Page 1

Series CG

HIGH CAP ACITY DIGIT AL FORCE GAUGES

User's GuideUser's Guide

User's GuideUser's Guide

User's Guide

Mark-10 Corporation has been an innovator in the Force and T orque

measurement fields since 1979. We strive to achieve 100% customer

satisfaction through excellence in product design, manufacturing and

customer support. In addition to our standard line of products we can

provide modifications and custom designs for OEM applications. Our

engineering team is eager to satisfy any special requirements. Please

contact us for further information or suggestions for improvement.

We make a measurable difference in f orce and torque measurement

Mark-10 Corporation

11 Dixon Avenue

Copiague, NY 11726

1-888-MARK-TEN

Tel: 631-842-9200

Fax: 631-842-9201

Internet: www.mark-10.com

E-mail: info@mark-10.com

32-1030

1003

.com

Page 2

Series CG

1

Thanks!

Thank you for purchasing a Mark-10 Series CG Digital Force Gauge. We are

confident that you will get many years of great service from this product.

Mark-10 digital force gauges are designed to be easy to use and ruggedly

constructed for many years of service in laboratory and industrial environments.

This User's Guide provides setup, operating, and programming instructions. Dimensions and specifications are also provided. For additional

information or answers to your application questions, contact us and our

technical support and engineering teams will be eager to help you.

Thank you again for your purchase and happy testing!

TABLE OF CONTENTS

GENERAL - Section 1.................................................................................... 2

Controls .......................................................................................... 2

Orientation ...................................................................................... 2

Mounting ......................................................................................... 3

POWER - Section 2 ....................................................................................... 3

CONFIGURATION - Section 3 ....................................................................... 3

FILTERS - Section 4 ...................................................................................... 6

EXTERNAL TRIGGER MODE - Section 5 ...................................................... 6

SET POINTS - Section 6................................................................................ 7

AVERAGE MODE - Section 7......................................................................... 7

GAUGE CONTROL LANGUAGE - Section 8.................................................. 8

OUTPUTS - Section 9.................................................................................. 10

RS-232 ......................................................................................... 10

Mitutoyo BCD ................................................................................ 10

Analog........................................................................................... 10

I/O connector pin diagram............................................................. 10

CALIBRATION - Section 10 ..........................................................................11

SPECIFICATIONS - Section 11 .....................................................................11

General..........................................................................................11

Capacity x graduation .................................................................... 11

Dimensions.................................................................................. 12

WARRANTY - Section 12............................................................................. 12

OTHER FORCE GAUGES BY MARK-10...................................................... 13

TEST STANDS BY MARK-10 ....................................................................... 14

User's Guide

14

TEST STANDS BY MARK-10

Force, Torque, Manual, and Motorized,

up to 1,000 lb and 100 lbin

Page 3

GENERAL

Controls

Six keys on the front panel are used for all functions and control of the instrument.

Some have more than one function, depending on the mode of operation. The main

functions are labeled above the keys and the secondary functions are below the keys

in smaller type. In the list below the secondary functions are in parenthesis. For a

detailed description of the secondary functions see Section 3.

POWER (ENTER) Turns power on and off

UNITS ( ) Selects units of measurement

ZERO ( ) Zeroes any tare value (up to the full capacity of the

instrument) and clears the peak readings

DATA Initiates a data transmission sequence

MODE (ADVANCE) Switches the display between normal and peak modes

of operation

CLEAR (ESCAPE) Clears peak readings from memory

Section 1

User's Guide

2

Series EG

• Reversible aluminum housing for hand-held use or stand

mounting

• Three units of measurement: lb, kg, N

• Programmable initial status of units and mode of operation

• Automatic peak memory

• Push-button calibration

• Battery or AC operation with programmable automatic

shutoff

• Permanent configuration memory

• Optional RS-232, Mitutoyo and analog outputs

Series MG

• Low cost and small size

• Aluminum housing is reversible for hand-held use or test

stand mounting

• Peak memory for tensile and compressive loads

• Selectable units of measurement programmable auto shutoff

• Push-button calibration

• IPM - Intelligent Power Management system for reliable

operation

Series BG (in addition to Series EG)

• RS-232, Mitutoyo and analog outputs

• GCL – Gauge Control Language for full control of all

functions

• Automatic timed output on RS-232

• Dual set points with outputs

• General purpose I/O for external device control

• Programmable analog and digital filters

• Averaging mode for obtaining average force readings over

time

OTHER FORCE GAUGES BY MARK-10

Capacities from 0.25 lb (1 N) to 500 lb (2500 N)

Series CG

13

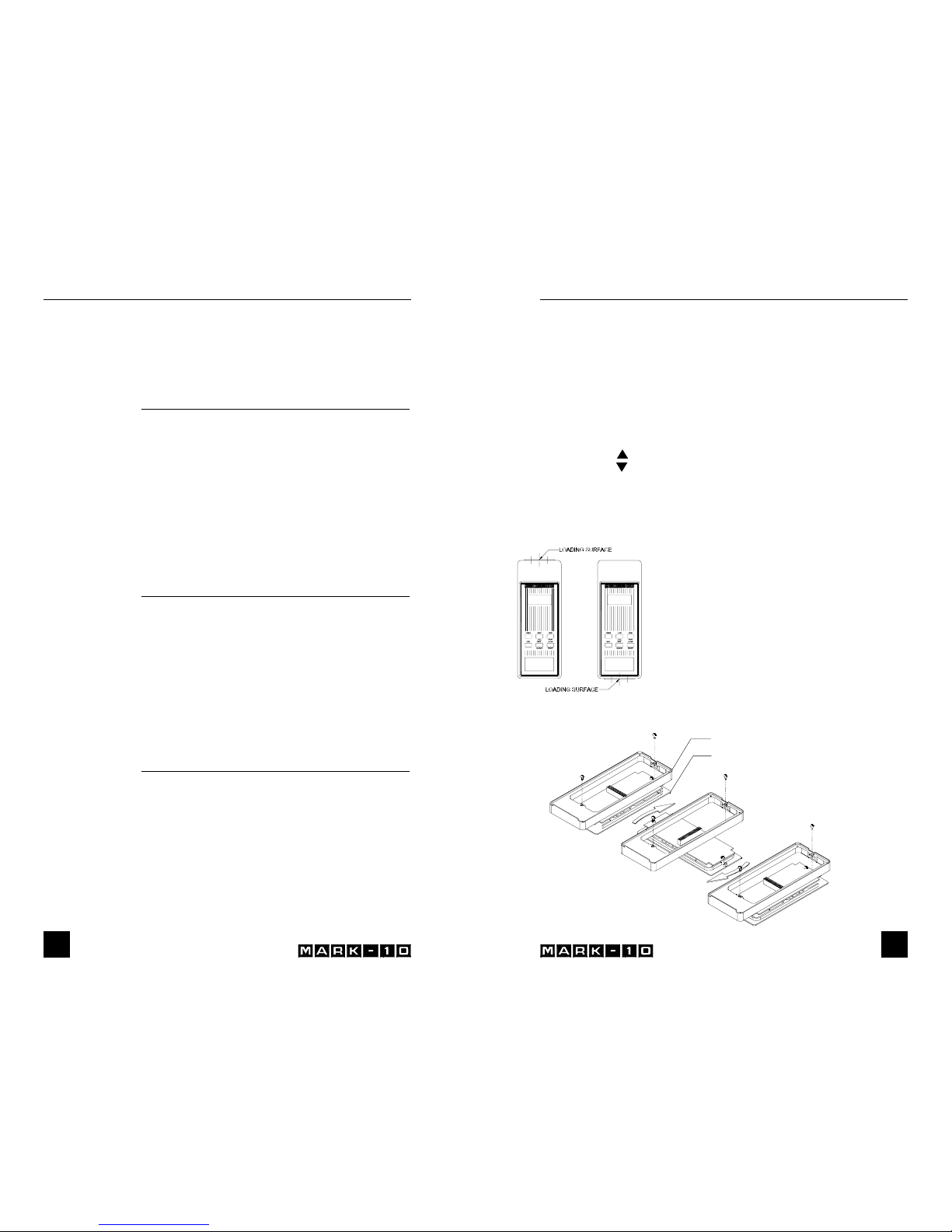

FRONT HOUSING

FRONT PANEL ASSEMBLY

Alternate orientation

(for test stand mounting, etc.)

1. Remove the four screws in the rear housing

2. Separate the front and rear housings

3. Remove the two inside screws, separating the front

housing and front panel assembly, as depicted below

4. Rotate the front panel assembly 180°

5. Reassemble the front housing and front panel assembly

6. Attach to the rear housing, and retighten the four screws

Orientation

In order to accomodate a variety of testing requirements,

the orientation of the loading surface may be set up in either

of the two positions shown below. Follow the instructions

below to change the loading surface orientation:

Upright orientation

(as supplied)

Page 4

1.87 [47.5]

2.76 [70.1]

2.650 [67.31] X2

0.55 [14.0] X2

5.300 [134.60] X2

2.350 [59.70] X2

7.45 [189.2]

0.70 [17.8]

0.500 [12.70]

1.40 [35.6]

1.000 [25.40]

2.00 [50.8]0.96 [24.4]

0.05 [1.2]

Mounting

POWER

The gauge is powered by a 7.2-volt NiCd rechargeable battery. Since batteries are subject to

self-discharge, it may be necessary to recharge the unit after a prolonged period of storage.

Plug the accompanying charger into the AC outlet and insert the charger plug into the receptacle on the gauge. The gauge may be operated for 8-10 hours after approximately 16-18

hours of charging. Do not use chargers other than supplied or instrument damage

may occur.

There are three levels of low battery voltage indication. At the first level, the display shows a

steady "LO BAT" indicating approximately one hour of charge remaining. The second level is

indicated by a flashing "LO BAT". At the third level, the whole display except the "LO BAT"

indicator will flash for three seconds after which time the gauge will turn itself off. This

prevents the instrument from working at voltages too low for reliable operation.

CONFIGURA TION

Series CG gauges have several features with programmable options allowing many userspecified choices. In order to access the configuration menu, perform the following:

1. Turn off the gauge

2. Press and hold MODE

3. Turn on the gauge

4. Release MODE

Gauge shown mounted

on a Model TSF test stand

Section 2

Section 3

Series CG

3

Dimensions

in [mm]

WARRANTY Section 12

Mark-10 Corporation expressly warrants to its buyer for one year from the date of

delivery that the goods sold are free from defects in workmanship and materials.

Mark-10 Corporation will, at its option, repair or replace or refund the purchased price

of goods found to be defective. This remedy shall be the buyer's sole and exclusive

remedy. Any modification, abuse, exposure to corrosive environment or use other than

intended will void this warranty. This warranty is in lieu of all other warranties,

including implied warranties of merchantability and fitness for an intended purpose. In

no event shall Mark-10 Corporation be liable for any incidental and consequential

damages in connection with goods sold or any part thereof.

User's Guide

12

To mount the gauge to a Mark-10 test stand, line up the 1/4" hole in the gauge's housing with

the protruding dowel pin in the gauge plate. Then, fasten four thumb screws through the

gauge plate into the gauge housing.

Page 5

The software version number will be displayed for a short time followed by "FLtA".

The following secondary functions of keys are used during the configuration process.

ADVANCE Step through menu choices

ENTER Select a menu choice

ESCAPE Quit any function (no change)

& Increment or decrement displayed values

The following list shows all configuration options. Italics indicate factory settings.

FLtA - Analog filter

FA 0 2.5 Hz RC filter disabled

FA 1 2.5 Hz RC filter enabled

FLTd - Digit al filters

FC 1 No filtering of current (displayed) readings

FC 2 Average of 2 samples for each reading

FC 4 Average of 4 samples for each reading

FC 8 Average of 8 samples for each reading

FP 1 No filtering of peak readings

FP 2 Average of 2 samples for each peak reading

FP 4 Average of 4 samples for each peak reading

FP 8 Average of 8 samples for each peak reading

232 - RS-232 settings

232D Output disabled

232E Output Enabled

300 300 baud

600 600 baud

1,200 1,200 baud

2,400 2,400 baud

4,800 4,800 baud

9,600 9,600 baud

7-1E 7 data bits, 1 stop bit, even parity

7-1o 7 data bits, 1 stop bit, odd parity

7-2E 7 data bits, 2 stop bits, even parity

7-2o 7 data bits, 2 stop bits, odd parity

7-2n 7 data bits, 2 stop bits, no parity

8-1E 8 data bits, 1 stop bit, even parity

8-1o 8 data bits, 1 stop bit, odd parity

8-1n 8 data bits, 1 stop bit, no parity

8-2n 8 data bits, 2 stop bits, no parity

Ft F Full data (numeric + units)

Ft n Numeric data only

User's Guide

4

CALIBRA TION

Mount the gauge firmly with the loading surface directed downward. Go into the

configuration mode as described in the previous section and select the calibration submenu by pressing ENTER three times when the display shows 'CAL'. After the display

shows 'null' press ZERO, while insuring that there is no weight on the loading surface

other than the weight of the required attachments (hooks, etc.). The next displayed

prompt is 'SPAn' at which time apply the exact weight equal to the full capacity of the

gauge in pounds and press ENTER. A successful calibration procedure is indicated by

'donE' on the display. Press ENTER to save the new calibration data and to return to

normal operation. In some cases the display will show 'nnnn' or 'uuuu' to indicate

excessive or insufficient calibration weight. This can be caused by incorrect weights,

tare weight of over 10% of the full capacity of the gauge or an overloaded sensor. The

calibration procedure may be aborted without changing the previous calibration

information at any time by pressing ESCAPE.

SPECIFICATIONS Section 11

General

Accuracy ±0.2% of full scale, ±1 count

Tare capacity 110% of capacity. Display shows "----" at 110%

Overload capacity 150% of capacity. Display shows "----" at 110%

Sampling rate 65 samples per second

Display update 2.5-10 times per second in normal mode, depending on

filter settings. 65 times per second in peak mode

Display 4-1/2-character LCD 0.3" [7.6 mm] high

Load cell deflection Maximum 0.010" [0.25 mm] at full scale

Outputs

RS-232 Baud rates between 300 and 9600

Mitutoyo S tandard Mitutoyo SPC BCD output

Analog ±1 VDC ±0.25% FS

Connector 9-pin D-type male

Power 7.2 NiCd battery or included AC adapter/charger

Battery life 8-10 hours per charge

Weight 1.8 lbs [0.8 kg]

Capacity x graduation

CG500 500.0 x 0.2 lbF 250.0 x 0.1 kgF 2500 x 1 N

CG1000 1000.0 x 0.5 lbF 500.0 x 0.2 kgF 5000 x 2 N

Section 10

Series CG

11

Page 6

out - Outputs selection (other than RS-232)

SP d Set point outputs disabled

SP E Set point outputs enabled

bcd d Mitutoyo BCD output disabled

bcd E Mitutoyo BCD output enabled

nPOL Mitutoyo readings without polarity (absolute value)

POL Mitutoyo readings with polarity; positive for compression, negative for

tension

Et d External trigger disabled

Et E External trigger enabled in edge mode

Et L External trigger enabled in level mode

EtHL Data capture during high to low transition of trigger signal

EtLH Data capture during low to high transition of trigger signal

Aout - Automatic output (RS-232)

no Automatic output disabled

1 Every sample transmitted

2 Every 2nd sample transmitted

4 Every 4th sample transmitted

8 Every 8th sample transmitted

16 Every 16th sample transmitted

32 Every 32nd sample transmitted

64 Every 64th sample transmitted

128 Every 128th sample transmitted

AoFF - Automatic shutoff settings

no Disabled

1 1-minute automatic shutoff

5 5-minute automatic shutoff

10 10-minute automatic shutoff

20 20-minute automatic shutoff

30 30-minute automatic shutoff

init - Initial (default) settings

LB Pounds as default units

KG Kilograms as default units

N Newtons as default units

A Average mode at turn on

EtE/EtL External trigger mode at turn on

TC Real time display at turn on

PEAK T Peak tension display at turn on

PEAK C Peak compression display at turn on

A - Average mode settings

A E Average mode enabled

A d Average mode disabled

dEL Initial delay prompt

At Average time prompt

trF Trigger force value prompt

CAL - Calibration. See Section 10.

Series CG

5

OUTPUTS

RS-232

The data transmission can be initiated by pressing the DATA key or by an external

device by sending ASCII "?" to the gauge. The gauge will respond by sending the

current reading in either full or numeric format, depending on the configuration settings

(see Section 3). Polarity sign indicates tensile (-) or compressive (+) forces. The

transmitted string has the following format:

[POLARITY (SPACE OR -)][DA T A][SP ACE][UNITS (IF ENABLED)][CRLF]

The display will flash "Err" and no data will be transmitted if DATA is pressed during

the average computation while in the Average mode or during the input scanning in the

External trigger mode.

Mitutoyo BCD

This output is useful for connection to data collectors, printers, multiplexers or any

other device capable of accepting Mitutoyo BCD data. The transmission is initiated by

the

DATA key or by the receiving device (see Section 3 for settings).

Analog

This output can be used for chart recorders, oscilloscopes, data acquisition systems,

or any other compatible devices with analog inputs. The output produces ±1 volt at full

scale of the instrument. The polarity of the signal is positive for compression and

negative for tension.

1 RS-232 receive Input

2 RS-232 transmit Output

3 Mitutoyo request Input

External trigger "

Input bit 3 "

4 Mitutoyo clock Output

"Within" set point output "

Output bit 2 "

5 Signal ground --6 +Analog signal Output

7 +12V DC Output

8 Mitutoyo ready Output

"Under" set point output "

Output bit 1 "

9 Mitutoyo data Output

"Over" set point output "

Output bit 0 "

Section 9

I/O connector pin diagram

7

DB-9P

6

1298345

User's Guide

10

Page 7

FILTERS

For maximum flexibility in noise suppression and peak capturing ability of the instrument, there are two types of filters available to the user: analog and digital.

The analog filter is a simple RC network with a cutoff frequency of 2.5 Hz and

attenuation of 20 dB/decade. It can be either turned on or off.

The digital filter utilizes the moving average technique in which consecutive readings

are "pushed" through a buffer and the displayed reading is the average of the buffer

contents. By varying the length of the buffer, a variable smoothing effect can be

achieved. The CG is equipped with a buffer which can hold up to eight readings. The

number of readings to be averaged can be set to 1,2,4 or 8. The selection of 1 will

disable the filter since the average of a single value is the value itself.

The analog and the digital filters should be disabled or set to their minimum acceptable values for highest peak capture speed.

EXTERNAL TRIGGER MODE

This mode of operation is useful for measuring electrical contact activation force as

well as synchronization of multiple instruments for a "snap-shot" view of applied

forces. When this mode is enabled through the configuration menu (see Section 3),

the MODE key will sequence through an additional state which is indicated by the

flashing "C" or "T" indicator.

When in this mode, the instrument stops updating the display when the trigger signal is

applied. It is possible to capture the reading with a normally open contact (high to low

transition of the trigger signal) or a

normally closed contact (low to high

transition).

The display will show the captured

reading until ZERO or CLEAR is

pressed if the "edge" mode is set.

The "level" mode provides for the

display to hold the reading only until

the trigger signal returns to its

original state.

Please refer to the diagram for

connection details and to Section 3

for configuration information.

USER - SUPPLIED

SWITCH UNDER TEST

47K

+5V

GND

TRIG

3

5

GAUGE

Section 4

Section 5

User's Guide

6

FULL RS-232 transmission with units

NUM RS-232 transmission without units (only numeric values)

MIT Enable Mitutoyo output

MITD Disable Mitutoyo output

POL Mitutoyo outputs with polarity. (+ for compression, - for tension)

NPOL Mitutoyo outputs without polarity (absolute value)

PM Print/send data to a Mitutoyo compatible device

Sn Set output bit (open collector, pull to ground). n=0,1,2

Cn Clear output bit. n=0,1,2

Rn Read current status of output bit or level of input pin. n=0,1,2,3

SAVE Save current settings in nonvolatile memory

CAL Enter Calibration mode. See Section 10 for more information

LIST L i s t c ur r e n t s e t t in g s a n d s t a tu s . H e r e i s a t y p i c a l L I ST o utput:

V3.00;LB;PC;FLTC8;FLTP1;FLTA1;AOUT00;AOFF05;FULL;MIT;POL;B0

All fields are separated by ";". The first field shows the software version,

the last field shows the remaining battery power (B0=full charge,

B3=minimum power). All other fields show the status of settings and fea

tures using the same abbreviations as the commands to set them.

Any detected errors are reported back by means of the following error codes.

*10 Illegal command

*11 Not applicable; e.g. SPHn command without enabling the set points

*21 Invalid specifier; e.g. AOFF2

*22 Value too large

*30 Calibration weight too high

*31 Calibration weight too low

*50 Communication error

*51 Command string too long

Following is a sample BASIC program illustrating the use of some commands. It switches

the units to kilograms and sets the display to zero. Press any key to get a reading on the

screen. Use "ESC" to exit the program.

10 CLS: OPEN "COM1:9600,N,8,1,RS,CS,DS,CD,LF" AS #1

20 PRINT #1 "KG"

30 PRINT #1 "Z"

40 PRINT "PRESS ANY KEY FOR READING OR <ESC> T O EXIT"

50 KEYPRS$=INKEY$: IF KEYPRS$="" THEN 50

60 IF KEYPRS$=CHR$(27) THEN SYSTEM

70 PRINT #1 "?"

80 LINE INPUT #1,A$

90 PRINT A$

100 GOTO 40

Series CG

9

Page 8

SET POINTS

This feature is useful for tolerance checking (GO/NO GO) or alarm indication in process

control applications. Two limits, high and low, are specified and stored in the nonvolatile memory of the instrument and all readings are compared to these limits. The

results of the comparisons are indicated through the three open-collector outputs

provided on the 9-pin connector, thus

providing "under", "in range" and "over"

signaling. These outputs can be

connected to indicators, buzzers or

relays as required for the application.

After the Set Point mode is enabled

through the configuration menu (see

Section 3), pressing the MODE key will

sequence through an additional step

indicated by "SP" on the display. To enter

or change the values of the set points

press ENTER. The high set point is

displayed. Use the and keys to increase or decrease the value and MODE for

changing between tension and compression. When the desired value is displayed,

press ENTER and repeat the above steps for the low set point. After entering both

values "donE" will appear on the display. Press ENTER to store the changes or ESCAPE

to quit. In either case "SP" will appear on the display and the ENTER key may be used

for re-entering the set point change mode or the MODE key for proceeding with the

normal operation of the gauge.

AVERAGE MODE

This mode is used for obtaining an average force reading over a specified period of

time. Applications include measurement of peel force, muscle strength, frictional force

and any other tests requiring time-averaged readings. There are three user-programmable parameters associated with this mode: trigger force, initial delay and average

time. The programming of these

parameters and the enabling of the

Average mode are done during the

gauge setup. Please refer to the

"Configuration" section for more

information.

Press MODE until "A" is displayed

and then CLEAR or ZERO to begin

testing. The process of averaging

begins as soon as the programmed

trigger force is reached and is

indicated by a flashing "A". The

conclusion of the test is indicated

by an alternating "A" and the calculated value. The readings obtained during the initial

delay will not be part of the average, but the peak value is stored for later recall. A new

test may be started by pressing CLEAR or ZERO.

DELAY

AVERAGE TIME

TIME

FORCE

PEAK

AVE

TRIGGER

FORCE

USER - SUPPLIED

40 ma MAX

AS ABOVE

SAME

2N3904

GAUGE

9

8

5

GND

4OUT

_

+

24V MAX

LOAD

Section 6

Section 7

Series CG

7

GAUGE CONTROL LANGUAGE

The instrument can be controlled by an external device through the RS-232 channel. The

following is a list of supported commands and their interpretations. All commands must be

terminated with a Carriage Return character (hex 0D) or with a Carriage Return/Line

Feed combination (hex 0D+0A). The gauge responses are always terminated with a

Carriage Return/Line Feed.

A Enable Average mode

AD Disable Average mode

AM Select Average mode (if enabled)

ATn Average time. n=0.1-300.0 seconds

DELn Initial delay. n=0.1-300.0 seconds

TRFn Trigger force. n=value (+ for compression, - for tension)

SP Enable Set Point mode

SP D Disable Set Point mode

SPHn High set point. n=value (+ for compression, - for tension)

SPLn Low set point. n=value (+ for compression, - for tension)

AOFFn Auto-shutoff. n=0,1,5,10,20,30 minutes. 0=always on

AOUTn Auto-transmit every nth reading. n=0,1,2,4,8,16,32,64,128. 0=disabled

LB Switch units to pounds

KG Switch units to kilograms

N Switch units to Newtons

G Switch units grams

E T Enable External trigger mode

ETD Disable External trigger mode

ET E Edge triggered External trigger mode

ETL Level triggered External trigger mode

HL Reading captured on a high to low transition

LH Reading captured on a low to high transition

CUR Current mode (real time display)

P T Peak Tension mode

P C Peak Compression mode

CLR Clear peaks, start a new average, or external trigger test

Z Zero display and perform the CLR function

? Request the displayed reading

?C Request the current reading

?PT Request the peak tension reading

?PC Request the peak compression reading

?ET Request the reading obtained during the External trigger mode

?A Request the average reading obtained during the Average mode

FLTCn Digital filter for current (displayed readings). n=1,2,4,8

FLTPn Digital filter for peak readings. n=1,2,4,8

FLTAn Analog filter (2.5 Hz). n=1,2. 1=on, 0=off

Section 8

User's Guide

8

Loading...

Loading...