Page 1

Models:

TABLE OF CONTENTS

F105 | F305 | F505 | F505H

F755 | F755S | F1505 | F1505S

®

IntelliMESUR

Software

Series F

TEST FRAMES

User’s Guide

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Series F Test Frames + IntelliMESUR® Software User’s Guide

2

TOC

TABLE OF CONTENTS

TABLE OF CONTENTS ......................................................................................................... 1

1 OVERVIEW .............................................................................................................................. 3

1.1 Intended purpose ............................................................................................................. 4

1.2 Models F105 / F305 / F505 / F505H ................................................................................ 4

1.3 Models F755 / F755S / F1505 / F1505S ......................................................................... 6

2 SAFETY ................................................................................................................................... 8

2.1 Checks and procedures ................................................................................................... 8

2.2 Connecting power ............................................................................................................ 9

2.3 Emergency Stop .............................................................................................................. 9

3 SETUP ................................................................................................................................... 10

3.1 Intended Use .................................................................................................................. 10

3.2 Moving the frame into position ....................................................................................... 10

3.3 Mounting and placement ............................................................................................... 10

3.4 Limit switches ................................................................................................................. 10

3.5 Connections and outputs ............................................................................................... 11

3.6 Installing Series FS05 Force Sensors to Models F105 / F305 / F505 / F505H ............. 12

3.7 Installing Series R07 Force Sensors to Models F755 / F755S / F1505 / F1505S ......... 13

3.8 Installing Series FS05 Force Sensors to Models F755 / F755S / F1505 / F1505S ....... 13

3.9 Installing a Third-Party Force Sensor ............................................................................ 14

3.10 Installing the IntelliMESUR control panel .................................................................... 15

4 INSTALLING INTELLIMESUR .............................................................................................. 16

4.1 Hardware Requirements ................................................................................................ 16

4.2 Installation ...................................................................................................................... 17

5 INTELLIMESUR BASICS ...................................................................................................... 18

5.1 Opening IntelliMESUR ................................................................................................... 18

5.2 Home Screen ................................................................................................................. 19

6 SETTINGS ............................................................................................................................. 21

6.1 Information ..................................................................................................................... 21

6.2 User Management ......................................................................................................... 22

6.3 Calibration ...................................................................................................................... 24

6.4 Preferences .................................................................................................................... 24

6.5 Optional Functions ......................................................................................................... 26

6.6 Overloads ....................................................................................................................... 27

6.7 Deflection Compensation ............................................................................................... 27

6.8 Update Software and Update Firmware ........................................................................ 27

7 MANUAL CONTROL ............................................................................................................. 28

7.1 Load and Distance Measurement .................................................................................. 29

7.2 Motion Control Modes .................................................................................................... 29

7.3 Height / Length Offset .................................................................................................... 30

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Series F Test Frames + IntelliMESUR® Software User’s Guide

3

TOC

7.4 Set Home ....................................................................................................................... 31

8 CREATING A BASIC TEST .................................................................................................. 31

8.1 Load Limit ...................................................................................................................... 31

8.2 Distance Limit ................................................................................................................ 42

8.3 Break Limit ..................................................................................................................... 43

8.4 Load Hold ....................................................................................................................... 43

8.5 Cycle Test ...................................................................................................................... 43

8.6 COF Test ....................................................................................................................... 46

9 CREATING A MULTI-STEP TEST ........................................................................................ 48

9.1 Multi-Step Overview ....................................................................................................... 48

9.2 Step Types ..................................................................................................................... 50

10 RUNNING A TEST ............................................................................................................... 53

10.1 Favorite Tests .............................................................................................................. 53

10.3 Results View ................................................................................................................ 58

10.4 Data Details View......................................................................................................... 62

10.5 Creating a Report......................................................................................................... 63

10.6 Recalling Previous Data .............................................................................................. 66

11 CALIBRATION .................................................................................................................... 66

11.1 Force Sensor Calibration ............................................................................................. 66

11.2 Speed and Distance Calibration .................................................................................. 71

11.3 Test Frame Deflection Compensation ......................................................................... 71

12 MAINTENANCE & SERVICE – MODELS F105 / F305 / F505 / F505H ............................. 72

12.1 Physical Maintenance .................................................................................................. 72

12.2 Removing the Motor Drive Unit (MDU) ........................................................................ 76

13 MAINTENANCE & SERVICE – MODELS F1505 / F1505S / F755 / F755S ....................... 77

13.1 Physical Maintenance .................................................................................................. 77

13.2 Removing the Motor Drive Unit (MDU) ........................................................................ 79

14 ACCESSORY INSTALLATION ........................................................................................... 80

14.1 Shield Installation ......................................................................................................... 80

14.2 Separating the Column From The Base / Column Extension Installation – F105 / F305 / F505 /

F505H .................................................................................................................................. 83

14.3 Installing a double column extension – F105 / F305 / F505 ................................... 86

15 UPDATING SOFTWARE AND FIRMWARE ....................................................................... 87

16 SPECIFICATIONS & DIMENSIONS ................................................................................... 88

16.1 Specifications ............................................................................................................... 88

16.2 Dimensions .................................................................................................................. 89

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

Series F Test Frames + IntelliMESUR® Software User’s Guide

4

TOC

Qty.

Description

1

Control panel, mounting bracket, and hardware (-IMT models only)

1

Mounting bracket, column end (F505H only)

1

USB flash drive containing software installation files (-IM models only)

1

USB dongle (-IM models only)

1

USB cable

-IM models: A to B

Accessories kit:

- Allen wrench set

1

Power cord

1

Allen wrench set

1 OVERVIEW

1.1 Intended purpose

Series F test frames produce tension and compression forces. When combined with a force sensor and

IntelliMESUR software, users can measure force and distance, set up a test, record, analyze, and output

data. Test frames are offered in several models, corresponding to different heights and force ranges.

Series FS05 or Series R07 force sensors are required for use with these test frames.

IntelliMESUR software is required to run Series F test frames and extract force and distance data from

the test frame and force sensor. IntelliMESUR is offered pre-configured on a tablet with mounting bracket,

or as a standalone software application which may be installed on the user’s device.

1.2 Models F105 / F305 / F505 / F505H

1.2.1 Included items

-IMT models: right-angle C to B

- #10-32M medium hook

- 5/16-18M large hook

- #10-32F 2” diameter compression plate

1

Find Quality Products Online at: sales@GlobalTestSupply.com

- #10-32 M/F 2” extension rod

- #10-32 F/F coupler

- Adapter, 5/16-18M to #10-32F

- Set screw, #10-32 x 3/4" (1)

- Hex nut, #10-32 (2)

www.GlobalTestSupply.com

Page 5

Series F Test Frames + IntelliMESUR® Software User’s Guide

5

TOC

Base

Base plate

Lower grip

Upper grip

Force

sensor

Column

Tablet control

panel

Emergency

stop

Upper limit

visible)

Test sample

Crosshead

Column

cap

1.2.2 Physical features

Note the following physical features. The user’s guide will reference this terminology. Model F305-IMT is

shown below:

switch

(lower limit

switch not

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

Series F Test Frames + IntelliMESUR® Software User’s Guide

6

TOC

Qty.

Description

1

Control panel, mounting bracket, and hardware (-IMT models only)

1

USB flash drive containing software installation files (-IM models only)

1

USB dongle (-IM models only)

1

USB cable

-IM models: A to B

1

Eye end kit for base

2

Lock ring for eye end

2

Spanner wrench

1

Power cord

1

Allen wrench set

1.2.3 Installing the Column End Cap for F505H

The end cap is shipped in a separate box within the main box for the F505H test frame. Line it up with the

right end of the column, then install with the four included screws, as shown below:

1.3 Models F755 / F755S / F1505 / F1505S

1.3.1 Included items

-IMT models: right-angle C to B

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

Series F Test Frames + IntelliMESUR® Software User’s Guide

7

TOC

Base

Base plate

Lower grip

Upper grip

Force sensor

Column

Bellows

Control panel

Emergency stop

Limit

(not visible)

Test sample

Crosshead

Column cap

Control panel

bracket

1.3.2 Physical features

Note the following physical features. The user’s guide will reference this terminology. Model F1505-IMT is

shown below:

switches

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 8

Series F Test Frames + IntelliMESUR® Software User’s Guide

8

TOC

2 SAFETY

Safety features provided by Series F test frames may be impaired if equipment is used in a

manner not specified by Mark-10.

2.1 Checks and procedures

The following safety checks and procedures should be performed before and during operation:

1. Always consider the characteristics of the sample being tested before initiating a test. A risk

assessment should be carried out beforehand to ensure that all safety measures have been

addressed and implemented.

2. Wear eye and face protection when testing, especially when testing brittle samples that have the

potential to shatter under force. Be aware of the dangers posed by potential energy that can

accumulate in the sample during testing. Extra bodily protection should be worn if a destructive

failure of a test sample is possible.

3. Keep away from moving parts of the test frame. Loose articles of clothing should not be worn.

Long hair should be covered to avoid a hazardous situation. A Crush Hazard warning label is

located on the base of the test frame. It appears as follows:

Definition: Keep any body parts and clothing clear of the area between the base of the test frame and the

moving crosshead.

4. Ensure that grips and fixtures are positioned to ensure axial load with respect to the load axis of

the force sensor.

slipping out during a test, which is a safety risk to the operator and others in the vicinity. If using a

grip or fixture from a supplier other than Mark-10, ensure that it is constructed of suitably rugged

materials and components.

5. In those applications where samples can shatter, or other applications that could lead to a

hazardous situation, use of a shield is strongly recommended.

6. When the test frame is not in use, ensure that the power is turned off to prevent accidental

engagement of any of the controls.

Ensure that they secure the sample in such a way that it is prevented from

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

Series F Test Frames + IntelliMESUR® Software User’s Guide

9

TOC

2.2 Connecting power

Plug one end of the power cord into its receptacle at the rear of the stand and the other end into a wall

outlet with local earth ground (3-prong connector).

Before turning on power, the following safety checks and procedures should be performed:

1. Never operate the test frame if there is any visible damage to the power cord or the test frame

itself. The test frame is powered by 110V/220V. Any contact with this high voltage can cause

serious injury or even death.

2. Ensure that the test frame is kept away from water or any electrically conductive liquids at all

times.

3. Make sure the electrical outlet powering the test frame has local earth ground (3-prong

connector).

4. The test frame should be serviced by a trained technician only. Power must be disconnected

before the column covers are removed.

5. Never use a detachable mains supply cord with inadequate ratings.

After the above safety checks and procedures have been performed, the test frame may be powered on

and is ready for operation.

2.3 Emergency Stop

The emergency stop switch is located where the lower right end of the column is attached to the base, as

shown below:

Models F105 / F305 / F505 / F505H Models F755 / F755S / F1505 / F1505S

Press down to stop crosshead motion. Rotate clockwise to release the switch.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

Series F Test Frames + IntelliMESUR® Software User’s Guide

10

TOC

3 SETUP

3.1 Intended Use

Series F test frames with IntelliMESUR software are designed for tension and compression force

measurement applications. The test frame applies force, while a force sensor measures the applied

forces. IntelliMESUR software displays force and position information, and includes analytical tools to

help quality control, engineering, and manufacturing professionals determine the mechanical properties

and quality of their samples.

3.2 Moving the frame into position

Place the frame on a sturdy, clean, and level work area free from vibration.

In Models F755, F755S, F1505, and F1505S, a recessed lifting hook is located at the top of the column,

for ease of lifting, as shown below:

For Models F105, F305, F505, and F505H frames, orient the rear of the test frame towards the edge of a

table, tilt backwards, then lift underneath the base and underneath the rear of the column.

3.3 Mounting and placement

Place the test frame on a clean, flat and level work area free from vibration. Ensure that the rear of the

column is easily accessible, so that the power cord can be disconnected in an emergency.

It is suggested to mount the test frame to a work bench via screws fastened into the underside of the

base. Failure to properly mount the test frame may make it more vulnerable to tipping, especially if a

column extension is used, causing a hazardous situation.

3.4 Limit switches

Upper and lower limit switches are supplied to stop travel in both directions. They may be moved

up and down by loosening and tightening the thumb screws, as shown at left.

A dual-graduated inch/mm ruler adjacent to the limit switches can be helpful for positioning.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

Series F Test Frames + IntelliMESUR® Software User’s Guide

11

TOC

Auxiliary Limits

3.5 Connections and outputs

The following connections and outputs are supplied in the rear of the test frame, as shown in the

illustration below:

For interfacing an external limit switch, such as an interlock for a

shield door. A pin diagram is shown in the next sub-section.

USB port

For interfacing with a Windows device running IntelliMESUR.

Control Panel

Inactive.

External Emergency Switch

May be used to connect an optional external emergency stop

switch. May be installed at the factory at time of order, or installed

in the field as a retrofit. Required for use with optional shields.

Refer to the Accessory Installation section for instructions.

Power switch

Refer to the Connecting Power sub-section for important safety

information.

Power plug receptacle

Plug the power cord in here. Refer to the Connecting Power

sub-section for important safety information.

3.5.1 Auxiliary Limits pin diagram

Note that when pins 3 and 4 are not connected, the auxiliary limits are inactive.

is connected to either pin 3 or pin 4, the respective limit becomes active and the crosshead is prevented

from movement in that direction.

When the +5V from pin 2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

Series F Test Frames + IntelliMESUR® Software User’s Guide

12

TOC

3.6 Installing Series FS05 Force Sensors to Models F105 / F305 / F505 / F505H

Series FS05 force sensors mount directly to the crosshead. Once the test frame is in a stable and secure

position, install the force sensor by matching the gold-plated pads on the top surface with the pins in the

underside of the crosshead, as shown below:

While holding the force sensor in place with one hand, use an Allen wrench with the other hand to tighten

the screw that joins the force sensor to the crosshead, as shown below:

To avoid overload and damage, select a force sensor with sufficient capacity to

accommodate the application.

Optionally cover the screw head with the included black plastic cap.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

Series F Test Frames + IntelliMESUR® Software User’s Guide

13

TOC

Grips and fixtures may be threaded onto the threaded shaft protruding from the bottom of the force

sensor, for example:

3.7 Installing Series R07 Force Sensors to Models F755 / F755S / F1505 / F1505S

Install the sensor to the underside of the crosshead using the supplied socket head screw and hardware.

Plug the connector into the receptacle in the top front surface of the crosshead, then fasten the thumb

screws into the crosshead, as shown below:

Grips and fixtures may be threaded onto the underside of the sensor.

3.8 Installing Series FS05 Force Sensors to Models F755 / F755S / F1505 / F1505S

To avoid damage to the internal load cell or shaft, do not use tools to tighten grips or

attachments onto the shaft. Hand-tighten only.

Series FS05 force sensors may be installed via the optional AC1083 adapter, as shown below:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

Series F Test Frames + IntelliMESUR® Software User’s Guide

14

TOC

3.9 Installing a Third-Party Force Sensor

3.9.1 Models F105 / F305 / F505 / F505H

Using the optional Model PTAF adapter, a third-party force sensor may be mounted to the test frame.

Insert a screw of sufficient length and appropriate thread size through the crosshead, through the PTAF,

and into the force sensor, as shown in the following example:

3.9.2 Models F755 / F755S / F1505 / F1505S

Before installing the sensor, refer to the Model PTA / PTAF user’s guide for complete

instructions.

Using the optional Model PTAF adapter and AC1083 adapter, a third-party force sensor cell may be

mounted to the test frame. Insert a screw of sufficient length and appropriate thread size through the

crosshead, through the AC1083 adapter, through the PTAF, and into the force sensor, as shown in the

following example:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

Series F Test Frames + IntelliMESUR® Software User’s Guide

15

TOC

3.10 Installing the IntelliMESUR control panel

For test frame part numbers ending in “-IMT”, for example Model F305-IMT, a Windows tablet with

attached ball mount and mounting bracket are included, packaged separately.

The mounting arm is pre-installed into the front right slot in the test frame column via two screws, as

shown below:

Loosen the knob sufficiently to slide the ball, mounted to the rear of the tablet, into the arm. Orient the

tablet horizontally, with the USB-C port positioned on the left side. Adjust the viewing angle as desired,

then tighten the knob.

Do not attempt to adjust the viewing angle before loosening the knob.

Connect the included USB cable between the USB-C port and the USB-B port in the rear of column, and

connect the AC adapter connector, as shown below:

Plug in the AC adapter and press the Power button, in the lower right corner of the tablet. The tablet will

boot up directly into the IntelliMESUR application. If not, select the IntelliMESUR icon in the Windows

home screen.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

Series F Test Frames + IntelliMESUR® Software User’s Guide

16

TOC

4 INSTALLING INTELLIMESUR

4.1 Hardware Requirements

4.1.1 Pre-configured tablet

IntelliMESUR is pre-installed onto the tablet provided with “-IMT” model numbers, ex. F305-IMT.

4.1.2 User device installation

For model numbers ending in “-IM”, a separate license is provided to install onto the user’s device,

provided it meets the following specifications:

- Windows 10 or later operating system

- Minimum 4GB RAM

- Minimum monitor resolution of 1310 x 885

- Minimum of two USB ports (one for a dongle, one for a cable to the test frame)

To ensure optimal performance for IntelliMESUR, do not install any additional applications

onto the tablet.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

Series F Test Frames + IntelliMESUR® Software User’s Guide

17

TOC

4.2 Installation

Windows Administrator privileges are required to install IntelliMESUR.

1. Insert the installation flash drive into the device’s USB port, or download the zipped installation

folder. Locate and double-click the file “setup.exe”. The screen appears as follows:

2. Accept the terms, then click Install. All required files will be installed, including the Mark-10 USB

driver. When installation is complete, the screen appears as follows:

3. Click Finish and run IntelliMESUR.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

Series F Test Frames + IntelliMESUR® Software User’s Guide

18

TOC

5 INTELLIMESUR BASICS

5.1 Opening IntelliMESUR

Ensure that the device is connected to the test frame with a USB cable. Then open IntelliMESUR.

5.1.1 Mark-10-supplied tablet

Press the Power button. The tablet will boot directly into IntelliMESUR. If the tablet was asleep or

hibernating, double-tap the IntelliMESUR icon.

5.1.2 Customer-supplied Windows device

1. Insert the dongle into a USB port, as shown below:

The dongle contains a one-seat license. It must be plugged in at all times to run IntelliMESUR. To

run IntelliMESUR on a different device, install the application, then move the dongle to that

device.

2. Double-tap or double-click the IntelliMESUR icon.

If the dongle is not installed, IntelliMESUR prompts a message asking if you would like to use a

90-day trial. Make the appropriate selection. The trial is fully functional, and allows full use.

3. After plugging in the dongle or starting the trial, a login screen will appear as follows, if User

Login is enabled:

Otherwise, IntelliMESUR opens directly to the Home screen.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

Series F Test Frames + IntelliMESUR® Software User’s Guide

19

TOC

5.2 Home Screen

IntelliMESUR launches into the Home Screen, with the following selections:

Open Test

Recall a previously saved test.

New Test

Create a new test.

Edit Test

Edit the parameters of a previously saved test.

Recall Test Data

Recall data from previously saved test runs.

Settings

Includes preferences, calibration, overload log, and other functions.

Manual Control

Manually control the up and down motion of the test frame, and see live load, peak load,

and live distance.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

Series F Test Frames + IntelliMESUR® Software User’s Guide

20

TOC

Lower Footer

Within the lower footer, note the following selections:

Home

This icon is present in most screens, and links back to the Home screen.

Reconnect

If the test frame has been disconnected, then reconnected, select this button to restore

communication.

Exit

Select to exit the software. If running IntelliMESUR on a Mark-10-supplied tablet, a prompt will

offer the user two choices:

- Exit into Windows

- Exit and shut down the tablet

Bottom Footer

Along the bottom edge of all IntelliMESUR screens, the following information is always displayed, from

left to right:

- Force sensor capacity or “Test Frame Not Connected” message

- Connection status of the test frame

- Calibration status of the force sensor

- Date and time

- License / demo time status (see following section)

- Current user

Question Mark

Select this button at any time to be directed to the PDF User’s Guide.

5.1.3 90-day trial

IntelliMESUR can be run as a 90-day fully-functional trial, without a license. The number of days

remaining is indicated when launching the application, and can be viewed at any time in the Information

screen or the bottom footer, visible at all times:

Optional functions may be evaluated for 90 days. If an evaluation is in progress, the number of remaining

days is shown in the bottom footer:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

Series F Test Frames + IntelliMESUR® Software User’s Guide

21

TOC

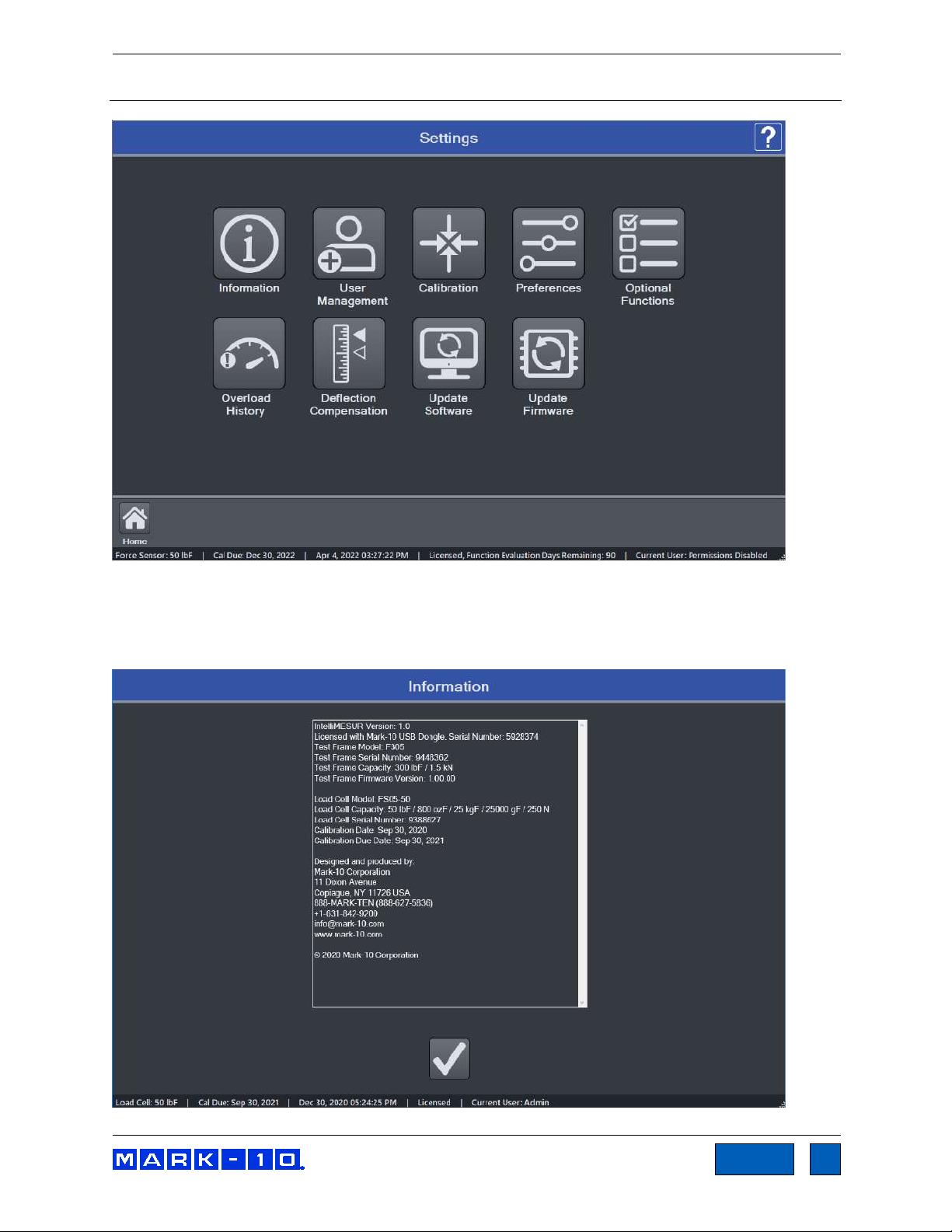

6 SETTINGS

6.1 Information

Contains serial numbers, software and firmware versions, and other information about the equipment.

The screen appears as follows:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

Series F Test Frames + IntelliMESUR® Software User’s Guide

22

TOC

Operator

Supervisor

Administrator

Manual Control

X X X

Recall and run a test

X X X

Create a test X

X

Create a report

X X X

Calibration X

X

Update software

X

User management

X

6.2 User Management

6.2.1 Enabling User Login

IntelliMESUR can be run with or without a user login. By default, User Login is not enabled. Make the

appropriate selection in the following screen:

When User Login is enabled, the User Login button is always present in the upper corner of the screen,

as follows:

Select this button to log out and log in as a new user.

6.2.2 User Permission Levels

IntelliMESUR provides three user permission levels, summarized as follows:

User name Admin is pre-installed, with Administrator level access. The default password is admin, and may be changed if desired. Refer to the following sections for instructions.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

Series F Test Frames + IntelliMESUR® Software User’s Guide

23

TOC

6.2.3 Adding a User

Select Add User. The screen appears as follows:

Specify the user name, type, and password, then select Add User.

To modify a user, select Modify User. The screen appears as follows:

Select the user, then modify the user type, change the password, and/or delete the user. Note that the

user Admin cannot be deleted.

To change the password, select Change Password. The screen appears as follows:

Optionally select Show Password to view the passwords.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

Series F Test Frames + IntelliMESUR® Software User’s Guide

24

TOC

Enter the requested passwords. If the password has been forgotten, select Forgot Password. The

screen appears as follows:

IntelliMESUR automatically generates a request code. Supply this code to Mark-10 or a distributor, who

will then provide a corresponding authorization code, which allow the user to reset the password.

6.3 Calibration

Refer to the Calibration section for instructions on calibrating a force sensor.

6.4 Preferences

Default units of measure, date and time format, and other settings may be accessed from the Preferences

screen. Select Settings, then Preferences.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

Series F Test Frames + IntelliMESUR® Software User’s Guide

25

TOC

Default Settings

Load and Distance Units

Select the desired units of measure. Note that not all units are supported by all force sensors. Refer to the

force sensor’s specifications for list of supported units.

Digital Filter

The digital filter smooths out load readings in situations where there is mechanical interference in the

work area or test sample. The filter utilizes a moving average technique in which consecutive readings

are pushed through a buffer and the displayed reading is the average of the buffer contents. By varying

the length of the buffer, a variable smoothing effect can be achieved. The selection of 1 will disable the

filter since the average of a single value is the value itself.

Available settings: 1 through 16,384.

It is recommended to keep the filter as low as possible for best performance.

Default Folders

Select the corresponding Open buttons to browse to the desired folder locations for test configuration

files, data, results, and reports.

All above file types created by IntelliMESUR are encrypted, for data integrity purposes, except .csv file

exports.

Date and Time Format

Select the desired date and time format.

The current date and time are linked to the Windows clock. To change the time on a touch-enabled

device, press and hold the clock in the lower-right corner of the screen. If using a mouse, right-click, then

select Adjust date/time. The time is displayed along the lower edge of the IntelliMESUR screen.

Note: if the device is not connected to the internet, the Windows clock may drift by up to several minutes

per year.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

Series F Test Frames + IntelliMESUR® Software User’s Guide

26

TOC

6.5 Optional Functions

A number of optional software functions are available within IntelliMESUR

means of evaluating optional functions for 90 days, and activating these options permanently.

®

. This section provides a

Activating a Function

To activate an optional function, select the desired function. Then, provide Mark-10 with the Test Frame

Serial Number or Licensing Dongle Serial Number. Mark-10 will supply a corresponding Activation Code.

Enter this code into the provided space, then select Activate to permanently enable the function.

Functions may also be evaluated for 90 days. Select Start to initialize the evaluation period. During this

period, “Evaluation Mode” will appear above the list of functions. A function may be activated at any time

before, during, or after the evaluation period.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

Series F Test Frames + IntelliMESUR® Software User’s Guide

27

TOC

6.6 Overloads

IntelliMESUR constantly monitors the force sensor, and stops the crosshead when the load reaches

120% of capacity. However, it is still possible to overload a force sensor when it is stationary by manually

applying excessive force to it.

Overload History provides a record of the 50 most recent overloads, containing a time stamp, motion

direction, and force direction for each occurrence. An example screen appears as follows:

Note: Overloads which may occur while the force sensor is disconnected from a Series F test frame, or

while the test frame is powered off, are not recorded in Overload History.

6.7 Deflection Compensation

Refer to the Calibration section for further information.

6.8 Update Software and Update Firmware

Refer to the Maintenance and Service section for further information.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

Series F Test Frames + IntelliMESUR® Software User’s Guide

28

TOC

7 MANUAL CONTROL

Manual Control allows the user to move the crosshead up and down and observe force and distance

data, without creating a test. Manual control is useful when needing to manually adjust the crosshead

prior to starting a test, and also provides a means of creating a reference point for Height Mode.

Note: Data cannot be saved in Manual Control.

The screen appears as follows:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

Series F Test Frames + IntelliMESUR® Software User’s Guide

29

TOC

7.1 Load and Distance Measurement

Load and distance measurement are displayed as below:

Load

Load is displayed in the unit of measurement selected in Default Settings. Use the Mode button to

toggle between three display modes:

Load

The real-time load.

Peak Compression Load

Maximum observed compression load.

Peak Tension Load

Maximum observed tension load.

The load bar below the load reading indicates when approaching an overload. The bar increases

to the right for compression readings, and to the left for tension readings. The bar colors are as

follows:

Green 0 - 80% of force sensor capacity

Yellow 80 to 100% of force sensor capacity

Red 100+% of force sensor capacity

At 110% of force sensor capacity, the load reading is replaced by the word, “OVER”, which

indicates an overload. The status window background color turns red.

Load Zero zeroes the live load and clears the peaks.

Distance Zero zeroes the distance.

7.2 Motion Control Modes

Jog Mode

The crosshead moves the specified distance each time Up or Down is selected. Three pre-sets

are available, as shown below:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

Series F Test Frames + IntelliMESUR® Software User’s Guide

30

TOC

Select the desired preset. Select Edit to change the jog distance for the corresponding preset.

Momentary Mode

The crosshead will move only while selecting and holding down the Up or Down button. To set

the speed, type the value into the box or drag the slider to the desired value, as shown below:

Maintained Mode

The crosshead will move continuously after selecting the Up or Down button. Set the speed in

the same manner as Momentary Mode.

®

FollowMe

Mode

The crosshead responds to pushing or pulling on the force sensor’s load cell shaft by hand.

Increasing force produces greater speeds.

Exercise extreme caution when using FollowMe® with low-capacity force

sensors, as overload can more easily occur.

If no load is detected for 5 seconds after selecting FollowMe

®

, the function deactivates.

7.3 Height / Length Offset

When measuring sample heights, for example in spring testing, a datum (base reference) must be

established. This function allows you to establish the datum at a preload. To configure the settings, select

Settings. The screen appears as follows:

Configure the Touch Load and Touch Speed, as desired. In many applications, a flat compression plate

is used to engage the top of the sample, for example, in compression spring testing. However, when a

grip with more complex geometry is used, and it is not possible to touch the sample contact surface to the

test frame base or the lower fixture, an Offset Distance may be specified. If specified, IntelliMESUR

automatically increases the displayed distance value by this value when the preload occurs.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

Series F Test Frames + IntelliMESUR® Software User’s Guide

31

TOC

When finished, select OK, then select Enable in the Manual Control screen. The button will be

highlighted. Then select Up or Down to perform the function. After the preload has been reached, the

crosshead will reverse until the Return Distance From Touch is reached.

7.4 Set Home

When Manual Control is accessed from an active test screen, instead of from the Home Screen, the Set

Home button appears as follows:

Selecting this button establishes the current crosshead position as Home. Refer to subsequent sections

for more details on how this position relates to test configurations.

8 CREATING A BASIC TEST

To create a new basic test, select “New Test” from the Home screen, then select “Basic Test”, then

select one of the following test types:

Load Limit

Crosshead stops at a specified load limit.

Distance Limit

Crosshead stops at a specified distance limit or height.

Break Limit

Crosshead stops when the sample breaks.

Load Hold

Crosshead moves until a specified load, then maintains the load for a specified period of time.

Cycle Test

Crosshead cycles a specified number of times between a selection of limit condition types.

COF Test (optional function)

Crosshead stops at a specified distance and calculates static and dynamic COF.

8.1 Load Limit

The screen appears as follows:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

Series F Test Frames + IntelliMESUR® Software User’s Guide

32

TOC

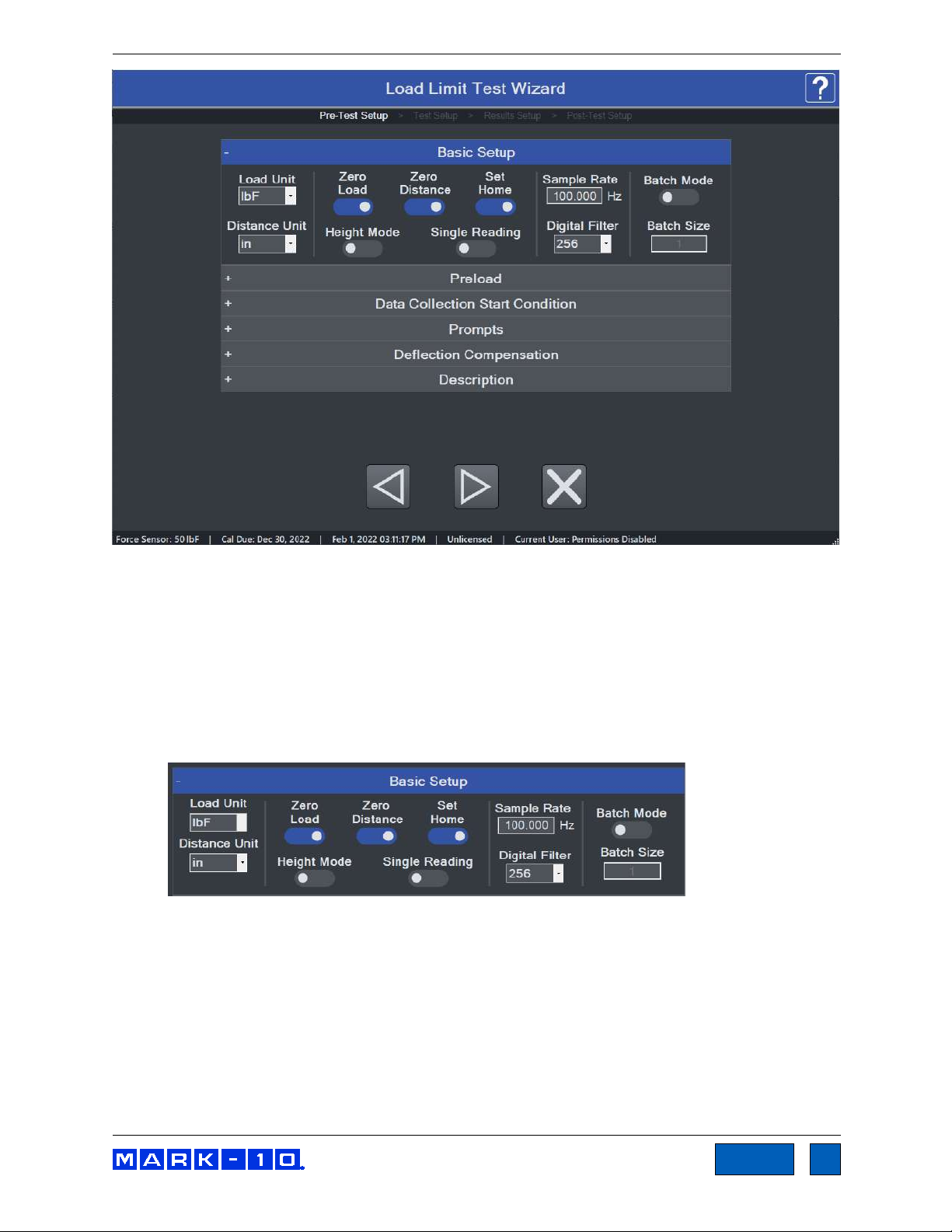

The Basic Test Wizard consists of four steps. Each stepped is grouped into panels containing settings.

The four steps are as follows:

1. Pre-Test Setup

2. Test Setup

3. Results Setup

4. Post-Test Setup

8.1.1 Pre-Test Setup

Basic Setup Panel

Load Unit

Select the desired unit of measurement. Note that not all units are supported by all force sensors

cells. Refer to the sensor’s specifications for a list of supported units.

Distance Unit

Select the desired unit of measurement.

Zero Load

Zero the load value at the start of the run.

Zero Distance

Zero the position value at the start of the run.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

Series F Test Frames + IntelliMESUR® Software User’s Guide

33

TOC

Set Home

Establish the starting position of the crosshead as the Home position. You can auto-return to this

position; this may be set in subsequent sections of the wizard.

Height Mode

To measure distance relative to a reference point established via the Height / Length Offset

function in Manual Control, enable Height Mode. Height measurements are commonly used in

spring testing.

Single Reading

Only a single result and graph data point are displayed, useful when running a batch of tests

requiring only one result, such as a maximum load. Select the desired result in Results Setup.

Sample Rate

By default, IntelliMESUR records continuous data points for each run. Set the desired rate, up to

1,000 Hz (data points per second). IntelliMESUR can capture up to 1 million data points per run,

up to 10 runs, for a total of 10 million data points.

Digital Filter

Smooths out load readings in situations where there is mechanical interference in the work area

or test sample, as explained in the Preferences section.

Batch Mode

To set up a batch of multiple runs, enable this mode, then specify the number of runs.

Preload Panel

The preload function zeroes the load and/or position values upon contact with the sample,

defined as a user-specified force. The speed of the preload phase of the test may also be set

independently of the main test speed, which is configured in the subsequent step, Load Limit

Setup.

If preload is desired, enable the appropriate functions and specify the desired preload force and

speed.

Data Collection Panel

Configure the trigger at which data collection will start. Select from an elapsed time (relative to the

start of crosshead motion), load, or distance. The default graph x-axis may be also be configured,

although this can be changed at time of test in the Graph screen.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

Series F Test Frames + IntelliMESUR® Software User’s Guide

34

TOC

Tell Prompt

Ask Prompt

Prompts Panel

IntelliMESUR can prompt a message or ask a question requiring a response. Up to three

consecutive prompts may be configured.

Select the Edit icon to configure the prompt. The screen appears as follows:

Select Tell to provide information to the user, or Ask to ask a question requiring a response, such

as a serial number or lot number. The response to an Ask prompt can be saved in the Results

table of a test.

Optionally include an image to be displayed with the prompt. Select Open or the empty image

frame, then browse to the desired location. To remove an image, select Delete.

The prompt can be displayed when the test is opened, at the start of a new batch, or at the start

of each run. Make the desired selection.

Example prompts, as they appear during a test:

For convenience in high-volume testing applications, a USB barcode scanner can be used to

input a response (not available from Mark-10).

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

Series F Test Frames + IntelliMESUR® Software User’s Guide

35

TOC

Deflection Compensation

Force sensors and test frames deflect under load, affecting the accuracy of distance

measurements. Series F test frames and force sensors are compensated at the factory.

To account for deflection within grips or fixtures associated with the test, IntelliMESUR provides a

utility for additional compensation. For instructions on running this utility, refer to the Deflection

Compensation section. When this process has been completed and the file has been saved,

browse to the desired file in this panel.

Description

Optionally type a test description, which can be useful in identifying tests at a later date. Example:

When opening a test, the description appears to the right of the file listing, as follows:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

Series F Test Frames + IntelliMESUR® Software User’s Guide

36

TOC

8.1.2 Load Limit Setup

Basic Setup Panel

The screen appears as follows:

Specify the target load and direction, then specify the test speed. To collect continuous data

points for each run, enable Display Results. Results may still be saved even if Display Results

is disabled.

Pass / Fail Limits

Pass and fail limits may be specified to differentiate an acceptable sample versus a reject. Enable

if desired, then specify upper and lower limits. The types of limits in this panel correspond to the

type of test. For Load Limit and Load Hold tests, the pass/fail limits are distance values. For

Distance Limit and Break Limit tests, the pass/fail conditions are load values.

When enabled, a Pass/Fail indicator appears in the upper right corner of the Graph and Results

screens. In addition, a color-coded Pass/Fail column is added to the Results table.

Exception Limits

If a test does not reach its target, a number of exception limits may be specified to abort the test.

Enable if desired, then specify exception limits. An exception is triggered at whichever trigger

occurs first. If an exception is triggered, the crosshead stops, and the Pass/Fail status becomes

“Exception”. Values obtained in an exception run are not included in results calculations.

Exception options:

Limit Switch

Refers to the physical upper and lower (or right and left) limit switches, positionable along the

length of the test frame column.

Distance Limit

A specified distance has been reached.

Break Threshold and Break % Drop

A specified drop in load has occurred, for example when a sample breaks or a sample slips out

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

Series F Test Frames + IntelliMESUR® Software User’s Guide

37

TOC

from a grip. Specify a drop in load from the maximum value (Break % Drop). IntelliMESUR starts

monitoring for a break after the Break Threshold has been reached.

8.1.3 Results Setup

IntelliMESUR can calculate a number of results and calculate statistics for results over multiple

runs. For example, IntelliMESUR can calculate the mean of Max Load values over a 5-run batch.

The Results appear as follows:

Load Results

Enable the desired results, then select Statistics to specify Statistics.

The screen appears as follows:

Make the desired selections, then continue.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 38

Series F Test Frames + IntelliMESUR® Software User’s Guide

38

TOC

Distance Results

Load Averaging

Load Averaging dynamically captures data points and averages the result over a distance or

period of time. This requirement is common in peel testing and coefficient of friction testing

applications.

Enable the result, and any required statistics, then configure the following settings:

Trigger Force

The minimum force required to start the averaging sequence. Select compression or

tension. To start averaging immediately, set this value to zero.

Post-Trigger Delay

An initial delay may be configured, for example to omit the initial force spike at the

beginning of a peel test. To start averaging immediately after the trigger force, set this

value to zero.

Stop Condition

Stop averaging when the specified distance is reached or time period elapses.

The following graph is a representative example of a time-based averaging test with post-trigger

delay:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

Series F Test Frames + IntelliMESUR® Software User’s Guide

39

TOC

Other

Optionally include the date and time of the test, along with corresponding crosshead speed.

8.1.4 Post-Test Setup

In this step, a number of post-test preferences and settings can be configured.

Basic Setup

Return Home

Crosshead returns to the prevously set Home position at the end of the test.

Save Data

Automatically save all raw, continuous data for each run.

Save Results

Automatically save results for the test. Results are visible in the Results screen.

Default View

When opening a test, default to the Graph view or Results view. Regardless of the default, you

can switch between views after the test has completed.

Export Settings

®

IntelliMESUR

both. Files are exported as .csv using the same formatting described in the manual export

function in the Running a Test section.

Find Quality Products Online at: sales@GlobalTestSupply.com

can automatically export data from a single run or results from a batch of runs, or

www.GlobalTestSupply.com

Page 40

Series F Test Frames + IntelliMESUR® Software User’s Guide

40

TOC

Export Run Data

Enable if desired, then select an export preference:

Create New File

Creates a new file automatically. The file name includes the test name and time stamp,

for example: Peel Test-Dec-7-2020-03-25-57-PM

Specify the destination folder by browsing to the appropriate location.

Overwrite File

Overwrites an existing file. This function is useful for third-party applications which read

periodically from the same file, such as SPC software. Specify the file name as desired.

Specify the file name and browse to an appropriate destination folder.

Export Results

Enable if desired, and follow the same instructions as above.

Graph Setup

Auto-Scale

Auto-Scale automatically increases the X- and Y-axis maximum values as the test proceeds,

ensuring that the graph curve is zoomed in as much as possible while fitting the entire curve.

Maximum & Minimum

To specify fixed maximum and minimum axis values instead of automatical scaling, enter the

desired values.

Invert

IntelliMESUR processes force, distance, and time data as follows:

Tension forces are plotted as negative values.

Compression forces are plotted as positive values.

Upward or rightward motion is displayed as increasing distance values, while downward

or leftward motion is displayed as decrementing values. If the movement continues past a

distance of 0, a positive values becomes negative, and vise versa, as illustrated below:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 41

Series F Test Frames + IntelliMESUR® Software User’s Guide

41

TOC

The most common method to plot a curve is to plot up and to the right. To achieve this trajectory,

or other type of trajectory, data for each axis may be inverted to compensate for the plotting

protocol mentioned above.

Example:

To plot a tension test up and to the right, invert the Y-axis (load), while leaving the X-axis uninverted. Had the Y-axis not been inverted, increasing tension force would be displayed by a

downward dipping plot, as illustrated below:

Default X-Axis

Set the default x-axis to distance or time. Note that following any test, you can toggle between

distance or time via dedicated buttons in the Graph screen.

Overlay Runs on Graph

Up to 10 most recent runs may be plotted on the graph simultaneously. For more information,

refer to the Graph screen section.

Folders

Browse to the desired folder locations for test configuration files, data, results, and reports.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 42

Series F Test Frames + IntelliMESUR® Software User’s Guide

42

TOC

Select Next to complete the test setup. When prompted, select Save & Run, Save & Go Home,

or Cancel. If saving the test, the screen appears as follows:

8.2 Distance Limit

A Distance Limit test shares most attributes with a Load Limit test, with the exception of the Basic

Setup panel of the Test Setup step. The panel appears as follows:

The unique settings are as follows:

Test Direction

Select upward or downward motion for vertical test frames, or rightward and leftward for model

F505H.

Target Distance

Crosshead will stop at the specified distance.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 43

Series F Test Frames + IntelliMESUR® Software User’s Guide

43

TOC

8.3 Break Limit

Break Limit tests are useful for a wide variety of destructive applications, including peel testing, wire

crimp pull-off testing, tensile testing, and many others. The crosshead will stop once IntelliMESUR has

detected that the sample has broken.

Setting up a Break Limit test is similar to Load Limit and Distance Limit tests, with the exception of the

Basic Setup panel of the Test Setup step. The panel appears as follows:

IntelliMESUR starts monitoring for a break when the Break Threshold has been reached. This value

should be set lower than the anticipated breaking load. IntelliMESUR identifies a break when the load has

dropped by the specified percentage from the maximum load.

Example: If Break % Drop is set to 40% and the maximum load is 100 lbF, the crosshead will stop when

the load drops to 60 lbF.

8.4 Load Hold

With IntelliMESUR’s load holding function, the crosshead stops at a specified load, then dynamically

adjusts its position to maintain that load over a specified period of time.

Setting up a Load Hold test is similar to Load Limit and Distance Limit tests, with the exception of the

Basic Setup panel of the Test Setup step. The panel appears as follows:

Set a target load, hold duration in hours, minutes, and seconds, then the approach speed.

8.5 Cycle Test

IntelliMESUR’s Cycle Test is designed for repetitive applications such as fatigue and durability.

Setting up a Cycle Test is mostly similar to Load Limit and Distance Limit tests. Note the following

unique features:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 44

Series F Test Frames + IntelliMESUR® Software User’s Guide

44

TOC

8.5.1 Cycle Test Setup

Basic Settings

Cycle Type

Select number of cycles, or specify a period of time, in hours, minutes, and seconds.

Up Stroke / Down Stroke Settings

Up Stroke (crosshead moving up or right) and Down Stroke (crosshead moving down or left)

settings may be set independently of each other. The crosshead will stop at one of the following

three targets:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 45

Series F Test Frames + IntelliMESUR® Software User’s Guide

45

TOC

Load

Select tension or compression, then specify the load.

Distance

Specify as desired.

Limit Switch

Crosshead stops when it reaches the upper physical limit switch.

Speed

Specify the crosshead speed.

Dwell Time

Specify how much time the crosshead waits at the target before reversing.

Exception Limits

Specify exception limits for each stroke independently.

8.5.2 Results Setup

Results setup is the same as in other tests, with the addition of the Cycles Results panel. The following

additional results may be displayed in the Results table:

Number of Cycles

Maximum Load Each Cycle

Optionally add statistics for this result.

Minimum Load Each Cycle

Optionally add statistics for this result.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 46

Series F Test Frames + IntelliMESUR® Software User’s Guide

46

TOC

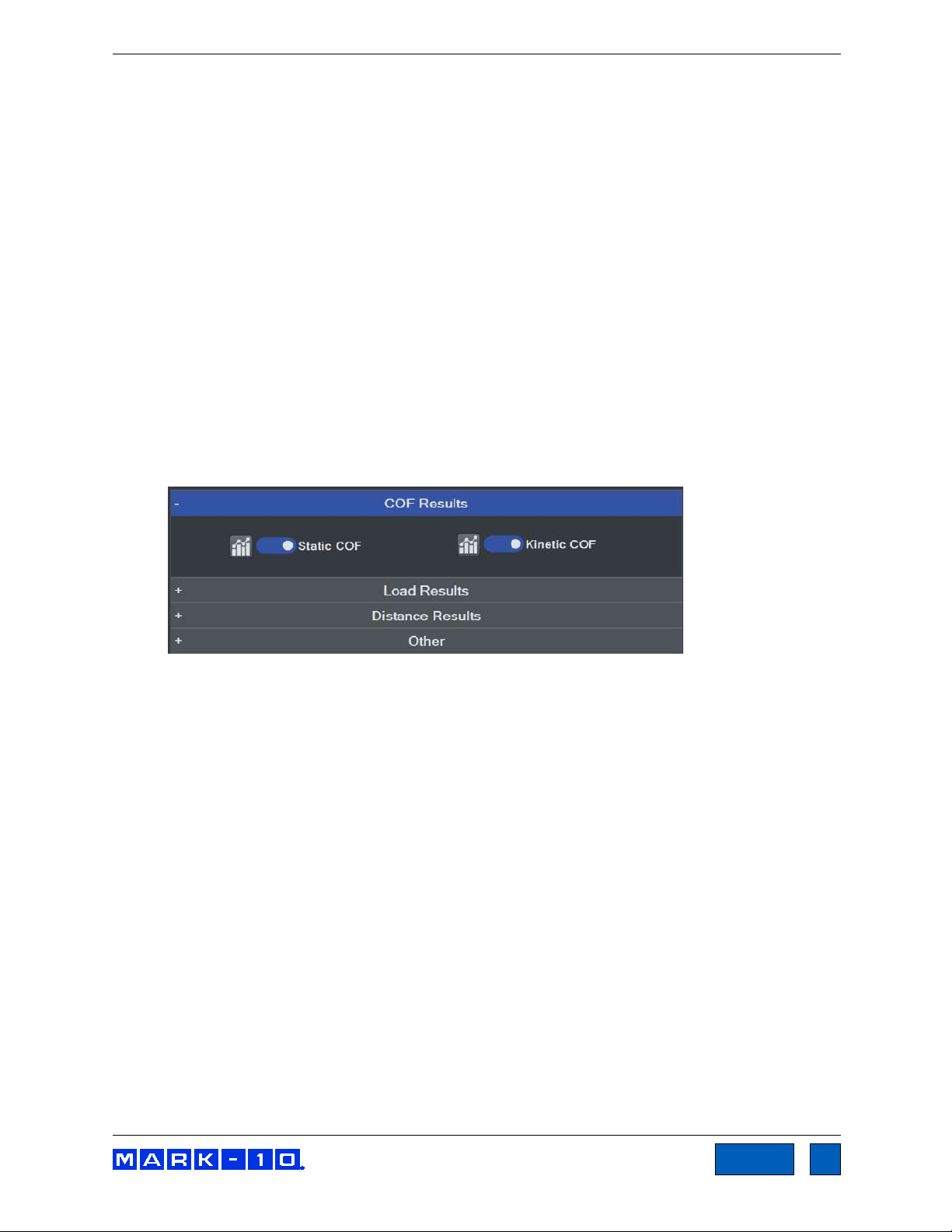

8.6 COF Test

Note: The COF Test module is optional. See Optional Functions under Settings for activation

instructions.

In a typical coefficient of friction test, a sled wrapped with sample material is dragged along another piece

of material clamped onto a base fixture. Below is an example configuration for paper testing:

A COF Test shares most attributes with a Distance Limit test, with the exception of the Basic Setup

panel of the Test Setup step. The panel appears as follows:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 47

Series F Test Frames + IntelliMESUR® Software User’s Guide

47

TOC

The settings are as follows:

Sled Weight

The weight of the sled.

Trigger Load

The load threshold at which IntelliMESUR starts to collect data.

Post-Trigger Delay

Specify a time delay after the Trigger Load before collecting data.

Test Distance

Specify as desired. Data collected between the Trigger Load and Test Distance are used to

calculate the static and dynamic coefficients of friction.

Speed

Specify the crosshead speed.

Display Result

Include results. The Results step adds the following COF results:

Static COF Maximum force divided by the sled weight.

Kinetic COF Average force divided by the sled weight.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 48

Series F Test Frames + IntelliMESUR® Software User’s Guide

48

TOC

9 CREATING A MULTI-STEP TEST

A Multi-Step test can string together any number of basic test functions, data collection steps, data zero

steps, cycling, and prompts. Steps may be placed in the desired order, then re-ordered as desired.

9.1 Multi-Step Overview

The initial screen appears as follows:

Available steps are listed in the left side of the screen, and may be inserted into the step sequence to the

right.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 49

Series F Test Frames + IntelliMESUR® Software User’s Guide

49

TOC

To insert a step, highlight an existing step. It will become blue. Then click the desired step. It will be

inserted after the currently selected step. An example test is below:

The step sequence must contain the three steps listed above: Pre-Test, Results, and Post-Test. To edit

these steps, select Edit, and configure the parameters the same way as in Basic Test setup.

To move a step forward or back, use the Up and Down buttons. Select the Delete button to remove the

step.

The selection of results is expanded as compared to Basic Test setup, as follows:

Load Results:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 50

Series F Test Frames + IntelliMESUR® Software User’s Guide

50

TOC

Distance Results:

9.2 Step Types

Multi-step tests build upon the same functions as in Basic Tests, while separating out datum, prompting,

zero, and go-home functions. Preload is not integrated into steps as in Basic Tests. Instead, a preload

must be manually configured as a separate Load Limit step, followed by a Zero step.

Available steps are as follows:

9.2.1 Load, Distance, and Break

Each of these steps may be set up in the same manner described in Basic Test setup.

9.2.2 Hold

Hold a load (as described in Basic Test setup) or hold a position. Specify the hold period in hours,

minutes, and seconds.

To include the data points received during the Hold step in the Results calculations, enable Display

Results.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 51

Series F Test Frames + IntelliMESUR® Software User’s Guide

51

TOC

9.2.3 Loop

The Loop function repeats a range of steps. Insert this step after the last step to be repeated.

Select either a number of loops or a time duration for constant looping. Then, enter the Starting Step

number. Enter Number of Loops or Duration.

9.2.4 Datum

A datum establishes a local offset of load and/or distance. When the datum step is reached, the load

and/or distance will change by the values set in the Load and Distance fields. Enable one or both of

these fields.

Note that datums do not change the system offset established in the Height / Length Offset utility, but

rather, only offsets the data collected during the test.

To include the data points received during the Hold step in the Results calculations, enable Display

Results.

Up to two datums may be used per test.

9.2.5 Prompt

Setting up a prompt in a multistep test is the same as described in the Basic Test Setup section.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 52

Series F Test Frames + IntelliMESUR® Software User’s Guide

52

TOC

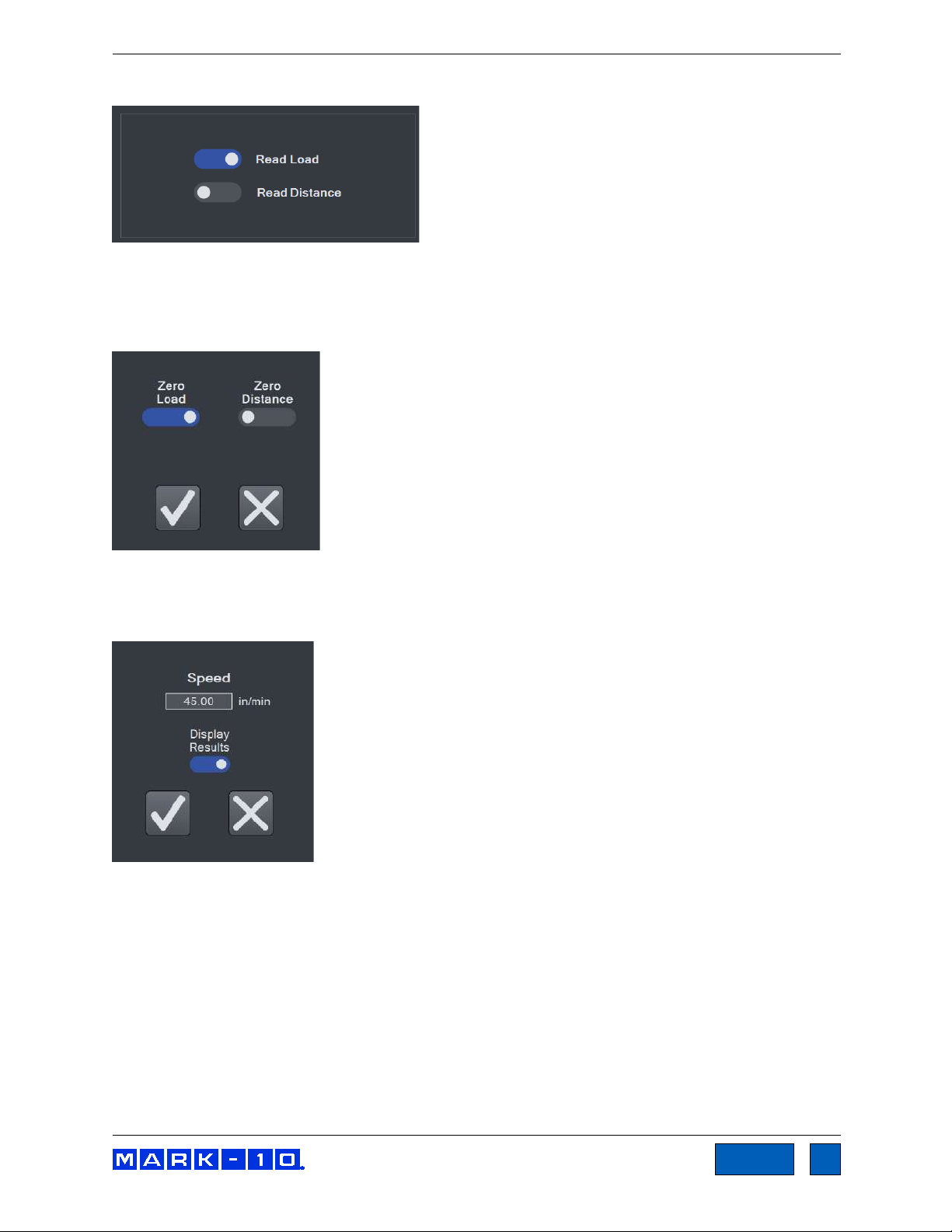

9.2.6 Data

A Data step saves the current load and/or distance value in the Results table. Make the desired

selections.

9.2.7 Zero

A Zero step zeroes the load and/or distance. Make the desired selections.

9.2.8 Home

A Home step returns the crosshead to the Home position at the specified speed.

To include the data points received during the Home step in the Results calculations, enable Display

Results.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 53

Series F Test Frames + IntelliMESUR® Software User’s Guide

53

TOC

10 RUNNING A TEST

10.1 Favorite Tests

Saved tests may be designated as favorites, for quick access when selecting Open Test from the Home

screen. The screen appears as follows:

10.1.1 Creating a Favorite

Select Assign Favorite, then select the desired box location. The screen appears as follows:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 54

Series F Test Frames + IntelliMESUR® Software User’s Guide

54

TOC

Browse to the desired file, then select Open. Optionally associate an image with the favorite box by

making the appropriate selection to the next screen:

If selecting Yes, browse to the desired image, then select Open. The screen appears as follows:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 55

Series F Test Frames + IntelliMESUR® Software User’s Guide

55

TOC

10.1.2 Unassigning a Favorite

Select Unassign Favorite, then select the desired test.

10.1.3 Edit a Test

Select Edit Test, then select the desired test.

10.1.4 Opening a Test

Select a previously assigned favorite, or select Other Test to browse for other tests not assigned as

favorites.

Depending on the test setup, the initial view is either Graph or Results.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 56

Series F Test Frames + IntelliMESUR® Software User’s Guide

56

TOC

10.2 Graph View

The screen appears as follows:

Multiple runs may be viewed on the graph at the same time. If Overlay Runs on Graph is selected in the

test setup, the screen appears as follows:

Select the desired runs to view.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 57

Series F Test Frames + IntelliMESUR® Software User’s Guide

57

TOC

10.2.1 Basic Information

Along the top of the screen, the following information is always displayed:

Batch counter – if Batch is enabled in the test setup, the current run number and batch size are

displayed. Ex. “Batch: 2/3” = 2 runs completed out of a batch of 3.

Load – current load.

Distance – current distance.

Status – crosshead motion status, such as Moving Up, Moving Down, Stopped, Home,

Emergency Stop, etc.

Pass / Fail Indicator – if Pass / Fail Limits are enabled in the test setup, a Pass, Fail, or

Exception indicator will be displayed at the end of each run. If an exception occurs, the type of

exception will be shown in the Status window and in the Results table.

For multi-step tests, a pass / fail indicator can be configured for each step, and is represented in

the Results table (refer to the Results View section for more information). If any step within a

multi-step test has failed, IntelliMESUR considers that the entire run has failed, and displays Fail

in the main indicator described above.

10.2.2 Graph Controls

The following controls are provided below the graph:

Line Width

Select the button, then choose the desired plot thickness:

Invert X-Axis, Invert Y-Axis

Invert the plots, as desired. Further explanation is provided in the Graph Setup sub-section of

Creating a Basic Test. Note that inverting axes in this screen will not be saved to the test setup.

Edit the test to save default axis settings.

Distance / Time selector

Select Distance or Time as the x-axis. The y-axis is always Load.

Cursor

Use the cursor to identify the x- and y-values along any point of a plot. Click or touch any point

along a plot to see the values. Example below:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 58

Series F Test Frames + IntelliMESUR® Software User’s Guide

58

TOC

The cursor will snap to the closest plot when multiple runs are displayed simultaneously.

Zoom

To zoom by hand, pinch fingers to zoom in and out. To zoom in via mouse, click and drag to

create a zoom window.

To zoom out, select Graph Reset.

Graph Reset

Zooms out to show the complete plot.

10.2.3 Starting The Test

To start the test, select Start. To interrupt a test while it is running, select Stop.

10.3 Results View

10.3.1 Basic and Multi-step Test Result Tables

The screen appears as follows for a basic test:

Results and statistics are presented as configured in the test setup. The Statistics table below the

Results table is aligned to the results, as depicted below:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 59

Series F Test Frames + IntelliMESUR® Software User’s Guide

59

TOC

Below is an example of a one-loop, two-cycle multi-step test:

The following additional information is displayed in a multi-step test versus a basic test:

Run No.

Run number.

Step No.

Indicates the step number within the multi-step sequence. Only steps configured to display results

are shown in this table.

If more than one loop is configured in the test, the table includes the Loop No. and Cycle Count

columns, as shown below:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 60

Series F Test Frames + IntelliMESUR® Software User’s Guide

60

TOC

Since any number of loops may be configured in a multi-step test, Loop No. identifies the loop

within the test. Cycle Count refers to the cycle number within a specific Loop step.

Overall Run Status

When there is more than one pass/fail status per run, an additional row is added to the Results

table, labeled Overall Run. This provides a comprehensive pass/fail determination for the entire

run. If all steps pass, the Overall Run status is Pass. If any step fails, the overall status is Fail.

Basic information and test start and stop functions are the same as in the Graph screen.

10.3.2 Results Presentation

If the run fails, the entire row will appear red, and the Status cell includes a description of the failure.

Example:

An exception is denoted in the same manner, highlighted orange. Example:

When an exception occurs, the crosshead stops. It will not return to the Home position, even if Return

Home is enabled in the test setup. To manually return home, select Return Home.

10.3.3 Invalidating a Result

There may be an occasion where the result must be invalidated, for example, if the test was started

accidentally, or the sample slipped out of the grip. In such instances, a run may be invalidated.

Highlight anywhere within the row, then select Invalidate Run. A message box appears as follows:

Select the reason from a pre-populated list, or select Other and enter a custom reason.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 61

Series F Test Frames + IntelliMESUR® Software User’s Guide

61

TOC

The Status cell will be highlighted yellow, as shown in the following example:

Note: once a run has been invalidated, it cannot be re-validated.

10.3.4 Results Processing

Save Results

Save results to a file, which can later be recalled. IntelliMESUR automatically assigns a file name

containing the test name, followed by a time stamp. Example: Peel test-Dec-7-2020-03-25-57-PM

The file name may be changed if desired.

Recall Results

Recall previously saved results.

Note: Any currently displayed results will be deleted when previous results are recalled. Consider

saving current results first.

Export Results

Export results to a .csv file. The file name is automatically assigned as described above. An

example results file opened in Excel appears as follows:

Clear Results

Clear all results from the table.

Note: Clearing results also clears the graph.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 62

Series F Test Frames + IntelliMESUR® Software User’s Guide

62

TOC

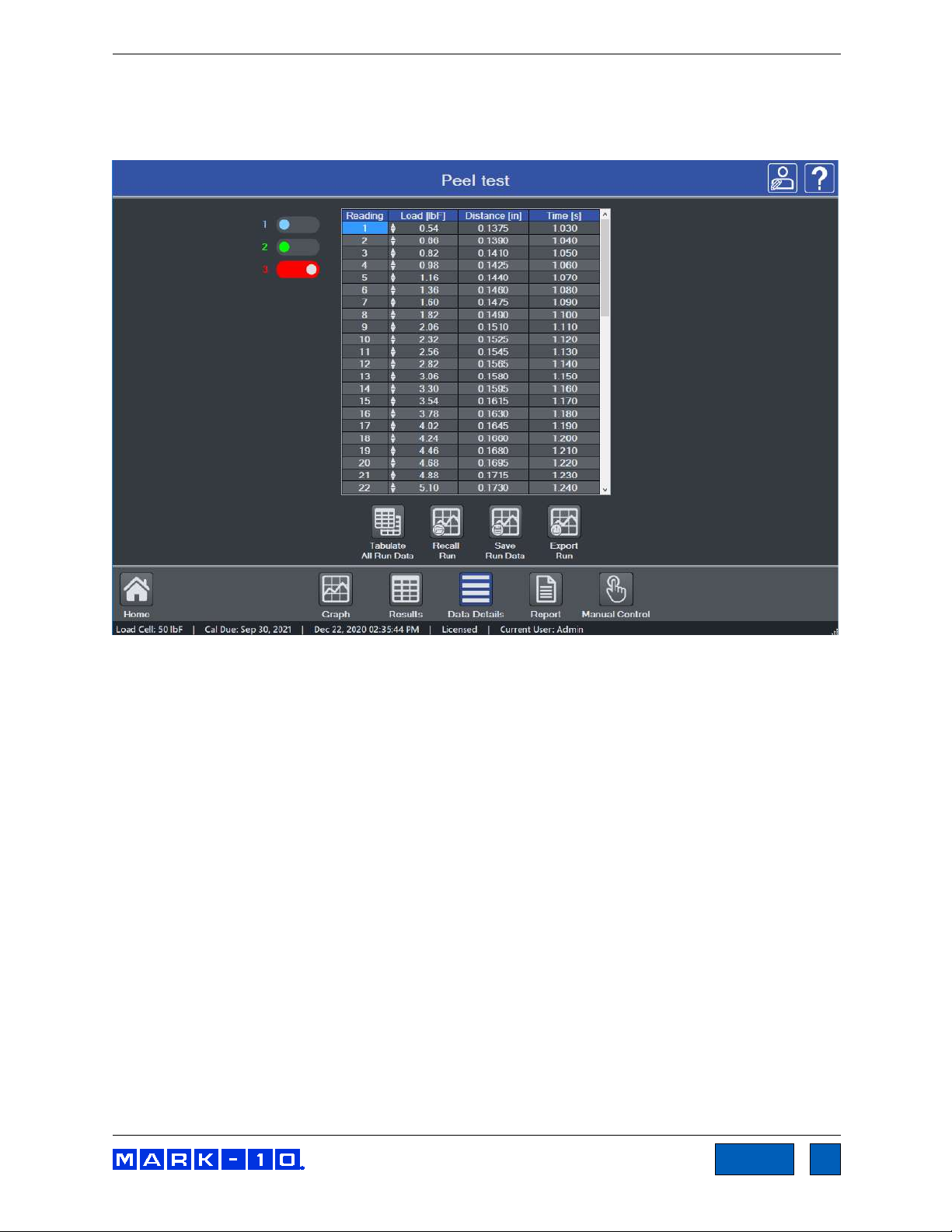

10.4 Data Details View

Data Details view tabulates raw data for a run, including reading number, load, distance, and elapsed

time. The screen appears as follows:

If Overlay Runs on Graph is selected in the test setup, data for up to 10 runs may be viewed by

selecting the desired run number to the left of the table.

10.4.1 Additional Functions

Tabulate All Run Data

The table populates up to 4,000 data points. If the run contains more than 4,000 points,

IntelliMESUR filters the data to maintain a maximum of 4,000 points. To view up to 1 million

points per run, the maximum per run, select Tabulate All Run Data. Larger data sets may

require several minutes to fully tabulate.

Recall Run

Recall data from a previously saved run.

Save Run Data

Save the run data for future recall.

Export Run

Export the run data to a .csv file. An example results file opened in Excel appears as follows:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 63

Series F Test Frames + IntelliMESUR® Software User’s Guide

63

TOC

10.5 Creating a Report

A report may be created, containing the results, graph, equipment used, and other pertinent information.

The screen appears as follows:

10.5.1 Creating a Template

Open a previously saved template by selecting Open Template, or create a new one. As shown in the

above image, any of the following information may be specified in a report template, as desired:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 64

Series F Test Frames + IntelliMESUR® Software User’s Guide

64

TOC

Company Logo

Browse for a company logo, or other image, and select the desired alignment at the top of the

report.

Test Image

If the test is saved in Favorites with an associated image, that same image is included in the

report template by default. Otherwise, browse to the desired image.

Include

System Information

IntelliMESUR software version

Test frame model number

Test frame force capacity

Test frame serial number

Test frame firmware version

Force sensor model number

Force sensor force capacity

Force sensor serial number

Force sensor previous calibration date

Force sensor next calibration date

Results

Graph

Company Info

Use this space to enter your company’s contact information, or any other pertinent information.