Mark-10 M2-20, M2-50, M2-5, M2-10, M2-2 User Manual

...

Series 2

DIGITAL FORCE GAUGES

User’ s Guide

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Series 2 Digital Force Gauges User’s Guide

Thank you…

Thank you for purchasing a Mark-10 Series 2 digital force gauge, designed

for tension and compression force testing applications from 2 to 500 lbF (10

to 2,500 N) full scale. The Series 2 is an essential component of a force

testing system, typically also comprising a test stand and grips.

With proper usage, we are confident that you will get many years of great

service with this product. Mark-10 force gauges are ruggedly built for many

years of service in laboratory and industrial environments.

This User’s Guide provides setup, safety, and operation instructions.

Dimensions and specifications are also provided. For additional information

or answers to your questions, please do not hesitate to contact us. Our

technical support and engineering teams are eager to assist you.

Before use, each person who is to use the Series 2 force gauge should

be fully trained in appropriate operation and safety procedures.

TABLE OF CONTENTS

OVERVIEW .........................................................2

POWER ...............................................................3

MECHANICAL SETUP .......................................4

HOME SCREEN AND CONTROLS ...................6

OPERATING MODES .........................................7

CHANGING THE UNITS .....................................7

DIGITAL FILTERS ..............................................8

CALIBRATION ...................................................8

OTHER SETTINGS ...........................................13

SPECIFICATIONS ............................................15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

1

Series 2 Digital Force Gauges User’s Guide

1 OVERVIEW

1.1 List of included items

Qty. Description

1 Digital force gauge

1 8.4V rechargeable battery (inside the gauge)

1 Resource CD

1.2 List of optional items

Part No. Description

12-1049 Carrying case

CERT

G1038

G1039

G1029

G1026

G1025

G1027

G1024

G1035

G1037

G1036

G1033

G1032

G1034

G1031

1.3 Safety / Proper Usage

Certificate of calibration with data

Medium hook, #10-32M (requires G1039)

Coupling, #10-32F/F

Flat head, #10-32F

Cone, #10-32F

Chisel point, #10-32F

V-groove, #10-32F

Extension rod, 5”, #10-32F

Large hook, 5/16-18M (requires G1037)

Coupling, 5/16-18F/F

Flat head, 5/16-18F

Cone, 5/16-18F

Chisel point, 5/16-18F

V-groove, 5/16-18F

Extension rod, 5”, 5/16-18F

Caution!

Note the force gauge’s capacity before use and ensure that the capaci ty is not exceeded.

Producing a force greater than 200% of the gauge’s capacity can damage the internal load cell. An

overload can occur whether the gauge is powered on or off.

Typical materials suitable for testing include many manufactured items, such as springs, electronic

components, fasteners, caps, films, mechanical assemblies, and many others. Items that should not be

used with the gauge include potentially flammable substances or products, items that can shatter in an

unsafe manner, and any other components that can present an exceedingly hazardous situation when

acted upon by a force.

The following safety checks and procedures should be performed before and during o peration:

1. Never operate the gauge if there is any visible damage to the AC adapter or the gauge itself.

2. Ensure that the gauge is kept away from water or any other electrically conductive liquids at all

times.

3. The gauge should be serviced by a trained technician only. AC power must be disconne cted and

the gauge must be powered off before the housing is opened.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

2

Series 2 Digital Force Gauges User’s Guide

4. Always consider the characteristics of the sample being tested before initiating a test. A risk

assessment should be carried out beforehand to ensure that all safety measures have been

addressed and implemented.

5. Wear eye and face protection when testing, especially when testing brittle samples that have the

potential to shatter under force. Be aware of the dangers posed by potential energy that can

accumulate in the sample during testing. Extra bodily protection should be worn if a destructive

failure of a test sample is possible.

6. In certain applications, such as the testing of brittle samples that can shatter, or other applications

that could lead to a hazardous situation, it is strongly recommended that a machine guarding

system be employed to protect the operator and others in the vicinity from shards or debris.

7. When the gauge is not in use, ensure that the power is turned off.

2 POWER

Caution!

Do not use AC adapters other than supplied or instrument damage may occur.

The gauge is powered either by an 8.4V rechargeable battery or by an AC adapter (input jack is located

in the left side of the housing).

If the AC adapter is plugged in, an icon appears in the lower left corner of the display, as follows:

If the AC adapter is not plugged in, battery power drainage is denoted in a five-step process:

1. When battery life is greater than 75%, the following indicator is present:

2. When battery life is between 50% and 75%, the following indicator is present:

3. When battery life is between 25% and 50%, the following indicator is present:

4. When battery life is less than 25%, the following indicator is present:

5. When battery life drops to approximately 2%, the indicator from step 4 will be flashing.

Several minutes after (timing depends on usage and whether the backli ght is turned on or

off), a message appears, “BATTERY VOLTAGE TOO LOW. POWERING OFF”. An audio

tone will sound and the gauge will power off.

The gauge can be configured to automatically power off following a period of inactivity. Refer to the Other

Settings section for details.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

3

Series 2 Digital Force Gauges User’s Guide

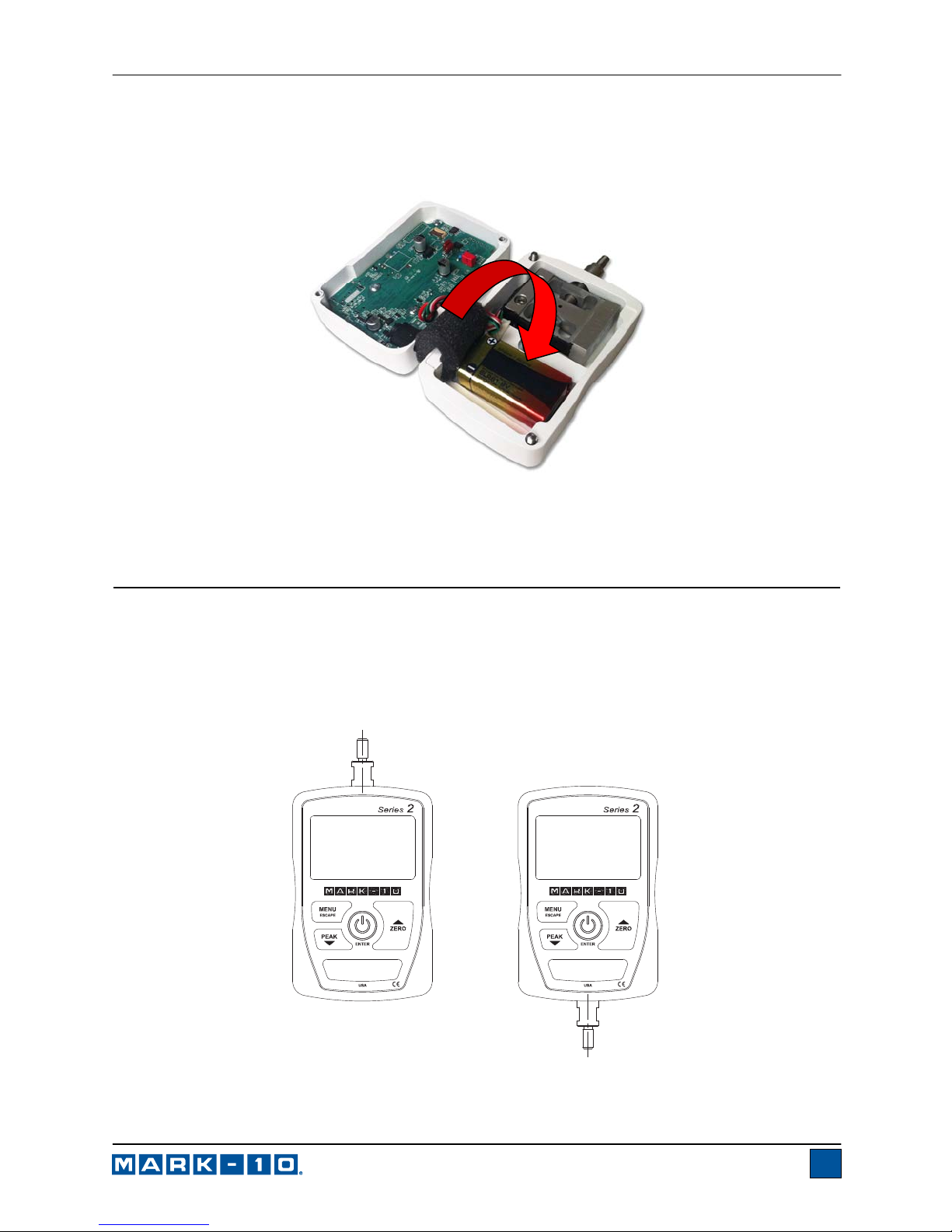

Battery life is approximately 24 hours with the backlight off, or 7 hours with the backlight on. To change

the battery, loosen the two captive screws on the back side of the housing and separate the two housing

halves. A foam strip separates the battery from the PCB, as shown in the illustration below:

Ensure that the foam is positioned above the battery when reassembling the housing. Exercise care whe n

reassembling the two halves of the housing, ensuring that internal wires do not interfere.

3 MECHANICAL SETUP

3.1 Loading shaft orientation

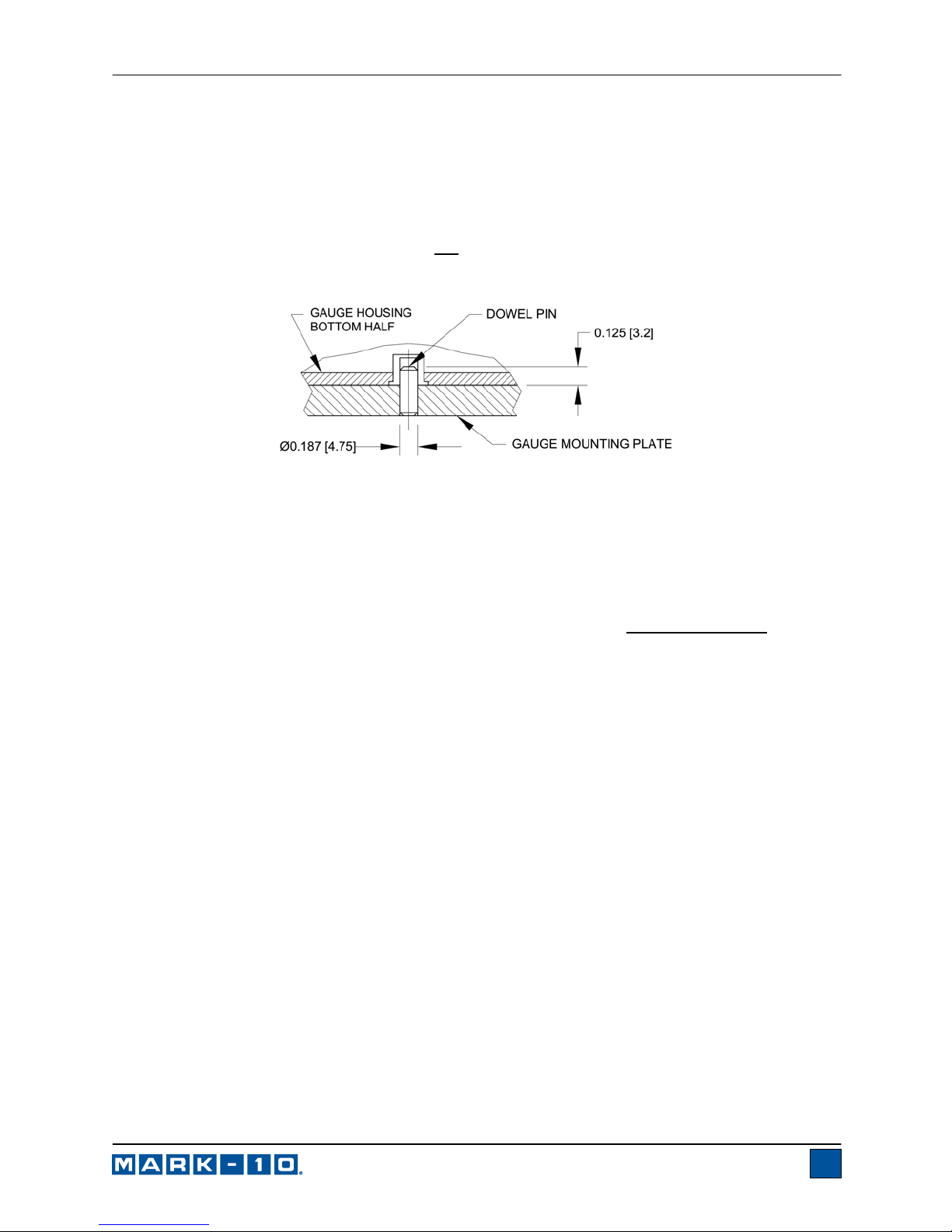

In order to accommodate a variety of testing requirements, the orientation of the loading shaft may be

oriented in either of the two positions shown below. To change the loading shaft orientation, loosen the

two captive screws on the back side of the housing, separate the two housing halves, rotate one half 180

degrees, and reassemble. Exercise care when reassembling the two halves of the housing, ensuring that

internal wires do not interfere.

Load cell shaft up Load cell shaft down

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

4

Series 2 Digital Force Gauges User’s Guide

3.2 Mounting to a plate

Although the gauge may be used by hand, proper mounting is important if attached to a fixture or test

stand. The round steel insert with a hole in the back of the housing is provided to withstand the load

during a test. A mating dowel pin should be used (see illustration below). Mounting plates on Mark-10 test

stands include a dowel pin and clearance holes for the four threaded holes located near the corners of

the housing. An additional two holes are supplied for metric screws. These holes are designed to

accommodate screws in order to hold the gauge in place (Mark-10 test stands include a set of thumb

screws for gauge mounting). The screws must not

dowel pin properly can result in a hazardous situation.

be used for load bearing purposes. Failure to use a

3.3 Mounting attachments to the gauge

The force gauge’s threaded loading shaft is designed to accommodate common grips and attachments

with female mounting holes. To mount a grip, gently thread it onto the shaft. Ensure that the grip or fixture

is positioned to ensure axial load with respect to the loading shaft of the force gauge. When using a grip,

ensure that it secures the sample in such a way that it is prevented from slipping out during a test,

preventing a potential safety risk to the operator and others in the vicinity. If using a grip or fixture from a

supplier other than Mark-10, ensure that it is constructed of suitably rugged materials and components.

Do not use jam nuts or tools to tighten grips or attachments onto the shaft. Finger-tighten only

.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

5

Loading...

Loading...