Page 1

Page 2

02

Page 3

ACCEPTABLE VENT PRODUCTS

START UP AND TESTING

INITIAL START UP

REFERENCE

SYSTEM SPECIFICATIONS

DIMENSIONS

NAMES OF MAJOR PARTS AND COMPONENTS

TEMPERATURE INCREASE CHART

CUSTOMER SERVICE

OTHER PRODUCTS

45

45

46

47

50

51

53

53

54

55

WARNING: If the information in these instructions is not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.Do not

store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

WHAT TO DO IF YOU SMELL GAS:

- Do not try to light any appliance.

- Do not touch any electrical switch; do not use any phone in your building.

- Immediately call your gas supplier from a neighbor's phone.

- Follow the gas supplier's instructions.

- If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency

or the gas supplier.

- Water heater for other than recreational vehicle installation only.

IMPORTANT WARNING! There is water contained in the coils of your water heater

at all times. If your water heater is exposed to freezing temperatures, the water in the

coils could freeze, causing a break in the heat exchanger of the unit, or the supply

and return lines. This kind of damage will result in water running freely into the space

where the water heater is located, with can cause flooding. If your water heater is

installed in a geographic location that sees very low sustained temperatures, you

MUST install a backflow preventer on your heater's vent pipe. This will ensure that

cold air cannot fall down into the water heater and cause freezing damage. DO NOT

install this water heater where it may be subjected to a freeze. If your water heater is

in an area where freezing is a possibility, you must turn off the water to the heater

and drain it of any water by using the valve stem at the bottom of the unit and

disconnecting the warm water line. Leave the valve stem and the warm water line

disconnected until you intend to use the water heater.

Thank you for purchasing a GA16ETL Gas Tankless Water Heater. In order to

ensure proper installation, safe operation, and long life, please carefully read these

instructions. Installation should only be completed by licensed professionals. The

use of professionals ensures the installation is in full compliance with all required

building, plumbing and electrical codes.

KEEP THIS MANUAL for future reference. This booklet includes useful information

about the product, maintenance requirements and the details of your product

warranty.

0504

Page 4

READ AND FOLLOW ALL INSTRUCTIONS.

When using this equipment, basic precautions should always be followed.

Safety Definitions

This symbol is the safety alert symbol which is used to alert you to

potential hazards that can kill or hurt you and/or others.

Indicates an imminently hazardous situation which if not avoided will

result in death or serious injury.

Indicates a potentially hazardous situation which if not avoided

could result in death or serious injury.

Indicates a potentially hazardous situation which if not avoided

could result in minor or moderate injury. It may also be used to alert

against unsafe practices.

- This heater is designed only for the heating of water and should not be used for

other applications or used to heat any other media.

- Never use a fuel gas that is not listed on the nameplate as compatible with the

water heater. Abnormal combustion or a deflagration may occur which can cause a

serious accident including damage to the heater.

- Do not use this appliance if any part has been under water. Consult a qualified

service technician to inspect the appliance and make any required repairs prior to

installation and operation.

- This water heater is designed for indoor mounting. Never mount it outdoors.

- This equipment should be installed in an area where water leakage from the unit or

connections will not result in damage.The manufacturer is not responsible for any

damages resulting from leaks.

- Only connect gas and water as instructed. Incorrect or reversed connections will

cause equipment damage.

- Do not over tighten connections or equipment may be damaged.

DO NOT use a fuel gas that is not listed on the nameplate as

compatible with the water heater. Abnormal combustion or a

deflagration may occur which can cause a serious accident.

DO NOT use the unit if the vent piping has been damaged or

altered in any way including cracking, separation, rusting,

melting, etc. Improper venting may cause a buildup of Carbon

Monoxide (CO) which can cause brain damage or death.

·If the water heater needs to be installed, moved, or serviced only utilize licensed

professionals. The use of professionals ensures all work is in full compliance with

required building, plumbing and electrical codes.

·

- Keep the area around the appliance clear and free of flammable materials such as

cloth, wood, aerosol cans, paper, gasoline, etc.

- When using hot water for a shower or bath always check the water temperature

before entry to avoid being scalded. Obey local codes for the maximum water

temperature setting allowed. Water temperatures over 125ºF (52ºC) can cause

severe burns or death from scalds. Households with small children, disabled or

elderly persons may require a setting of 120ºF (49ºC) or lower.

- Do not install in areas that are subject to vibration.

- This equipment may not be operated without the vent pipe properly connected. The

exhaust pipe must not terminate in an area where the exhausting vapor or collecting

condensate could create a hazardous situation or cause property damage. Exhaust

gases must be vented out of the building in compliance with all building codes.

- The exhaust piping is very hot during and for a period after use. Do not touch the

pipe.

- Ensure that snow, ice or other debris does not block the inlet or exhaust pipes.

- Regular housekeeping should be done in areas around the heaters to prevent

insect intrusion and possible equipment malfunction.

- The unit should be serviced on a routine basis to ensure optimum performance.

Service needs will vary based on local water conditions including acidity, alkalinity,

hardness, etc.

- Freezing temperatures will cause damage to the heater. Install in locations where

freezing temperatures are not reached and follow procedures to drain the unit if it will

be out of service for a period of time.

0706

Page 5

- A 120 V / 60 Hz power source should be used. Fire, electrical shock or damage to

the water heater may occur if an incorrect power supply is used.

- This appliance is equipped with a three-prong grounded plug for increased

protection against electrical shock. Ensure the plug is properly inserted into a clean,

dry outlet that complies with all electrical codes. Only insert and remove the plug

using the plug head and never use a wet hand to plug or unplug the power plug.

- Any alterations to the appliance will void the warranty.

Normal Operation

This section of the manual instructs an owner on routine operating procedures and

assumes that the water heater has already been installed, tested, and approved for

operation. Initial start up requirements is detailed in the “Installation” section of this

manual.

Routine Start Up

Follow this procedure for a heater that has been out of service.

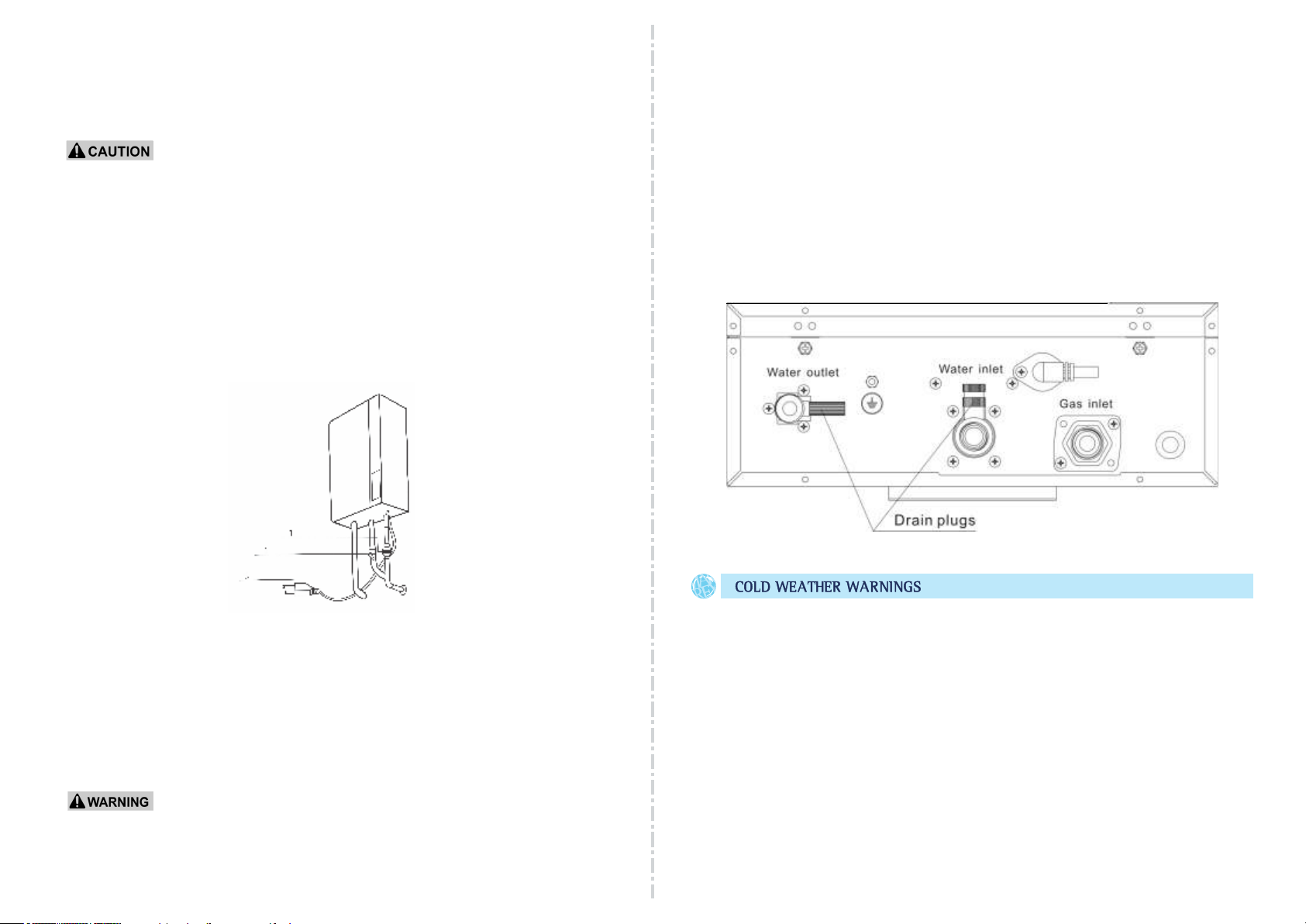

1. Ensure all drain plugs are installed in unit.

- GAS16LPETL gas tankless water heaters provide an efficient reliable supply of hot

water.

- The temperature can be adjusted between 95ºF and 149ºF (35ºC - 65ºC).

- Only a small amount of water and a low water pressure (15psi) are required for the

unit. Unit requires 0.67 gpm (2.5 l/min) to enable the unit. Unit stays in operation until

the flow drops below 0.53 gpm (2 l/min).

- The burner ignition is electronic. The unit has no pilot light and consumes no gas

when the heater is not being used.

- Air is brought into the unit from outside, efficiently burned with the appropriate

source of fuel and then exhausted externally.

- The unit's integrated control system constantly monitors the temperature of the

water being produced and adjusts the burner accordingly to deliver a stable supply

of hot water.

- The unit is highly flexible and provides hot water over a wide range of flow rates and

incoming water temperatures across the capacity range of the unit.

- GA16ETL heaters include a digital functionality that allows owners to control hot

water consumption and conserve water.

- Multiple protective functions are included such as no-load heating prevention,

automatic shutdown in case of accidental flame out, automatic pressure relief, etc.

to make the appliance both safe and reliable

2. Ensure all hot water use points (faucets, etc) are closed.

3. Open the water inlet valve.

4. Open a hot water faucet to confirm water flow and then close the faucet.

5. Open the fuel gas valve.

6. Plug in the unit, The message “CL” will be displayed indicating “Cold” state.

7. Press the “ON/OFF” key to turn on the unit.

8. Set temperature (see “Temperature Control” section of this manual).

- In the event of a disruption in operation, a failure code is displayed and an alarm

sounds an alert.

0908

Page 6

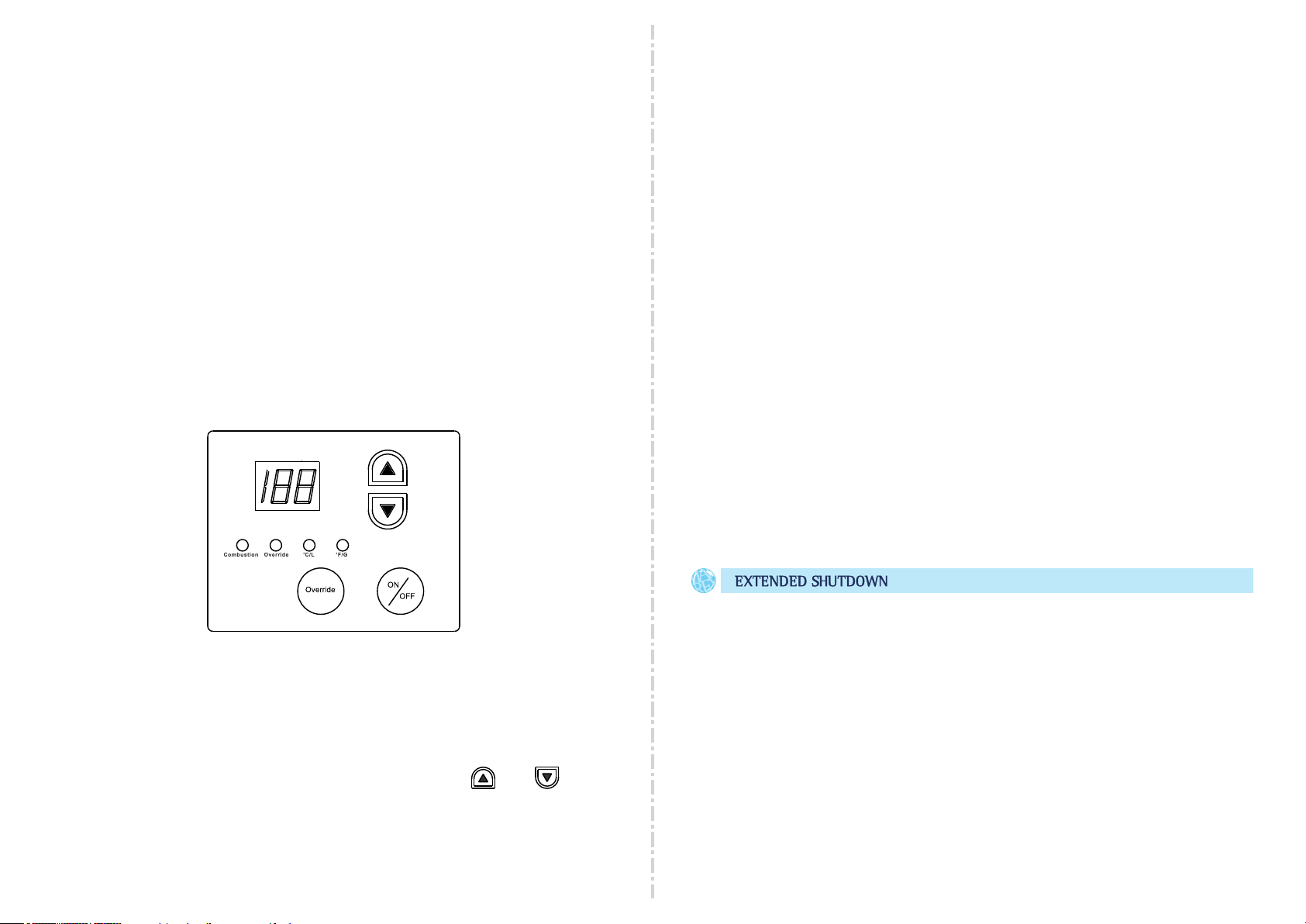

Control Panel

“Water valve” - Indicates one of the following three states:

The Control Panel and display are used to adjust the operational settings of the unit

as well as give information about the current state of operation. The following

illustration shows all possible symbols and signs that may appear in various states

of operation. In operation only the symbol or sign corresponding to the actual state

will appear on the control panel display. The water heater is in an operating state

when the hot water temperature is shown.

Failure mode displays

when a failure occurs,

When the water

temperature is above

95° F (35° C) the

lamps are lit one by

one from bottom to

top.

temperature display

mode is switched to

failure display mode.

Switch between

metric and English

units: Press and hold

the “+” and “-”keys at

the same time for

about 3 seconds.

Description of the

mode key F3 current

water quantity F4

preset water quantity

1. No light indicates water heater is operating normally.

2. Blinking: Indicates there is no water flow through the water heater or the water

flow is less than 0.66 gallons per minute (2.5 liters per minute)

3. When on and remaining lit, the firepower of the water heater is operating at either

the minimum or maximum operating point. The actual water temperature may not

reach the preset temperature. The water flow rate needs to be adjusted so the unit is

operating within its capacity range. This will allow the desired temperature to be

reached.

“ºC/L” - Indicates metric units are being displayed (degrees Celsius, liters)

“ºF/G” - Indicates English units are being displayed (degrees Fahrenheit, gallons)

“Up + / Down ” keys - Used for setting the water temperature and water quantity.

“Mode” key - Used to Set (F4) the water quantity or Display (F3) the water volume

already delivered.

“ON /OFF” key: This button enables or disables the water heater. In the “ON” mode,

the temperature set point is displayed. The factory default temperature setting is

107ºF (42ºC). In the “OFF” mode, “CL” (Cold) is displayed.

TEMPERATURE CONTROL

Set the Desired Temperature

CONTROL PANEL INDICATIONS

LED display

1. Indicates the “Temperature Set Point” when blinking. Displays the “Actual

Temperature” when the display remains lit.

2. It displays both the “Preset Water Quantity” and the “Actual Water Quantity”.

“Combustion” - When lit indicates that the water heater is operating and burning gas.

1. The temperature adjustment range is 95ºF - 149ºF (35ºC – 65ºC).

2. Press the “ON/ OFF” key. The temperature display unit lights up and displays the

current temperature set point. The factory default set point is 107ºF (42ºC).

3. Press the “UP” or “DOWN” key to set any desired temperature between 95ºF

(35ºC) and 122ºF (50ºC). The temperature set point goes up or down by one degree

with each press.

4. To set a temperature above 122ºF (50ºC): Press and hold the “UP” key

continuously for about 4 seconds until 131ºF (55ºC) is displayed.

5. Note: When the temperature is above 122ºF (50ºC), each press of the “UP

(DOWN)” key causes the temperature to go up (down) by 9ºF (5ºC).

1110

Page 7

6. When the desired temperature is set above 122ºF (50ºC), the temperature

display blinks for approximately 4 seconds before the display switches to show

actual water temperature.

3. Displayed volume: Please note that the readout indicates the water quantity

divided by ten (10). Example – if the display shows “10”, this correlates to a volume

of 10x10 = 100 gallons (English unit mode) or 100 liters (metric unit mode).

7. Along the left side of the temperature display, a series of bars indicates the level of

the temperature set point. At each 9ºF (5ºC) increment, an additional bar lights.

When the set point is above 122ºF (50ºC), the first red bar appears indicating the set

point is in a zone where a scalding hazard exists.

8. The heater will retain the temperature set point unless there is a loss of power.

9. After the temperature is set, open the water valve and observe. The “Combustion”

indicator should light indicating the unit is operating normally.

SCALD PREVENTION

- Water temperatures over 125ºF will scald and

can instantly cause severe burns or death!

- Children, disabled and elderly are at highest

risk of being scalded

- Always test the water temperature by feeling

the water prior to entering a shower, bath, etc.

- Obey all codes regarding temperature set

point. Contact a licensed plumber or local

plumbing authority for clarification or additional

information.

4. Adjust the “Volume Set Point” by pressing the “UP” or “DOWN” key briefly. Each

press corresponds to a change of 10 gallons of volume (English unit mode) or a

change of 50 liter (metric mode).

Example 1: English unit mode: The digit 7 is currently being displayed. This

indicates a set point of 70 gallons. Pressing the “UP” key once changes the

set point to “8” indicating a water quantity of 8×10 = 80 gallons as the new set

point.

Example 2: Metric unit mode: The digit 25 is displayed. This indicates a set

point of 250 liters. Pressing the “UP” key once changes the display to “30”

indicating a water quantity of 30x10 = 300 liters as the new set point.

5. When the water heater is discharging water to the bathtub and the volume set

point is reached, the alarm on the remote controller will sound an alert for about 10

seconds.

Note: The output of hot water will not stop automatically.

IMPORTANT! The volume measurement only keeps track of the

water volume that passes through the water heater. For example, if hot water going

to a tub is combined with cold water, the volume computed would not be

representative of the total amount that may have filled the tub. This could lead to an

overflow or damage!

Monitoring the Volume Delivered

Press the “MODE” key. The message “F3” will be displayed. Press the “UP” (or

DOWN) key briefly. The mode will switch from temperature display mode to water

quantity display mode. The water volume already delivered is displayed. Example:

“5” = 5×10 (50L or 50G).

Set a Desired Volume

1. The volume display range is 0-250 gallons when system is set to use English units

or 0-950 liters when in metric mode.

2. Press the “MODE” key briefly to display the message “F4”, then press the “UP” (or

“DOWN”) key. The mode will switch from temperature display mode to water

quantity display mode.

Power Outage

In the event of a power outage or if the unit is unplugged, settings are restored to

their factory default values.

1312

Page 8

OPTIONAL WIRED REMOTE CONTROL PANEL (GA16ETL)

The heater may be controlled by a wired remote control (optional). The controller

can be located near a bath, shower or other location. Figure - Wired Remote Control

Panel

to the system. At any given time, one of the control panels can become the “priority”

controller. The priority controller becomes the master temperature control device for

the system. To set priority:

Method A:

Remote Control Panel Indications

“Combustion” - When lit indicates that the water heater is operating and burning gas.

“Override” - When this indicator light is on. The wired control panel can change the

temperature set point.

“ºC/L” - Indicates metric units are being displayed (degrees Celsius, liters).

“ºF/G” - Indicates English units are being displayed (degrees Fahrenheit, gallons)

Remote Control Panel Functions (GASETL)

1. Turn off the override if it is set on another controller. Press the “Override” key to

release priority. The Override indicator light will go out.

2. Select the new controller to take control. Press the “Override” key on the wired

operation panel which should have priority. The “Override” indicator will turn on and

the temperature set point may be adjusted from this controller.

Method B:

Another way to gain priority is to press the “ON/OFF” key twice on the units

operation panel. The first press will shut the unit off, which will invalidate the

Override ownership of the remote, and the second press will reactivate the unit

which will reinstall factory defaults and set the unit's panel the Override position, the

“Override” indicator will turn on. When unit is in standby, the first wired controller to

activate the unit will have priority and the Override indicator will turn on.

- Change the Temperature Set Point: First, enable “Override” or priority control for

this remote control. Adjust the temperature using the “Up” and “Down” arrows.

- The temperature may be adjusted in one degree increments between 95ºF (35ºC)

and 122ºF (50ºC).

Extended Outage Procedure

- Remote shut down: If the water heater needs to be stopped when it is operating,

press the “ON/ OFF” key. The displayed hot water temperature disappears. The

water heater has stopped operating. The “Combustion” indicating light will go out.

The water flow is not controlled by the remote. The water flow will continue until the

faucet or shower is turned off.

Switch between metric and English units: Press and hold the and keys at

the same time for about three seconds.

- Override (Priority) Control: Up to three remote control panels may be connected

14

If a heater will be out of service for an extended amount of time, use the following

procedure to protect the unit.

NOTES

- Cold air may enter the unit through the air intake or the exhaust system. Take

precaution for extended shutdowns even if unit is installed indoors in an area that

does not allow direct exposure to freezing temperatures.

- Temperatures at or below 32ºF (0ºC) can cause permanent damage the unit and/or

the piping system due to freezing.

15

Page 9

- After a power outage, all settings return to their factory default values.

The heater and water within the unit may be very hot. Allow time for

the system to cool and use caution when draining to minimize risk of

injury.

1. Shut down the water heater by pressing the “ON/OFF” button. “CL” will appear

indicating “Cold” state.

2. Close the fuel gas valve (1).

3. Unplug the power cord (3). Use dry hands. Exercise caution and only unplug by

grasping the plug head and pulling. Note, all factory settings will be restored next

time unit is re-powered.

7. Open the drain valve plugs and completely drain the water heater.

8. Continue draining to empty the whole hot water system.

Note: Freezing temperatures below 32ºF (0ºC) can cause permanent damage to

the heater and/or the piping system.

9. Reinstall the drain valve plugs and close the hot water faucets.

10. To return a unit to operation, please refer to “Routine Start Up” found in the

Operating Instructions section of this manual.

4. Close the water inlet valve. (4)

5. Open all hot water faucets.

6. Obtain an appropriate container to collect the residual water from the system.

Prevent water from being discharged on the floor to avoid damage.

Prevent water contact with any electrical source in the vicinity

Freezing Damage Potential and Precautions

Freezing temperatures can damage the water heater and/or water piping. Freezing

water expands rapidly and can create tremendous mechanical forces. Mechanical

damage and pipe ruptures can result from only brief exposure to freezing

temperatures.

For best results, completely shut down the system by following the Extended

Outage Procedure section of this manual.

In cold regions, insulating material or heat tracing can be used to protect pipes and

fittings. Please consult your dealer if necessary.

1716

Page 10

Cold Weather with Potential Freezing Temperatures

Keep water flowing through the system to guard against freezing.

Follow these steps:

1. Close the fuel gas valve.

Routine Inspection

The heater and exhaust piping will be hot during and shortly after

use. Use caution when working in the area around the

heater.

2. Turn off the power by pressing the “ON/OFF” button. “CL” will be displayed when

off.

3. Open the hot water faucet at one or more points of use (sink, upstairs bathtub,

etc.) Maintain a constant trickle. Monitor the stream of water to ensure it is still

flowing.

No Flow Due to Expected Frozen Heater

1. Close both the fuel gas valve and the water inlet valve.

2. Turn off the power switch.

3. Open a hot water faucet.

4. Open the water inlet valve now and then to check for a water flow.

5. If no flow, attempt to thaw heater by using a portable heat source such as a hair

dryer or portable electric heater.

6. Check occasionally to see if water flow has started.

7. When water flow resumes, carefully check for any signs of water leakage.

8. Resume normal operation.

To keep your water heater operating optimally please refer to the below

recommended inspection and maintenance checklists. We recommend a periodic

inspection performed by a qualified service technician. An annual inspection is

normally sufficient. Frequent visual inspections by the owner are also

recommended. Any repairs should be performed by a qualified service technician

using only factory authorized components. Contact qualified technician for

assistance.

Routine Inspection Checklist

Any flammable materials in the vicinity of the water heater or exhaust piping?

Any unusual noises coming from the heater while in operation?

Are the air intake and exhaust free from any blockage or foreign objects?

Any signs of water leaking near heater or pipes?

Any abnormal appearance to unit casing?

Any Discharge from Relief Valve?

Maintenance Checklist

Clean outside of unit and control panel.

To prevent damage, NEVER force a heater to operate while in a

frozen state. NEVER bypass any safety feature.

Warranty

Damage caused by freezing is NOT covered by Warranty.

- Use a wet cloth to remove any surface dirt. Use a dry cloth to wipe it dry.

- A very mild detergent may be used if unit is very dirty.

- Never use any petroleum based cleaners or solvents. These solvents can

damage the panel.

Check and clear Air Intake of any debris that might impede air flow.

Clean inlet water screen.

1918

Page 11

Examine venting system to insure system is clear of blockages, debris, and

damage.

Clean inside of unit by vacuuming or blowing out dust that collects in the unit.

The burner and heat exchange are sealed units and should not be opened.

Visual flame inspection

Lime scale cleaning (if required), see procedure in Maintenance Procedures

that follow.

- Four gallons of virgin food grade white vinegar or virgin food grade citric acid.

- Small inline recirculation pump capable of circulating 2 - 4 gpm (8 – 16 l/m).

- Set of hoses for connecting recirculation pump to and from the pump and the five

gallon container.

Refer to the figure on following page while performing this procedure.

1. Disconnect electrical power to the water heater.

MAINTENANCE PROCEDURES

BURNER INSPECTION AND CLEANING

1. The burner must flame evenly over the entire surface of the burner head when

operating correctly.

2. The flame should burn with a clear, blue, stable flame.

3. Presence of a yellow flame or of black deposits on the burner head indicates

cleaning and/or burner replacement should occur. THIS MUST BE DONE BY A

TRAINED SERVICE PROFESSIONAL ONLY.

BLOWER MOTOR MAINTENANCE

1. The Blower Motor is permanently lubricated and does not need periodic

lubrication.

2. If Blower Motor fails it should only be replaced by trained service professionals

only.

RELIEF VALVE DISCHARGE

If a relief valve discharges periodically, this may be due to thermal expansion in a

closed water supply system. Contact the water supplier or local plumbing inspector

on how to correct this situation. Do not plug the relief valve.

2. Close the shutoff valves V3 and V4 on both the hot water and cold water lines.

3. Connect a hose H1 form the pump outlet to the cold water line V2 into the heater.

4. Connect drain hose H2 from the hot water outlet line V1 and route into five gallon

recirculation container.

5. Pour approx. four (4) gallons of virgin, food grade, white vinegar or citric acid into

pail.

6. Place the pump suction hose H2 into the cleaning solution

LIME SCALE CLEANING PROCEDURE

Materials required:

- Five gallon container .

2120

Page 12

7. Open valves V1 and V2 into the water heater.

Trouble Possible Cause Remedy

8. Operate the pump. Circulate the cleaning solution through the water heater for at

least 45 minutes.

9. Turn off the pump.

10. Rinse the cleaning solution from the water heater by closing valve V2 and

opening valve V4, flow water through the heater and into a container or drain for at

least five minutes.

11. Close Valve V1 and Open Valve V3 this places the house back online.

12. Disconnect all hoses.

13. It is also wise to clean the water inlet screen at this time. Close Valve V3 and V4

to do so. Clean the water inlet screen and remove any debris.

14. Replace the screen and open valves V3 and V4 once more. Checks for leaks.

15. Return heater to operation by following start up instructions.

ELECTRICAL MAINTENANCE WARNINGS

Label all wires prior to disconnection when serving controls. Wiring

errors can cause improper and dangerous operation. Always verify

proper operation after servicing.

No “CL”

displaying.

There is no hot

water flow when

a hot water faucet

is opened.

Power outage.

Unit is unplugged.

No/empty fuel source.

Water valve closed.

Power outage.

Flow is too low or

became too low. (less

than 0.66 gallons per

minute (gpm) or 2.5

liters per minute (l/m).

Unit requires 120V power. Use

unit when power is restored.

Check circuit breaker and reset if

needed. Check ground fault

circuit interrupter (GFCI) if circuit

includes one and reset if

necessary.

Check power plug and ensure

properly plugged. Plug the power

plug properly.

Fuel gas valve needs to be open.

Refill source tank (if applicable).

Open the water inlet valve.

Unit requires 120V power to

operate.

Flow is below the lower limit

necessary for stable burner

operation and proper temperature control. Increase the hot

water flow to enable system.

For operating difficulties with your unit, please consult the following table for

guidance. If you need further assistance, call qualified technician. Please have

product information ready when you call including serial number, date of purchase

and error code if shown on the control panel.

Note: Please check water heater for an error code and respond according to

recommendations found in “Error Codes” portion of this manual.

Freezing

temperatures may

have frozen water in

the heater or hot

water system.

Fuel gas meter

special control

restrictions.

Distance from heater

to source is long.

See “No Flow Due to Expected

Frozen Heater” section of this

manual for procedure to thaw

unit.

Some fuel gas valves may have

special restrictions or digital

controls that use. Consult your

gas supplier and/or a service

professional for assistance.

Allow time for hot water to travel

through system to reach the point

of use.

2322

Page 13

Trouble Possible Cause Remedy

Trouble Possible Cause Remedy

Hot water is not

the right

temperature

(too hot or too

cold).

Temperature set

point was reset due

to power outage.

Temperature set

point incorrect.

Flow is beyond

capacity.

Incoming water is

too warm.

Power outage restores default

settings and custom set points

must be re-entered to unit

A remote wired controller is

controlling temperature set

point. Release override control

of this remote (see “Remote

Control Panel Functions”) or

change set point to desired

temperature with that remote.

Desired water flow is above

maximum capacity of unit.

Reduce user flows to reestablish control of temperature

If incoming water to unit is very

warm and the flow is just above

minimum requirements, the heat

generated by the burner while

operating at minimum capacity

can make the water hotter than

desired. Increase the hot water

user flow so that the burner

system can control the

temperature.

The hot water

coming appears

white and turbid.

Vent system

trouble.

“Smoke” observed

coming from

exhaust system

during cold

temperatures.

mall bubbles may

S

appear when water

is heated. Air

dissolved in water

may evolve when

water is heated.

Vent system is

restricted in some

manner.

Water vapor

produced during

combustion is

condensed in the

exhaust as the hot

gas is cooled by the

outside air.

Although the amount of heat

output from the unit is still at full

capacity, you must reduce the

user flow and operate within the

capacity range of the heater.

None. Normal operation.

Check air intake and exhaust

ducts to ensure they are not

damaged, corroded, blocked,

etc.

None. Normal operation.

Hot water flow

produced is lower

than expected.

Water source is

restricted.

Heat exchanger in

unit is scaled.

Incoming water

temperature is

colder than

expected.

Check and fully open water inlet

valve(s)

Check and clean inlet water filter

Clean heat exchanger by flushing

per maintenance procedure.

Colder than normal incoming

supply water will reduce the

amount of hot water than can be

produced.

Water leaking from

safety valve outlet.

Blower fan noise

can be heard for

some time after

operation stops.

Water system is

operating above

design pressure.

Safety valve is

damaged.

The blower is

designed to run for

30 seconds after

burner shuts off.

Consult professional for system

review.

Replace safety valve. Consult

professional as required.

None. Normal operation.

2524

Page 14

Trouble Possible Cause Remedy

Code Indication

Remedy

The volume alarm

does not sound

even though the

volume appears to

be adequate.

Units incorrect

during input

Refer to “Set a Desired

Volume” section to ensure units

(metric vs. English) and volume

(displayed volume number

represents 1/10th of the actual

total flow) is correctly set.

The volume measurement only

Measuring flow of

only hot water

instead of hot water

and cold water

combined

keeps track of the water volume

that passes through the water

heater. If hot water going to a tub

is combined with cold water, the

volume computed would not be

representative of the total

amount that may have been

dispensed.

Unresolved

problem.

Other assistance

required.

Consult qualified technician or

contact an authorized service

professional.

Whenever a failure occurs, an alert sounds and a

diagnostic code is displayed to indicate the failure mode

at the time of occurrence.

The following table includes a list of diagnostic codes that

can be displayed as well as recommended remedies to

address the problem.

Combustion

UP

Water

valve

o

C L

DOWN

E0 Blower system problem

occurred.

1. The blower jammed or

stopped operating because of a

foreign object.

2. The blower fan suffered a

1. Check to see if fan turns freely.

Remove any foreign objects

jamming the fan.

2. Replace the blower fan.

mechanical breakdown.

3. The fan power control module

3. Replace the control module.

has broken down.

4. Wiring harness or wiring

4. Reconnect as required.

connection somewhere in fan

connection has come loose.

E1 Outlet water temperature

sensor error.

1. The sensor plug has come

1. Plug in the element properly.

loose or failed to connect

properly to the circuit board.

2. The sensor broke down (A

2. Replace the temperature sensor.

short circuit, open circuit, or

accidental contact with the

casing occurred.)

3.The circuit board of the

3. Replace the controller

controller malfunctioned.

o

F G

4. Sensor is scaled

4. Clean sensor

Control Panel Example - Displaying Error Code E2

ONOFF

E2 Flame detection error.

1. The detection circuitry for

ignition and flame detection has

come loose or failed to

connect.

1. Connect the relevant circuit

properly and eliminate the bad

connection.

Replace any failed circuit elements.

2726

Page 15

Code

Indication Remedy

Code Indication

Remedy

2.Ignition sequence was

unsuccessful.

3.An accidental flameout

occurred.

4.The ignition and flame

detection circuitry malfunctioned

or broke down. Igniter is not

activating.

5. Wrong gas type is used.

E3

E4 High temperature automatic

Inlet water temperature

sensor problem.

Same possible causes

described in Section E1.

shutdown.

2. Check fuel gas supply (especially

when first installed as air pockets

might exist in the gas line. Retry the

ignition process several times).

3. Check if the fuel gas pressure is

too high or too low

4. Replace or repair igniter or flame

detection system.

5.Check the gas type, if the gas type

that the building is supplied with is

not the one indicated in rating plate

on unit, contact the dealer for the

proper unit to match the gas type

Same troubleshooting methods

described in E1.

sudden event such as

excessively low pressure in

water supply or excessively high

gas supply pressure.

2. The temperature controller or

the high temperature fusible

protection wire has separated.

E6 Solenoid valve error.

1. The wiring is loose or a bad

connection occurred.

2. The solenoid valve is faulty.

3. Controller has failed.

E8 Exhaust system error.

1. Wiring harness or wiring

connection somewhere in air

pressure switch connection has

come loose.

2. Replace the fusible protection

wire.

1. Mount plug-in wiring properly and

replace bad elements.

2. Replace solenoid valve.

3. Repair or replace the controller.

1. Plug the plug-in element in place,

or replace the bad element.

For ten (10) seconds a water

temperature above 185ºF

(85ºC) was detected. The

controller has automatically

closed the electromagnetic

valve and unit shut down.

E5 Overheating occurred

1. Overheating occurred.

Possible causes include

operating at a very high load for

a long period and then there is a

Normal safety precaution to protect

against a rare occurrence in which

unit is enabled and then the water

flow is dramatically reduced

causing a small slug of very hot

water.

1. Normal system function. This

should be a very infrequent event.

Correct gas or water supply issues

if there are frequent reoccurrence.

2. Exhaust(air intake) ducts is

jammed.

3. The pressure vent is jammed.

4. The wind pressure switch is

damaged.

5. Too many elbows or too long

vent pipes caused excessive

exhausting resistance.

2.Replace and/or clean Exhaust(air

intake) ducts.

3. Replace and/or clean the vent.

4.Replace the wind pressure

switch.

5.Choose proper location for

terminal installation, and follow the

instruction about Max Vent length to

choose right number of elbows and

length of total vent pipes.

2928

Page 16

Only properly qualified personnel should install this equipment. Improper

installation or installation by a non-qualified installer may void warranty. Failure to

comply with state and local codes pertaining to water heater installations may void

also warranty.

GA16ETL water heaters are suitable for installation as a single standalone unit or in

installations involving combinations of multiple units (i.e. parallel or series). These

guidelines are for the installation of a single unit. Please contact authorized service

center for multiple device connection assistance.

This appliance shall NOT be installed outdoors.

A qualified installer or service technician should inspect and leak test system before

use.

The installation must comply with local codes. In the absence of local codes the

National Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane

Installation Code, CSA B149.1 shall prevail.

The following contents are included. If any items are missing contact authorized

after sales service.

Item

Water Heater

Installation and Operation Manual

Expansion Bolts

Seal Ring

Self-tapping Screw

Item #

A

B

C

D

E

Quantity

1

1

5

5

4

The appliance must be electrically grounded in accordance with local codes. In the

event there are no local codes, the National Electrical Code, ANSI/NFPA 70, or the

Canadian Electrical Code, CSA C22.1 shall prevail.

Maximum inlet gas pressure must not exceed the value specified by the

manufacturer and that the minimum value listed is for purposes of input adjustment.

Disconnect the heater and the heater main gas valve from the gas supply piping

system during any pressure testing. Isolate the heater from the gas supply piping

system by closing the inlet manual shutoff valve. The gas pressure will be between

these values 3.5 in W.C. (870 Pa) 10.5 in W.C. (2610 Pa) for Natural Gas and 8.0 in

W.C. (1990 Pa) 13.0 in W.C. (3230 Pa) for Liquid Propane.

The appliance should be located in an area where water leakage of the unit or

connections will not result in damage. Take precaution by properly installing a drain

pan under the heater if required to protect area where leakage would travel.

Do not obstruct the combustion air intake or heater exhaust and ensure air intake is

not near an area that will allow chemical fumes to enter the combustion air system.

Do not use to heat pools or spas (hot tubs) that uses chemically treated water.

If a water heater is installed in a closed water supply system, special precautions are

required such as installation of a backflow preventer and allowance for thermal

expansion. Consult an authorized professional for proper installation requirements.

Expansion Anchors F 4

Vent Adaptor (AL-0303A) G 1

Vent Adaptor (AL-0303B)

A. Water Heater

B. Installation and

Operation Manual

C. Expansion Bolts

D. Seal Ring

H

E. Self-tapping Screw

F. Expansion Anchors

G. Vent Adaptor

(AL-0303A)

H. Vent Adaptor

(AL-0303B)

2

3130

Page 17

- Ventilation requirements must be considered when choosing installation location.

- Minimizing vent piping will reduce installation costs and maximize efficiency. We

recommend that a service valve kit be used for the installation as it will reduce

installation costs and make servicing the water heater easier. The Webstone

44043PR or similar service valve kit. These kits include the Service Valves, Unions,

Ball Valves and Temperature / Pressure relief valves specified in the Typical

Installation Figure above in one convenient easy to install kit.

CLEARANCE REQUIREMENTS

ADJACENT MATERIAL COMPOSITION

NON-COMBUSTIBLE COMBUSTIBLE

SIDE: 2 inches (50 mm) 2 inches (50 mm)

TOP: 2 inches (50 mm) 6 inches (300 mm)

FLOOR: 12 inches (300 mm) 12 inches (300 mm)

FRONT: 24 inches (600 mm) 24 inches(600 mm)

BACK: zero (zero) 1 inch (25 mm) fireproof

Insulating panel required.

LOCATION

Choose a location for unit installation taking into account the following guidelines.

- Unit must be installed indoors. Installation is not recommended in bathrooms,

bedrooms or occupied rooms that are normally kept closed.

- Unit should have proper clearance as indicated below including ample clearance in

front of unit for proper service access.

Installation is recommended to be at a height that will allow easy viewing and

operation of the control panel.

- Heater requires a standard three prong, 120 V /60 Hz grounded AC power outlet

within 5 feet (1.6 meters) of installation location.

- Heater requires a ½” gas supply line (12mm).

The heater MUST be installed in a vertical position with fuel gas inlet

at the bottom and exhaust vent positioned at the top. Installation in

any other orientation will result in damage and will void warranty.

1. Identify a suitable location per the “Location and Clearance Guidelines”. Ensure

that the heater will be attached in a manner that is sufficient to support the weight of

the heater in operation.

2. The system should only be mounted on a fire rated wall or piece of fire rated board

that is mounted with spacers 1/3in (10mm) off the wall and protrudes at least 4in

(100mm) beyond the sides of the water heater will have to be mounted. (Check with

local codes).

3332

Page 18

3. Measure and mark the center locations for three (3) holes according to the

installation measurements below.

Ensure compliance with applicable electrical codes during

installation including the U.S. National Electric Code (NFPA 70) or

the Canadian Electrical Code – Part 1 (CGAS C22.1) depending on

location.

1. Ensure that a properly grounded 120 V/ 60 Hz three prong outlet is available. DO

NOT PLUG IN THE UNIT UNTIL INSTALLATION IS COMPLETE, TESTED, AND

READY FOR INITIAL START UP.

Optional WIRED REMOTE CONTROL

Choose a location for the optional wired controller to be installed per the following

specifications and in compliance with all local code requirements.

1. The controller should be located out of the reach of small children.

2. Avoid installing in an area where set point can be adjusted by non-authorized

personnel.

3. Avoid locations where the controller can become wet or be splashed.

4. The cable for the temperature controller shall be 18/2 Thermostat Wire. The

maximum recommended cable length is 328' (100 m).

5. Pull wire from remote location to water heater location.

4. (For installation on Concrete or Block) Drill three each 5/16” (or 8 mm) holes at the

marked locations. Insert the supplied ¼” (6 mm) Steel expansion bolts into the

holes.

5. (For wall installation) Locate a stud and use supplied mounting screws or hollow

Wall Anchors. To use the hollow wall anchors, drill 5/16” holes at marked locations

and insert the anchors into the hole. A combination of mounting screws and anchors

is acceptable.

6. Remove the cover of water heater from carton.

7. Position the water heater into place. Fasten to the wall.

6. ENSURE POWER TO WATER HEATER IS DISCONNECTED! Remove cover

from unit.

7. Terminate wires at the Remote Control Terminals as shown threading the wire

through wire guides.

3534

Page 19

8. Attach the wires to the terminal connectors using Y shaped crimp connections or

wrap the thermostat wires around the screws then fasten the screws to secure the

terminal connectors. Inspect and insure that the Y connectors or the thermostat

wires are not touching each other.

5. Reinstall the PCB controller and replace the front cover of unit.

9. Mount controller to wall by drilling 2) 6mm holes 92mm (4") apart at installation

location, and insert the Expansion Anchors supplied.

10. Remove the panel cover from the remote base, secure remote base to wall with

(provided) screws.

11. Replace front cover.

12. Attach remote wires to the UNIT as follows:

1. Remove the front cover of unit.

2. Thread the cable through the access hole and wire bushing at bottom

cover of unit and reinsert the wire bushing into the hole.

3. Remove the PCB and lift out of unit slightly to access wire terminal screws.

4. Insert the wire into terminals ② on PCB controller and tighten using a

screw driver. If using Thermostat Wire proceed to step 5a.

Gas piping should be sized, installed, and tested only by a licensed

professional! Improper installation can result in improper equipment

performance or a hazardous situation.

1. Check the fuel gas type before installation. DO NOT connect a unit if the gas type

is not compatible. Contact your dealer for the proper unit to match the gas type.

2. Check the gas inlet pressure immediately upstream at a location provided by the

gas company. Ensure the gas pressure is within the limits shown in the

Specifications section.

3. Review the installation location taking into account all gas users on site. Calculate

the gas piping that will be required to service the installation. The gas supply line

shall be sized and installed to provide a supply of gas sufficient to meet the

maximum demand of the heater and all other gas consuming appliances at the

location.

Note: Reference the National Fuel Gas Code, NFPA 54, for proper line sizing.

4. Ensure any compound used on the threaded joints of the gas piping is compatible

with LPG/Propane or Natural Gas.

5. Use only approved materials to connect the unit to the gas line.

6. Install a manual gas valve in the gas supply line to the water heater. For best

performance the water heater should be the first user downstream from the gas

supply meter. A union can be used on the heater sized of the valve to allow for future

servicing or disconnection of the unit.

②

7. Manufacturer recommends installation of gas pressure regulator (ex. Maxitrol

325-5A or equivalent) on gas line to ensure gas pressure is at optimum level for

proper unit operation.

②

8. Purge the gas line of any debris and liquid before connection to the water heater.

9. Connect to the water heater.

10. Leak check all joints including the heater for gas tightness. Use a leak detection

solution, soap and water, or an equivalent nonflammable solution, as applicable.

3736

Page 20

Ensure any leak check solution is non-corrosive and is completely

rinsed from the piping after leak check is complete.

Corrosion of the gas piping and subsequent leaks could occur.

Never use flammable solutions or an open flame to test for gas leaks!

1. All piping, including soldering material, and components connected to this heater

shall be approved for use in potable water systems.

Install proper drainage for discharge of temperature and pressure relief valves per

local code when relief occurs and do not reduce or restrict line. Discharge line shall

be installed to allow complete drainage of both valve and line. See the page for relief

valve discharge.

Do not place a valve between the combination temperature and pressure relief

valve and the water heater.

2. If the heater has ever been previously used for heating non-potable water, never

install the heater later into a potable water system.

3. The installation of manual shutoff valves, drain valves and unions are

recommended. A professional should review each installation and ensure adequate

ability to isolate, drain, and disconnect heater for service needs.

4. Connect suitable piping from water supply to the water heater. Note, water heater

connections are ½” NPT.

5. Purge the water line to remove debris and air. Debris can plug and damage the

heater.

6. Test water connections for leaks. Turn on water and purge water through the

water heater and system. Flow for 1-2 minutes. Ensure all air is eliminated.

7. After filling and flushing the system, check the inlet water filter for debris and clean

as required.

8. Consider insulation on hot water piping for energy conservation and personal

protection. Do not insulate the pressure relief valve!

This unit requires an approved temperature and pressure relief

valve. For protection against excessive temperatures and pressure,

install temperature and pressure protective equipment required by

local codes. The relief valve must be installed near the hot water

outlet and must comply with Standard for Relief Valves for Hot Water

Supply Systems, ANSI Z21.22 CSA 4.4.

Improper venting of a water heater can result in excessive levels of

Carbon Monoxide which can result in severe injury or death!

This water heater must be vented in accordance with the “Venting of

Equipment” section of ANSI Z223.1 / NFPA 54 National Fuel Gas

Code – latest versions, or in Canada, the most recent version of

CAN/CGA B149.1 Natural Gas and Propane Installation Code. In

additional, all installations must completely comply with all

applicable local building codes.Failure to comply can result in

equipment failure, fire, personal injury or death!

Use only stainless steel vent materials with this model! Plastic vent

systems are not compatible and the failure of the vent system could

result indamage, equipment failure, personal injury or death.

- For best results always minimize the length of the vent system. Keep the vent pipe

routing as short and straight as possible.

- The water heater vent must not be combined with the vent from any other gas

appliance or vent stack.

- The water heater vent must not be connected to a chimney.

- You must use vent components that are certified for use with this water heater as

indicated within this manual. Do not combine components from multiple

manufacturers.

3938

Page 21

- Air intake pipe may be ABS, PVC, galvanized steel, corrugated aluminum or other

materials acceptable to local codes.

- The heater requires a direct vent. Exhaust vent must be of AL 29-4C® Stainless

Steel vent directly to the outside of the building.

- The exhaust vent will have been tested to meet Underwriters Laboratories, Inc. to

UL 1738 and ULC-S636.

- The system must use outside air for combustion. Ensure the incoming air is not

contaminated by any potential source of fumes or chemicals.

- Avoid any dips or sags in horizontal pipe runs.

- Ensure vent piping is supported every four (4) feet (horizontal runs) or six (6) feet

(vertical runs) or in accordance with local code requirements.

The exhaust pipe must maintain adequate clearances and be insulated with a

fireproof material if it passes through walls made of flammable materials. Consult

local codes and vent pipe manufacture documentation for proper material selection

and installation requirements.

If the heater will be installed in a building that has a system that

maintains a negative pressure, it is possible for a back-draft to allow

outside air to be pulled into the heater while not in operation. This

can create a situation where freezing might occur within the heater.

Please consult a professional for a properly designed venting

solution or contact qualified technician for guidance.

AIR INTAKE PIPE ASSEMBLY

1. Drill 2 small holes at the end of the air intake pipe.

- Do not reduce the diameter of the vent piping.

- Ensure all vent connections are installed, properly connected, and sealed air tight

per manufacturer's instructions.

- Any vent pipe seams should be installed so they are oriented on the top of

horizontal pipe runs.

- Slope exhaust piping towards the exhaust terminal with a 2% slope (1/4 inch per

foot; 19 mm/ m) to ensure rain or any accumulating condensate near termination are

drained.

- A condensate collector is required for this system when there is a vertical vent

configuration. A condensate collection point should be installed on the vertical run of

piping just prior to the heater to ensure proper condensate drainage. Check with

local codes for proper disposition and handling of condensate water, an air gaped

drain is usually required and in some cases a condensate neutralization system is

also required.

- Do not store hazardous or combustible materials near the vent piping

- Ensure the air intake and vent termination points are at least 12” (300 mm) above

any possible snow accumulation level. The flows must not be impeded by snow or

debris.

- Ensure the air intake and vent termination points are at least 24” (600 mm) from

any obstruction or other objects.

2. Slide the pipe over the air intake terminal.

3. Using a level, ensure the pipe is straight up and down.

4. With self tapping screws, attach the pipe to the air intake terminal.

5. Apply a bead of silicone around the pipe and air intake terminal, ensuring an air

tight connection.

1. Use manufactures universal Adapter to connect the vent pipe to the unit.

2. Then follow the Manufactures vent pipe assembly guidelines and standard vent

pipe location selection diagram below.

4140

Page 22

Ref. Clearance Description US Install Canada InstalI

A Above grade, veranda, porch, deck, or

balcony.

B To window or door that may be opened. 12 inches (300

C Permanently closed window. * *

12 inches

(300 mm)

mm)

12 inches

(300 mm)

36 (910 mm)

THIS TABLE IS PROVIDED FOR REFERENCE ONLY.

Please consult latest version of these standards to ensure installation is in

compliance with current guidelines.

* For clearances not specified in ANS Z223.1/NFPA 54 or CSA B149.1, clearances

are in accordance with local installation codes and the requirements of the gas

supplier.

D Vertical to ventilated soffit, located

above the terminal within a horizontal

distance of 2 feet (61 cm) from the

center line of the terminal.

E

To unventilated soffit. *

F To outside corner. * *

G To inside corner. * *

H

To each side of center line extended

above meter regulator assembly.

I To service regulator vent outlet. * 36 inches

J

To non-mechanical air supply inlet to

building or the combustion air inlet to

any other appliance.

K To a mechanical air supply inlet. 3 feet (91cm)

* *

*

12 inches

(300 mm)

above if within

10 feet (3000

mm)

horizontally

*

3 feet (910

mm) within a

height 15 feet

(4.5 m) above

the meter/

regulator

assembly

(910 mm)

36 inches

(910 mm)

6 feet (1.83 m)

** A vent shall not terminate directly above a sidewalk or paved driveway that is

located between two single family dwellings and serves both dwellings.

*** Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of

two sides beneath the floor.

Maximum Vent Length

1. Determine the number of 90 degree elbows in the vent system (Two 45 degree

elbows count as one 90 degree elbow).

2. Refer to below table to find the maximum vent length based on the number of

elbows

Example: If you have one elbow, then your maximum vent length is 35ft (10.7m)

Number of 900 elbows

0 1 2 3 4 5 6

41 feet

(12.5m)

]

Vertical Terminations

35 feet

(10.7m)

29 feet

(8.8m)

23 feet

(7.0m)

17 feet

(5.2m)

11 feet

(3.4m)

5 feet

(1.5m)

L Above paved sidewalk or paved

driveway located on public property.

M Under veranda, porch, deck, or

balcony.

* 7 feet (2.13 m)

**

* 12 inches

(300 mm)

The air intake requires a return bend or tow 90º elbows to prevent entry of rain.

The vent termination and air intake must be in the same pressure zone.

4342

Page 23

Manufacture Product

Appliance

Adapter

Horizontal

Termination

Vertical

Termination

Horizontal

Concentric

Termination

Vertical

Concentric

Termination

Horizontal Terminations

The air intake must be located in relation to the exhaust as shown below.

The air intake must 1/4 inch per foot to the termination to prevent entry of rain.

Z-Flex

Hart & Cooley Model

Centrotherm

Eco System

Z-Vent

SW

InnoFlue

SW Vent

System

2SVSNA03.

5 with ALV0303B

above and

expander

2SVSIO304

Use

another AL-

V303B for

PVC air

intake

3SUTI with

AL-V0304A

above and

expander

3SI4

Alternately

use

3SANID

with

expander

3SI4 for

intake air

use AL-

V303B for

PVC air

intake

For Air

intake only

this 3 inch

system pipe

can be

used.

2SVSTPX04 2SVSRCF04

4STWP

4SRC

2SVSHTC43 NA

4STM, 4CHT,

4C12, 4CTAI

4STM, 4CVT,

4CF(A,B,C),

7SSC, 4C36,

4CRC

If the information in these instructions is not followed exactly, a fire or

explosion may result causing property damage, personal injury or

death.

4544

Page 24

Do not store or use gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

- Do not try to light any appliance.

7. If no gas is detected, proceed.

8. Open the water supply valve to the unit. Inspect for any leaks.

9. Visually inspect air intake inlet and exhaust piping to ensure they are not

obstructed.

- Do not touch any electrical switch; do not use any phone in your building.

- Immediately call your gas supplier from a neighbor's phone.

- Follow the gas supplier's instructions.

- If you cannot reach your gas supplier, call the fire department.

- This appliance does not have a pilot. A built in ignition device will automatically light

the burner. Do not try to light the burner by hand.

- Use only your hand to push in or turn the gas control knob. Never use tools. If the

knob will not push in or turn by hand, do not try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire or explosion.

- Do not use this appliance if any part has been under water. Immediately call a

qualified service technician to inspect the appliance and to replace any part of the

control system and any gas control that has been under water.

1. STOP! Read the safety information from the previous page.

2. Ensure unit is unplugged and all electric power to the appliance is off.

10. Plug in the unit. “CL” is displayed indicated “cold”.

11. Press the “ON” button to turn on the unit.

12. Adjust the temperature set point per “Temperature Control” Section of this

manual.

13. This appliance is equipped with an ignition device that automatically lights the

burner. Do not try to light the burner by hand.

14. Open a hot water tap to a flow above the minimum flow point (0.66 gpm/ 2.5

l/min).

15. The burner control system will fire the igniter, the burner will light, and hot water

will be produced.

16. If the heater will not operate, follow the shut down instructions. Wait 5 minutes

and attempt to repeat this start up procedure.

17. If system does not operate, begin troubleshooting per “Trouble Shooting”

section of this manual. Contact qualified technician for assistance.

3. Locate the manual gas valve to the heater. Open the manual gas valve for 15-30

seconds.

4. Turn the manual valve clockwise to the full OFF position.

5. Carefully check for any sign or smell of gas. If gas is detected, wait five (5) minutes

for it to clear. STOP and go no further until gas leak point is detected.

6. If no gas is detected, open the manual gas valve for five (5) minutes and again

check area for any signs of gas. At any sign of gas, STOP and go no further. Follow

the safety precautions from the previous page.

WIRING DIAGRAMS

GASETL wiring diagram (without wired remote)

4746

Page 25

GASETL wiring diagram (with wired remote)

4948

Page 26

TECHNICAL SPECIFICATIONS

Type of Appliance

Operation

Flue System

Available default Temperatures

Rated gas

pressure

Temperature Range

Width x Height x Depth

Weight

Connections

Ignition System

Max./Min. Gas

Consumption

Hot Water Delivery Capacity Max

Noise level

Thermal efficiency

NOXaf

Minimum Operating Water Flow 0.66 GPM (2.5 L/min)

Minimum Operating Pressure

Power Supply

Water temperature control

Water flow control

Safety Device

Remote Control

Cable Optional

Electrical Consumption( Normal)

Natural Gas

Propane (LPG) 11 inch W.C.(2 740Pa)

Gas

Cold Water Supply

Hot Water Supply

Natural Gas

Propane Gas

Flame Failure Flame rod

Boil dry

Over temperature

Fusible link

Pressure relief

valve

Combustion fan

rpm check

Over current

Bathroom,

Second Bathroom,

Kitchen,

(universal / Up to

3 Controllers )

GA16ETL

Temp. controlled continuous Flow Gas Hot Water Unit

With/without remote controls, mounted in kitchen,

bathroom, etc

Room Sealed-Forced Draught Flue

Factory setting 107ºF

7 inch W.C.(1 740Pa)

Within 95ºF~149ºF(35ºC~65ºC)

14" x 22" x 6" (353mm x 568mm x 142mm)

35lbs (16kg)

½ in.NPT

½ in.NPT

½ in.NPT

Direct Electronic Ignition

110,000 Btu/h-20,000 Btu/h

107,000 Btu/h-20,000 Btu/h

4.2 GPM (45ºF rise)

5.4 GPM (35ºF rise)

70 dB(A)

0.82

40 ppm Max

1.45 PSI (0.1 bar)

120 Volts ~ 60Hz

Input and output water temperature signals

Electronic Water flow sensor

Water flow sensor /194ºF thermistor

185ºF (Integrated circuit system)

320ºF Thermal Fuse

Opens 145 PSI

Integrated circuit system

Glass fuse (5 Amp/3Amp)

Kitchen/Bathroom/Second Bathroom

(universal / Up to 3 Controllers)

55W

5150

Page 27

DIM DESCRIPTION Inches (mm)

A Width 13.90 (353)

B Depth 5.59 (142)

C Height-Unit 22.37 (568.2)

D Height-with brackets 25.43 (646)

E Hot Water Outlet-from wall 2.59 (65.8)

F Hot Water Outlet-from center 5.16 (131)

G Cold Water Inlet-from wall 1.80 (45.8)

(H) Cold Water Inlet-from center 0.04 (1)

I Gas Connection-from wall 1.57 (39.8)

J Gas Connection -from center 3.15 (80)

K From base to gas valve connection 1.78 (45.2)

From base to cold water inlet

2.38 (60.4)

connection

From base to hot water outlet

1.24 (31.4)

connection

L Air intake center to gas exhaust center 3.82 (97)

M Gas exhaust center to unit center 0.75 (19)

N Air intake center to wall 2.82 (72)

Gas exhaust center to wall 3.04 (77.3)

Points

of Use

For incoming

water

temperatures

below 68ºF

For incoming

water

temperatures

above 68ºF

*Typical flow rates are based on 40 PSI to the home and faucets with standard flow restrictors. Higher PSI and

unrestricted faucets may result in higher flow rates, which may result in a maximum temperature increase of 72ºF.

**Incoming flow rates lower than 1 GPM through the water heater, or incoming water temperatures higher than 80ºF,

may result in water heating to higher than its set point. Avoid scalds!! Always test the water with your hand before using it

to be sure that cold water doesn't need to be mixed in first.

1 100 (1 GPM Typical)** 72 2.25 GPM

2 90 (.75 GPM Typical) 72 1.15 GPM

3 85 (.6 GPM Typical) 72 .75 GPM

4 80 (.5 GPM Typical) 72 .6 GPM

5 72 (.45 GPM Typical) 72 .45 GPM

1 100 (1 GPM Typical)** 72 4 GPM

2 90 (1 GPM Typical) 72 2 GPM

3 85 (1 GPM Typical) 72 1.3 GPM

4 80 (.75 GPM Typical) 72 1 GPM

5 72 (.65 GPM Typical) 72 .8 GPM

Temp. Increase at

Typical per Faucet

Flow Rate (Hot Side)*

Temp. Increase

at Max Posible

Flow Rate

Max Posible

Flow Rate per

Faucet

5352

Page 28

At Marey, we pride ourselves on the excellence of our customer service and support

team.

Please feel free to contact us if you have any questions about our products, warranty

service, or if you need assistance installing a unit. We also strive for continuous

improvement, so we welcome your comments, feedback and suggestions.

Marey proudly manufactures water heaters and accessories for use in almost any

application. Please visit our website to learn more about other Marey products.

1-855-MAREY-55

customerservice@marey.com

ECO110

GAS PORTABLE

POWER PAK

POWER GAS

ECO126

POWER GAS

16L ETL

Marey:

1924 HWY 95 North

Bastrop, TX 78602

Toll Free: 1-855-627-3955

1-855-MAREY-55

www.marey.com

5554

Loading...

Loading...