.markes.com

Loading...

Loading...