Maretron TLM150 User Manual

®®

TLM150

Gasoline Tank Level Monitor

User’s Manual

Revision 1.2

Copyright © 2010 Maretron, LLP All Rights Reserved

Maretron, LLP

9014 N. 23

Phoenix, AZ 85021

http://www.maretron.com

Maretron Manual Part #: M002301

rd

Ave #10

Revision 1.2 Page i

TLM150 User’s Manual

Revision History

Revision Description

1.0 Original document

1.1 Corrected typo in NMEA 2000 protocol PGN list

Corrected maximum depth in specification table

1.2 Added documentation on mounting locations and theory of operation

Corrected torque specifications

Added prohibition of red Loctite threadlocking compound and cleaning agents

containing acetone

Updated troubleshooting section

Updated referenced firmware version number

Typographical corrections

Page ii Revision 1.2

®®

Table of Contents

1 General ................................................................................................................................ 1

1.1 Introduction .................................................................................................................... 1

1.2 Gasoline Tanks .............................................................................................................. 1

1.3 Firmware Revision ......................................................................................................... 1

1.4 Features ........................................................................................................................ 1

1.5 TLM150 Accessories ..................................................................................................... 2

1.6 Quick Install ................................................................................................................... 2

2 Installation ............................................................................................................................ 2

2.1 Unpacking the Box ......................................................................................................... 2

2.2 Theory of Operation ....................................................................................................... 2

2.3 Choosing a Mounting Location ...................................................................................... 3

2.3.1 Effect of Pitch and Roll on the TLM150 ............................................................... 4

2.4 Mounting the TLM150 .................................................................................................... 4

2.4.1 Mounting the TLM150 Sensor Component ......................................................... 4

2.4.2 Mounting the TLM150 Interface Component ....................................................... 9

2.5 Connecting the TLM150 ................................................................................................ 9

2.5.1 Connecting to NMEA 2000® Interface ................................................................. 9

3 Configuring the TLM150 ..................................................................................................... 10

3.1 Configuring Tank Number ............................................................................................ 10

3.2 Configuring Tank Capacity .......................................................................................... 11

3.3 Tank Depth or Custom Calibration ............................................................................... 11

3.3.1 Tank Depth Programming ................................................................................. 11

3.3.2 Custom Calibration............................................................................................ 11

4 Maintenance ....................................................................................................................... 11

5 Troubleshooting ................................................................................................................. 12

6 Technical Specifications ..................................................................................................... 14

7 Technical Support .............................................................................................................. 15

8 Maretron (2 Year) Limited Warranty ................................................................................... 16

Revision 1.2 Page iii

TLM150 User’s Manual

Table of Figures

Figure 1 – TLM150 Mounting – SAE 5-Hole Bolt Pattern .......................................................... 5

Figure 2 – Mounting TLM150 to SAE 5-Hole Tank with Focus Tube ......................................... 6

Figure 3 – TLM150 Mounting With Threaded Adapter ............................................................... 7

Figure 4 – Mounting TLM150 with Focus Tube on Threaded Tank Fitting................................. 8

Figure 5 – TLM150 Connections ............................................................................................... 9

Figure 6 – NMEA 2000® Connector Face Views ..................................................................... 10

Figure 7 – Troubleshooting Guide ........................................................................................... 13

Table of Appendices

Appendix A – NMEA 2000® Interfacing .................................................................................... A1

Page iv Revision 1.2

®®

1 General

1.1 Introduction

Congratulations on your purchase of the Maretron Tank Level Monitor (TLM150). Maretron has

designed and built your monitor to the highest standards for years of reliable, dependable, and

accurate service.

The TLM150 is used to sense levels of gasoline tanks using ultrasonic technology and transmit

the gasoline levels over the NMEA 2000® network. This allows you to observe gasoline tank

levels anywhere on the vessel where there is an NMEA 2000® compatible display such as the

Maretron DSM250. The TLM150 is capable of sensing gasoline tanks up to 24” (0.61m) in

depth. It must be used only for tanks containing gasoline. Unlike most tank senders that only

work with rectangular tanks, the TLM150 can be calibrated for irregular tank shapes so you

know the true level of your tanks. The TLM150 can be mounted on tanks with a SAE J1810 5hole mounting pattern, or to tanks using 1.5” NPT or 1.25” BSP threaded openings via

available adapters. The TLM150 has an optional focus tube to allow use on boats with planing

hulls when the vessel spends a significant amount of time with the bow pitched up.

The Maretron TLM150 is designed to operate within the harsh demands of the marine

environment. However, no piece of marine electronic equipment can function properly unless

installed, calibrated, and maintained in the correct manner. Please read carefully and follow

these instructions for installation, calibration, and usage of the Maretron TLM150 in order to

ensure optimal performance.

1.2 Gasoline Tanks

The TLM150 is ONLY intended for use in tanks containing gasoline. Do not use the TLM150

in tanks containing diesel fuel, water, oil, or other liquids. Use in tanks containing other liquids

will result in inaccurate readings.

1.3 Firmware Revision

This manual corresponds to TLM150 firmware revision 1.1.5.

1.4 Features

The Maretron TLM150 has the following features:

• Transmits liquid levels over an NMEA 2000® Interface

• Integrated ultrasonic level sensor

• Can be used in tanks up to 24” (0.61m) deep

• SAE J1810 5-hole, 1.5” NPT, or 1.25” BSP Mounting

• Accommodates Irregularly Shaped Tanks with 16 Point Calibration

• Tank Type: Fuel (Gasoline only)

• Programmable Tank Number(s) Up to 16 per Tank Type

• Programmable Tank Capacity

Revision 1.2 Page 1

TLM150 User’s Manual

1.5 TLM150 Accessories

Maretron offers the following accessories for the TLM150:

• TA-5H-1.5NPT 1.5” NPT Displacement Hull Tank Adapter

• TA-5H-1.25BSP 1.25” BSP Displacement Hull Tank Adapter

• TFT-5H SAE 5-Bolt Pattern Non-Displacement Hull Focus Tube

• TFT-1.5NPT 1.5” NPT Non-Displacement Hull Focus Tube

• TFT-1.25BSP 1.25” BSP Non-Displacement Hull Focus Tube

1.6 Quick Install

Installing the Maretron TLM150 involves the following steps. Please refer to the individual

sections for additional details.

1. Unpack the Box (Section 2.1)

2. Choose a Mounting Location (Section 0)

3. Mount the TLM150 (Section 2.4)

4. Connect the TLM150 (Section 2.5)

5. Configure or Program the Tank Number (Section 3.1)

6. Configure or Program Tank Capacity (Section 3.2)

7. Configure for Tank Depth and Shape

o Configure or Program the Tank Depth (Section 3.3.1)

o Custom Calibration (Section 3.3.2)

2 Installation

2.1 Unpacking the Box

When unpacking the box containing the Maretron TLM150, you should find the following items:

• 1 – TLM150 Tank Level Monitor

• 1 – TLM150 Gasket

• 1 – TLM150 User’s Manual

• 1 – Warranty Registration Card

If any of these items are missing or damaged, please contact Maretron.

2.2 Theory of Operation

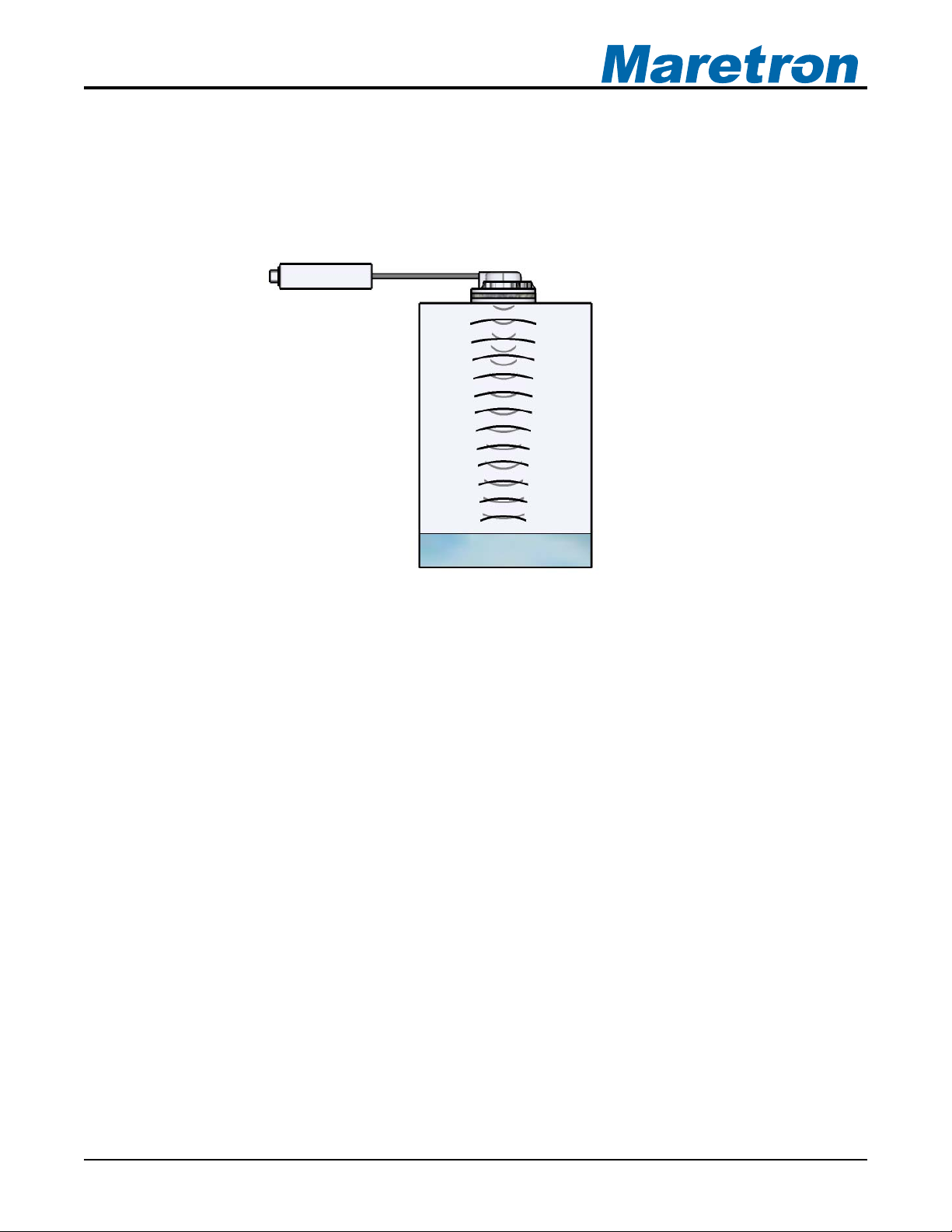

The TLM150 operates by directing a pulse of ultrasonic sound from the sensor component at

the top of the tank down to the surface of the liquid in the tank. The TLM150 then measures

the time it takes this pulse to travel down to the surface of the liquid, be reflected back up, and

then be received back at the sensor component. Using the speed of sound, it uses this time to

calculate the distance between the face of the sensor component and the surface of the liquid

(or the tank bottom if the tank is empty). The cone width of the beam transmitted by the

Page 2 Revision 1.2

®®

TLM150 sensor component is 6°. Please refer to Figure 1 below for a diagram of the waves

emitted and received by the TLM150.

Please note that due to limitations of ultrasonic technology, the minimum depth that can be

measured by the TLM150 is 2” (5.08cm).

Figure 1 - TLM150 Operation

2.3 Choosing a Mounting Location

The primary function of the TLM150 is to sense levels of gasoline in tanks using ultrasonic

technology and transmit this information over NMEA 2000® network so that gasoline fuel tank

level information can be viewed anywhere on the vessel where there is an NMEA 2000®

compatible display.

The TLM150 tank level monitor consists of two parts: 1) the sensor, which mounts onto the top

of the tank and contains the ultrasonic level measurement components, and 2) the interface,

which converts the measured data into NMEA 2000

NMEA 2000® network.

The interface component of the TLM150 may be mounted anywhere, subject to the length of

the cable connecting it to the sensor component.

The sensor component of the TLM150 must be mounted on the tank whose level is to be

monitored. Choosing a proper mounting location for the sensor component of the TLM150 is

critical to obtaining accurate tank level readings. For best results, please follow these

recommendations:

• The sensor component of the TLM150 must be mounted flat, so that the round

transceiver portion of the TLM150 faces straight downward.

®

format and transmits the data over the

Revision 1.2 Page 3

Loading...

Loading...