Page 1

Thermal Desorption:

A Practical Applications Guide

I. Environmental Monitoring &

Exposure to Chemicals at Work

2nd Edition

www.markes.com

www.markes.com

Page 2

Introduction to Markes International Ltd

What is analytical TD?

Formed in 1997, Markes International is world leader in

the development and manufacture of analytical thermal

desorption (TD) instrumentation and associated sampling

equipment for measuring VOCs and semi-volatiles in air

& materials.

Markes has pioneered major TD innovations such as

quantitative re-collection for repeat analysis

(SecureTD-Q™), TubeTAG™ RFID tube labels,

DiffLok™ enabling technology for robust tube

automation and cryogen-free analysis of multiple

canister air samples. All these innovations feature in

Markes’ well known modular range of TD instruments:

UNITY™, U

addition, the TD-100™. Other ground-breaking TD

products from Markes International include the

twin-trap TT24-7™ for continuous, online air monitoring,

and unique sampling accessories such as the

Micro-chamber/Thermal Extractor™ and HS5-TD™

for liquid and solid samples.

Markes’ TD units can be seamlessly combined with all

major brands of GC and GC/MS to provide trace or high

level monitoring solutions.

LTRA™, Air Server™ and the most recent

Analytical thermal desorption is a sample introduction

technique for GC and GC/MS, which uses heat and a

flow of inert gas, rather than an organic solvent, to

extract/desorb analytes from the sample media,

delivering them directly to the gas chromatograph.

Since the early 1980s, TD has provided the ultimate

versatile sample introduction technology for GC, by

combining selective concentration enhancement with

direct extraction into the carrier gas and efficient

transfer/injection, all in one fully automated and

labour-saving package.

Markes International Ltd, UK headquarters

1

Page 3

Applications

Environmental monitoring

Thermal desorption is now recognised as the technique

of choice for environmental and workplace air

monitoring. Relevant standard methods include: EN ISO

16017, EN 14662 (parts 1 & 4), prEN 13649, ASTM

D6196, US EPA TO-17 and NIOSH 2549. Related

applications include monitoring chemical warfare agents

(CWA) in demilitarisation/destruction facilities & civilian

locations (counter-terrorism).

TD is also routinely used for monitoring volatile and

semi-volatile organic compounds [(S)VOCs] in products

and materials. Examples include residual solvents in

packaging & pharmaceuticals, material emissions testing

and food, flavour & fragrance profiling.

This publication presents several real world applications

in environmental air monitoring and occupational health

& safety. Accompanying publications cover the

application areas of:

• Food, flavour, fragrance & odour profiling

• Defence & forensic

• Chemical emissions from products & materials

• Atmospheric research

• Ambient/urban air monitoring

• Industrial (stack) emissions testing

• Odour monitoring

• Indoor air quality

• Soil gas & vapour intrusion assessment

• Trace volatiles and odours in water

• Workplace air monitoring/industrial hygiene

• Personal exposure monitoring (inhalation)

• Biological exposure assessment (breath testing)

Markes International Ltd

T: +44 (0)1443 230935 F: +44 (0)1443 231531

2

E: enquiries@markes.com W: www.markes.com

Page 4

Atmospheric research

Ions: 35

79

127

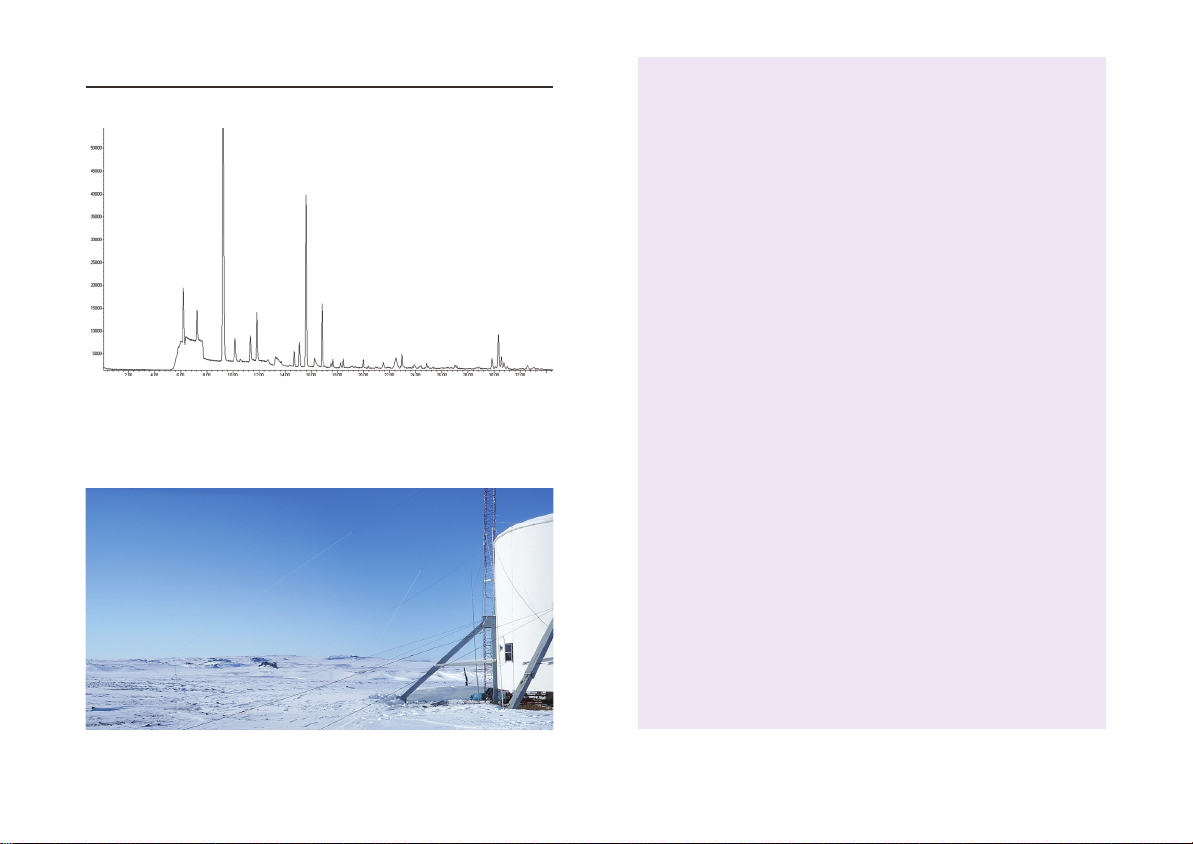

30 ml of air from bubbles in the ice core collected in canisters.

Analysis by TD-GC/MS in NCI mode. Low ppt detection limits

Background:

Markes thermal desorption instrumentation is used

extensively in atmospheric research for monitoring

trace organic vapours. For example:

• Global migration of pollution

• Research into stratospheric chemistry

• Marine research: Studying the oceans as a

potential ‘sink’ or reservoir for air pollutants

• Historical pollution data e.g. levels of freons in

air bubbles trapped in polar ice

Markes TD systems offer best available desorption

efficiency allowing splitless operation & optimum

sensitivity without liquid cryogen

Std. methods: EN ISO 16017-1, ASTM D 6196, US

EPA TO-17, (tubes) or US EPA TO-15 (canisters)

Typical analytical conditions:

Sampling: Pumped multi-sorbent tube or canister

TD: Series 2 (U

LTRA-)UNITY or TD-100 for tubes,

UNITY-CIA 8 (+ dryer) for canisters

Dry purge if no dryer used during sampling

Splitless desorption

Trap: U-T16GHG-2S or U-T15ATA-2S

Analysis by GC/MS using SIM, NCI or TOF MS

References: TDTS 81 (TO-15), 86 (TO-17) & 87

(ultra-volatile freons & other greenhouse gases)

3

Page 5

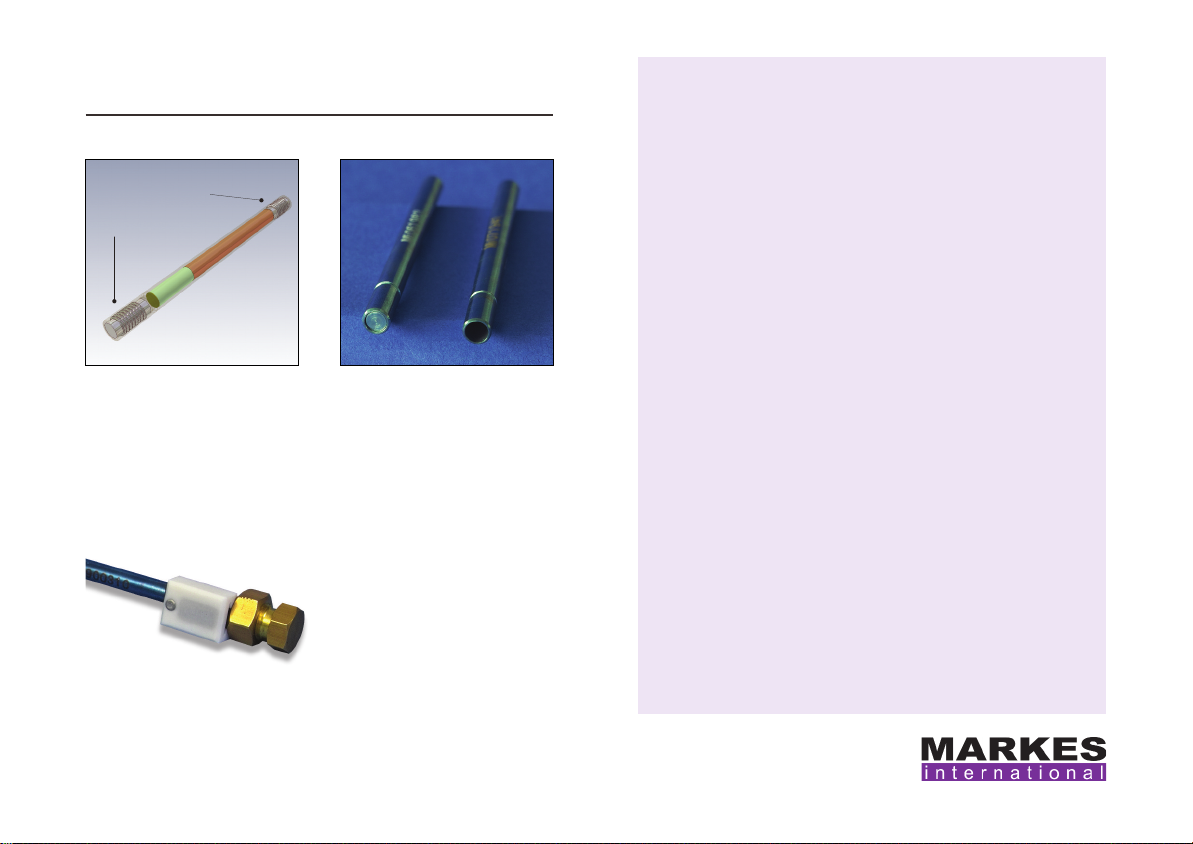

SafeLok™ – Specialist sample tubes for

trace detection

Threaded DiffLok

inserts protect

both ends of the

sorbent tube

Background:

SafeLok samplers have the same sorbent capacity

as standard tubes but incorporate Markes patented*

diffusion-locking (DiffLok) technology at both ends

of the tube to prevent artefact ingress.

With the same external dimensions as standard

TD tubes, SafeLok tubes are uniquely suited to

monitoring ultra-low concentration environments

e.g. at the North Pole or mid-Pacific. Samples

are protected from contamination during

storage/transport & during subsequent TD-GC/MS

analysis in a conventional laboratory.

SafeLok samplers incorporate Markes patented DiffLok technology

to prevent artifact ingress. This aids trace level monitoring

TubeTAG

All Markes tubes, including SafeLok tubes, are now

available with or without TubeTAG electronic (RFID)

tube labels. TubeTAG offers fail-safe tracking of tubes

in transit for field monitoring. It also enhances tube

traceability for GLP and laboratory

accreditation. Recorded

information includes: sorbent

details, number of thermal

cycles, date of packing, etc.

* GB 2337513

US 6,564,656 B1

Markes International Ltd

T: +44 (0)1443 230935 F: +44 (0)1443 231531

4

E: enquiries@markes.com W: www.markes.com

Implementation of TubeTAG with SafeLok tubes

significantly enhances the traceability of key

samples.

Std methods: EN ISO 16017-1, US EPA TO-17,

ASTM D 6196

Typical analytical conditions:

Sampling: Pumped multi-sorbent SafeLok tube

TD: Series 2 (U

LTRA-)UNITY or TD-100

Dry purge

Splitless desorption

Trap: Select according to target analyte range

Analysis by GC/MS

References: TDTS 61 (diffusion locking technology)

& Markes TD accessories & consumables catalogue

Page 6

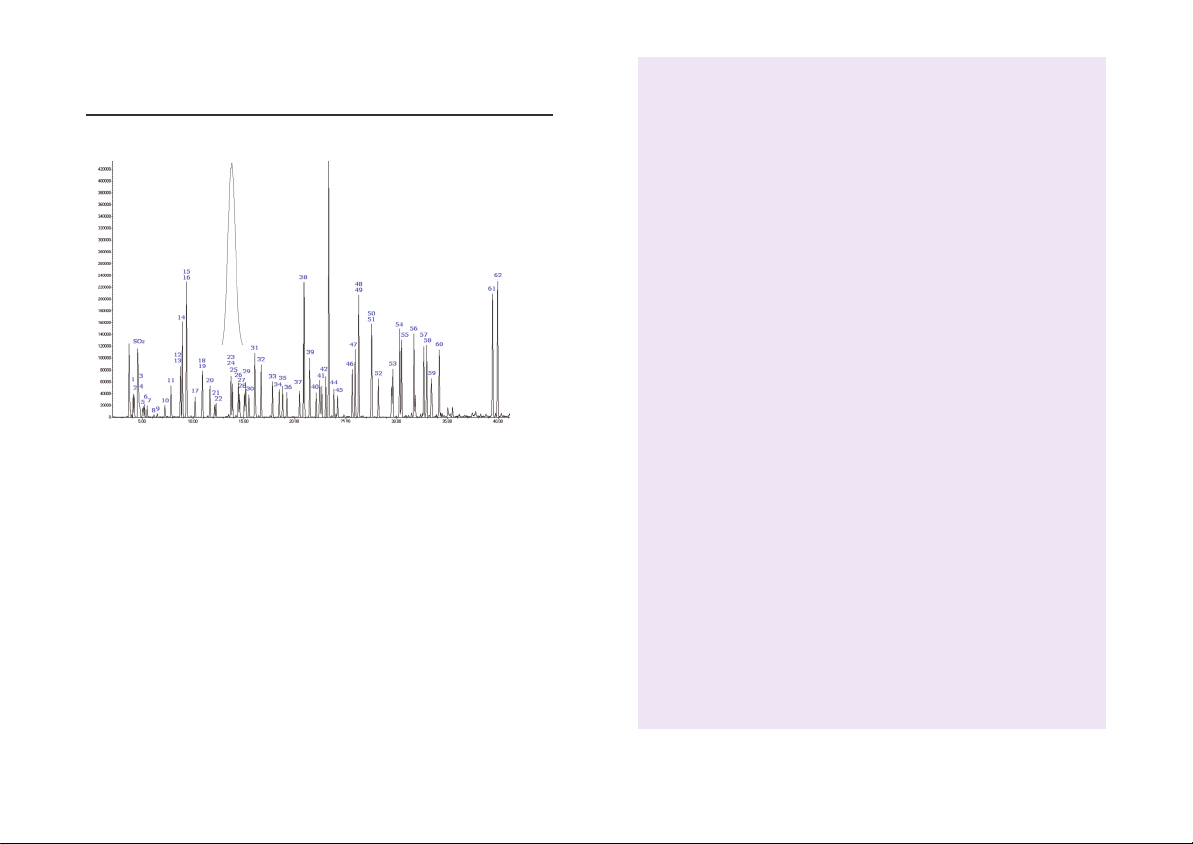

TO-17: ‘Air toxics’ in urban air using

pumped sampling onto sorbent tubes

3

4

1 Propylene

2 Dichlorodifluoromethane

3 1,2–Dichlorotetrafluoroethane

4 Methyl chloride

5 1,2-Dichloroethane

6 1,3–Butadiene

7 Vinyl chloride

8 Methyl bromide (bromomethane)

9 Chloroethane

10 Trichlorotrifluoroethane

(Freon 113)

11 Ethanol

12 1,2-Dichloroethlyene

13 1,1,2-Trichlorotrifluoroethane

14 Acetone

15 Carbon disulfide

16 Isopropyl alcohol

17 Methylene chloride

18 Tert-butyl methyl ether

19 n-Hexane

20 1,1-Dichloroethane

Pumped sampling of 1 L of 1 ppb air toxics standard analysed

splitless using ATA tubes. Inset shows close-up of extracted

mass ion 45 for IPA, demonstrating excellent peak shape

21 Vinyl acetate

22 Cis-1,2-Dichloroethylene

23 Methyl ethyl ketone

24 Ethyl acetate

25 Tetrahydrofuran

26 Chloroform

27 1,1,1-Trichloroethane

28 Cyclohexane

29 Carbon tetrachloride

30 Benzene

31 n-Heptane

32 Trichloroethylene

33 1,2–Dichloropropane

34 1,4-Dioxane

35 Bromodichloromethane

36 Trans-1,3-dichloropropene

37 Methyl isobutyl ketone

38 Toluene

39 Cis-1,3-Dichloropropene

40 Trans-1,2-Dichloroethylene

41 1,1,2-Trichloroethane

42 Tetrachloroethylene

43 Methyl n-butyl ketone

44 Dibromochloromethane

45 1,2–Dibromoethane

46 Chlorobenzene

47 Xylene

48 Xylene

49 Xylene

50 Styrene

51 Tribromomethane

52 1,1,2,2-Tetrachloroethane

53 1,2,4-Trimethylbenzene

54 1,3,5-Trimethylbenzene

55 1-Ethyl-4-methyl benzene

56 Ethylbenzene

57 1,2-Dichlorobenzene

58 1,3-Dichlorobenzene

59 alpha-Chloromethylbenzene

60 1,4-Dichlorobenzene

61 1,2,4-Trichlorobenzene

62 Hexachloro-1,3-butadiene

Background:

US Clean Air Act regulations have identified specific

‘Hazardous Air Pollutants’ (HAPs) also known as

‘air toxics’. These analytes cover a wide range of

polarities & volatilities & are most effectively

monitored using pumped sampling onto multisorbent tubes with automated TD-GC/MS (scan)

analysis.

Markes cryogen-free TD technology meets all the

requirements of TO-17 compliant air toxics analysis

Std. method: US EPA Method TO-17

Typical analytical conditions:

Sampling: Pumped sorbent tube (20-50 ml/min)

Sorbent: ‘Air Toxics’ (ATA) or ‘Universal’ tubes

TD system: Series 2 (U

LTRA-)UNITY or TD-100

On or offline dry purge before desorption

Desorption: 10 mins at 320ºC

Trap: U-T15ATA-2S (Air toxics/soil gas): +25 to

330ºC

Split: Splitless or low split during trap desorption

only

Column: 60 m x 0.32 mm x >1 µm for ‘volatiles’

Analysis: GC/MS (scan)

References: Markes Technical Support Document

for TO-17, TDTS 86 (using sorbent tubes to

monitor air toxics in air as per TO-17)

5

Page 7

MTS-32™ Sequential tube sampler

Office air

Laboratory air

Semi-rural outside air

1 Methanol

2 2-methyl butane

3 Ethanol

4 Acetone

5 Isopropyl alcohol

6 2-methyl pentane

7 3-methyl pentane

8 Hexane

9 Ethyl acetate

10 2-methyl hexane

11 Cyclohexane

12 3-methyl hexane

13 Heptane

14 Acetic acid

15 1-methyl-2-propanol

16 Toluene

17 Hexanal

18 Xylene

19 Xylene

20 Alpha-pinene

21 Cyclohexanone

22 Alpha-myrcene

23 D-limonene

24 Phenol

25 Menthol

26 2-phenoxy ethanol

Three 1 L real air samples collected using ‘Universal’ sorbent

tubes and desorbed splitless using TO-17 conditions as above

Applying TO-17:

TO-17-type methods, based on pumped air

monitoring with multi-sorbent tubes, can be applied

to ambient indoor and outdoor air samples. They

facilitate simultaneous analysis of a wide range of

apolar & polar organic vapours including veryvolatile, volatile & semi-volatile components.

Markes TD systems uniquely feature quantitative

re-collection of any split flow (primary or secondary)

for repeat analysis and simple validation of recovery

per standard methods, such as ASTM D6196

(SecureTD-Q).

Example analytical conditions are listed above

TO-17 performance data using Markes TD

technology with GC/MS (scan):

Retention volumes for lightest components (propene,

methyl chloride):

• >2 L on ‘Air Toxic’ (ATA) tubes at 25ºC

• >1 L on ‘Universal’ tubes at 25ºC

Detection limits: <0.1 ppb for all compounds in scan

Linearity: Typical R

2

values of 0.99 at low ppb

Precision: Typical % RSDs <6

Carryover: <0.1%

SecureTD-Q confirms quantitative recovery across

the volatility range

T: +44 (0)1443 230935 F: +44 (0)1443 231531

Markes International Ltd

6

E: enquiries@markes.com W: www.markes.com

Page 8

Soil gas and vapour intrusion assessment

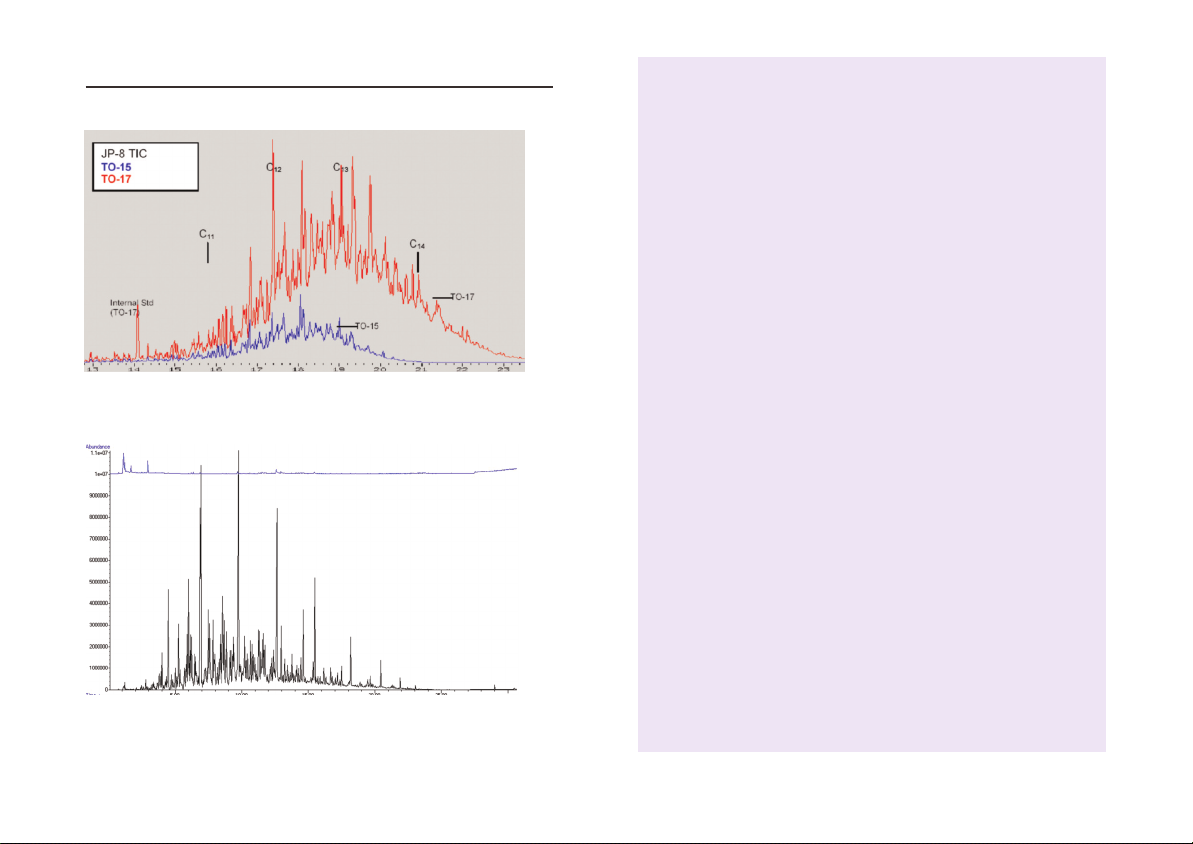

Profiles of soil gas contaminated with kerosene (JP-8) sampled

using sorbent tubes (red) and canisters (blue). Data presented

courtesy of Air Toxics Inc., CA, USA

Second desorption

Shows no carryover

First desorption

First and second desorptions of a Soil Gas tube used to sample

diesel vapour in contaminated soil

Background:

Soil gas measurements are used to assess the

potential risk to human health from vapour intrusion

into nearby buildings & to identify sources for

mitigation & liability management. Key target

analytes include gasoline & middle distillate fuels

plus solvents e.g. dry cleaning or degreasing agents.

Canister, bag and sorbent tube sampling

methodologies are used.

Markes Soil Gas tubes allow quantitative recovery of

the widest range of potential target analytes, without

water interference. Markes’ TD systems also benefit

this application by accommodating tube & canister

samples on the same analytical platform & by offering

re-collection for repeat analysis of tube samples.

Standard methods: US EPA Methods TO-17 or TO-15

Typical analytical conditions:

Pumped sampling onto Soil Gas tubes

TD system: Series 2 (ULTRA-)UNITY or TD-100

Desorption: 300ºC for 5 mins

Trap: U-T15ATA-2S (Air toxics/soil gas):+25 to 330ºC

Splitless to 5,000:1 (double) split depending on

contamination level

Apolar analytical capillary column

Analysis: GC/MS (scan)

References: TDTS 80 (Soil gas) & Hayes, H. C.,

et al. (2007), Evaluation of sorbent methodology

for petroleum impacted site investigations,

Proc. Air & Waste Man. Assoc. conf. on

vapor intrusion

7

Page 9

In situ monitoring of underground

contamination

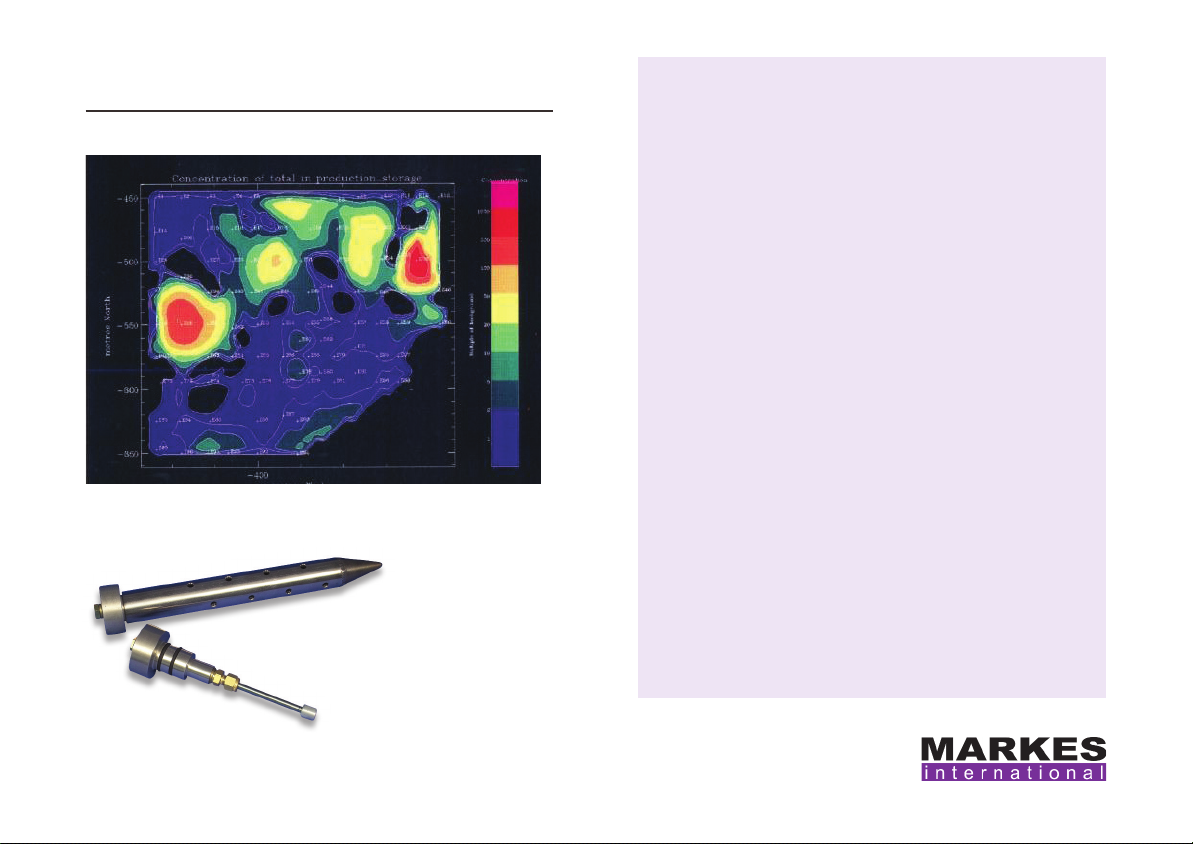

Soil probes arranged in a grid pattern around an industrial site

allow low-cost mapping of contaminated ground

VOC-Mole soil probe fitted with a

sorbent tube configured for diffusive

(passive) sampling

Background:

Underground fuel or chemical leaks present a grave

environmental risk. Markes VOC-Mole™ soil probes

containing standard diffusive or pumped tube

samplers allow cost-effective, in situ screening of

large areas of land including active production sites.

They can also be placed along the length of fuel

pipelines to provide early warning of a leak. VOCMoles configured with diffusive (passive) samplers

are easy to deploy & allow rapid (e.g. 15 minute)

or longer term (24 to 48 hour) exposure. The soil

probes themselves can be left in situ if regular

monitoring is required. Subsequent automated

TD-GC/MS analysis allows identification of the

nature, source & spread of ground contamination.

Typical analytical conditions:

Sampling: Sorbent tubes used diffusively inside

soil probes

®

Sorbent: Tenax

TD system: Series 2 (U

TA or Soil Gas tubes

LTRA-)UNITY or TD-100

Desorption: 5 mins at 280ºC

Trap: Tenax TA or U-T15ATA-2S: +25ºC to 320ºC

Splitless to 5000:1 double split, depending on the

contamination level

Analysis: GC/MS (scan) or GC-FID

References: TDTS 29 (monitoring soil pollution

using soil probes) & TDTS 80 (Soil gas analysis)

T: +44 (0)1443 230935 F: +44 (0)1443 231531

Markes International Ltd

8

E: enquiries@markes.com W: www.markes.com

Page 10

TO-15 ‘air toxics’ in urban air

using canisters

9.40

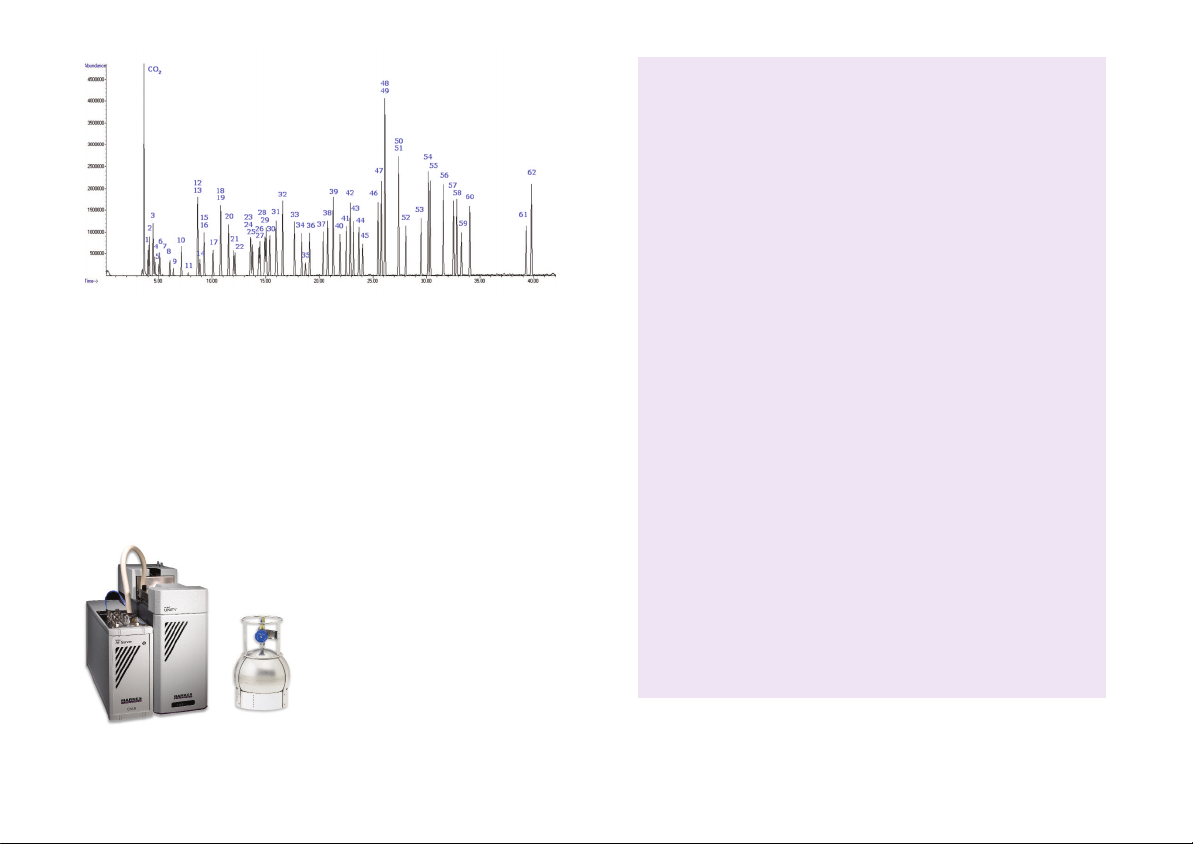

1 Propylene

2 Dichlorodifluoromethane

3 1,2-

Dichlorotetrafluoroethane

4 Methyl chloride

5 Chloroethane

6 1,3-Butadiene

7 Vinyl chloride

8 Methyl bromide

(bromomethane)

9 1,2-Dichloroethane

10 Trichlorotrifluoroethane

®

113)

(Freon

11 Ethanol

12 1,1-Dichloroethylene

13 1,1,2-

Trichlorotrifluoroethane

14 Acetone

15 Carbon disulfide

16 Isopropyl alcohol

17 Methylene chloride

18 Tert-butyl methyl ether

19 Cis-1,2-dichloroethylene

Splitless analysis of 1 L x 1 ppb air toxics standard in a canister.

Inset shows close-up of extracted mass ion 45 for IPA,

demonstrating excellent peak shape.

9.60

20 n-Hexane

21 1,1-Dichloroethane

22 Vinyl acetate

23 Trans-1,2-dichloroethylene

24 Methyl ethyl ketone

25 Ethyl acetate

26 Tetrahydrofuran

27 Chloroform

28 1,1,1-Trichloroethane

29 Cyclohexane

30 Carbon tetrachloride

31 Benzene

32 n-Heptane

33 Trichloroethylene

34 1,2-Dichloropropane

35 1,4-Dioxane

36 Bromodichloromethane

37 Cis-1,3-dichloropropene

38 Methyl isobutyl ketone

39 Toluene

40 Trans-1,3-Dichloropropene

41 1,1,2-Trichloroethane

42 Tetrachloroethylene

43 Methyl n-butyl ketone

44 Dibromochloromethane

45 1,2-Dibromoethane

46 Chlorobenzene

47)

48) Xylene

49)

50)

51 Styrene

52 Tribromomethane

53 1,1,2,2-Tetrachloroethane

54 Trimethylbenzene

55 Trimethylbenzene

56 1-Ethyl-4-methyl benzene

57 Dichlorobenzene

58 Dichlorobenzene

59 Chloromethylbenzene

(alpha)

60 Dichlorobenzene

61 1,2,4-Trichlorobenzene

62 Hexachloro-1,3-butadiene

Background:

For the ultimate in air sampling flexibility (canisters,

bags & sorbent tubes), Markes TD systems offer full

compliance with US EPA Methods TO-15 and TO-17.

Systems offer automated sequencing for up to

8 canisters/bags together with manual or automated

tube desorption. Electrically-cooled focusing

(no liquid cryogen required), versatile water

management & uniquely efficient trap desorption all

combine to minimize running costs, optimize uptime

and ensure uncompromised analytical performance

(sensitivity, repeatability, etc.).

Standard method: US EPA TO-15

(supersedes TO-14)

Typical analytical conditions:

TD system: Series 2 UNITY-CIA 8

Volume sampled from canister: 100 ml to 1 L

Trap: U-T15ATA-2S or U-T16GHG-2S: 25ºC. 40ºC/s

to 320ºC (3 mins)

Split: Splitless or low split during trap desorption only

60 m x 0.32 mm ID x 1.80 µm thick film capillary

column for ‘volatiles’

Analysis: GC/MS (scan)

Reference: TDTS 81 (Analysis of canister air

samples using cryogen-free thermal desorption

in compliance with US EPA method TO-15)

9

Page 11

1 Propylene

2 Dichlorodifluoromethane

3 1,2-

Dichlorotetrafluoroethane

4 Methyl chloride

5 Chloroethane

6 1,3-Butadiene

7 Vinyl chloride

8 Methyl bromide

(bromomethane)

9 1,2-Dichloroethane

10 Trichlorotrifluoroethane

®

113)

(Freon

11 Ethanol

12 1,1-Dichloroethylene

13 1,1,2-

Trichlorotrifluoroethane

14 Acetone

15 Carbon disulfide

16 Isopropyl alcohol

17 Methylene chloride

18 Tert-butyl methyl ether

19 Cis-1,2-dichloroethylene

20 n-Hexane

21 1,1-Dichloroethane

22 Vinyl acetate

23 Trans-1,2-dichloroethylene

24 Methyl ethyl ketone

25 Ethyl acetate

26 Tetrahydrofuran

27 Chloroform

28 1,1,1-Trichloroethane

29 Cyclohexane

30 Carbon tetrachloride

31 Benzene

32 n-Heptane

33 Trichloroethylene

34 1,2-Dichloropropane

35 1,4-Dioxane

36 Bromodichloromethane

37 Cis-1,3-dichloropropene

38 Methyl isobutyl ketone

39 Toluene

40 Trans-1,3-dichloropropene

41 1,1,2-Trichloroethane

42 Tetrachloroethylene

43 Methyl n-butyl ketone

44 Dibromochloromethane

45 1,2-Dibromoethane

46 Chlorobenzene

47)

48) Xylene

49)

50)

51 Styrene

52 Tribromomethane

53 1,1,2,2-Tetrachloroethane

54 Trimethylbenzene

55 Trimethylbenzene

56 1-Ethyl-4-methyl benzene

57 Dichlorobenzene

58 Dichlorobenzene

59 Chloromethylbenzene

(alpha)

60 Dichlorobenzene

61 1,2,4-Trichlorobenzene

62 Hexachloro-1,3-butadiene

Splitless analysis of 1 L x 1 ppb air

toxics standard in a canister using

a series 2 UNITY-CIA 8 system

configured for analysis of trace

ultra-volatile greenhouse gases

Applying TO-15:

Canisters are ideally suited to ultra-volatile organics

such as freons & C

hydrocarbons which are difficult

2

to trap on sorbent tubes at ambient temperature.

They also offer convenient grab sampling.

Markes TD systems are uniquely suited to split or

splitless analysis of volatiles in canisters and operate

cryogen-free.

TO-15 performance data using series 2 UNITYCIA 8 with GC/MS (scan):

Retention volumes for lightest components (propene,

methylchloride):

• >2 L on focusing trap U-T16GHG-2S at 25ºC

• >1 L on focusing trap U-T15ATA-2S at 25ºC

Detection limits: <0.1 ppb for all compounds in

scan mode

2

Linearity: Typical R

values of 0.99 at low ppb

Precision: Typical % RSDs <6

Carryover: <0.1%*

* N.B. Canisters themselves are prone to incomplete

recovery of polar sepcies and components boiling

above n-C

, such as naphthalene. They may

8/10

also be difficult to clean.

10

Page 12

Monitoring trace ultra-volatiles with high

global warming/ozone depletion potential

SF

6

N2O

Extracted ions 69 (black), 172 (green) and 30 (red) from a full

scan analysis of 25 ml of a 100 ppb standard of CF

and N2O

, C2F6, SF

4

6

Background:

Some of the regulations developed in response to

the Kyoto protocol require the monitoring of trace

level ultra-volatile compounds with high global

warming & ozone depletion potential such as

perfluorinated hydrocarbons (CF4, C2F6, etc), the

tracer gas SF

and N2O. These compounds boil from

6

-128°C and are extremely difficult to

trap/concentrate and measure at low levels.

Markes online or canister-based TD systems feature

cryogen-free operation and efficient splitless

desorption and are uniquely suited to monitoring

these compounds on- or offline. Detection limits

range down to 0.05 - 0.2 ppt for SF

and C2F

6

6

respectively, using TD-GC/MS (quadrupole, SIM)

Typical analytical conditions:

Sample volume: 25 ml (CF

(SF

, C2F6)

6

), 150 ml (N2O) to 1 L

4

System: Series 2 UNITY-CIA 8

Trap: U-T16GHG-2S: -30ºC. 40ºC/s to 320ºC (3 mins)

Splitless desorption

50 m x 0.53 mm ID alumina PLOT column + 5 m x

0.18 mm restrictor

Analysis: GC/MS (SIM), or ECD or TOF MS

Reference: TDTS 87 (A cryogen-free method for

measuring trace greenhouse gases in air)

11

T: +44 (0)1443 230935 F: +44 (0)1443 231531

Markes International Ltd

E: enquiries@markes.com W: www.markes.com

Page 13

‘Ozone precursors’ (C2to C10hydrocarbons)

in ambient air

PLOT Column

BP1 Column

1 Ethane

2 Ethylene

3 Propane

4 Propylene

5 Isobutane

6 n-Butane

7 Acetylene

8 trans-2-Butene

9 1-Butene

10 cis-2-Butene

11 Cyclopentane

12 Isopentane

13 n-Pentane

14 trans-2-Pentene

15 1-Pentene

16 cis-2-pentene

17 2,2-Dimethylbutane

18 2,3-Dimethylbutane

19 2-Methylpentane

Splitless desorption of 56-compound US EPA mix of ozone

precursors using series 2 UNITY-Air Server with dual

column/dual FID GC and Deans switch

12

20 3-Methylpentane

21 Isoprene

22 2-Methyl-1-Pentene

23 Methylcyclopentane

25 2,4-Dimethylpentane

26 Benzene

27 Cyclohexane

28 2-Methylhexane

29 2,3-Dimethylpentane

30 3-Methylhexane

31 2,2,4-Trimethylpentane

32 n-Heptane

33 Methylcyclohexane

34 2,3,4-Trimethylpentane

35 Toluene

36 2-Methylheptane

37 3-Methylheptane

38 n-Octane

39 Ethylbenzene

40 m/p-Xylene

41 Styrene

42 o-Xylene

43 n-Nonane

44 Isopropylbenzene

45 n-Propylbenzene

46 m-Ethyltoluene

47 p-Ethyltoluene

48 1,3,5-Trimethylbenzene

49 o-Ethyltoluene

50 1,2,4-Trimethylbenzene

51 n-Decane

52 1,2,3-Trimethylbenzene

53 m-Diethylbenzene

54 p-Diethylbenzene

55 n-Undecane

56 n-Dodecane

Markes International Ltd

T: +44 (0)1443 230935 F: +44 (0)1443 231531

E: enquiries@markes.com W: www.markes.com

Background:

C

to C10hydrocarbons, originating from car

2

exhausts, have been identified as precursors to the

formation of street level ozone and urban smog. US,

European and other regulators require round-theclock monitoring of these compounds in major urban

centres during the summer months. Series 2 UNITYAir Server allows continuous, unattended and

cryogen-free monitoring at low to sub-ppb levels and

automatic sequencing between a minimum of 3

channels (sample, standard & blank). Markes series

2 TD systems offer splitless desorption & uniquely

high cryogen-free retention volumes for ultra-volatiles

such as acetylene & ethane. Systems are operated in

remote, unattended monitoring stations, with data

accessed via telemetry and processed/validated at

remote network control centres.

Official guidance: US EPA Tech. Assist. Document for

sampling and analysis of ozone precursors

Typical analytical conditions:

Sampling: Online from manifold at 25 ml/min

Sampling volume: 400 - 1000 ml

TD system: Series 2 UNITY-Air Server with dryer

Trap: U-T17O3P-2S: -30 to 320ºC at 40ºC/sec

Splitless desorption

GC configuration: Either GC, dual column, dual FID

& Deans switch, or single FID with “PoraPLOT” type

column

Reference: TDTS 16

Page 14

Online monitoring of diurnal variation of

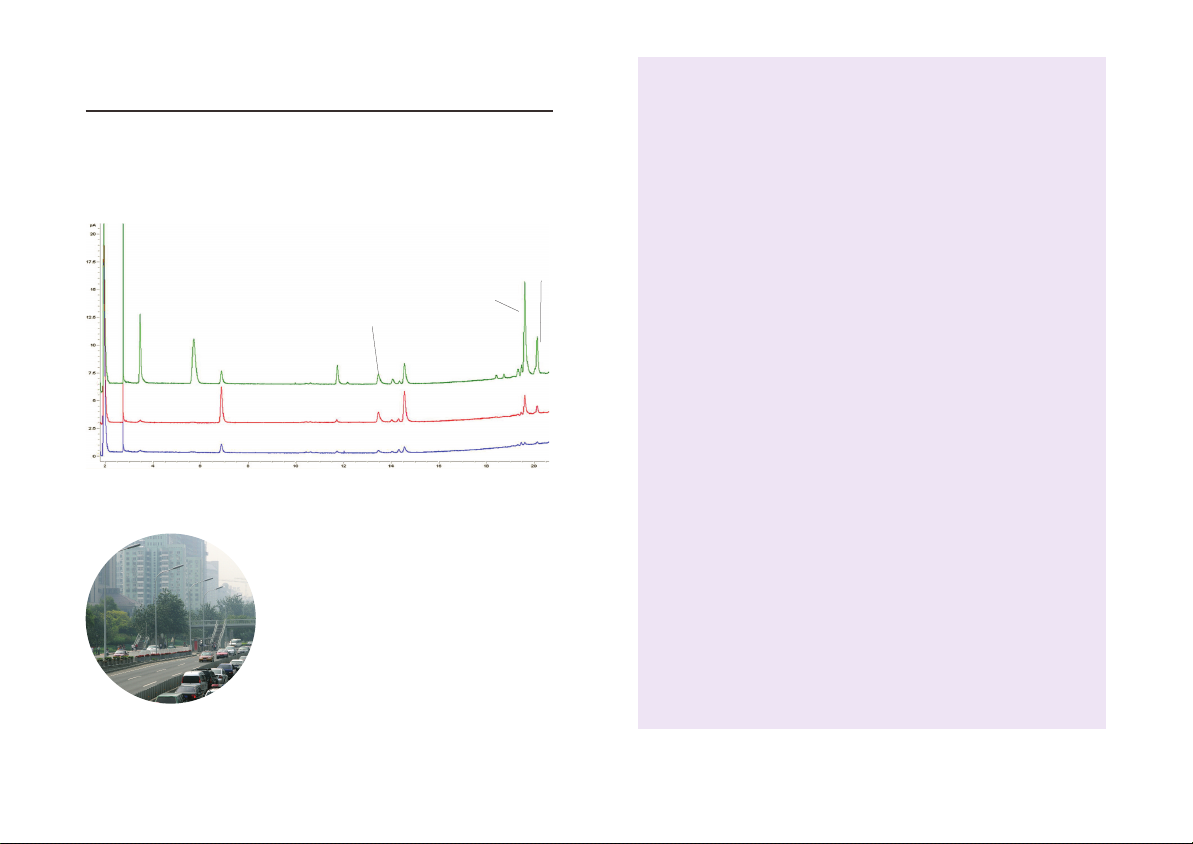

pollutants in ambient air

Key:

Blue (3 am),

Red (12 noon),

Green (5:30 pm)

Ethane

Pentane

Ethene

Acetylene

Propane

Online monitoring of semi-rural/semi-industrial

ambient air using series 2 UNITY-Air Server

GC/FID and GS-GasPro-type ‘PoraPLOT’

column showing how the VOC profile

varies with time

2-Methyl propane

Propene

Butane

1-Butene

Background:

Markes series 2 UNITY-Air Server systems offer

cryogen-free, online monitoring of trace volatiles in

ambient air, using GC/FID or GC/MS. The optimised

focusing trap contains an extended (60 mm) bed of

multiple sorbents which is held at -30ºC and

desorbed in backflush mode at rates up to 100ºC/s.

This enables ultra-volatile hydrocarbons/freons to be

quantitatively retained and efficiently released at the

same time as much higher boiling components, such

as naphthalene, trimethyl benzene & hexachloro

butadiene.

A wide range of vapour-phase components (ozone

precursors, hazardous air pollutants and odour

components) can all be monitored simultaneously.

Typical analytical conditions:

Sample: A 200 to 1000 ml volume of air sampled at

10-25 ml/min (optional dryer)

System: Series 2 UNITY-Air Server (with Nafion

®

dryer)

Trap: U-T17O3P-2S: -30ºC to +25ºC. 40ºC/s to

320ºC (3 mins)

Splitless desorption

GS-GasPro™ 30 m x 0.32 mm capillary column for

‘volatiles’

Analysis: GC/FID

References: TDTS 16 (online round-the-clock air

monitoring), 32 (analysis of sulphur compounds),

81 (analysis of canister air samples with US EPA

method TO-15) & 87 (monitoring trace greenhouse

gases in air)

13

Page 15

Mapping criteria pollutants in ambient

air by diffusive sampling

Rouen (Northern France).

Interpolated benzene

isoconcentration plot.

Measurements performed

from 19-23/01/98

RFID tagged sorbent tube (TubeTAG)

References: TDTS 10 (diffusive monitoring of ambient

air), TDTS 01 (uptake rates), TDTS 42 (radial diffusion

for TD) & TubeTAG brochure

Background:

Accurate mapping of pollution levels across a major

urban centre requires hundreds of sampling points.

Diffusive (passive) samplers are low-cost and easy

to deploy facilitating large-scale and/or detailed

environmental surveys. Markes unique TubeTAG

electronic tube labelling system benefits large scale

field monitoring studies, by eliminating transcription

errors & enhancing traceability.

Series 2 (U

LTRA-)UNITY and TD-100 systems feature

the option of onboard read/write of tagged tubes for

complete, error-free automation

Std. methods: EN 14662-4, EN ISO 16017-2, ASTM

D 6196

Typical analytical conditions:

Sampling: Diffusive (passive)

Sorbent: Carbograph™ 1TD (benzene), Carbopack™

X (1,3-butadiene)

Monitoring time: 7-14 days (axial), 4-6 hours (radial)

TD system: Series 2 (U

LTRA-)UNITY or TD-100 with

onboard TubeTAG read/write

Desorption: 5-10 minutes at 320ºC

Trap: Carbograph 1TD/Carbopack X from +30

to 320ºC

Split: ~20:1 during trap desorption only

Analysis by GC-FID or GC/MS

14

T: +44 (0)1443 230935 F: +44 (0)1443 231531

Markes International Ltd

E: enquiries@markes.com W: www.markes.com

Page 16

Odorous industrial emissions

2

S

6

H

2

C

2

S

6

H

2

C

2

S

6

H

2

C

Reproducibility

(% RSD at

20 ppb)

QA/QC sample

20 ppb

10 ppb

Compound

H2S

CH3SH

C2H6S

C2H6S

2

S

2

SH

3

H

CH

S

6

H

2

C

S

2

SH

H

3

S

6

CH

H

2

C

S

SH

S

2

3

H

6

H

2

CH

C

Detection

limit

(ppb)

0.15 0.9973 4.1 93

0.15 0.9983 1.8 108

0.15 0.9999 0.8 107

0.10 0.9993 0.8 108

Linearity

(at ppb

levels)

Recovery

(% at 80%

relative

humidity)

Background:

Highly odorous sulphur compounds in industrial or

landfill emissions must be controlled to sub or lowppb levels. These very volatile & highly reactive

compounds are usually sampled online or in

canisters/bags & analysed using TD-GC/PFPD.

Markes series 2 UNITY is a uniquely versatile TD

platform. The standard system allows selection of

low flow path temperatures without installation of

special valving. This facilitates analysis of thermally

labile components such as mercaptans & other

odorous species. Markes online TD systems have

also demonstrated exceptional analytical

performance and reliability in unattended field

operation

Std. method: Korean Government Guidance Method

- Standard Method for Off-Odour Analysis (2005)

Typical analytical conditions:

Sample volume: 100-500 ml

TD system: Series 2 UNITY-Air Server with dryer

TD flowpath: 80ºC

Trap: U-T14H2S-2S (H

S): -30 to 250ºC

2

Split: 12:1 during trap desorption only

Column: 60 m x 0.32 mm x 5.0 µm, apolar

Analysis: GC/PFPD

References: TDTS 32 (analysis of sulphur compounds),

Ki-Pong Song, et al., (2007), Korean Journal of Odour

search and Engineering, Vol 6 (1), 33-39

15

Page 17

Biogenic emissions: Vapour-phase organic

chemicals from moulds, plants, etc.

Monoterpenes & terpenoids

Sesquiterpenes

Terpenoids

ppb-Level terpenes in air above leaf litter

Background:

Plants, moulds, animals & other life forms emit VOCs

& contribute to the ‘cocktail’ of organic vapours in

ambient air. Monoterpenes are emitted by pine trees

on sunny days, possibly as a defence against

potential photochemical damage. These reactive

hydrocarbons are monitored using pumped sampling

onto inert tubes packed with Tenax TA followed by

TD-GC/MS analysis. Similarly, the detection of

methyl benzoate in indoor air can indicate mould

growth & geosmin in water indicates the presence of

certain algae (see also page 20). The profile of

vapour-phase organics can also sometimes be used

to identify the precise species of plant, mould, etc

and/or the phase of growth.

Markes series 2 (U

LTRA-)UNITY or TD-100 systems

offer quantitative re-collection for repeat analysis

(SecureTD-Q). This is an invaluable feature for

validating quantitative recovery of biogenic emission

components (some of which are extremely reactive)

through the analytical system.

Typical analytical conditions:

Sampling: Pumped sorbent tube

®

Sorbent: Tenax TA in stainless/Silcosteel

TD system: Series 2 (U

LTRA-)UNITY or TD-100

tube

Desorption: 5 mins at 220ºC

Trap: U-T9TNX-2S (Tenax): -10 to 250ºC

Split: Low split during trap desorption only

Analysis: GC/MS (scan)

16

T: +44 (0)1443 230935 F: +44 (0)1443 231531

Markes International Ltd

E: enquiries@markes.com W: www.markes.com

Page 18

Odours & toxics in landfill gas

Toluene

Redesorption blank

Butan-2-ol

Chloroethane

Vinyl chloride

1-pentene

Dimethyl sulphide

Furan

1,1-dichloroethane

Carbon disulphide

Butan-1-ol

Benzene

1,1- & 1,2-dichloroethene

Trichloroethene

1,1,1-trichloroethane

Dimethyl disulphide

100 ml landfill gas with trace target analytes & many major

components identified

1 Vinyl chloride (Toxic)

2 1,3-Butadiene (Toxic)

3 Methyl Mmercaptan

(Odour)

4 Chloroethane (Toxic)

5 1-Pentene (Odour)

6 Furan (Toxic)

7 Ethyl mercaptan

(Odour)

8 1,1- Dichloroethene

(Toxic)

9 Dimethylsulphide

(Odour)

10 Carbon disulphide

(Odour) (Toxic)

11 1,2-Dichloroethene

(Toxic)

12 1,1-Dichloroethane

(Toxic)

13 Propyl mercaptan

(Odour)

14 Tetrachloromethane

(Toxic)

References: TDTS 32 (sulphur compounds) &

TDTS 47 (analysis of landfill gas)

a-pinene

Decane

Butanoic acid ethyl ester

Nonane

Xylene

15 Benzene (Toxic)

16 Trichloroethene (Toxic)

17 Butyl mercaptan

(Odour)

18 Dimethyldisulphide

(Odour)

19 Ethylbutyrate (Odour)

20 2-Butoxyethanol

(Toxic)

Background:

New regulations in Europe & several Asian countries

require monitoring of trace toxic & odorous

compounds in landfill gas. Such analysis is either

carried out online (see page 15) or by drawing 100200 ml samples through a special sorbent tube using

a simple bellows pump or large gas syringe.

Limonene

The patented inert valve within series 2 (U

LTRA-)

UNITY and TD-100 facilitates subsequent offline

analysis of the sampled tubes by allowing low flow

path temperatures to be selected e.g. 120ºC in this

example. Quantitative recovery of labile odorous

analytes, such as ethanethiol, can also be validated

using SecureTD-Q.

Official guidance: UK Env. Agency publication

‘Monitoring trace components in landfill gas.’

Typical analytical conditions:

Sample volume: 100-500 ml

Sorbent: Silcosteel tube with Tenax TA/UniCarb™

(at same temp as gas)

TD system: Series 2 (U

LTRA-)UNITY or TD-100

TD flowpath: 120ºC

Trap: Sulphur trap -15 to 220ºC (40º/min)

Benzene

Split: From 10:1 to 50:1

Column: 60 m x 0.25 mm ID x 1.4 µm

film DBVRX

Ethanethiol

Analysis: GC/MS (scan)

SecureTD-Q: Repeat analysis validates

quantitative recovery of ethanethiol

through the TD flowpath

17

Page 19

Software tools for minimising GC/MS

background & enhancing trace analysis

Analysis of a trace level landfill gas standard

using the thick film capillary column

described above. ClearView completely

eliminates interference from column bleed

ClearView™

Original data

ClearView

reprocessed data

S/N ~3:1

Unidentified

Peak at 16.48 mins

unidentified in original data

Peak at 16.48 mins

automatically identified as

thiophene in ClearView

reprocessed data

S/N 30:1

Thiophene

Background:

ClearView™ uses a sophisticated algorithm to

accurately & dynamically compensate for

chromatographic background as it changes

throughout a run. The process works even if the

same mass ion is present in both the background

and the peaks of interest. Original data files are

retained intact so implementation of ClearView is

risk free.

ClearView™ works with all makes of GC/MS & can be

used to reprocess stored data files individually or in

batches. Reprocessing takes seconds. ClearView can

also be executed/implemented within the

environment of several leading brands of GC/MS

data processing software during an automated

sequence of analyses.

Key advantages include:

• Improvement in spectral purity for enhanced

automatic identification of trace components

• Reduced signal to noise for improved

sensitivity/detection

• Facilitates scanning from low masses

• Productivity: Reduces/de-skills data

interpretation, boosting sample throughput

• Compatible with scan, SIM/scan & SIM data

(see page 20)

References: TDTS 83 & 85 (Using ClearView

reprocessing to enhance trace GC/MS analysis)

18

T: +44 (0)1443 230935 F: +44 (0)1443 231531

Markes International Ltd

E: enquiries@markes.com W: www.markes.com

Page 20

HS-TD: Simple & sensitive analysis of

purgeable VOCs in water

Analysis by HS-TD

Analysis by HS

Trace level purgeable VOCs in drinking water analysed by

conventional HS (black) and HS-TD (blue)

Background:

Headspace–thermal desorption (HS-TD) brings

together two of the most powerful GC introduction

techniques & offers optimum sensitivity for tracelevel volatiles in solid, liquid and gas-phase samples.

Pressurised headspace vapours are transferred from

the sample vial & into the UNITY 2 focusing trap

before being desorbed/injected into the GC(MS) in a

reverse flow of carrier gas. The process of

headspace vapour transfer & focusing can be done in

a single stage, or repeated several times to optimise

sensitivity before the trap is finally desorbed to

trigger GC analysis.

Repeated pressurisation & evacuation of headspace

vials also extends the compatible analyte volatility

range relative to conventional equilibrium

headspace. This allows lower boiling compounds to

be measured at the same time as the volatiles.

HS-TD options available for UNITY 2 include:

• The cost-effective manual HS5

module (5 vial capacity)

• A range of leading brand HS

autosamplers

Typical analytical

conditions are shown

below

Reference: HS5-TD

brochure

19

Page 21

Trace (ppt) level odorants in drinking

water using HS-TD with ClearView

Without ClearView data reprocessing

MIB

5 ppt level odorants in drinking water analysed by HS-TD-GC/MS

(SIM) shown with & without ClearView reprocessing

Trichloroanisole (1)

With ClearView data reprocessing

Reference: TDTS 78 (ppt-levels

of odorants in drinking water

using HS-TD)

Geosmin

TCA (2)

Background:

Drinking water is prone to contamination by

naturally-occurring odorous compounds such as

geosmin, methyl-i-borneol & trihaloanisoles. These

components produce a musty/’earthy’ smell that is

detectable by consumers at concentration levels

down to 10 ppt.

HS-TD offers a simple, innovative & readilyautomated approach to routine analysis of odorants

in drinking water. Detection limits down to 1 ppt can

be achieved using conventional 20 ml HS vials/caps

and GC/MS (quad/SIM). ClearView reprocessing

software optimises signal-to-noise (sensitivity) at the

lowest levels. Further enhancements could be

possible e.g. by employing aluminium-coated vial

caps, by including a salting-out step and/or by using

enhanced MS technology.

Typical analytical conditions:

HS vials: 45-50ºC

Sample cycles:10

U-T2GPH-2S trap held at 30ºC (purgeables), & 50ºC

(odorants)

60 m x 0.32 mm x 1.8 µm film ‘volatiles’ column for

purgeables

60 m x 0.25 mm ID x 0.25µm film 1701 capillary

column for odorants

Analysis: GC/MS (scan or SIM)

20

T: +44 (0)1443 230935 F: +44 (0)1443 231531

Markes International Ltd

E: enquiries@markes.com W: www.markes.com

Page 22

Profiling indoor air quality (IAQ)

Hexane

Freon 113

Trichlorofluoromethane

Dichloromethane

1,1-difluoro-1-chloroethane

1,1,1,2-tetrafluoroethane

Dichlorodifluoromethane

1,1-difluoroethane

Propanol

Isopentane

Ethanol

Ethyl acetate

Acetone

Tetrachloromethane

Clean indoor air pumped onto a multi-sorbent tube & analysed

by TD-GC/MS

Typical analytical conditions:

Sampling: Pumped sampling: 2-20 L

Sorbent: Tenax TA or an IAQ tube (quartz/Tenax TA/

Carbopack X)

TD system: Series 2 (U

LTRA-)UNITY or TD-100

Desorption: 5 mins at 280ºC (depends on sorbent)

Trap: To match tube (-30 to 300ºC)

Split: During trap desorption only ~15:1

Analysis: GC/MS (scan)

Toluene

Trimethylbenzene

Ethyl benzene

o/p xylene

a-pinene

Tetrachloroethane

Ethylcyclohexane

Styrene

Decane

Benzene

Hexanal

Methylcyclohexane

Nonanal

Benzyl alcohol

Undecane

Dodecane

Limonene

Background:

Most people in the developed world spend an

estimated 70-90% of their time indoors or in

vehicles. Regulators & scientists around the world

are increasingly concerned about the impact of poor

indoor (or in-vehicle) air quality (IAQ/IVAQ) on

human health & comfort.

Sources of indoor pollutants include construction

(or car trim) materials, furnishings, cleaning

products, fuels, general consumer goods &

human/animal activity (cooking, smoking, etc.)

Tridecane

Tetradecane

Recent environmental developments (e.g. the EC

directive on Energy Performance of Buildings) are

putting further pressure on IAQ by reducing building

ventilation rates.

TD is used extensively for monitoring IAQ & for

related applications such as materials emissions

testing. In this example, pumped tube samplers

were used with subsequent TD-GC/MS analysis for

profiling of ppt-ppb level VOCs.

Std. methods: US EPA Method TO-17, EN ISO

16017-1, ASTM D 6196

References: TDTS 28 (monitoring

indoor air), Thermal Desorption:

A Practical Applications Guide. II.

Residual Volatiles & Materials

Emissions Testing

21

Page 23

Personal exposure indoors

Personal

Indoor

Outdoor

Poor indoor air quality & high personal exposure in this home were

linked to a diesel car parked in a garage under the living space

Markes TubeTAG

technology facilitates large

scale surveys of IAQ and

human exposure, by

making it easier to record

& check tube & sampling

information without

transcription errors

Background:

TD-GC/MS is used for several applications relating to

poor IAQ and ‘sick building syndrome’. In this case

residents were complaining of poor air quality in

their home. Diffusive sampling with ‘axial’ sorbent

tubes was used to monitor indoor & outdoor air

quality at the house and to monitor the personal

exposure of residents.

Diffusive monitors are unobtrusive, low cost, simple

to deploy (no pumps) & available with Markes

unique TubeTAG technology. This makes them ideal

for large-scale personal exposure studies.

Std. methods: EN 14662-4, EN ISO 16017-2, ASTM

D6196

Typical analytical conditions:

Sampling: Diffusive sampling

Sorbent: Carbograph 1TD, Carbopack X or Tenax TA

depending on target analyte range

TD system: Series 2 (U

LTRA-)UNITY or TD-100

Desorption: 5 mins at 320ºC

Trap: U-T2GPH-2S or to match tube sorbent

Split: ~10:1 during trap desorption only

Analysis: GC/MS (scan)

References: TDTS 10 (diffusive sampling in indoor

air), TDTS 01 (uptake rates)

22

T: +44 (0)1443 230935 F: +44 (0)1443 231531

Markes International Ltd

E: enquiries@markes.com W: www.markes.com

Page 24

Building ventilation tests with

tracer gases

Different PFCs

placed in separate

rooms allow the

monitoring of air

exchange

6

monitored using

PMCH

PMCP

PDCB

PMCP

PMCH

Perfluorocarbon tracer gases

monitored using TD-GC/ECD

or TD-GC/MS

First Floor

Ground Floor

PDCB

0.1 ppb SF

online TD-GC/MS as described

on page 11

Background:

SF

and perfluorocarbons (PFCs) are commonly used

6

as tracer gases to determine ventilation rates &

pathways in buildings & vehicles. The rise &

subsequent decay of tracer gas concentrations is

monitored using on- or offline TD with GC and

electron capture detection (ECD) or GC/MS. SF6can

be sampled using low volume (100-500 ml)

sampling onto strong sorbent tubes but is more

commonly monitored online (see page 11).

Different PFCs (e.g. perfluoromethyl cyclohexane

(PMCH), perfluoromethyl cyclopentane (PMCP) &

perfluorodimethyl cyclobutane (PDCB)) placed in

different locations within a building allow the

monitoring of air exchange. They are sampled

diffusively or with pumps onto tubes packed with

Carbograph 1TD or Carbopack B™.

Typical analytical conditions for PFCs:

Sampling: diffusive or pumped

Sorbent: 40-60 mesh Carbograph 1 TD

TD system: Series 2 (U

LTRA-)UNITY or TD-100

Desorption: 5 mins at 320ºC

Trap: Carbograph 1 TD -30 to 300ºC

Split: Splitless or low split

Analysis: GC/MS or GC/ECD

Reference: H. Bloemen et al,

(1992), Ventilation rate and

exchange of air in dwellings,

RIVM rpt, NL.

23

Page 25

Monitoring car cabin air

Car cabin air 23°C

TVOC 3.7 ppm

Toluene

m-/p-xylene

n-Hexane

MEK

Methylcyclohexane

Benzene

NN DMF

Heptane

Cyclohexane

Styrene

Ethyl benzene

n-Octane

Isooctane

Car cabin air 40°C

TVOC 9.7 ppm

Toluene

m-/p-xylene

Ethyl benzene

NN DMF

Methylcyclohexane

Styrene

Air from the cabin of a small car showing a complex range of

VOCs and high total-VOC levels

Dimethylbenylamine

11

C

12

C

n-Decane

13

C

11/12

C

Trimethyl benzene

o-Xylene

n-Nonane

Ethyl toluene

n-decane

Dimethylbenzylamine

Trimethylbenzene

o-xylene

n-nonane

Silyl ester

13

Cubebene/Copaene

n-C

2-(2-butoxy-ethoxy)ethanol

12

C

11/12

C

11

13

C

C

13

14

n-C

n-C

2-(2-butoxy-ethoxy)ethanol

Silyl ester

Copaene

Dodecane

Background:

Car cabins are small confined spaces. Vapour-phase

(S)VOC levels can build up, especially in parked cars

on a hot day. Car manufacturers & their suppliers are

currently focused on improving the quality of cabin

air and reducing emissions from vehicle interior trim

components. IVAQ samples are typically sampled

using pumped, multi-sorbent tubes and analysed by

TD-GC/MS.

Markes TD systems are ideally suited to IVAQ

monitoring. They offer simultaneous analysis of VOCs

& SVOCs & feature a short, inert flow path that can

be set at low or moderate temperatures, if required,

to optimise recovery of labile odorous analytes such

as amines.

Std. methods: EN ISO 16017-1, ISO 16000-6, ASTM

D6196.

Typical analytical conditions:

Sampling: Pumped sampling of 2-10 L volume

Sorbent: Tenax TA or an “IAQ” tube (e.g. quartz,

Tenax, Carbopack X)

TD system: Series 2 (U

LTRA-)UNITY or TD-100

Desorption: 6 mins at 280ºC

Trap: U-T12ME-2S (“IAQ”) Tenax TA or

Tenax/Carbopack X (-30 to 300ºC)

Split: 50-200:1 (single or double split)

Analysis: GC/MS (scan)

Reference: TDTS 33 (profiling car cabin air)

24

T: +44 (0)1443 230935 F: +44 (0)1443 231531

Markes International Ltd

E: enquiries@markes.com W: www.markes.com

Page 26

Vapour-phase semi-volatiles by thermal

desorption: n-C40& phthalates

Phthalate standard mixture with internal standard

Re-collection & repeat analysis

Hexadecane

Diethyl phthalate

Dimethyl phthalate

Dibutyl phthalate

Diethyl-hexyl phthalate

Di-n-decyl phthalate

Markes TD systems are compatible with the analysis of semivolatiles such as n-C40 and didecyl phthalate. SecureTD-Q

(quantitative re-collection for repeat analysis) provides a

convenient means of demonstrating quantitative recovery

through the system

C

14

C

16

C

18

C

20

Recovery validated using SecureTD-Q

C

24

C

28

C

32

Hydrocarbon standard:

C

36

Sample

C

40

Background:

Thermal desorption is usually associated with

analysis of volatile organic chemicals. However, the

short, inert, heated flow path of Markes TD systems

also ensures quantitative recovery of semi-volatiles

such as n-C40& didecyl phthalate.

Markes SecureTD-Q technology uniquely offers

quantitative re-collection of split flows from both

tube & trap desorption onto a single conditioned

sorbent tube. This provides a convenient means of

demonstrating quantitative recovery of all analytes

through the entire TD system as described in

standard methods such as ASTM D6196.

Typical analytical conditions:

Sampling: Pumped sorbent tube

Sorbent: Quartz wool with 1 or 2 carbon blacks

Sample volume: Up to 100 L at up to 500 ml/min

TD system: Series 2 U

LTRA-UNITY

Desorption: 15 mins at 360ºC

Trap: High boilers trap (U-T1HBL-2S): -30 to 375ºC

Split: Typically 50:2.5 during trap desorption only

Column: 30 m x 0.25 mm ID x 0.25 mm film apolar

Analysis: GC/MS (SIM or scan)

Reference: TDTS 53 (quantitative recovery of

semi-volatiles)

25

Page 27

Vapour-phase semi-volatiles by thermal

desorption: PAHs & PCBs

PAH standard mixture

Benzo(a)pyrene

Chrysene

Benzo(a)anthracene

Quantitative recovery of polychlorinated biphenyls (PCBs) and

poly aromatic hydrocarbons (PAHs), including benzo-a-pyrene,

through series 2 ULTRA-UNITY demonstrated using SecureTD-Q

PCB standard mixture

(Aroclor 1260)

Benzo(k)fluoranthene

Benzo(b)fluoranthene

R

Dibenzo(a,h)anthracene

Benzo(g,h,i)perylene

Indeno(1,2,3-cd)pyrene

e-collection & repeat analysis

Sample

Re-collection

& repeat analysis

Background:

Markes’ thermal desorbers owe

their unsurpassed performance

with semi-volatiles to the short,

inert, uniformly-heated flow path &

patented TD heated valve used in each

(ULTRA-)UNITY 2 and TD-100 system.

It is the unique valve & flow path configuration of

Markes TD systems that also allows quantitative

recovery of both inlet (tube desorption) & outlet

(trap desorption) split flow onto the same

conditioned sorbent tube for repeat analysis &

validation of analyte recovery (i.e. SecureTD-Q).

Typical analytical conditions:

As shown on page 25.

Reference: TDTS 53 (quantitative

recovery of semi-volatiles)

26

Sample

Markes International Ltd

T: +44 (0)1443 230935 F: +44 (0)1443 231531

E: enquiries@markes.com W: www.markes.com

Page 28

Industrial (stack) emissions – solvents

Second re-collected sample

First re-collected sample

Original sample

Quantitative stack analysis carried out using double splitting & an

overall split ratio of 3,000:1, confirmed by SecureTD-Q

Analyte Mass (µg) for 3 repeats using SecureTD-Q

MEK 580 583 580

Benzene 0.14 0.18 0.18

Toluene 94 91 93

Ethyl benzene 30 30 29

PGMEA 43 43 43

Xylene 274 275 271

DMS 28 28 28

Trimethylbenzene 43 44 42

Background:

Stack gases are aggressive matrices requiring a

sampling train to remove particles, acids, etc. The

sample gas is collected onto sorbent tubes using

either grab sampling (using a large gas syringe or a

bellows-type pump to pull a 50-100 ml sample of

stack gas through the tube) or time weighted

average monitoring (using a pump with a slow flow

rate of ~15/ml to pull stack gas through the tube)

throughout a process.

Markes TD systems facilitate quantitative analysis of

high conc. samples (>1000 ppm) by offering the

option of splitting during tube & trap desorption.

Vapour from ppt to high ppm can be accommodated

on one analytical platform. Quantitative re-collection

of both split flows facilitates simple method & data

validation.

Official guidance: Revised European standard prEN

13649

Typical analytical conditions:

Sample volume: 50-1500 ml

Sampling: Pull through tube (grab sampling or pump)

Sorbent: Tenax TA/carbon or carbon/carbon

TD system: Series 2 (U

LTRA-)UNITY or TD-100

Desorption: 5 mins at 330ºC or 280ºC (if TenaxTA)

Trap: Tenax TA/carbon or 2 carbons (-30 to 300ºC)

Split: 3,000:1 double split with SecureTD-Q

Analysis: GC/MS (scan) or GC/FID

Reference: TDTS 77 (stack emissions monitoring)

27

Page 29

Industrial fence-line (perimeter)

monitoring for fugitive emissions

References: TDTS 49 (fence-line

monitoring), TDTS 1 (list of

diffusive uptake rates for

environmental monitoring) &

TDTS 10 (diffusive sampling in

ambient air)

Hexane

Pentane

Benzene

Heptane

2-week diffusive sampling around a refinery perimeter.

VOCs detected include benzene, toluene & xylene

Toluene

Methylcyclohexane

Background:

Is your industrial site a good neighbour?

Unobtrusive diffusive (passive) samplers may be

placed around a factory fence-line for extended time

periods (e.g. 3-14 days) to monitor key ‘criteria’

pollutants (e.g. benzene & 1,3-butadiene).

Diffusive sampling provides a low cost, well-validated

& quantitative monitoring method. Subsequent

analysis by TD-GC(MS) offers sub-ppb detection

limits. Markes’ TubeTAG technology benefits fugitive

emissions & industrial fence-line studies by making it

easier to record & track sampling locations & other

details. The onboard RFID tag read/write option

available for U

LTRA 2 and TD-100 allows automatic

entry of sample details into the sequence log.

Std. methods: EN 14662-4, EN ISO 16017-2, ASTM

D 6196

Typical analytical conditions:

Sampling: Diffusive (passive) tubes

Sorbent: Carbograph 1TD, Carbopack X or other to

suit target analyte

Xylene

Desorption: 5 mins at 320ºC

TD system: Series 2 (U

LTRA-)UNITY or TD-100

Trap: Selected to suit target analyte (U-T11GPC-2S

in example shown: -30 to 320ºC)

Split: Low split during trap desorption only

Analysis: GC/MS (scan) or GC/FID

28

T: +44 (0)1443 230935 F: +44 (0)1443 231531

Markes International Ltd

E: enquiries@markes.com W: www.markes.com

Page 30

Oc

c

u

pa

ti

o

n

a

l

h

ygi

en

e – mo

perso

Reactive amines in workplace air

Personal exposure to solvents at work

n

a

l

expo

FAN

PNCB

Sulphur dioxide

Acetone

su

re by i

Chloroform

1-chloro-1,3-butadiene

Carbon disulphide

n

i

to

ri

n

g

n

h

a

l

a

ti

o

n

1PPD

4A

4N

Benzene

Background:

Health & safety at work legislation requires personal

exposure assessment of workers potentially exposed

to toxic chemicals by inhalation. Pumped or diffusive

sampling onto sorbent tubes followed by TD-GC(MS)

analysis provides a solvent-free, safe analytical

option with ~1000x more sensitivity than

conventional charcoal tube/CS2extraction methods.

TD tubes are also reusable indefinitely & may be

RFID tagged (TubeTAG) for enhanced sample

traceability.

Standard methods: UK MDHS series, EN ISO 16017,

ASTM D 6196, NIOSH 2549.

Typical analytical conditions:

Sampling: Diffusive or pumped

Typical tube sorbent: Tenax or Chromosorb

TD system: Series 2 (U

Desorption: 5 mins at 300ºC or 200ºC (for C106)

Trap: U-T2GPH-2S (Tenax/Carbograph 1TD) :-30 to

300ºC

Split: 50:1 to 500:1 (typically double split)

Column: Selected to suit target analyte

range

Analysis: GC/MS (scan)

References: TDTS 37

(industrial air monitoring)

& TDTS 38 (occupational

exposure limit levels)

LTRA-)UNITY or TD-100

®

106

29

Page 31

Monitoring inhalation exposure

to pesticides

Dichlorvos

Primary & repeat analysis of pesticides for personal exposure

monitoring. Secure TD-Q confirmed quantitative recovery

through the analytical system

Methacrifos

SecureTD-Q:

Repeat analysis

Primary analysis

Diazinon

Etrimfos

Methylchlorpyrifos

Fenitrothion

Phosphamidon

Background:

Agricultural workers involved in pesticide application

must be monitored to ensure that their exposure to

these highly toxic chemicals does not exceed safe

levels. Pumped monitoring using inert (glass or

Chlorpyrifos

Malathion

Methylpirimifos

Silcosteel) tubes together with TD-GC/MS analysis

provides a reliable & highly sensitive monitoring

method.

In the example shown, Markes SecureTD-Q was

used to demonstrate quantitative recovery of these

difficult compounds through the system. SecureTD-Q

can also benefit occupational hygiene applications by

allowing samples to be archived for repeat analysis

under different analytical conditions.

Standard methods: UK MDHS series,

EN ISO 16017-1, ASTM D 6196, NIOSH 2549

Typical analytical conditions:

Sampling: Pumped

Sorbent: Tenax TA in glass or Silcosteel tubes

TD system: Series 2 (U

LTRA-)UNITY or TD-100

Desorption: 10 mins at 280ºC

Trap: U-T9TNX-2S (Tenax TA): -10 to 300ºC

Split: ~10:1 during trap desorption only

Analysis: GC/MS (SIM)

Reference: TDTS 39 (using TD with SecureTD-Q

to monitor vapour phase pesticides)

30

T: +44 (0)1443 230935 F: +44 (0)1443 231531

Markes International Ltd

E: enquiries@markes.com W: www.markes.com

Page 32

The advantages of TD vs. solvent

extraction for monitoring organic

vapours in air

Background:

Early methods for monitoring vapour-phase organics

in air involved charcoal tubes & solvent extraction,

typically with CS

occupational limit levels & widespread adoption of

GC/MS technology, thermal desorption is rapidly

superseding solvent extraction as the analytical

method of choice.

Key advantages of thermal desorption vs.

charcoal/CS2methods include:

• 1000 fold enhancement in sensitivity

• Reliable (>95%) desorption efficiency

• Higher degree of automation and greatly reduced

running costs

• Elimination of the danger and expense associated

with hazardous solvents and their disposal

• Reduced analytical interference

• Reusable sample tubes

Furthermore, Markes’ introduction of SecureTD-Q

now means TD is no longer a one-shot technique.

Samples can be quantitatively re-collected for repeat

analysis.

References: TDTS 38 (workplace limit levels) &

TDTS 46 (comparing TD with CS

charcoal for air monitoring)

. However, with the lowering of

2

extraction of

2

31

Page 33

Diffusive (passive) sampling in

the workplace

Standard sorbent tube fitted with a diffusion cap at the sampling

(grooved) end

Background:

Unobtrusive, low-cost diffusive (passive) samplers

facilitate personal exposure monitoring because they

can be worn close to the breathing zone without

impacting worker behaviour. Analysis by thermal

desorption means tubes are reusable indefinitely.

The enhanced sensitivity of TD, relative to solvent

extraction, also allows compliance with new, lower

threshold limit values.

Diffusive sampling tubes can be fitted with Markes

TubeTAG RFID tagging technology to simplify logging

& tracking of key sample-related information

Std. methods: UK MDHS series, EN ISO 16017,

ASTM D 6196, NIOSH 2549

Typical analytical conditions:

Sorbent: Tenax TA, Carbograph 1TD or porous

polymer sorbent (various)

TD system: Series 2 (U

LTRA-)UNITY or TD-100

Desorption: 5-10 mins. Temp depends on sorbent

Trap: U-T2GPH-2S (General purpose)

Split: Between 10:1 & 500:1

Analysis: GC(MS)

References: TDTS 01 (diffusive uptake rates), TDTS

08 (principles of diffusive sampling), TDTS 38

(limit levels) & TDTS 50 (workplace air monitoring)

32

T: +44 (0)1443 230935 F: +44 (0)1443 231531

Markes International Ltd

E: enquiries@markes.com W: www.markes.com

Page 34

Biological monitoring via alveolar breath

2-butanone

Acetone

Toluene

1-methyoxy-2-propanol

Skin-absorbed solvents in the breath of shoe workers collected

using the Bio-VOC™

Chromatogram of a clinical breath sample.

Sample collected using the Bio-VOC and analysed using

TD-GC/MS (single ion monitoring at mass 43)

Reproduced by kind permission from Pyschiatric Diagnostics Ltd., Inverness, Scotland

Xylene

Background:

Biological exposure monitoring allows assessment of

the whole body burden of chemicals via all routes of

exposure (skin absorption, ingestion & inhalation).

Alveolar breath sampling using Markes’ disposable

Bio-VOC™ allows large-scale, non-invasive biological

monitoring of workers using personal protective

equipment (PPE) or handling skin-absorbed

chemicals.

Detection of specific VOCs/VOC profiles in breath can

also be used to monitor halitosis or help diagnose

certain diseases (e.g. lung cancer & diabetes).

After breath collection, the Bio-VOC breath sample is

discharged into a tube containing hydrophobic

sorbents & analysed by TD-GC/MS.

Official guidance: Suite of breath sampling guidance

notes available from UK HSL.

Typical analytical conditions:

Sorbent: Tenax TA or Tenax/Carbopack X

TD system: Series 2 (U

LTRA-)UNITY or TD-100

Desorption: 5 mins at 280ºC

Trap: Tenax TA or Tenax/Carbopack X (25-280ºC)

Splitless or low split

Analysis: GC/MS (SIM) or

GCxGC/TOF MS

References: TDTS 13, TDTS 48

& TDTS 18

33

Page 35

The Markes International advantage

Markes is the world leader in analytical thermal

desorption and has pioneered important technical

innovations such as SecureTD-Q (quantitative sample

re-collection for repeat analysis), TubeTAG electronic

labels for sorbent tubes and universal (multi-application)

heated valve technology.

Markes leadership in TD now extends to:

• The widest available product portfolio and

application range

• Product quality and reliability

• Excellence in technical and applications support

Trademarks

UNITY™, ULTRA™, Air Server™, CIA 8™, TD-100™, µ-CTE™, SafeLok™,

DiffLok™, VOC-Mole™, Bio-VOC™, TT24-7™, TC-20™, TD-100™, UniCarb™,

TubeTAG™ & SecureTD-Q™ are trademarks of Markes International Ltd, UK

®

is a registered trademark of Buchem B.V., Netherlands

Tenax

Carbograph™ is a trademark of LARA s.r.l., Italy

Carbopack™ is a trademark of Supelco Inc., USA

®

Silcosteel

Chromosorb

Nafion

Wilmington, DE, USA

GS-GasPro™ is a trademark of Agilent Technologies, Inc, Santa Clara, CA, USA

is a registered trademark of Restek Inc., USA

®

is a trademark of Manville Corp., USA

®

is a registered trademark of E.I. du Pont de Nemours & Company,

For more information on Markes comprehensive range of

thermal desorption instruments and sampling accessories

request your free copy of Markes TD Accessories and

Consumables catalogue

34

T: +44 (0)1443 230935 F: +44 (0)1443 231531

Markes International Ltd

E: enquiries@markes.com W: www.markes.com

Page 36

Markes International Ltd

Gwaun Elai Medi Science Campus

Llantrisant

RCT

CF72 8XL

United Kingdom

T: +44 (0)1443 230935 F: +44 (0)1443 231531

E: enquiries@markes.com W: www.markes.com

www.markes.com

Loading...

Loading...