Maretron LLP FFM100 User Manual

®®

FFM100

Fuel Flow Monitor

User’s Manual

Revision 1.2

Copyright © 2012 Maretron, LLP All Rights Reserved

Maretron, LLP

9014 N. 23

Phoenix, AZ 85021

http://www.maretron.com

Maretron Manual Part #: M003010

rd

Ave #10

Revision 1.2 Page i

FFM100 User’s Manual

Revision History

Revision Description

1.0 Release for Review

1.1 Public Release

1.2 Corrected formatting problems in certain figures

Added notes about tamper-proof silicone seals on sensor screws

Added information about location of sensors

Page ii Revision 1.2

®®

Table of Contents

1 General ................................................................................................................................ 1

1.1 Introduction .................................................................................................................... 1

1.2 Firmware Revision ......................................................................................................... 1

1.3 Features ........................................................................................................................ 1

1.4 FFM100 Accessories ..................................................................................................... 1

1.5 Quick Install ................................................................................................................... 1

1.6 Theory of Operation ....................................................................................................... 2

1.6.1 Operating Modes ................................................................................................ 2

1.6.2 Sensor Accuracy ................................................................................................. 2

1.6.3 Diesel Fuel Flow Measurement ........................................................................... 4

1.6.4 Temperature Compensation ............................................................................... 5

1.6.5 Fuel Flow Sensor Selection ................................................................................ 6

1.6.6 Accuracy of Diesel Fuel Flow Measurement ....................................................... 7

1.6.7 Choosing a Fluid Flow Sensor Mounting Location .............................................. 8

2 Installation ............................................................................................................................ 8

2.1 Unpacking the Box ......................................................................................................... 8

2.2 Choosing a Mounting Location ...................................................................................... 8

2.3 Mounting the FFM100 .................................................................................................... 9

2.4 Mounting the Fluid Flow Sensor .................................................................................... 9

2.5 Connecting the FFM100 ................................................................................................ 9

2.5.1 Fluid flow sensor Connections ............................................................................ 9

2.5.2 NMEA 2000® Connection .................................................................................. 10

3 Configuring the FFM100 .................................................................................................... 11

3.1 Advanced Configuration .............................................................................................. 12

3.1.1 Configuring Device Instance ............................................................................. 12

3.1.2 Configuring Channel #0 Installation Orientation ................................................ 12

3.1.3 Configuring Channel #1 Installation Orientation ................................................ 12

3.1.4 Configuring Channel #0 Allow Negative Flow ................................................... 12

3.1.5 Configuring Channel #1 Allow Negative Flow ................................................... 13

3.1.6 Configuring Differential Mode Allow Negative Flow .......................................... 13

3.1.7 Configuring Installation Description ................................................................... 13

3.1.8 Configuring NMEA 2000 PGN Enable/Disable .................................................. 13

3.1.9 Restoring Factory Default Settings ................................................................... 13

3.2 Configuring the Device Label ....................................................................................... 13

3.3 Configuring the Operating Mode .................................................................................. 13

3.4 Configuring Channel #0 ............................................................................................... 14

3.4.1 Enabling/Disabling Channel #0 ......................................................................... 14

3.4.2 Configuring Channel #0 Engine Instance .......................................................... 14

3.4.3 Configuring Channel #0 Engine Label............................................................... 14

3.4.4 Configuring Channel #0 K-factor ....................................................................... 14

3.4.5 Configuring Channel #0 Data Damping Period ................................................. 14

3.4.6 Resetting the Total Volume Recorded for Channel #0 ...................................... 14

3.4.7 Configuring Channel #0 Temperature Instance ................................................ 14

3.4.8 Configuring Channel #0 Temperature Source ................................................... 14

3.4.9 Configuring Channel #0 Temperature Label ..................................................... 15

Revision 1.2 Page iii

FFM100 User’s Manual

3.5 Configuring Channel #1 ............................................................................................... 15

3.5.1 Enabling/Disabling Channel #1 ......................................................................... 15

3.5.2 Configuring Channel #1 Engine Instance .......................................................... 15

3.5.3 Configuring Channel #1 Engine Label............................................................... 15

3.5.4 Configuring Channel #1 K-factor ....................................................................... 15

3.5.5 Configuring Channel #1 Temperature Coefficient ............................................. 15

3.5.6 Configuring Channel #1 Data Damping Period ................................................. 16

3.5.7 Resetting the Total Volume Recorded for Channel #1 ...................................... 16

3.5.8 Configuring Channel #1 Temperature Instance ................................................ 16

3.5.9 Configuring Channel #1 Temperature Source ................................................... 16

3.5.10Configuring Channel #1 Temperature Label ..................................................... 16

4 Maintenance ....................................................................................................................... 16

5 Troubleshooting ................................................................................................................. 18

6 Technical Specifications ..................................................................................................... 19

7 Technical Support .............................................................................................................. 20

8 Installation Template .......................................................................................................... 21

9 Maretron (2 Year) Limited Warranty ................................................................................... 22

Table of Figures

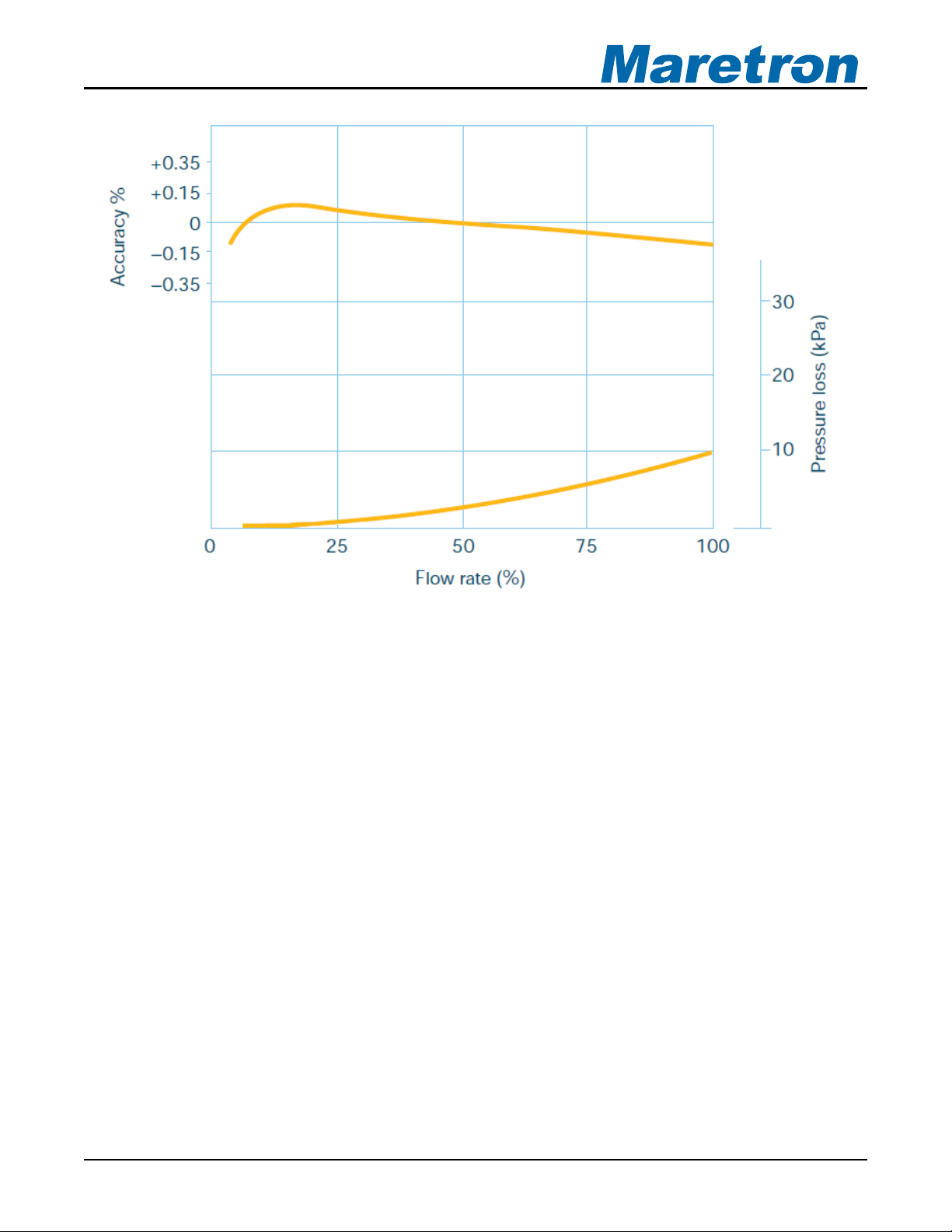

Figure 1 - M1RSP-2R-E8 and M2RSP-2R-E8 Accuracy and Pressure Loss ............................. 3

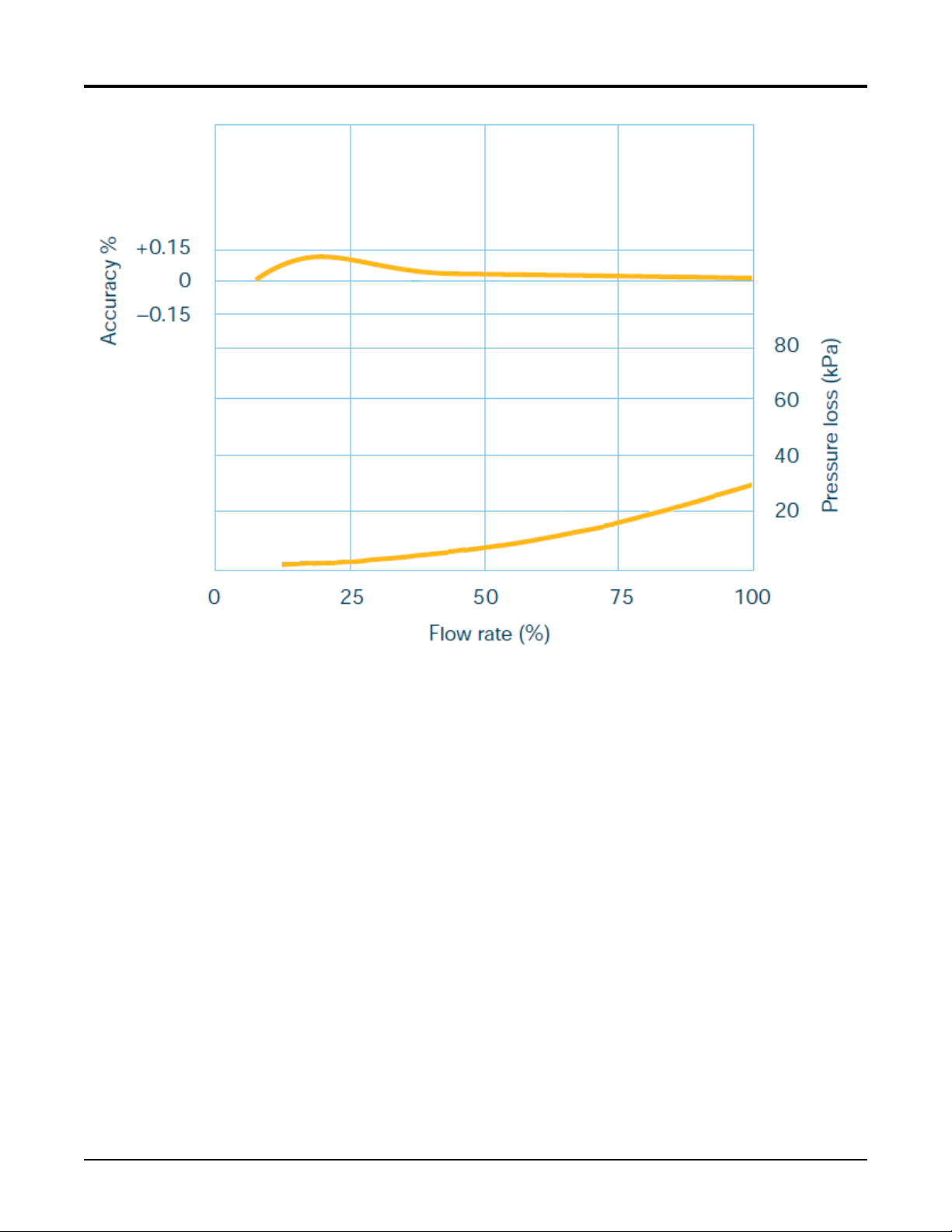

Figure 2 - M4ARP-2-E8 Typical Accuracy and Pressure Loss .................................................. 4

Figure 3 - Diesel Fuel Rate Measurement Fluid Flow Sensor Locations ................................... 5

Figure 4 – Fluid Flow Sensor Selection Chart for Diesel Engine Applications ........................... 6

Figure 5 – Mounting the FFM100 .............................................................................................. 9

Figure 6 – Fluid flow sensor Connection Diagram ................................................................... 10

Figure 7 – NMEA 2000® Connector Face Views ..................................................................... 11

Figure 8 – Troubleshooting Guide ........................................................................................... 18

Figure 9 – Mounting Surface Template ................................................................................... 21

Table of Appendices

Appendix A – NMEA 2000® Interfacing .................................................................................... A1

Page iv Revision 1.2

®®

1 General

1.1 Introduction

Congratulations on your purchase of the Maretron Fuel Flow Monitor (FFM100). Maretron has

designed and built your monitor to the highest standards for years of reliable, dependable, and

accurate service.

Maretron’s Fuel Flow Monitor (FFM100) is used to adapt up to two positive displacement fluid

flow sensors to the NMEA 2000® network (Fluid Flow sensors sold separately). This allows you

to observe engine fuel usage on a vessel where there are NMEA 2000® compatible displays.

With the appropriate sensor, the FFM100 reports flow rate for diesel engines or gasoline

engines.

The FFM100 can be used with the positive displacement sensors to detect flow rates of many

other types of fluid as well, including water, hydraulic oil, or other fluids.

The Maretron FFM100 is designed to operate within the harsh demands of the marine

environment. However, no piece of marine electronic equipment can function properly unless

installed, calibrated, and maintained in the correct manner. Please read carefully and follow

these instructions for installation, calibration, and usage of the Maretron FFM100 in order to

ensure optimal performance.

1.2 Firmware Revision

This manual corresponds to FFM100 firmware revision 1.0.1.

1.3 Features

The Maretron FFM100 has the following features:

• NMEA 2000® interface

• Adapts up to two fluid flow sensors to the NMEA 2000 network

• Each channel independently programmable to match fluid flow sensor characteristics

• The FFM100 can be programmed to measure a differential flow rate using two fluid flow

sensors (supply and return flow for diesel engines) or two completely independent flow

rates.

1.4 FFM100 Accessories

Maretron offers the following accessories for the FFM100:

• M1RSP-2R-E8 Fuel Flow Sensor 20 to 200 HP (0.53 to 26.4 GPH, 2 to 100 LPH)

• M2RSP-2R-E8 Fuel Flow Sensor 200 to 1000 HP (4 to 132 GPH, 15 To 500 LPH)

• M4ARP-2-E8 Fuel Flow Sensor 1000 to 3000 HP (48 to 396 GPH, 180 To 1500

LPH)

1.5 Quick Install

Installing the Maretron FFM100 involves the following steps. Please refer to the individual

sections for additional details.

Revision 1.2 Page 1

FFM100 User’s Manual

1. Unpack the Box (Section 2.1)

2. Choose a Mounting Location (Section 2.2)

3. Mount the FFM100 (Section 2.3)

4. Mount the Flow Sensors and Connect Fluid Lines (Section 2.4)

5. Connect the Flow Sensors to the FFM100 (Section 2.5.1)

6. Connect the FFM100 to the NMEA 2000® network (Section 2.5.1)

7. Configure the FFM100 (Section 3)

1.6 Theory of Operation

The FFM100 operates by using positive displacement fluid flow sensors. These sensors are

volumetric (they measure the volume of fluid passing through them as opposed to the mass of

the fluid).

1.6.1 Operating Modes

The FFM100 can operate in one of two user-selectable operating modes:

1) Differential Flow Rate – this mode is used for diesel engines that recirculate unused fuel

back into the fuel tank. These engines will have separate supply and return fuel lines.

2) Two Independent Flow Rates – the FFM100 can measure flow rates from two

independent sources; for example, a water flow rate on one channel and a gasoline fuel

flow rate on another channel.

1.6.2 Sensor Accuracy

The M1RSP-2R-E8, M2RSP-2R-E8, and M4ARP-2-E8 fuel flow sensors use positive

displacement technology. These sensors are extremely accuracy over a wide flow range.

Please refer to Figure 1 below for a chart detailing typical accuracy and pressure loss versus

flow rate for the M1RSP-2R-E8 and M2RSP-2R-E8 fuel flow sensors.

Page 2 Revision 1.2

®®

Figure 1 - M1RSP-2R-E8 and M2RSP-2R-E8 Accuracy and Pressure Loss

Please refer to Figure 2 below for a chart detailing typical accuracy and pressure loss versus

flow rate for the M4ARP-2-E8 fuel flow sensor.

Revision 1.2 Page 3

FFM100 User’s Manual

Figure 2 - M4ARP-2-E8 Typical Accuracy and Pressure Loss

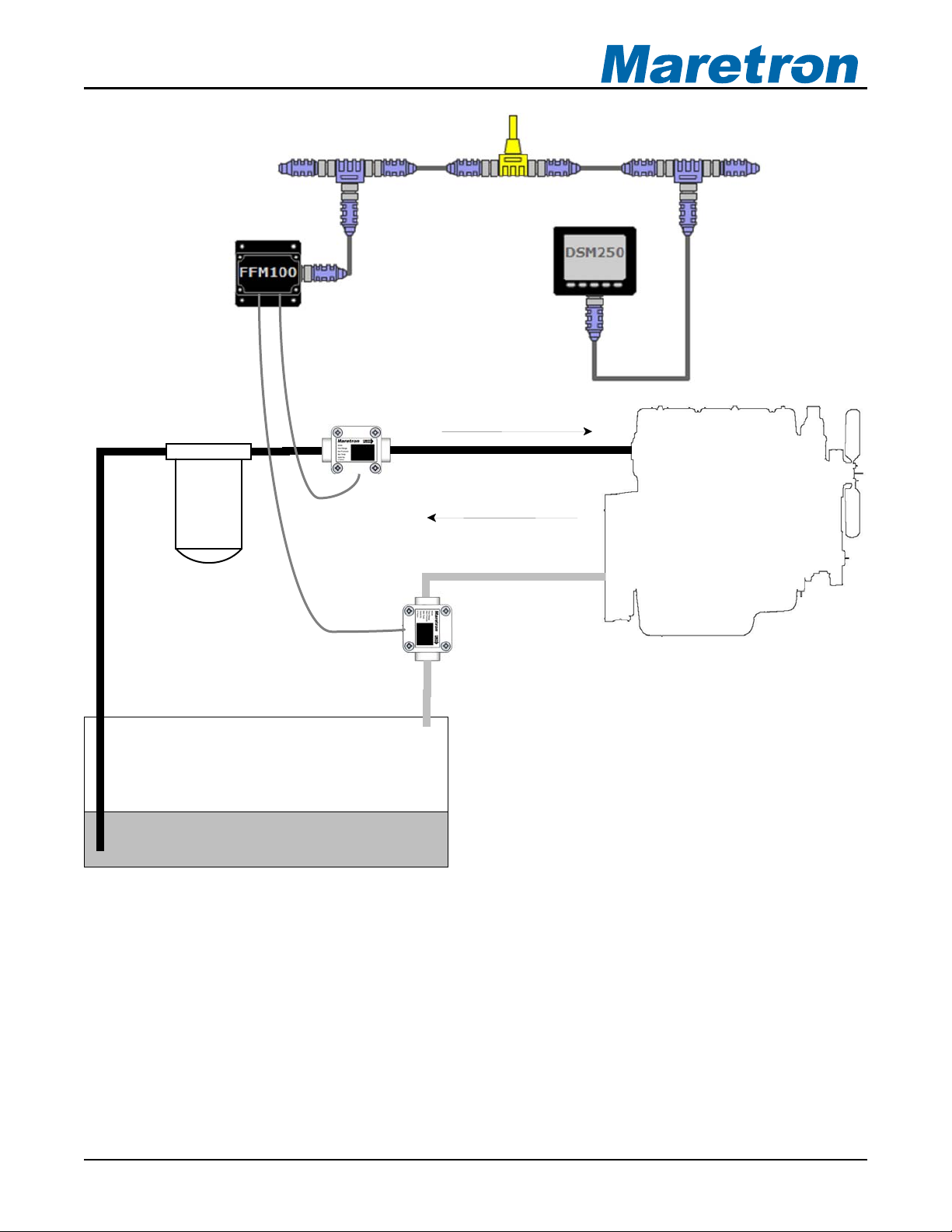

1.6.3 Diesel Fuel Flow Measurement

Most diesel engines do not use all of the fuel that is supplied to them by the fuel pump via the

supply line. A portion of the fuel is consumed by the engine, but the majority of the fuel is used

for cooling the injection system and returned to the fuel tank via the return line.

For diesel engines, the FFM100 will operate in its differential mode, and will measure the net

fuel consumption of these engines by separately measuring the fuel sent to the engine via the

supply line and the fuel returned to the fuel tank from the engine via the return line. The

difference between these two readings is the fuel consumption of the engine. Please refer to

Figure 3 below for a system diagram demonstrating the location of the supply and return fuel

flow sensors in a diesel fuel system.

Page 4 Revision 1.2

®®

Display/MFD

Supply Fuel

Flow Sensor

Fuel Filter

Engine

Return Fuel

Flow Sensor

Fuel Tank

Figure 3 - Diesel Fuel Rate Measurement Fluid Flow Sensor Locations

1.6.4 Temperature Compensation

The task of computing fuel consumption for a diesel engine is further complicated by the

following two factors:

1) Diesel fuel expands when heated

2) Diesel fuel is heated as it passes through the engine

When using volumetric sensors such as positive displacement sensors or turbine flow sensors,

simply subtracting the return flow rate from the supply flow rate without taking these factors

Revision 1.2 Page 5

Loading...

Loading...