Page 1

Series 2

Air Server

Thermal Desorption

Options

Automated canister and on-line air/gas analysis

Page 2

Series 2

Air Server

A range of accessories for series 2

UNITY thermal desorbers offering

automated canister analysis and

on-line air/gas monitoring

1. Patent# GB 2395785 (Automated re-collection using a single TD autosampler), 2. Patent# US 6,446,515 B2, 3. Patent# GB 2337513 US 6,564656 B1

4. Patent# GB 2336649

Thermal desorption technology

Thermal desorption (TD) is a highly versatile, sensitive

and labour-saving sample preparation technique for the

measurement of volatile and semi-volatile organic

compounds (VOC and SVOC) in air and materials. It is

applicable to GC-compatible organics ranging in

volatility from acetylene to n-C40and a few inorganic

gases; including nitrous oxide, SF6, CS2and H2S. Key

applications include:

• Environmental and workplace air monitoring

• Civil defence and forensic analysis

• Materials and materials emissions testing

• Food, flavour and fragrance profiling

Many material samples such as drugs, foods, textiles,

polymers, paints etc. can be directly thermally

desorbed by weighing them into empty TD sample

tubes.

Alternatively, vapours in gas or air can be concentrated

on- or off-line onto sorbent traps/tubes before TDGC(MS) analysis.

Innovation and excellence in

thermal desorption

Since 1997 Markes International has re-engineered

analytical thermal desorption for the 21st century.

Harnessing unparalleled technical expertise, the

company has developed a suite of “universal” TD

systems and unique sampling accessories incorporating

key proprietary innovations such as:

• SecureTD-Q™ and automated sample recollection using a single TD autosampler

1

• RFID tube tagging (TubeTAG™)

2

• Diffusion-locking for effective tube sealing and

robust automation

3

• Innovative low volume valving specifically

designed for TD

4

Many of these innovations now set the standard for TD

instrumentation worldwide.

Page 3

Introducing the series 2 Air

Server range

Series 2 Air Server modules add to any series 2

(ULTRA-)UNITY system to allow a controlled flow of

whole-air or gas to be introduced directly into the

electrically-cooled focusing trap of the desorber. The

combined systems operate cryogen-free (to minimise

running costs/maintenance) and offer optimum

analytical performance/sensitivity.

With 3- (Air Server) or 8-channel (Canister Interface

Accessory - CIA 8) options available, method-compliant

series 2 (U

LTRA-)UNITY-Air Server systems are suitable

for both automated analysis of canister/bag samples

and round-the-clock unattended monitoring of on-line

air/gas streams.

Key applications include:

• Continuous monitoring of ozone precursors (C

2

to C10hydrocarbons) in ambient air and/or

vehicle emissions

• On- or off-line odour monitoring e.g. measuring

reduced sulphur species such as H

2

S, mercaptans

and sulphides in canister, bags or on-line air

streams at sub- to low-ppb levels

• “Air Toxics” in ambient air e.g. US EPA Method

TO-(14)15

• Industrial process control of gas purity and

odour

• Atmospheric research e.g. global background

pollution levels, pollution transport and kinetic

studies, such as monitoring diurnal changes in

urban air pollution or biogenic emission profiles

Series 2 (U

LTRA-)UNITY-Air Server systems connect to

any Agilent or other brand of GC(MS)

Air Server 2 Main Features

• Adds automated canister and on-line air/gas stream analytical capability to any series 2 (ULTRA-)UNITY

thermal desorption (TD) system.

• Cryogen-free operation and low consumption of gas supplies for lower running costs and higher uptime.

• 3 or 8 channel operation for sequencing between sample, zero and standard air/gas streams during

unattended on-line monitoring or automated canister/bag analysis

• Quantitative retention of ultra-volatiles such as acetylene from increased sample volumes (up to 1.5 L)

combined with peerless high-resolution capillary chromatographic performance (even under splitless conditions)

ensure optimum sensitivity. Parts per trillion (ppt) levels are readily detected.

• Method compliant tube desorption capability included with every system. Can be automated.

• Thermostatted flow path and internal standard addition options for compliance with standard canister

methods.

• Negligible sample carryover plus versatile sampling flows & flexible splitting options allow analysis of both

high and low concentration samples.

• Small footprint: Especially useful for installation in mobile labs.

• Versatile water management options for analysis of both dry and humid air/gas samples.

Page 4

Overview of Air Server operation

Series 2 Air Servers connect to any series 2 UNITY or

ULTRA-UNITY TD system. They contain 3, or 8 inert

sample/stream selection valves uniquely configured to

eliminate dead volumes and prevent carryover. Each

whole air/gas sample (pressurised or at

(sub-)atmospheric pressure) is introduced directly into

the electrically-cooled, sorbent-packed, focusing trap of

the UNITY 2 thermal desorber for a user-specified

sampling time. Conventional sorbent sampling tubes

are not used in this process.

The sampling flow is regulated by an electronic mass

flow controller (MFC) and optional pump located

downstream of the trap to eliminate risk of

contamination. Focusing trap sorbent and trapping

temperatures are selected for quantitative retention of

the compounds of interest and for selective purging of

potential interferences such as CO

2

and water. No

liquid cryogen is required and only inert, non-emitting

components come into contact with the sample. All

sampling parameters are monitored by system

software as an integral part of the analytical method.

At the end of sample introduction, the flow path is

purged with carrier gas to prevent carryover and

eliminate oxygen from the focusing trap. The trap then

heats rapidly in a reverse stream of carrier gas to

inject/transfer retained compounds into the

measurement system and trigger the analysis. This

transfer/injection may be performed splitless for

maximum sensitivity. (See UNITY 2 brochure for

more details.)

Once the focusing trap has desorbed, it cools and reequilibrates at the trapping temperature. Focusing of

the next air/gas sample in the sequence may begin

while analysis of the previous sample is ongoing to

optimise throughput.

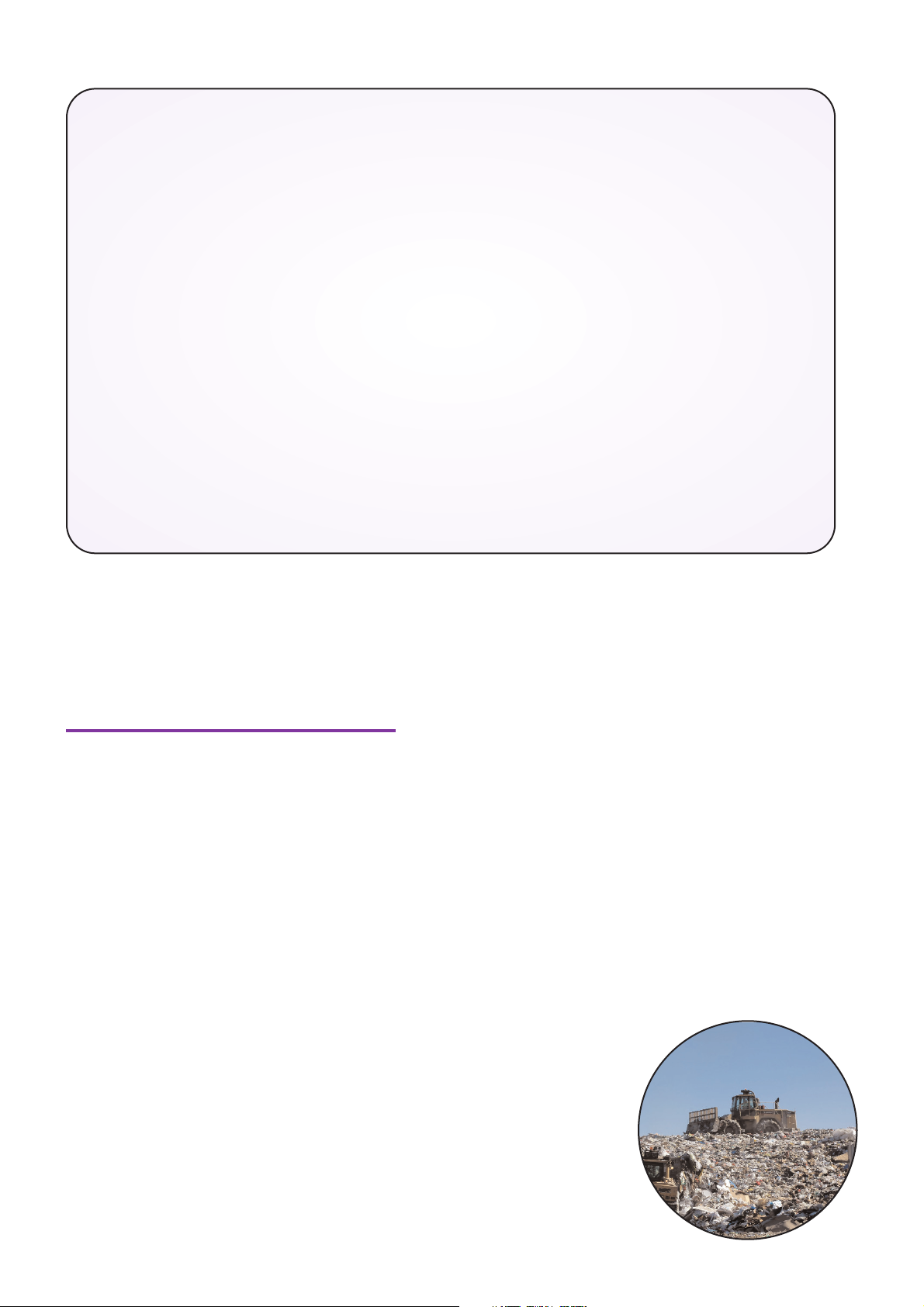

Series 2 Air Server range

The table below highlights the differences between the

Air Server 3 and CIA 8.

Note: Air Server 3 is integrated with UNITY 2 prior to

shipment or during field installation to minimize bench space in

confined locations such as mobile labs or remote monitoring

stations. The CIA 8 is a separate module.

Air Server 3

Canister Interface

Accessory (CIA 8)

Number of channels 3 8

Thermostatted flow path

Internal standard addition

Schematic of Air Server 3 operation

Sample

selection

valves

Series 2

Air Server

UNITY 2 GC(MS)

Cold

trap

Optional

split

Desorption

flow

Sampling

flow

Page 5

Intuitive user interface

Control of series 2 (ULTRA-)UNITY-Air Server systems

(Air Server 3 or CIA 8) is intuitive and integrated with

the UNITY 2 TD software to provide one comprehensive

and easy to understand user interface (UI).

The UI offers a specific mode for on-line/canister

operation (see figure opposite) and, once selected,

users are prompted to enter the relevant sampling

parameters such as sampling time, flow rate and purge

times.

Sequence building

Automated sequences for on-line monitoring and/or

automated canister/bag analysis are easily constructed

via the sequence builder. Samples may be assigned

individual desorption methods. Each sample is

classified as sample, calibrant or blank and all

sequences may be stored and recalled for future

reference or repeat use.

Graphical sequence viewer

The sequence viewer presents a clear graphical display

of current sequence status.

Sequence reporting

Information associated with each analysis, such as the

time, date and any deviations, are all recorded in the

sequence reporter. Any sample sequence failure

triggers the GC(MS) system to start a blank run to

keep the analyser in step with the autosampler.

Up to 8-channels for

optimum throughput

Control method screen (top) of user interface.

Complete user interface screen (bottom)

Page 6

Round-the-clock,

cryogen-free monitoring

On-line operation

On-line monitoring systems typically comprise a

series 2 UNITY with integrated 3-channel Air Server

module. The combined system is programmed to

repeatedly introduce air/gas from the sample

stream(s) and to automatically sequence calibration

gas and zero air/gas at user-defined frequencies,

typically once every 24 hours. Sequences may be

recycled indefinitely to minimise system programming.

Continuous monitoring of ozone precursors (C2–

C10hydrocarbons) in urban air, as required by both

European and US regulations

1,2

, is a key application for

series 2 UNITY-Air Server systems.

Key advantages of Markes series 2 UNITY-Air Server

systems for ozone precursor monitoring include:

• Unattended operation for extended periods:

Cryogen-free operation and low consumption of

gases simplifies installation in mobile labs and

offers extended periods of unattended operation

in remote field monitoring stations. Markes

cryogen-free series 2 UNITY-Air Server systems

consume only 40 ml/min dry gas/air when

configured without a Nafion dryer and less than

200 ml/min when a dryer is configured. This is

between 3 and 10 times less than other cryogenfree ozone precursor monitoring systems and

allows extended operation without cylinder

replacement

• Sensitivity: Quantitative retention of ultravolatiles such as acetylene from up to 1.5 L air

sample volumes combined with efficient splitless

desorption at low (<2 ml/min) flows ensures best

possible detection limits (typically 1-50 ppt

levels)

1. Council Directive 96/62/EC: On ambient air quality assessment and

management, and the daughter directive - 2002/3/EC relating to ozone in

ambient air

2. 1990 US Clean Air Act Ammendment

Splitless desorption of 56-compound US EPA mix of ozone precursors using series 2 UNITY-Air

Server 3 with dual column/dual FID GC with Dean’s switch

Compound

Det limit

(ppb)

450 ml

sample

Column

%RSD

(n=12) R

t

450 ml

sample

% RSD

(n=12)

peak area

450 ml

sample

Ethane 0.026 Al PLOT 0.07 0.3

Butane 0.010 Al PLOT 0.01 0.4

Hexane 0.019 DB1 0.01 0.5

Octane 0.017 DB1 0.01 1.0

Data courtesy of Ecole des Mines de

Douai, France

Page 7

Field-proven, robust on-line monitoring of H2S and other reduced sulphur compounds down

to sub-ppb levels in ambient air

On-line odour monitoring - Another key application for series 2 UNITY with integrated Air Server 3 option

y = 0.2953x + 5.2249

R

2

= 0.9999

Sample Volume (mL)

Acetylene Peak Area

H

2

S

CH

3

SH

DMS

DMDS

H

2

S

CH

3

SH

DMS

DMDS

10 ppb

20 ppb

Compound

Minimum

Detection

Limit (ppb)

%RSD

(n=10,

20ppb)

Hydrogen sulphide

(H2S)

0.15

4.1

Methyl mercaptan

(CH3SH)

0.15 1.8

Dimethyl sulphide

(C2H6S)

0.15 0.8

Dimethyl disulphide

(C2H6S2)

0.10

0.8

Data courtesy of Ecole des Mines de

Douai, France

Data courtesy of ITC, South Korea

Cryogen-free trapping of ultra-volatile compounds

including acetylene (ethyne) from up to 1.5 L of air

• Reliably excellent chromatographic

performance: Great resolution, stable retention

times and repeatable concentration data minimise

measurement uncertainty and simplify data

interpretation/validation

• Small footprint: The Series 2 UNITY with

integrated 3-channel Air Server is only 22 cm

(9-inches) wide

Timed start

Series 2 UNITY-Air Server systems allow the start of a

monitoring sequence to be programmed for a specific

date and time (e.g. noon on Monday May 1st) and for

the period between each sampling cycle to be fixed.

The sampling cycle used for ozone precursor

monitoring for example, is typically 1 hour. In this case

air is usually sampled into the UNITY 2 focusing trap

for 40 minutes of every hour starting on the hour.

Page 8

Automated off-line analysis of

Cryogen-free operation saves

thousands of dollars a month...

Schematic of series 2 UNITY - CIA 8 operation

Versatile sample splitting options offer compatibility

with vapour concentrations ranging from ppt to ppm

CIA 8

Stream

selection

Internal

standard

addition

Samples

Internal

standard

Sampling

flow

Desorption

flow

UNITY

GCMS

Optional split

canister/bag samples

Key issues associated with automated canister analysis

include throughput, running costs, sensitivity, water

management and method compliance. A typical Air

Server system configuration in this case would include:

The series 2 (ULTRA-)UNITY with a Canister Interface

Accessory (CIA 8) for 8 channels.

Series 2 UNITY with CIA 8 features a thermostatted

sample flow path and internal standard (IS)

addition to the focusing trap. The system is fully

compliant with relevant standard methods such as

US EPA Method TO-15 for “Air Toxics”.

Air toxics monitoring

Key advantages of Markes series 2 (ULTRA-)UNITY-

CIA 8 technology for Air Toxics monitoring and for

canister air analysis generally include:

• Productivity: Markes systems offer 8-channels

for automated operation over extended periods.

Confirmatory repeat analysis of each canister

may be included in the automation sequence

• Cost reduction. Cryogen-free operation

minimises:

• Capital costs (no liquid nitrogen dewar

required)

unning costs (cryo-cooled systems require

• R

fresh supplies of liquid coolant as often as

every 2 or 3 days)

• Manpower (changing/refilling of liquid

coolant dewars takes time and effort)

• Downtime (replenishing liquid cryogen often

interrupts an automated sequence)

Page 9

TO-15 standard chromatogram (1ppb in 1 L) (main) and real air sample (insert)

Canisters, bags and sorbent tubes

1

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

1 Dichlorodifluoromethane

2 1,2–Dichlorotetrafluoroethane

3 1,3–Butadiene

4 Trichlorofluoromethane

5 1,1,2–Trichlorotrifluoroethane

(Freon 113)

6 Isopropyl alcohol

7 Carbon disulfide

8 Methylene chloride

9 Tert-butyl methyl ether

10 n-Hexane

11 1,1-Dichloroethane

12 Ethyl acetate, methyl ethyl ketone

13 Tetrahydrofuran

14 Cyclohexane

15 Benzene

16 n-Heptane

17 Trichloroethylene

18 1,2–Dichloropropane

19 Bromodichloromethane

20 Trans-1,3-dichloropropene

21 Methyl isobutyl ketone

22 Toluene

23 Cis-1,3-Dichloropropene

24 Tetrachloroethylene

25 Methyl n-butyl ketone

26 Dibromochloromethane

27 1,2–Dibromoethane

28 Chlorobenzene

29 Ethylbenzene

30 Xylene

31 Styrene

32 Tribromomethane

33 1,1,2,2-Tetrachloroethane

34 1,2,4-Trimethylbenzene

35 1,3,5-Trimethylbenzene

36 1,2-Dichlorobenzene

37 1,3-Dichlorobenzene

38 Chloromethylbenzene (alpha)

39 1,4–Dichlorobenzene

40 1,2,4–Trichlorobenzene

41 Hexachloro-1,3-butadiene

Isopropyl alcohol

DCM

Hexane

Methyl cyclopentane

Cyclohexane

1-Methyloxy-2-propanol

Toluene

2-Methyl butane

Benzene

2,4-Dimethyl pentane

0.1 ppb level

Time (mins)

• Analytical excellence: Super-efficient trap

desorption and reliably excellent chromatographic

performance, even under splitless conditions and

without on-column focusing (see Series 2 UNITY

brochure), optimise sensitivity and simplify

identification of target air toxic analytes even in

complex backgrounds.

• Versatile water management: Markes TD

systems offer selective purging of water,

sophisticated sample splitting and the option of

in-line dryers for effective water management

under any air monitoring conditions.

Page 10

ppm...ppb...ppt

Versatility

The application range of series 2 Air

Server technology

Series 2 (ULTRA-)UNITY–Air Server systems (Air Server

3 or CIA 8) offer quantitative and cryogen-free

retention, even of ultra-volatile species such as freons

and C2hydrocarbons, together with complete recovery

across the air toxics boiling range. Labile, odorous

analytes, such as H2S and mercaptans may also be

measured at sub-ppb concentrations. Markes systems

are compatible with the highest boiling compounds that

can be recovered from canisters or ambient

temperature air/gas streams.

New improved stream selection valves and an inert,

thermostatted flow path eliminate sample carryover

even when monitoring over a wide concentration range

(ppt to ppm). This allows ambient air samples to be

calibrated with small volumes of relatively concentrated

standard gas. It also allows automated sequencing of

samples varying widely in concentration without fear of

contamination.

Compatibility with samples over a wide concentration

range is further enhanced by sophisticated,

electronically-controlled sample splitting during trap

desorption (and during tube desorption, if applicable).

On-line monitoring, canisters/bags

AND tube desorption

Whether they are used for on-line monitoring or offline canister/bag analysis, all systems incorporating

series 2 Air Server technology, offer complementary

tube desorption.

Every series 2 Air Server is connected to a Markes

(U

LTRA-)UNITY 2 system. The UNITY 2 TD platform

offers method-compliant desorption of single tubes and

the addition of a series 2 ULTRA allows automatic

analysis of up to 100 sorbent tubes. Series 2 (ULTRA-)

UNITY systems are described in detail in the associated

brochures and their performance is not compromised in

any way by the addition of an Air Server module.

In summary, key advantages of series 2 (U

systems for tube desorption include:

• Application versatility. Series 2 (U

systems are compatible with every TD application

on one analytical platform; ultra-volatiles (e.g. C

hydrocarbons), semi-volatiles (up to n-C40) and

reactive compounds. Samples for tube desorption

either comprise sorbent tubes used to collect

organic vapours or material samples (solid or

liquid) weighed directly into empty TD sample

tubes for direct desorption. Splitless, single or

double split options allow analysis of samples

ranging in concentration from ppt to percent

without overloading the analytical system

LTRA-)UNITY

LTRA-)UNITY

2

• Method compliance. Markes’ tube desorption

technology complies with all key standard

methods; US EPA Method TO-17 (ambient and

indoor air), ISO 16017 (workplace, ambient and

indoor air), EN ISO 16000 (materials emission

testing), NIOSH 2549 (workplace indoor air), etc.

Important features for method compliance include

effective tube sealing during automation,

stringent (ambient-temperature/no-flow) leak

testing, cryogen-free cooling and the option of IS

addition

Page 11

Detection of trace level analytes aids atmospheric

research

Real time monitoring -

real time detection

30 ml of air from bubbles in the ice core

collected in canisters. Analysis by TD-GCMS in NCI mode. Unit ppt detection limits

Toluene

Subsequent blank run

Contaminated air sample

Negligible carryover with series 2 UNITY-Air Server

• Repeat analysis. The proprietary SecureTD-Q

facility is supplied as standard with every series 2

(ULTR

A-)UNITY system. It offers quantitative recollection of any split flow (during tube or trap

desorption) facilitating repeat analysis and

simplifying method/data validation.

SecureTD-Q

overcomes the one-shot limitation of other

thermal desorbers

• High throughput. 100-tube capacity and

overlap mode (the ability to begin desorption of a

subsequent sample while analysis of a previous

sample is ongoing) optimise productivity/revenue

generation

• Compatibility with RFID tagged tubes

(TubeTAG) for enhanced tube/sample

traceability

Trademarks

SecureTD-Q™ and TubeTAG™ are trademarks of

Markes International Ltd.

Page 12

Markes International Ltd.

Gwaun Elai Medi Science Campus

Llantrisant

RCT

CF72 8XL

United Kingdom

T: +44 (0)1443 230935 F: +44 (0)1443 231531

E: enquiries@markes.com W: www.markes.com

Loading...

Loading...