Operation/Service Manual

m

Cimjet

®

®

RFID

Cimjet® RFID

Operation/Service Manual

150 Congress Street, PO Box 2100, Keene, New Hampshire 03431-7100

m®

TEL : 603-352-1130 FAX: 603-357-5871 http://WWW.MARKEM.com

WARRANTY

All MARKEM products are warranted to be free of defects in materials and workmanship and to conform to MARKEM

specifications in effect at the date of shipment to Buyer. Any changes Buyer requests to MARKEM specifications are not

effective without advance, written authorization by MARKEM. The warranty period is as follows:

Machines: One year from date of shipment to Buyer or 2000 operating hours, whichever expires first, unless any

specific machine is designated on an order or otherwise as Made to Order (“MTO”), in which event the

warranty period is 90 days from date of shipment to Buyer.

Ink Jet Orifice Plates (on new machines and as replacement parts): 90 days from date of shipment to Buyer.

Replacement Parts: 90 days from date of shipment to Buyer.

Software: 90 days from date of shipment to Buyer. Warranty does not entitle Buyer to new releases, upgrades or

enhancements introduced during the warranty period.

Supply Products: For the period of shelf life of the supplies as stated in the applicable specification standards or

one year from the date of shipment to Buyer if not specified.

During the warranty period, MARKEM will, at its option, repair, replace or refund the purchase price of MARKEM products

which prove to be defective in materials or workmanship or which do not conform to the applicable MARKEM specifications.

Within MARKEM service travel areas for certain products designated by MARKEM, warranty service for machines and parts

will be provided at the installation site. In all other cases, products must be returned to a service facility designated by

MARKEM.

For products returned to MARKEM for warranty repair or replacement, Buyer shall obtain a return authorization number and

shipping instructions from MARKEM and return the product shipping charges prepaid. Shipping charges for the return of

products to Buyer shall be paid by MARKEM within the contiguous forty-eight United States and the District of Columbia; for

all other locations, the warranty excludes all costs of shipping, customs clearance and any other related charges. All replaced

products shall become the property of MARKEM.

The foregoing warranty shall not apply to any custom work performed by MARKEM. The foregoing warranty shall also not

apply to defects or non-conformance with MARKEM specifications which result from: (l) improper installation, use, storage,

care or maintenance by Buyer; (2) wear resulting from normal use of parts subject to wear, such as ink rolls, offset pads, foil

feeds, thermal transfer print heads, etc.; (3) modification, alteration or retiming of a MARKEM machine; (4) cycling a

MARKEM machine out of specification; or (5) adding a unit timed or driven by a MARKEM machine; (6) use of products

(including supplies) or software not furnished by MARKEM (7) accident, neglect, misuse or abuse; or (8) exposure conditions

outside the range of the environmental, power and operating specifications provided by MARKEM.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. MARKEM SPECIFICALLY DISCLAIMS ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Determination of the suitability of

the products described on the face of the quote and/or invoice is the sole responsibility of the Buyer and MARKEM shall have

no responsibility in connection therewith. BUYER WARRANTS THAT HE IS NOT PURCHASING THE PRODUCTS FOR

PERSONAL, FAMILY OR HOUSEHOLD PURPOSES. THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND

EXCLUSIVE REMEDIES.

LIMITATION OF LIABILITY: MARKEM SHALL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, WHETHER BASED IN CONTRACT, TORT OR ANY OTHER LEGAL THEORY, OR FOR

THE COST OF SUBSTITUTE GOODS. CONSEQUENTIAL DAMAGES for purposes of this Agreement shall include, without

limitation:

1. Loss of use, income or profit, or losses sustained as a result of the injury (including death) to any person or loss or

damage to property, including, without limitation, materials manufactured, processed or labeled by the use of the

products.

2. Damages arising out of or in connection with delays in delivery, MARKEM’s performance, non-performance or

breach of this contract, defects in the equipment, failure of the products to perform properly or non-conformance of

the products with specifications or the operation, use, installation, repair or replacement of the products.

0874339 Rev. 08 11/03

This guide explains the basic operation and care of the Model Cimjet® RFID System.

To the best of our knowledge, the information contained in this guide was correct at the time

of publication. However, continual enhancement of our products can result in some

differences between the instructions represented in this guide and your printer.

MARKEM is a registered trademark of MARKEM Corporation.

This guide was written by:

MARKEM Corporation

150 Congress Street

Keene, New Hampshire 03431 U.S.A.

Copyright © 2005 by MARKEM Corporation

All rights reserved. Reproducing this publication in whole or in part without written

permission is expressly prohibited.

Reference List

The information on your packing slips can be written below for reference. When contacting

MARKEM please give your Model Number, Serial Number, and Customer Account Number.

Model ____________ Serial Number_________________ Date Installed______________

Customer Account Number__________________________________________________

Name of MARKEM Representative_____________________________________________

Options/

Accessories_______________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

0855904enb 4/05 m® i

TABLE OF CONTENTS

Section 1 General Information

1.0 Welcome to the Model Cimjet RFID. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 What is in this Guide?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2.0 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2.1 Applicable Safety Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2.2 Modifications to Cimjet RFID . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2.3 Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2.4 Machine Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2.5 Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

2.6 Isopropanol Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

2.7 Foreseen Use/misuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

2.8 MARKEM Training Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

2.9 Removal from Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

3.0 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

3.1 Components of Cimjet RFID. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

3.1.1 Dispenser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

3.1.2 Applicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

3.2 Tag Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

3.3 Beacon Light (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

3.4 Networking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

4.0 Dimensional Drawings (in Millimeters) . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Section 2 Installation Guide

1.0 Installation of the Cimjet RFID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.1 Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.0 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1 Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

3.0 Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

3.1 Air Regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

4.0 I/O Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

5.0 Positioning the Applicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

0855904enb 4/05 m® iii

TABLE OF CONTENTS

Section 3 Operating Guide

1.0 Preparing Cimjet RFID for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

2.0 Operating the Cimjet RFID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.0 Loading Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

4.0 Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

5.0 Operator Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

5.1 Menu Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

5.2 The Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

5.3 Operator Interface LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

5.4 Guidelines for Entering Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

6.0 Auto and Set Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

6.1 Auto Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

6.2 Set Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

7.0 Engineer Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

7.1 Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

7.2 Set Tag Optic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

8.0 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Section 4 Restricted Access Mode User Guide

1.0 Restricted Access Mode User Guide . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

2.0 Entering Restricted Access Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

3.0 Machine Init (Initialization) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

3.1 Reset Params. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.0 Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.1 Password Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.2 Password Key Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

5.0 Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

6.0 Restricted Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

7.0 Set Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

8.0 Communications Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

9.0 Machine Options Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

9.1 Machine Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . .4-12

9.2 Applicator Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

10.0 Feeder Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Section 5 Operating Modes

1.0 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

2.0 Application Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

2.1 Auto Apply Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

2.2 On Demand Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

3.0 Connecting External Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

3.1 Wiring the Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

3.2 Testing the Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

4.0 Positioning Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

iv m® 0855904enb 4/05

TABLE OF CONTENTS

4.1 Auto Apply Sensor Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

4.2 On Demand Mode Sensor Position . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.0 Fitting the Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

6.0 Apply Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Section 6 Preventive Maintenance Guide

1.0 General Maintenance and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.2 Positioning of Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

2.0 Cleaning of all Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

3.0 Changing the Tag Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

4.0 Tag Unwind Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

5.0 Clutches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

5.1 Replacing the Felt Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

5.2 Setting the Clutch Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.0 Sensor Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.1 Low Reel Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.2 Nip Home Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.3 Tag Gap Optic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

7.0 Drive Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

8.0 Maintaining the Compressed Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Section 7 Technical Information

1.0 Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

1.1 Power Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

1.2 Power Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

2.0 The Cimjet RFID Main Processor Board . . . . . . . . . . . . . . . . . . . . . . . . 7-3

2.1 On-board Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

2.2 Input and Output LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

2.3 Processor Board Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

2.4 Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

2.5 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

2.6 Firmware and RAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

2.7 Switch Settings and Potentiometers . . . . . . . . . . . . . . . . . . . . . . 7-15

3.0 External Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

3.1 X28 Communications (Comms) . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

3.2 X23 External Sensor Connection . . . . . . . . . . . . . . . . . . . . . . . . 7-18

3.3 X12 External I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

4.0 Status Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

5.0 Status Reset Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

6.0 Display I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

7.0 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

8.0 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

9.0 Pneumatics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

0855904enb 4/05 m® v

TABLE OF CONTENTS

9.1 Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-29

9.2 Compressed Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . .7-29

Section 8 Troubleshooting Guide

1.0 Error Messages in Auto Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

2.0 Power-up Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

3.0 Start-up Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

4.0 Other Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4

5.0 Communications Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

6.0 Tag Feed Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-8

6.1 Incorrect Tag Stopping Position . . . . . . . . . . . . . . . . . . . . . . . . . . .8-8

6.2 Erratic Tag Feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-8

6.3 Inconsistent Tag Stopping Position . . . . . . . . . . . . . . . . . . . . . . . .8-9

6.3.1 If the Tag Stops in the Correct Position . . . . . . . . . . . . . . .8-9

6.3.2 If the Tag Stops in an Inconsistent Position . . . . . . . . . . . .8-9

7.0 No Driving of Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

8.0 Motor Stalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

Section 9 Recommended Spares

1.0 Recommended Spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

1.1 Preventive Maintenance Spares Kits . . . . . . . . . . . . . . . . . . . . . . .9-1

1.2 General Spares Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

1.3 Left-hand Change Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

Section 10 Parts Illustrations and Electrical Schematics

vi m® 0855904enb 4/05

SECTION 1

General Information

m

®

Cimjet ® RFID

Operation/Service Manual

SECTION 1 General Information

1.0 Welcome to the Model Cimjet RFID

The Cimjet RFID is a high speed, compact RFID tag dispenser and

applicator that is compatible with a full range of MARKEM products.

1.1 What is in this Guide?

The Cimjet RFID manual addresses the basic installation, operation

and care of the RFID tag dispenser , as well as safety, maintenance,

troubleshooting, and service information. For more applicator

information, refer to the Cimjet RFID Blow Applicator Manual

(0855906) and the Cimjet RFID Tamp Applicator Manual

(0855907).

1.2 Glossary

active tags – tags that use batteries as a source of power (can be

either partial or complete power); there are tags with replaceable

batteries and tags that have the batteries inside a sealed unit –

sometimes called unitized active tags

addressability – ability to address bits, fields, files or other portions

of storage in a tag

antenna – conductive elements that radiate and/or receive energy

in the radio frequency spectrum to or from the tag

bi-directional – a tag that can be read or written from either side

capacity – amount of bits or bytes that can be programmed into a

tag; these may be bits accessible to the user, or the total number,

including those reserved for the manufacturer (such as parity or

control bits)

electronic tag – a tag that has an electronic RFID tag embedded

within it

EMC – electromagnetic compatibility

frequency – number of times a signal makes a complete pass

through its maximum and minimum values and returns to the same

value (cycles)

misread – a condition that exists when the data presented by the

reader does not match the corresponding data in the tag

passive tags – tags that do not contain an internal power source;

they are externally powered and usually get their power from the

carrier signal radiated from the scanner

programming – adding information to or altering a tag

programmability – data and identification information must be

entered into tags in order for them to become identifiers of specific

objects; this capability is called programmability

0855904enb 4/05 m® 1–1

SECTION 1 General Information

programmer – tag contents can be changed by a set of electronics

in close proximity or in electrical contact with them; those electronics

and their packaging are called a programmer

RFID – systems that read or write data to RF (radio frequency) tags

that are present in a radio frequency field projected from RF

reading/writing equipment; data may be contained in one or more

bits for the purpose of providing identification and other information

relevant to the object the tag is attached to; it uses electromagnetic

or electrostatic coupling in the radio frequency portion of the

spectrum to communicate to or from a tag through a variety of

modulation and encodation schemes

range – distance at which successful reading and/or writing can be

attained

read – decoding, extraction and presentation of data from

formatting, control and error management bits sent from a tag

readability – ability to extract data under less than optimal

conditions

read rate – maximum rate at which data can be read from a tag,

expressed in bits or bytes per second

read/write – many applications require that new data, or revisions to

data already in the tag, be entered into the tag while it is still

attached to its object; tags with this capability are said to be

reprogrammable and are called read/write tags, memory cards, or

memory modules

reader – device containing the digital electronics that extract and

separate the information from the format definition and error

management bits; digital electronics perform the actual reading

function; these read electronics may also interface to an integral

display and/or provide a parallel or serial communications interface

to a host computer or industrial controller

reader/writer – the set of electronics can change the contents of the

tags while they are still attached to their object; they are called the

reader/writer (see reader)

reprogrammable – many applications require that new data, or

revisions to data already in the tag, be entered into the tag while it is

still attached to its object; the ability to read from and write data to

the tag while it is attached to its object is called in-use

programming; tags with this capability are said to be

reprogrammable and are called read/write tags, memory cards, or

memory modules

1–2 m® 0855804enb 4/05

SECTION 1 General Information

scanner – the antennae, transmitter (or exciter) and receiver

electronics are integrated in a single package called the scanner;

they may be combined with additional digital electronics, including a

microprocessor in a package called a reader

tag – the transmitter/receiver pair, or the transceiver plus the

information storage mechanism, attached to the object, is referred to

as the tag, transponder , electronic tag, code plate, and various other

terms. Although transponder is technically the most accurate, the

most common term and the one preferred by the Automatic

Identification manufacturers is tag

transponder – see tag

verify – assure that the desired operation was performed correctly

write – transfer of data to a tag; the tag’s internal operation of

storing the data, sometimes including the data, in order to verify the

operation

write rate – rate at which information is transferred to a tag, written

into the tag’s memory and verified as being correct; it is quantified

as the average number of bits or bytes per second in which the

complete transaction can be performed

0855904enb 4/05 m® 1–3

2.0 Safety Information

2.1 EMC (Electromagnetic Compatibility) Considerations

To maintain the integrity of the EMC precautions taken with the

Cimjet RFID, all connecting cables must be fully screened, and the

screen must have 360 degree cont act with the metal connector and,

in turn, the unit’s case at both ends.

2.2 Modifications to Cimjet RFID

Any changes or modifications not expressly approved by MARKEM

that could affect FCC Compliance could void the user’s authority to

operate the Cimjet RFID.

SECTION 1 General Information

1–4 m® 0855804enb 4/05

2.3 Electrical Safety

• Incoming supply cable should be rated at 10A minimum for the

Cimjet RFID (independent of nominal supply voltage)

Maximum switch-on supply current surge for the Cimjet RFID is as

follows: Cimjet RFID Maximum current level = 70A,

Duration = 6ms

Recommended cable protection is as follows:

• MCB (Miniature Circuit Breaker): to IEC 947-2 / EN 60947-2 and

BS EN 60898 with a minimum instantaneous release response

current of 10x rated current (type D)

• Klockner Moeller type FAZNS 6-2 (6A, 2 pole type D)

• Merlin Gerin type C60 HD 206 (6A, 2 pole type D)

Note: The Klockner Moeller or Merlin Gerin circuit breakers are

SECTION 1 General Information

recommended. An equivalent MCB can be used.

0855904enb 4/05 m® 1–5

SECTION 1 General Information

Fuses

• Use 10A HRC or HBC type fuses with a minimum of 95A RMS

symmetrical prospective current rating, at a 10ms minimum prearcing time, such as ASTA certified to BS88 part 2 ‘pullcap’ type

or equivalent.

Electrical safety testing (after installation)

WARNING: It is essential that the continuity of the protective

bonding circuit and the prospective short circuit

current level be checked after the machine is

installed and the electrical connections, including

those to the power supply, are complete. A

competent person must carry out these tests.

Test equipment required: Digital Loop and PSC Tester (such as

Robin Model KMP4120 Digital PSC-LOOP Tester)

• Connect tester to incoming mains supply to machine.

• Check that the supply voltage is within specification and that the

connections are correctly wired (indicated on the tester).

• Select the 20 ohms scale on the tester and press the Test

button to check the value of earth fault loop impedance for the

power supply provided.

If a class D MCB to BS EN 60898 or equivalent protects the supply,

then the maximum impedance should be 2 ohms.

If the supply is protected by a BS88 part 2 style fuse, then the

maximum impedance should be 5.33 ohms.

Select the PSC (Prospective Short Circuit Current) test and check that

the PSC level does not exceed 1500A.

WARNING: Failure to carry out these tests will potentially

result in an unsafe installation, and the equipment

fault-clearance ability may not function correctly.

1–6 m® 0855804enb 4/05

2.4 Machine Safety

The product is designed to conform to all current Machine Safety

Regulations. Please read through this section before operating

this machine.

This feeder is designed for use with the following supply systems

that conform to IEC 664 light industrial / domestic installation

category II main supply.

• ‘TN’ (any of following - TN-C, TN-S or TN-C-S) For example: a

system having one or more points of the source of energy

directly earthed; the exposed conductive parts of the installation

being connected to that point by protective conductors

• ‘TT’ - For example: a system having one point of the source of

energy directly earthed; the exposed conductive parts of the

installation being connected to earth electrodes electrically

independent of the earth electrodes of the source

• It is NOT suitable for connection to an ‘IT’ system. For example:

a system having no direct connection between live parts and

earth, the exposed conductive parts of the installation being

earthed; this, therefore, excludes any ‘phase to phase’

connected supplies such as what might be available in some

factories and/or countries

SECTION 1 General Information

If either supply fuse (located on the rear of the controller, below the

supply connector) is replaced, it must be replaced by an HBC Style

ceramic fuse with the rating shown as ‘T5AH250V.’

WARNING: Installation must only be performed by qualified

MARKEM personnel. For customer installations,

authorization must be obtained from MARKEM. All

relevant Safety Procedures must be followed.

Failure to do so may void the warranty.

1. The Cimjet RFID must be disconnected from the main power

supply before removing the cover from the I/O interface board.

Make sure that any external interlocked machines are also

disconnected from the power supply.

2. DO NOT touch restrictors/regulators that are mounted inside the

rear dispenser cover. These are pre-set at the factory for your

safety.

3. ALWAYS disconnect the power to the machine before removing

any covers. You must remove the plug from the main power

supply.

4. DO NOT operate the machine with any covers removed. All

covers must be in place using the appropriate number of

fasteners. It is essential that electrical and non-electrical

0855904enb 4/05 m® 1–7

SECTION 1 General Information

connector dust covers provided with the machine are fitted to all

unused connectors to protect against dust and dirt and prevent

possible static damage to internal components.

5. DISCONNECT the air supply before undertaking work on the

applicator.

6. DO NOT adjust the internal cylinder regulator pressure under

any circumstances. Doing so could make the Cimjet RFID

unsafe.

7. It is possible for the machine to become unstable when being

moved. The machine must be lowered to its lowest possible

position before moving, and care must taken to prevent personal

injury.

8. Loading tags can present a risk if the machine is mounted high

up as the tag reels are heavy. It may be necessary to provide a

platform on which to stand, enabling the operator to load tag

reels safely, without risk of personal injury. When lowering the

machine, be sure a minimum of two people reposition or move

the machine and that it is fully supported.

9. Always take care when moving around the machine not to slip,

trip, or fall, especially when the machine is used in areas where

the floor may be wet or greasy.

10.Be aware of the operating zone required by the Cimjet RFID

when working with and near the machine. Allow ample space

beyond the applicator operation zone to ensure operator safety.

Be certain all reasonable safety precautions have been

undertaken; however , when working with or around the machine,

take care to avoid potential hazards. If the customer has any

safety concerns, guarding must be provided by the customer.

11. Be aware that free items, such as loose clothing or long hair,

could become entangled or trapped in the Tag Nip Roller or

paper path during the operation of the machine. A warning

sticker is fitted locally to highlight the hazard.

12.Beware of the unlikely event of an electronic fault causing an

unexpected start-up or overrun of the pneumatic cylinders or

feeder drive motors, which could cause possible injury.

13.The regulator mounted inside the rear dispenser cover is set to

1.86 Bar for safety reasons and should only be serviced or

replaced by trained personnel. If the cylinder pressure is raised

above 1.86 Bar, the customer must provide additional guarding

for operator safety.

14.Make sure that the maximum light emission power and

classification for any/all laser(s) used on this machine, do not

1–8 m® 0855804enb 4/05

SECTION 1 General Information

exceed those specifications stated in the appropriate laser safety

standards IEC825. When irregularities are detected in the laser

beam generation, internal protective devices must switch the

laser beam off.

15.Various safety and warning labels are placed on the Cimjet RFID

(see following pages).

WARNING: These labels are provided for your safety and

should not be ignored or removed.

16.All fixing screws in all covers must be used to ensure EMC

integrity.

0855904enb 4/05 m® 1–9

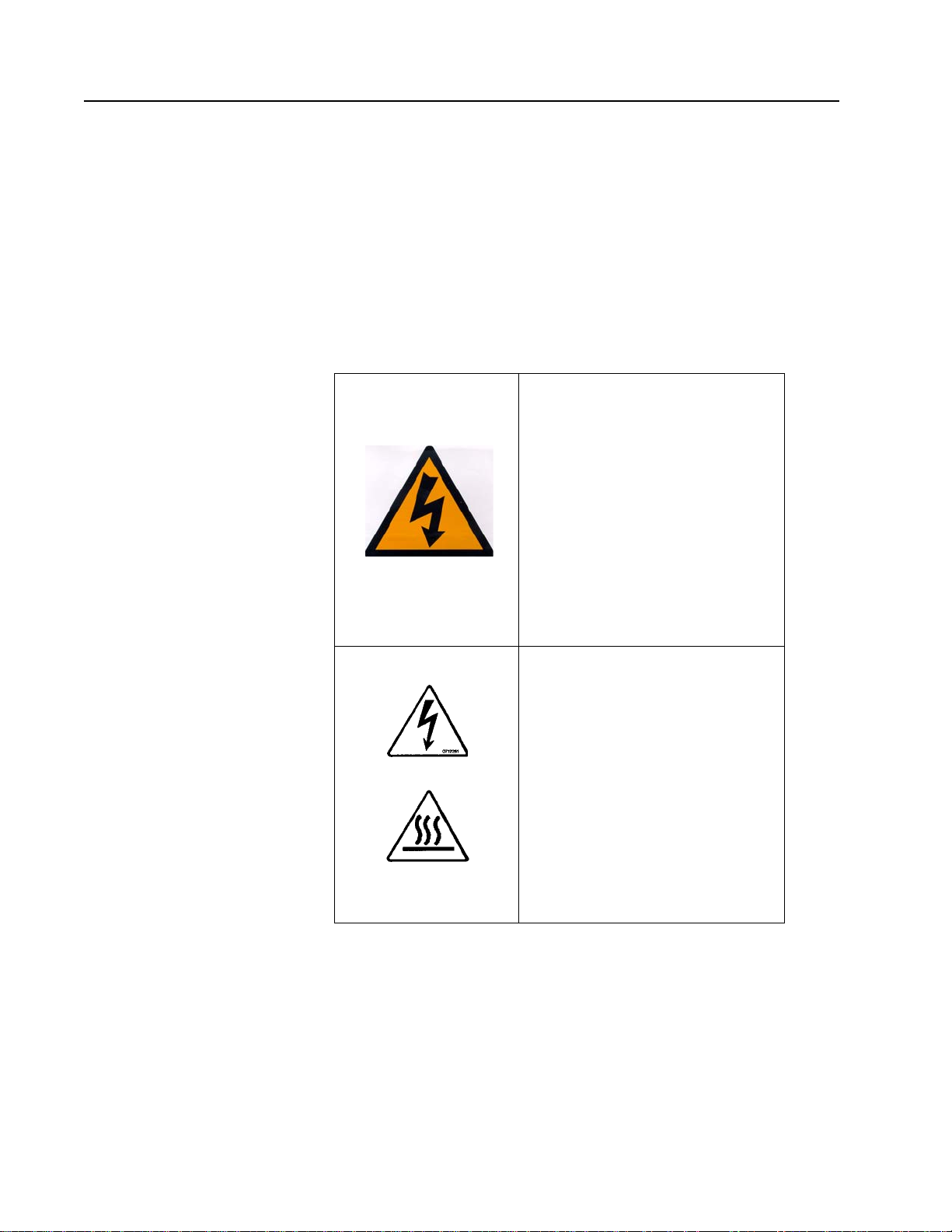

2.5 Safety Labels

The safety information in this manual is correct to the best of our

knowledge, information, and belief at the date of this publication.

The information given is designed only as guidance for safe

handling use, processing, storage, transportation, disposal and

release and is not considered a warranty or quality specification.

The information relates only to the specific material designated and

may not be valid for such material used in combination with any

other materials or in any process unless specified in text.

SECTION 1 General Information

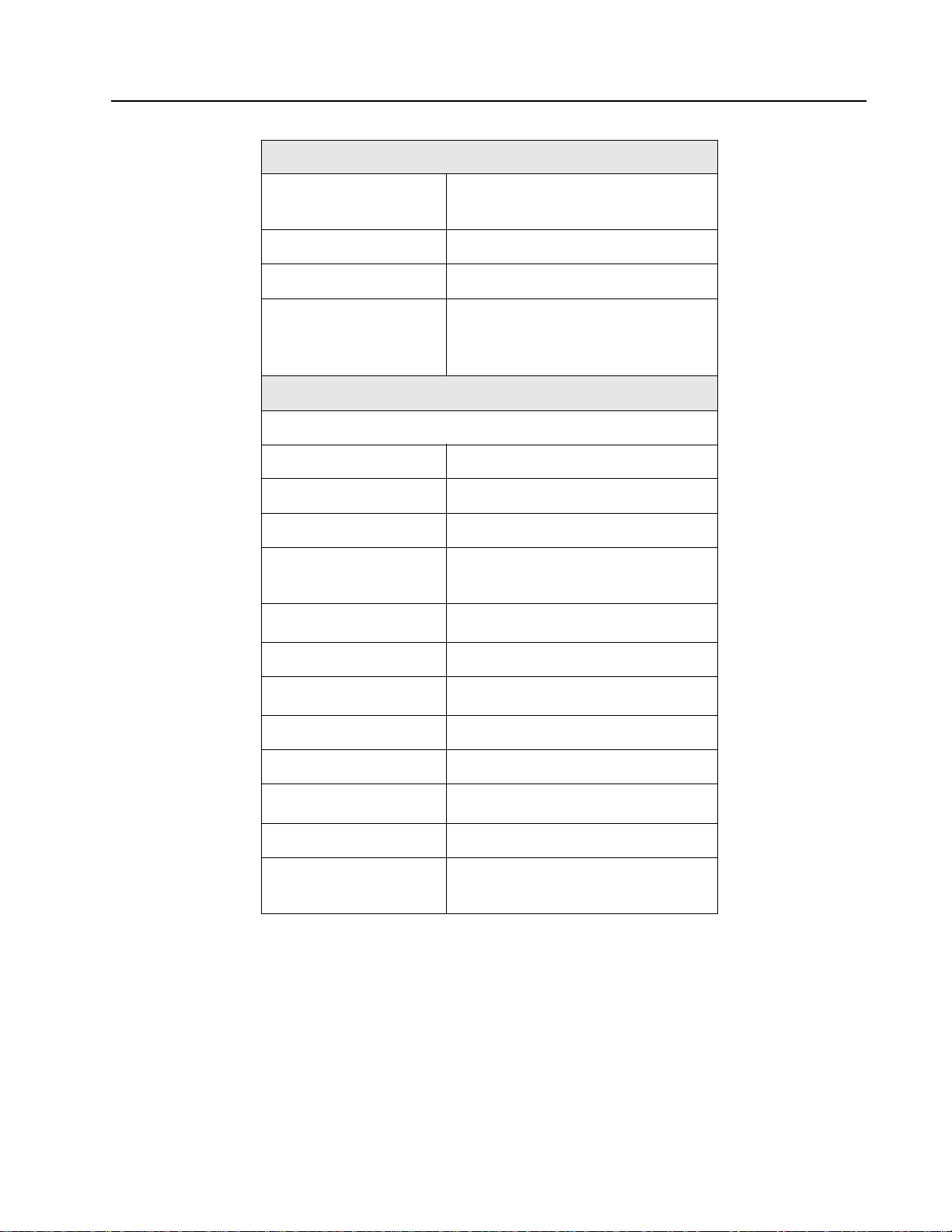

Table 1–1 Safety Labels

There is a danger of electrical

Line V oltage

shock during checks and

repair .

Remove the power cord from

the electrical outlet before

performing all checks and

repair .

Part Number

BO5263AA

Hot Surfaces

Part Number

BO5265AA

All electronic checks must be

performed by a qualified

technician.

To prevent mild injury from

burns, be careful not to

directly touch any surface

where this safety sticker is

placed.

1–10 m® 0855804enb 4/05

SECTION 1 General Information

Table 1–1 Safety Labels

Hazard Warning

Part Number

BO5262AA

Earth

Part Number

BO5264AA

Hazard warning safety labels

are placed in strategic

positions around the machine

to highlight potential hazards

to the operator.

Earth labels are placed in

strategic positions around the

machine to highlight the

machines earthing point.

Use only 115V conne ctions

where you find this safety

label.

Part Number

34976BA

Use only 230V connections

where you find this safety

label.

Part Number

34977BA

0855904enb 4/05 m® 1–11

2.6 Isopropanol Safety

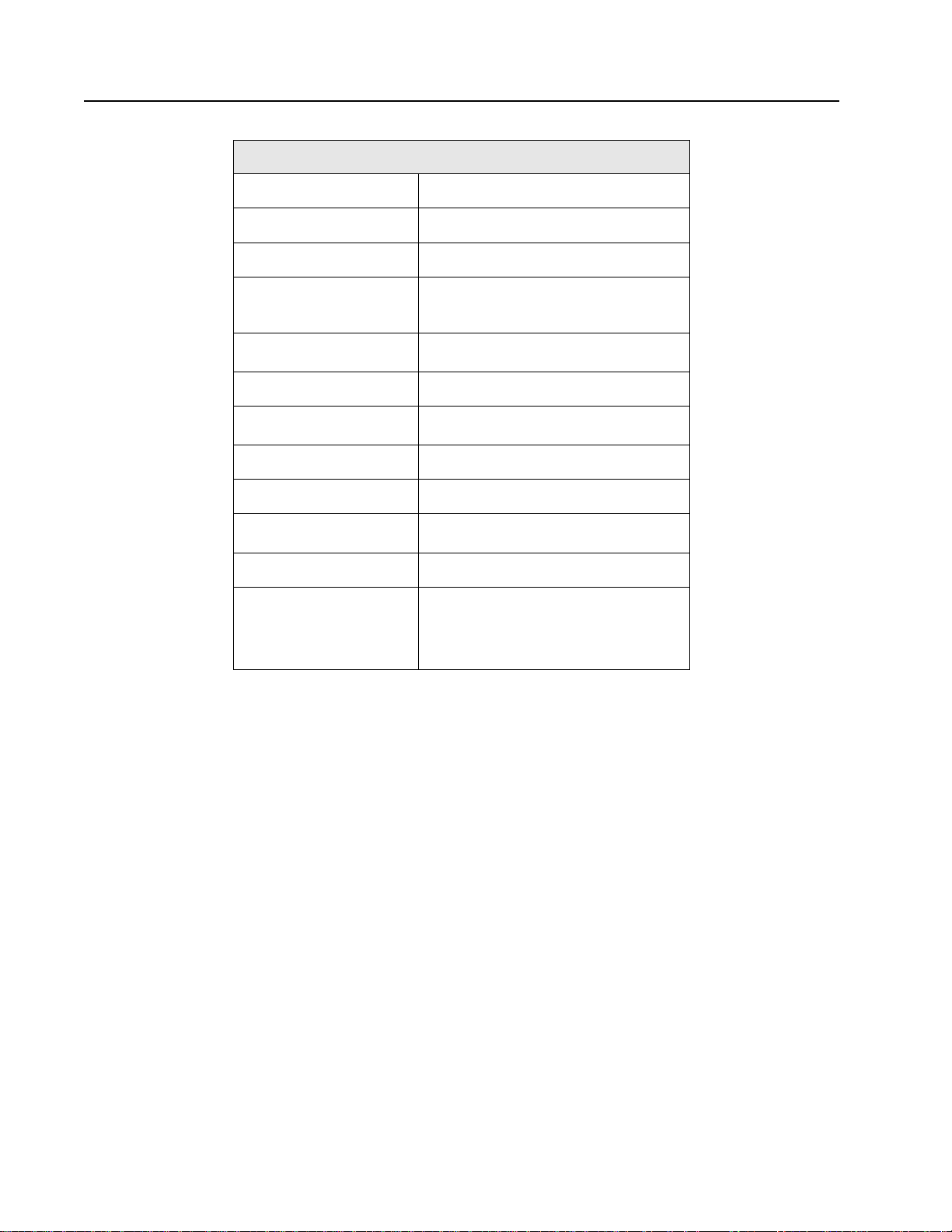

Table 1–2 Isopropanol Safety

Product Name Isopropanol Wipes

Part Number BO4985AA

Product Name Isopropanol Cleaning Kit

Part Number BO3285AA

Product Name Isopropanol Top Up Kit

Part Number BO3286AA

Supplier MARKEM Technologies Ltd.

SECTION 1 General Information

Alexander Fleming Building,

Nottingham Science and

Technology Park, University

Boulevard,

Nottingham,

NG7 2RF

Composition/Information on Ingredients

Identification of the

preparation

Chemical Name

CAS-No EEC No

Class Weight%

Isopropanol Wipes Cloth

impregnated with 2ml fluid

~PROPAN-2-OL 67-63-0 200746-9 F:R11<90 Sweden:

V:R30 / 322, R313 Non

Hazardous Constituents>10

Isopropanol Kits

Alcohol ~PROPAN-2-OL 6763-0 200-661-7

1–12 m® 0855804enb 4/05

SECTION 1 General Information

Table 1–2 Isopropanol Safety

Hazards Identification

Isopropanol Wipes

Most Important

Hazards

Isopropanol Kits

Most Important

Hazards

Specific Hazards May cause slight eye / skin

General Advice Use in well ventilated areas

Inhalation Take patient to fresh air. Do

Highly Flammable

Highly Flammable

irritation. May cause irritation

of respiratory tract. High

concentration of vapors may

induce unconsciousness /

narcosis. Solvents may

degrease the skin.

First Aid Measures

not move about. Obtain

medical advice.

Skin Contact Remove spillage with soft

tissue and / or wash off skin

with cool water. Obtain

medical advice in extreme

cases.

Eye Contact Irrigate thoroughly with water

for at least 10 minutes. Obtain

medical advice.

Ingestion

Isopropanol Wipes Wash out mouth thoroughly

and obtain medical advice.

Isopropanol

Cleaning Kit /

Isopropanol Top Up

Kit

Drink water and obtain

medical advice.

0855904enb 4/05 m® 1–13

SECTION 1 General Information

Table 1–2 Isopropanol Safety

Fire Fighting Measures

Isopropanol Wipes Carbon Dioxide, Dry Chemical

Foam / Water Spray

Isopropanol

Cleaning Kit

Isopropanol Top Up

Kit

Accidental Release

Personal

Precautions

Environmental

Precautions

Water Spray, Dry Powder or

Vaporizing Liquids

Carbon Dioxide, Dry Chemical

Foam / Water Spray

Remove all sources of ignition.

Wear suitable gloves and eye/

face protection.

Clean with water and dispose

of water and isopropanol

according to your local

environmental regulations.

Otherwise, absorb on an inert

absorbent (sand, silica gel,

acid binder, universal binder,

sawdust) transfer to container

and arrange removal by

disposal company. Ventilate

area to dispel residual vapor.

Handling and Storage

Handling Use only in well ventilated

areas. Do not breathe vapors

or spray mist. Avoid contact

with the skin and the eyes.

When using isopropanol, do

not eat, drink or smoke.

Storage Keep in a cool, well ventilated

place. Keep product and

empty container away from

heat and sources of ignition.

Take precautionary

measures against static

discharges.

1–14 m® 0855804enb 4/05

SECTION 1 General Information

Table 1–2 Isopropanol Safety

Exposure Control/Personal Protection

Personal Protection

Equipment

Hand Protection Solvent resistant gloves

Eye Protection Safety glasses/face shield

Skin and Body

Protection

Physical and Chemical Properties

Isopropanol Wipes

Form Of Liquid

Color Colorless

Odor Characteristic

Melting

Temperature

Boiling Temperature

Respiratory protection;

adequate ventilation

Plastic apron/sleeves/boots

(dependent on amount

handled)

-89oC

82oC

Density (g/ml) 0.78

Vapor Pressure

(Density) (2.07)

Solubility in Water Miscible in all proportions

Flash Point

Explosion Limits Lower: 2.3%, Upper: 12%

Auto Ignition

Temperature

33 mmHg, 20oC

12oC

o

C

425

0855904enb 4/05 m® 1–15

SECTION 1 General Information

Table 1–2 Isopropanol Safety

Isopropanol Kits

Form Liquid

Color Colorless

Odor Characteristic

Melting

Temperature

Boiling Temperature

Density (g/ml) 0.78

Vapor Pressure

(Density) (2.07)

Solubility in Water Miscible in all proportions

Flash Point

Explosion Limits Lower: 2.3%, Upper: 12%

Auto Ignition

Temperature

-89oC

82oC

33 mmHg, 20oC

12oC

425oC

1–16 m® 0855804enb 4/05

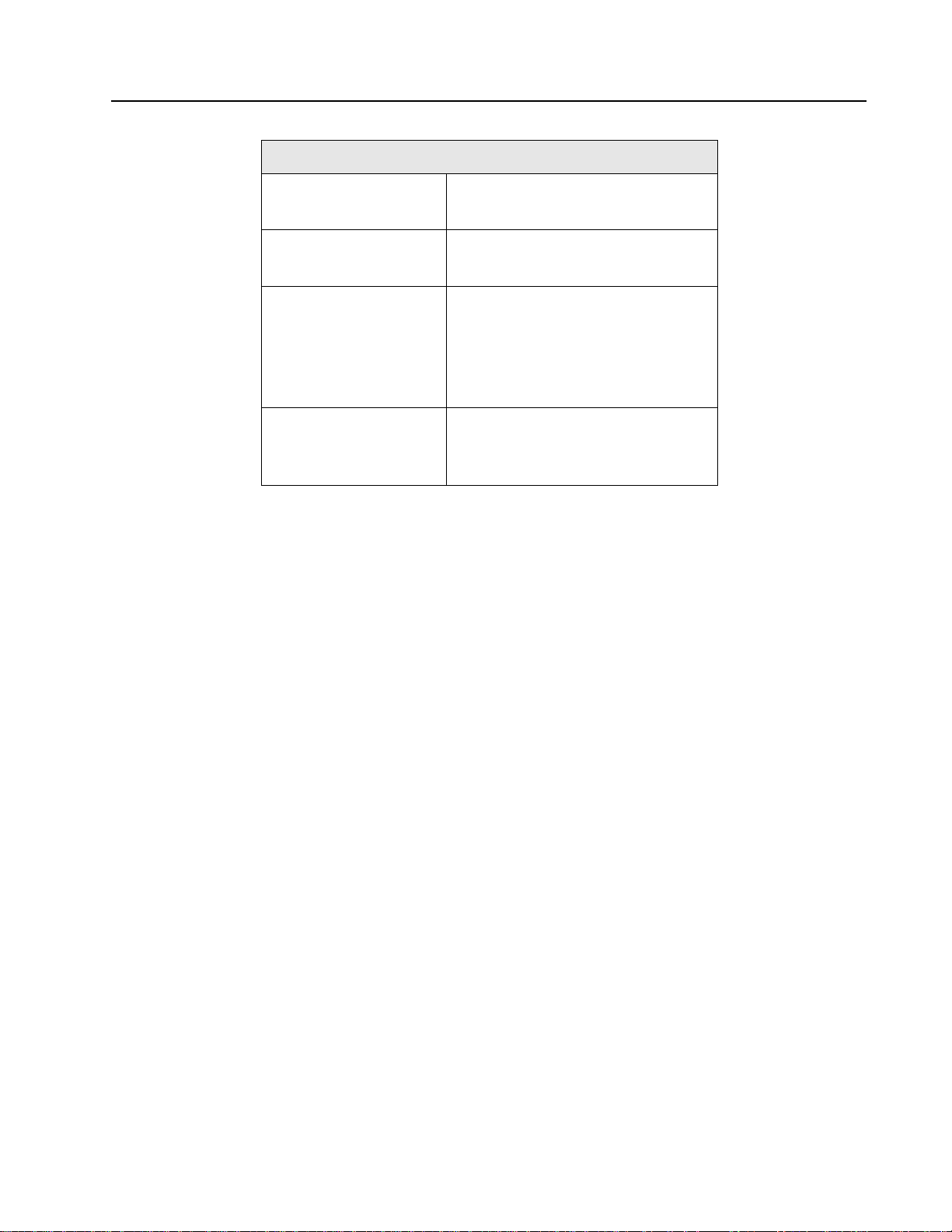

SECTION 1 General Information

Table 1–2 Isopropanol Safety

Stability and Reactivity

Stability Stable; vapors may form

explosive mixture with air

Conditions to Avoid Keep away from heat and

sources of ignition

Materials to Avoid Oxidizing agents, strong

bases, aldehydes, ammonia,

chlorinated compounds,

amines, organic nitro

compounds, aluminium

Hazardous

Decomposition

Products

Peroxides

0855904enb 4/05 m® 1–17

SECTION 1 General Information

Table 1–2 Isopropanol Safety

Toxicological Information

Isopropanol Wipes

Acute Toxicity IPA: LD50/oral/rat= 5.04 g/kg

LD50/dermal/rabbit = 16.4 ml/

kg

Local Effects May cause skin irritation in

susceptible persons

Sensitization May cause sensitization by

skin contact

Long-term Toxicity Liver injury may occur

Chronic Toxicity Effects of excessive

exposures may include liver

toxicity

Isopropanol Kits

After Inhalation Irritation symptoms in the

respiratory tract

After Absorption Headache, dizziness,

inebriation, unconsciousness,

narcosis

After Uptake of

Large Quantities

After Skin Contact Irritation

After Eye Contact Irritation

Further Data LD50 5045 mg/kg oral, rat. No

Respiratory paralysis, coma

evidence of carcinogenic

properties; evidence of

reproductive effects

1–18 m® 0855804enb 4/05

SECTION 1 General Information

Table 1–2 Isopropanol Safety

Ecological Information

Isopropanol Wipes Not readily biodegradable

IPA LC50/96h fathead minnows =

9600mg/1

Isopropanol Kits No environmental hazard

provided that the material is

handled and disposed of with

due care and attention

Disposal Considerations

Waste from

Residues/Unused

Products

Regulations 1980,

Contaminated

Packaging

Dispose of as special waste in

compliance with local

regulations

Store containers and offer for

recycling of material according

to local regulations

0855904enb 4/05 m® 1–19

SECTION 1 General Information

Table 1–2 Isopropanol Safety

Transport Information

Isopropanol Wipes

UN-No 1219

Item

HI/UN No 1219

Proper Shipping

Name

IMO Class 3.2

IMDG Page 3244

EmS 3-06

MFAG 305

Proper Shipping

Name

ICAO Class 3

UN/ID No 1219

Proper Shipping

Name

Isopropanol Kits

3o(b)

Isopropanol

Isopropanol

Isopropanol

UN-No 1219

IMDG Class II

IMO 3.2/1219

Packaging Group II

TATA 1219

Packaging Group II

Correct Technical

Name

ADR/RID

Isopropanol (Isopropyl

Alcohol)

o

(b)

3, 3

1–20 m® 0855804enb 4/05

SECTION 1 General Information

Table 1–2 Isopropanol Safety

Regulatory Information

Labeling According

to EEC Directives

Symbol F Highly Flammable

R Phrase (s) R11 Highly Flammable

S Phrase (s) S2, Keep out of reach of

90/492/EEC

children. Keep container

tightly closed in a cool, well

ventilated place.

S7-16, Keep away from

sources of ignition - NO

SMOKING.

S33, Take precautionary

measures against static

discharges.

0855904enb 4/05 m® 1–21

2.7 Foreseen Use/Misuse

This manual provides information about Safety, Installation,

Operation, Troubleshooting, Illustrated Parts, Electrical Schematics,

Recommended Spares and Preventive Maintenance Procedures.

Using the Cimjet RFID in any other manner is considered a misuse

of the product. Please consult your local MARKEM Business Center

before using this Cimjet RFID for anything other than the foreseen

use.

Misuses include, but are not limited to:

• Operating a system that is incomplete, cannot be serviced, or

has been modified without authorization

• Failing to observe hazard requirements in the manual and/or on

safety labels

• Combining or interfacing non-MARKEM equipment with this

system, other than as intended

• Permitting a person who has not been fully trained to operate

and/or service the system

SECTION 1 General Information

• Using unspecified supplies or material which may produce

unsatisfactory or unexpected results

2.8 MARKEM Training Programs

Operators, maintenance personnel, and service technicians are

considered “qualified” when they have gained, through training and

experience, an understanding of safe and correct methods of

operation, maintenance, or repair.

MARKEM conducts training programs. In addition to ongoing

courses about current machine models, customers are invited to

inquire about any training need.

1–22 m® 0855804enb 4/05

2.9 Removal from Service

Follow these instructions to remove the Cimjet RFID tag applicator

from service. These instructions also pertain to transporting or

storing the applicator.

1. Turn off the power to the Cimjet RFID

2. Disconnect the power cables from the system

3. Disconnect all other cables from the system

4. Disconnect the air supply

5. Carefully move the Cimjet RFID to the desired location and

repackage the system in the original shipping containers

SECTION 1 General Information

0855904enb 4/05 m® 1–23

3.0 Overview

SECTION 1 General Information

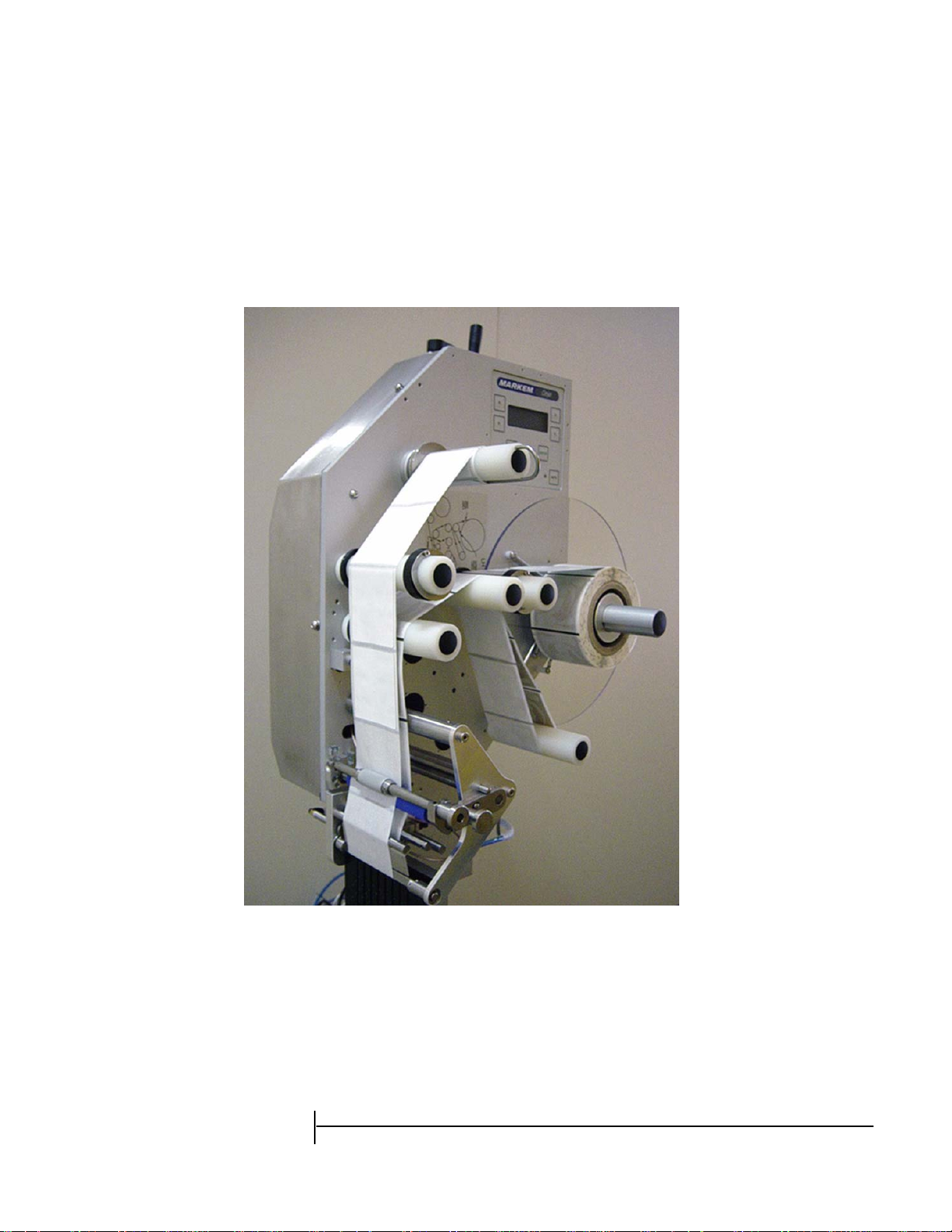

The Cimjet RFID is a high speed, compact RFID tag dispenser and

applicator.

The key features of the Cimjet RFID are:

Different applicator modules to suit specific applications -

Front, top, side, or front and side apply. For more applicator

information, refer to the Cimjet RFID Blow Applicator Manual

(0855906) and the Cimjet RFID Tamp Applicator Manual

(0855907).

• Left- or right-hand machine orientation to suit the

application

• Easy loading of tags

• Networking and stand-alone operation

• Operator and maintenance diagnostics - On-screen display of

Error and Warning messages with corrective action to be taken

• Compatibility - Compatible with the full range of MARKEM

products (Cimpak®, SmartDate®, Series 5000, 9096,

SmartLase®, Cimjet 300®), all of which can share the same

network

1–24 m® 0855804enb 4/05

SECTION 1 General Information

Figure 1–1 Cimjet RFID Dispenser (left-hand option shown)

0855904enb 4/05 m® 1–25

SECTION 1 General Information

3.1 Components of Cimjet RFID

The Cimjet RFID consists of a Dispenser and an Applicator.

The main components of the Cimjet RFID are shown in Figures 1-2,

1-3, and 1-4. In addition, Cimjet RFID is usually supplied with an

adjustable height stand.

3.1.1 Dispenser

The tag dispenser provides the tag supply and can be left-hand or

right-hand. It consists of:

• Tag drive

• Sensors for tag control

• Operator interface

The dispenser is the main body of the Cimjet RFID and supports a

variety of different mountable applicator modules.

3.1.2 Applicator

Several modular applicators are available to meet your different

requirements.

3.2 Tag Sizes

The different applicators apply tags in different ways (for example:

air-blow, or telescopic tamp). The choice of applicator also

determines the face of the product that is tagged.

The applicator selected may vary from the type shown in the

following figures.

For more applicator information, refer to the Cimjet RFID Blow

Applicator Manual (0855906) and the Cimjet RFID Tamp

Applicator Manual (0855907).

Tag sizes are applicator-specific.

For more information, refer to the Cimjet RFID Blow Applicator

Manual (0855906) and the Cimjet RFID Tamp Applicator Manual

(0855907).

1–26 m® 0855804enb 4/05

SECTION 1 General Information

Figure 1–2 Cimjet RFID - Front

Figure 1–3 Cimjet RFID - Rear

0855904enb 4/05 m® 1–27

SECTION 1 General Information

Figure 1–4 Cimjet RFID - Tag Optic

1–28 m® 0855804enb 4/05

3.3 Beacon Light (Optional)

The beacon light is situated in a prominent position on the Cimjet

RFID. The beacon has a three light system: green, blue, yellow.

• When the yellow light is on, the Cimjet RFID has switched out of

Auto Mode (to Set Mode) or there is a fault on the machine

• When the green light is on, Cimjet RFID is awaiting a signal to

start the Program, Verify, Reject, Apply sequence

• When the blue light is on, the tag is programmed successfully

and is ready to carry out the apply process

3.4 Networking

Cimjet RFID provides options for communicating with PCs and other

computers. The methods available are:

• A Serial link to a single PC

• Ethernet link

SECTION 1 General Information

0855904enb 4/05 m® 1–29

SECTION 1 General Information

4.0 Dimensional Drawings (in Millimeters)

Figure 1–5 Cimjet RFID - Dispenser (applicator not shown)

1–30 m® 0855804enb 4/05

SECTION 1 General Information

Figure 1–6 Cimjet RFID - Dispenser Stand

0855904enb 4/05 m® 1–31

SECTION 1 General Information

1–32 m® 0855804enb 4/05

SECTION 2

Installation Guide

m

®

Cimjet ® RFID

Operation/Service Manual

1.0 Installation of the Cimjet RFID

Installation should only be performed by qualified and trained

personnel; customer installation should be sanctioned by MARKEM.

WARNING: Failure to perform installation as stated above will

invalidate the machine warranty.

1.1 Installation Requirements

Ensure that the required services and control signals are available:

• Power: 110-240V single phase power supply rated at 300VA

continuous (750VA maximum at switch on)

• Compressed air: a dry, clean, non-lubricated air supply at 6.2

Bar (90psi)

• Trigger signals depending on the application

• Sufficient space for installation and operation

WARNING: All applicator cylinders have been factory-set to

1.86 Bar for safety. If the cylinders are operated

over 1.86 Bar, the machine must be protected by

guarding, supplied by the customer.

SECTION 2 Installation Guide

SAFETY: Do not adjust the applicator regulator pressure

above 1.86 Bar under any circumstances. Doing so

could make the Cimjet RFID unsafe.

CAUTION: It is essential that the connector dust covers

provided with the machine are fitted to all unused

connectors to protect against dust and dirt and

prevent possible static damage to internal

components.

0855904enb 4/05 m® 2–1

2.0 Power

2.1 Power Configuration

SECTION 2 Installation Guide

The power connector (Type STASEI2) is supplied with the machine

and conforms to EC regulations.

Before installing the machine, check that the power supply is

correctly configured.

The power supply is configured by:

• Power connections to the toroidal transformer located at the rear

of the machine

• Fitting of the corresponding fuse

Details of this procedure are given in Section 7 - Technical

Information.

Power Connector

Power ON/OFF Switch

Fuse

Compressed Air Input

Figure 2–1 External Connectors

For full details of electrical connections, see Section 7 – Technical

Information and Section 10 – Parts Illustrations and Electrical

Schematics.

2–2 m® 0855904enb 4/05

3.0 Air Requirements

A compressed air supply is normally required by the Cimjet RFID to

drive the applicator module. This must be set to 6.2 Bar (90psi) with

a minimum flow rate of 4cfm (cubic feet per minute) (113 liters/

minute) and should be dry, uncontaminated air which should not be

lubricated.

3.1 Air Regulator

A filter regulator assembly is fitted to the base of the stand; this is

comprised of a manual isolation valve, a water trap and pressure

regulator. The air supply is via a 6mm or 8mm flexible pipe.

A single connection is supplied to the main filter regulator unit; from

here, the regulated supply goes to the applicator (if air operated)

and the unregulated supply goes to the air input on the dispenser .

SECTION 2 Installation Guide

to dispenser

to applicator

0855904enb 4/05 m® 2–3

4.0 I/O Interface

Connections for all sensors and solenoids are accessed by

removing the rear cover. External I/O is connected via the External

I/O connector (25-way D-type connector (X12)) located on the rear

of the Cimjet RFID.

For full details, see Section 7– Technical Information.

5.0 Positioning the Applicator

The Cimjet RFID is normally supplied with a stand which allows the

positioned tag height on the product to be adjusted within a limited

range. The applicator height will be determined by the conveyor

height and required position of the tag on the product.

Leveling feet are not provided as standard, so care should be taken

to align the machine with the product transportation system.

Before final positioning, the machine should be placed so that the

applicator arm is square to the product and the position of the

machine provides the correct tag position on the product.

CAUTION: If the machine is not secured to the floor, it is

SECTION 2 Installation Guide

possible for the machine to gradually change

position during use. It is, therefore, important to

mark the provisional position of the machine prior

to starting tagging trials.

Installation drawings are available which show the range over which

the Cimjet RFID can apply tags. Refer to the previous pages in this

section and also to Section 10 – Illustrations and Schematics.

For more applicator information, refer to the Cimjet RFID Blow

Applicator Manual (0855906) and the Cimjet RFID Tamp

Applicator Manual (0855907).

2–4 m® 0855904enb 4/05

SECTION 3

Operating Guide

m

®

Cimjet ® RFID

Operation/Service Manual

1.0 Preparing Cimjet RFID for Operation

Installation of Cimjet RFID would normally be carried out by a

qualified MARKEM service technician. This would usually involve

connecting an apply sensor to the product conveyor transport

system. The application cycles and type of apply sequence required

would also be set up in the Cimjet RFID applicator parameters. For

full details on connections, please consult Section 7 – Technical

Information.

2.0 Operating the Cimjet RFID

Once the Cimjet RFID has been installed and checked for safety,

the machine can be loaded with tags ready for use.

3.0 Loading Tags

Cimjet RFID uses inside-wound tags.

To load tags, do the following:

• Load a full tag reel onto the tag supply shaft, ensuring that the

tags are facing the correct direction.

• If the tag roll does not have a lead-in with tags on it, remove

approximately 1 meter (1.09 yards) of tags from the backing

web.

• Manually adjust the outside guide collars on the drive rollers to

accommodate the width of the tag roll. The tag roll should not rub

on the collars.

• Feed the backing web around the idler rollers, between the

optional post and the RF shield, around the peel bar and

between the drive rollers (removal of some tags makes this

easier). The optional post is provided to guide the label vertically

down to the peel bar . It should be used in all cases where it does

not interfere with the RF antenna placement.

• Thread the tags onto the machine, ensuring that the tags pass

though the tag gap optic. Do not stick the tag web to the roller.

• Feed the backing web around the drive roller and secure to the

waste web rewind shaft with the clip provided.

• Manually wind the web so that the tag at the peel bar is located

1mm to 3mm (0.039” x 0.118”) beyond the peel edge.

• Secure the nip roller.

• Adjust the position of the RF antenna so that it is close to the RF

chip in the tag. The antenna should not rub on the tag.

• The reel of tags used on this machine may be heavy. Be sure to

take appropriate precautions when loading tags to prevent injury.

• An optional clear plastic disk and clamp are provided to hold the

supply roll on the supply shaft.

SECTION 3 Operating Guide

0855904enb 4/05 m® 3–1

SECTION 3 Operating Guide

Figure 3–1 Webbing Diagram (left-hand option shown)

3–2 m® 0855904enb 4/05

4.0 Power-up

SECTION 3 Operating Guide

To prepare the machine for use:

• To turn the air supply ON; rotate the air supply control valve

handle.

• Check that tags are correctly loaded and that the nip roller is

latched in position.

WARNING:Be aware that free items, such as loose clothing or

long hair, could become entangled or trapped in the

tag nip roller or paper path during the operation of

the machine. A warning sticker highlights the

hazard.

• Make sure that the power cable is connected, and switch on the

power at the rear of the machine.

• During power-up, the user interface defaults to Set Mode and

displays the current software version.

• Press AUTO.

• The Cimjet RFID automatically feeds Datum tags to set the

correct tag stop position and measure the length of the tags in

use. The number of tags varies with software versions.

The message: REMOVE DATUM TAGS, THEN PRESS AUTO is

displayed on the user interface. To continue:

• Remove the tags.

• Press AUTO.

The Cimjet RFID is now ready to operate.

0855904enb 4/05 m® 3–3

5.0 Operator Interface

5.1 Menu Operation

The control panel (user interface) provides:

• Machine setup and fault finding

• Error and Warning Messages

5.2 The Control Panel

This drawing is a representation and is not to scale.

SECTION 3 Operating Guide

Exit

• Four option soft keys

• Liquid Crystal Display (LCD) with 4 lines of 20 characters

• Three fixed keys: EXIT, ENTER, and AUTO

Enter

3–4 m® 0855904enb 4/05

5.3 Operator Interface LEDs

Three LEDs provide a visual indication of machine status.

LED Description

Mode LED Indicates if the machine is in

SECTION 3 Operating Guide

Auto or Set Mode

Green LED: Auto Mode

Red LED: Set Mode

Machine

Busy LED

Status LED Green LED: Machine OK

5.4 Guidelines for Entering Data

Many of the screens in both Auto and Set Mode require the

operator to enter information using the menu.

To select an option:

• Press the ‘soft key’ next to the required option.

NEXT and PREVIOUS

Yellow LED: Cimjet RFID is

feeding or applying in Auto

Mode

Amber / Yellow LED : Warning,

such as low paper

Red LED: Fault, such as no tags

Generally only one parameter can be displayed on the screen at

one time.

To scroll through available options:

• Press NEXT to view the next available parameter

• Press PREVIOUS to view the previous available parameter

Saving and Discarding Changes

The method of saving and discarding changes depends on the

particular screen. Generally, to save changes:

• Press ENTER; the new parameter value is saved

To discard changes and retain the previous value:

• Press EXIT

Also press EXIT to step back up through the menu structure.

0855904enb 4/05 m® 3–5

6.0 Auto and Set Mode

The Cimjet RFID has two modes of operation:

• Auto Mode

Cimjet RFID automatically responds to Apply signals. Application

is triggered by sensors or other inputs. For further details, refer to

the Cimjet RFID Section 7-Technical Information.

• Set Mode

This mode provides a series of menus which allow you to:

Fixed Keys

•

•

SECTION 3 Operating Guide

a) Run diagnostic tests

b) Control applicator parameters such as apply delays, etc.

c) Set the time and date

ENTER

EXIT

•

This AUTO key is used in place of a keyswitch and toggles

Cimjet RFID between Auto and Set Mode.

3–6 m® 0855904enb 4/05

6.1 Auto Mode

SECTION 3 Operating Guide

In Auto Mode, Cimjet RFID automatically applies tags.

Application is triggered by sensors or other inputs such as PLC

control. For details, refer to the Cimjet RFID Section 7-Technical

Information.

AUTO

COUNTS

TEST

NEXT

PREV

RESET

Figure 3–2 Auto Mode Menu Tree

To select Auto Mode:

• Press AUTO

The Auto Mode LED is green and the following LCD screen is

displayed:

:

COUNT: 0

TEST COUNTS

0855904enb 4/05 m® 3–7

6.2 Set Mode

SECTION 3 Operating Guide

In Set Mode, Cimjet RFID does NOT respond to Apply requests.

SET

MODE

CIM3

DIAGNOSTICS MANUAL

DISP

I/O

INPUTS /

OUTPUTS

TOGGLE

NEXT

PREV

TIMINGS

FEED

RETRIEVE

TAG

FEED/

APPLY

TEST

FEED

RETRIEVE

RETRIEVE

APPLY

ALL

SET TAG

OPTIC

RIBBON

FEED

FREE

SPACE

DATABASEENGINEER MODESELECT PRODUCT

SET

PARAMETER

VIEW TIME /

DELETE

NEXT

PREV

CHANGE

DATE

NEXT

PREV

DELETE

PARAMETERS

TIME /

DATE

SET

DATE

VIEW

NEXT

PREV

MOVE

PRINT

SET

TIME

-X

+X

-Y

+Y

Figure 3–3 Set Mode Menu Tree

3–8 m® 0855904enb 4/05

SECTION 3 Operating Guide

Set Mode provides a series of menus which allow you to:

• Run diagnostic tests

• Control applicator parameters

• Set the time and date

Cimjet RFID has a further level of restricted access menus, which

give access to other infrequently changed parameters. For further

information, see Section 4 - Restricted Access Mode User Guide.

To select Set Mode:

• Press AUTO

The display shows the four main options available:

SELECT ENGINEER

PRODUCT MODE

DATABASE PARAMETERS

0855904enb 4/05 m® 3–9

7.0 Engineer Mode

7.1 Diagnostics

SECTION 3 Operating Guide

These options provide a number of first line machine maintenance

functions:

DIAGNOSTICS MANUAL

TEST SET TAG

DISP I/O TIMINGS

Disp I/O

This screen allows the operator to view the current status of the

Cimjet RFID inputs and to test the various Cimjet RFID Outputs.

Full details can be found in Section 7 – Technical Information.

7.2 Set Tag Optic

Cimjet RFID feeds tags to automatically determine the optimum

setting for the tag sensor. This function can be used, if for example,

different tag stock is used.

3–10 m® 0855904enb 4/05

8.0 Parameters

SECTION 3 Operating Guide

This option allows the operator to alter various operating

parameters:

TIME/ SET

DATE PARAMETERS

Time / Date

VIEW TIME/DATE

SET SET

TIME DATE

• Enter the required date and time

Time is entered in the 24-hour format.

0855904enb 4/05 m® 3–11

SECTION 3 Operating Guide

Set Parameters

This lists the Set Parameters available to view and/or change.

Other parameters are also available; for further information, refer to

Section 4 - Restricted Access Mode User Guide.

Table 3–1

Parameter Description

This parameter allows the

Apply Delay

25

Darkness*

100

application of the tag onto the

package to be delayed. It is used for

positioning.

Feed Speed

Range: 50-

250mm/s

Default: 15

0mm/s

Direction*

0

Feed speed (mm/s) is the time taken

for the tag to pass the nip roll.

*Does not apply to Cimjet RFID

3–12 m® 0855904enb 4/05

SECTION 4

Restricted Access Mode User Guide

m

®

Cimjet ® RFID

Operation/Service Manual

SECTION 4 Restricted Access Mode User Guide

1.0 Restricted Access Mode User Guide

The Restricted Access Mode in Cimjet RFID, has a series of

menus. These menus allow the configuration to be altered.

CAUTION: The accessed parameters should only require

changing directly after installation. Access

parameters must be changed by qualified MARKEM

personnel or under close instruction from MARKEM.

2.0 Entering Restricted Access Mode

To enter Restricted Access Mode:

• Select Set Mode

• Press and hold the ENTER and EXIT keys

After approximately five seconds, the restricted access main menu

appears. Release the EXIT key first.

The restricted access main menu has four main options:

RESTRICTED MACHINE

SETUP INIT

P ASSWORD CYCLE

• Restricted Setup

• Machine Init (Initialization)

• Password

• Cycle

Further details on these menus can be found on the following

pages.

0855904enb 4/05 m® 4–1

SECTION 4 Restricted Access Mode User Guide

3.0 Machine Init (Initialization)

From the main menu:

:

• Press MACHINE INIT

The Machine Init menu is displayed:

RESTRICTED MACHINE

SETUP INIT

PASSWORD CYCLE

RESET CLEAR

PARAMS DATABASE

CLEAR

3.1 Reset Params

This option resets all parameters to their default values. The current

selected applicator is not changed, but the applicator parameters

are set to the corresponding default values.

From the Machine Init menu:

• Press RESET PARAMS

The following screen is displayed:

:

COUNTS

FLASH FILE

RESET P ARAMETERS

ARE YOU SURE?

YES NO

4–2 m® 0855904enb 4/05

SECTION 4 Restricted Access Mode User Guide

4.0 Password

Cimjet RFID can have passwor d protection of the various Set Mode

functions.

Passwords are entered using the four soft keys. These keys are:

12

43

An asterik (*) will be displayed for each digit entered, and the

ENTER key should be pressed when the complete password has

been typed.

The passwords for each access level are fixed. The key sequences

are given on the last page of this section. This page may be

removed if passwords are being used, and if this manual is freely

available.

When a password is enabled for a key, Cimjet RFID will request

entry of the key sequence before allowing access to the option. The

four levels are for access by different user types:

• Level 1 - Operators

• Level 2 - Line Supervisors

• Level 3 - Maintenance Personnel

• SYSTEM - MARKEM Personnel and Line Managers

0855904enb 4/05 m® 4–3

SECTION 4 Restricted Access Mode User Guide

4.1 Password Configuration

On selection of the PASSWORD option from the top level restricted

access menu, the following screen is displayed:

NEXT PREVIOUS

• Select CHANGE; the following screen is displayed:

:

ENABLE DISABLE

CHANGE

LEVEL 1

- ----

LEVEL 1

- ----

The NEXT and PREVIOUS keys are used to scroll through the four

access levels.

To activate a specific button on any level, press ENABLE with the

cursor flashing on the required function (- E---) indicates which

functions are available to users of this password level.

ENABLE DISABLE

LEVEL 1

- E---

4–4 m® 0855904enb 4/05

SECTION 4 Restricted Access Mode User Guide

In the above example, LEVEL 1 has access, via the level 1

password, to the SELECT PRODUCT option (Button 1).

The underscores on the screen indicate which function button is

associated with the button numbers shown at the beginning of this

section.

For example, reading from left to right, the first underscore activates

the Restricted Setup buttons (ENTER and EXIT pressed at the

same time). The next underscores are buttons 1, 2, 3, and 4.

Access to the other soft keys and restricted access mode will

depend on the other users’ protection level.

If all users have a ‘-’ for a particular key (or restricted access), then

no password protection will exist on that key.

The protection level for the particular user may then be changed

using the soft keys.

Note: The SYSTEM password, when active, will allow access to

change the password settings.

0855904enb 4/05 m® 4–5

SECTION 4 Restricted Access Mode User Guide

4.2 Password Key Sequences

The Key sequences for each access level are fixed and are as

follows:

• Level 1 – 2-1-1-1

• Level 2 – 2-3-3-1

• Level 3 – 4-1-2-3

• System 4– 2-4-4-1

CAUTION: If you have password protection to restricted access

mode, the SYSTEM user will automatically have

access to this mode regardless of the SYSTEM

password configuration. The SYSTEM user will be

the only user with access to the password

configuration menus.

Note: Remove this page if this manual is in common circulation and

passwords are in use.

4–6 m® 0855904enb 4/05

5.0 Cycle

SECTION 4 Restricted Access Mode User Guide

This cycle option allows the various elements of the machine to be

set into continuous operation (for example: to continuously cycle the

Cimjet RFID unit).

See the main menu below:

RESTRICTED MACHINE

SETUP INIT

P ASSWORD CYCLE

• Select CYCLE; the following screen is displayed:

FEED APPLY

CYCLE

CYCLES/MIN

FEED/APPLY FEED

To start a cycle:

• Press the required soft key

To stop the cycle:

• Press the required soft key again

0855904enb 4/05 m® 4–7

SECTION 4 Restricted Access Mode User Guide

6.0 Restricted Setup

From the main menu:

• Press RESTRICTED SETUP

The following screen is displayed:

7.0 Set Parameters

This option allows various parameters to be viewed and changed.

From Restricted Setup menu:

• Press SET PARAMETERS

The Set Parameters screen is displayed:

SET NODES

SET SELECT

PARAMETERS LANGUAGE

FEEDER COMMS.

MACHINE

OPTIONS TAG

The operator can change:

• Feeder Parameters

• Communications Parameters

• Machine Options

4–8 m® 0855904enb 4/05

SECTION 4 Restricted Access Mode User Guide

8.0 Communications Parameters

These parameters configure the Communications port.

From the Set Parameters screen:

• Press COMMS

FEEDER COMMS.

MACHINE

OPTIONS TAG

The first parameter is displayed:

.

NEXT PREVIOUS

CHANGE

EMULATION MODE

CIMCOMMS

• Press CHANGE to select a different option

See the following table for a full list of available communications

parameters.

0855904enb 4/05 m® 4–9

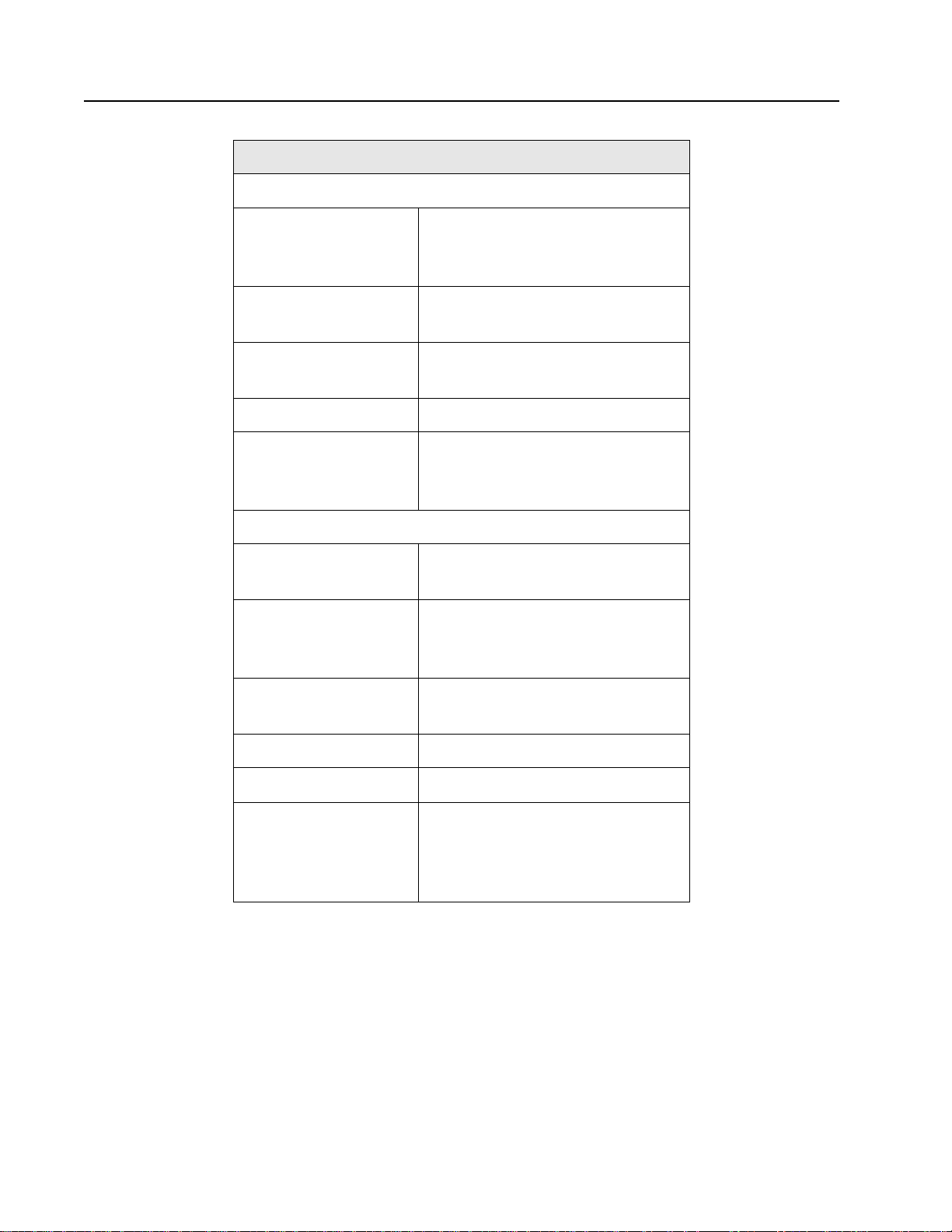

SECTION 4 Restricted Access Mode User Guide

Table 4–1 Communications Parameters

Parameter Description

Determines whether the

Emulation Mode

Range: CIMCOMMS,

EMULATION Z or S

Default: CIMCOMMS

Cimjet RFID Host

communication channel

is set to respond to

CIMCOMMS protocol or

desktop EMULATION

protocol

Comms Baud

Range: 2400, 4800, 9600,

19200, 38400, 57600, 115200

Default : 19200

Comms Link

Range: RS232

ETHERNET

Default: RS232

Comms Mode

Range: LOCAL, SLAVE

Default: LOCAL

Network Node*

Range: 1 to 31

Default: 1 (RS232 operation)

Transfer Timeout

Range: 30 seconds to 10

minutes

Default: 30 seconds

Host communications

link baud rate

Host communication link

type

In SLAVE mode, the

Cimjet RFID responds to

remote product select

commands

This allows the

download transfer

timeout to be increased

*Does not apply to Cimjet RFID

4–10 m® 0855904enb 4/05

SECTION 4 Restricted Access Mode User Guide

9.0 Machine Options Parameters

These parameters configure the machine options available.

From the Set Parameters screen:

• Press MACHINE OPTIONS

FEEDER COMMS

MACHINE

OPTIONS TAG

The following screen is displayed:

APPLICATOR

MACHINE

CONFIG

This screen provides access to:

• Applicator Parameters

• Machine Options

• Laser Setup Parameters

0855904enb 4/05 m® 4–11

SECTION 4 Restricted Access Mode User Guide

9.1 Machine Configuration Parameters

These parameters configure various machine setup options:

From the Machine Option screen:

• Press MACHINE CONFIG

APPLICATOR

MACHINE

CONFIG

The first parameter is displayed:

MACHINE TYPE

CIMJET RFID

NEXT PREVIOUS

CHANGE

The options can be accessed by using the NEXT and PREVIOUS

soft keys.

4–12 m® 0855904enb 4/05

SECTION 4 Restricted Access Mode User Guide

Table 4–2 Machine Configuration Parameters

Parameter Description

Machine Type

Range RFID: 306, 311, 312,

313, 314P, 316, 321, 331,

334, 342, 344, 345, 346,

2112, 2113, 2132, 2341,

2422, Cimpak 300

Default: RFID

Database Mode

Range: LOCAL RAM, Host

PC

Default: LOCAL RAM

Sensor Debounce

Range: 0 to 2000

Default: 0

These options are for the

Cimjet series machines and

define the Applicator type

fitted.

Cimjet RFID has two methods

of product selection:

Local RAM Mode: Cimjet

RFID selects tags resident in

the local memory

Host PC Mode: Cimjet RFID

requests the required data

from the Host PC

Delays the response to

external sensors

This is useful, for example, if

the shrink wrap on a product

is causing the product sensor

to trigger a number of times

for each pack.

By setting a higher Sensor

Debounce value, Cimjet

RFID only responds to signals

that stay on or off for the

debounce time.

Enable Counts in Run

Range: Yes, No

Default: Yes

Test In Run

Range: Yes, No

Default: Yes

0855904enb 4/05 m® 4–13

Allows the product counts to

be displayed on the RUN

Mode screen.

Most applicators provide a

TEST option in RUN Mode

that allows a tag to be fed

without an external signal.

Set to No to disable this

function.

SECTION 4 Restricted Access Mode User Guide

Table 4–2 Machine Configuration Parameters

Parameter Description

Allocation Warning

Range: Off, On

Default: Off

Measurement Units

Range: Metric, Imperial