Mareli PB18 Assembly And Exploitation Manual

1

PB18 Pellet stove assembly and exploitation manual

The present stove is designed and manufactured according to

Standards:

BNS (Bulgarian National Standard) EN 14785-2006

2

Observing the prescriptions of the present manual is in the user’s favor and is one of

the warranty conditions.

Compliance with this instruction is in the interest of the consumer and one of the

warranty terms.

INSTRUCTIONS FOR SECURITY:

- This appliance is not intended for use by persons (including children) with limited physical,

sensory or mental abilities or lack of experience and knowledge. The installation must be

performed by a qualified expert in the field of heating installations or authorized by "Marelli

Systems' service. The place and way of connecting the stove should be selected carefully in

accord with the safety instructions. Install away from flammable objects!

- Before starting any operation, the user must read and fully understand the contents of this

instruction manual. Incorrect setup may cause hazardous conditions and / or incorrect function

of the stove;

- Do not wash the stove with water. Water can get inside the fireplace and damage the

electronics and cause an electric shock;

- Do not put clothes to dry on the stove. Any clothes hangers and other objects must be located

within a reasonable distance from the fireplace. Fire hazard;

- The user is fully responsible for the proper use of the product which exempts the company from

liability of any users errors or misbehaviour or omissions;

- Any intervention or replacement that is made by unauthorized persons or using non original

spare parts for the product can be risky for the user and release the company from all liability;

- Most surfaces of the stove are extremely hot (the door handle, glass, flue pipe, etc.). Avoid

contact with these parts before assuring yourself that you us temperature resistant gloves as

well as suitable temperature resistant instruments;

- Under no circumstances should the fire be ignited with the door open or broken glass;

- The product must be electrically connected to a system equipped with an effective earth

conductor. (Must be grounded);

- Turn off the stove in case of failure or malfunction;

- All unburned pellets in the burner after each unsuccessful attempt ignition must be removed

before a new ignition;

- When installing the product all fire safety requirements must be respected

- If there is a fire in the flue pipe, extinguish the stove, disconnect the power cord and never

open the door. Call competent authorized service technicians;

- Do not light the stove with flammable materials if the ignition system failed;

- Periodically check and clean the smoke outlet ducts of the stove (connection to the flue pipe);

- Pellet stove is not cooker;

- Always keep the cover closed;

Safe distances:

When installing the product a safe distance of at least 600 mm must be respected. This distance

applies to the product located near materials of B or C flammability level. The safe distance is

doubled if the product is close to materials of C3 combustion level.

3

1. Purpose

The stove is purposed to heat domestic and public premises by the means of pellets. The

stove is equipped with a steel water jacket designed for heating systems with water temperature up

to 90º C at a maximum super pressure up to 0,15 Mpa. Tests are run at pressure of 0,3 Mpa.

The stove is designed and manufactured to work with A-class pellets only

( DIN plus 51731 ) with the following characteristics:

- Material 100% pure conifer or broadleaf wood;

- Diameter Ф6/8 mm;

- Length 20-30mm;

- Calorie capacity 5.2 kW/kg;

- Ash content < 8%;

The use of pellets with characteristics different from the recommended may result in power

decrease, unstable and inconsistent work of the stove.

What are the pellets.

The pellets are produced by compressed wooden waste left from the production of various

furniture, sawmills and others. This type of fuel is environmentally friendly because in the

production process no agglutinant agents (glues, resins and others) are added. Actually, the

integrity of the pellets is guaranteed by the lignite – a natural ingredient contained in the wood

itself. While the wood has a calorie capacity of 4.4 kW/kg (15% humidity at 18 months drying),

the pellets have 5.2 kW/kg.

info

To ensure the proper work of the stove the pellets must be stored in a dry place!

Recharging of pellets can be done during work, with the following sequence:

1. Open the bunker (located at the top rear of the product);

2. Fill the hopper, using noncombustible container;

3. Close the lid of the bunker;

Attention!!!

Use gloves! Beware of hot surfaces!

4

2. Technical data

MAXIMAL CAPACITY

KW

18

HEATED AREA UP TO

m³

350

HEIGHT H

mm

1010

WIDTH W

mm

568

DEPTH D

mm

665

MAX. PELLETS LOAD

kg

30

AIR INLET

ф mm

48

FUME EXHAUST OUTLET

ф mm

80

WEIGHT

kg

180

FUEL

Pellets ф6-ф8

THE CHIMNEY DRAFT

Pa

12

MIN/MAX FUEL CONSUMPTION PER H

kg/h

1,6-6,0

POWER CONSUMPTION

V/Hz

60/310

ELECTRIC POWER SUPPLY

V/Hz

230/50

VOLUME WATER

L

41

PRESSURE

bar

0,5-2,0

MAX POWER WATER JACKET

Kw

17

WORKING ENVIRONMENTAL TEMPERATURE

C

5-40

HUMIDITY LEVEL, WORKING RANGE 30 C

%

85

EFFICIENCY

%

>91

CO EMISSIONS

ppm

<383

TEMPERATURE OF THE FLUE GAS

C

160

MAX WATER TEMPERATURE

C

90

3. Assembly

5

3.1 General conditions.

For ensuring the proper and safe work of the stove the observation of the following prescriptions

is required:

The assembly of the stove and the related equipment must be performed by authorized personnel

only.

The foundation upon which the stove is going to be placed must be even and horizontal, made out

of non-flammable materials with a dimension of at least 40 cm. in front of the stove and not less

than 20 cm from both sides and the rear side.

If flammable materials or constructions are present, the distance between them and the stove must

be at least 80 cm.

When assembling the stove make sure that the joints between the separate pipes and the chimney

socket are well insulated.

A smell on first startup of the stove is due to the burning of the paint.

The stove is painted with thermal resistant paint which reaches its final resistance after a couple

startups and warm ups. THAT IS WHY THE OUTER SURFACES MUST NOT BE TOUCHED

in order to avoid damage to the casing.

The periodic cleaning of the ash tray must be done only when the stove is cold.

3.2 Basic rules and prescriptions.

The stove with water jacket operates on water heating boiler principle.

The advantage of this type of heating system is the maximum utilization of the heat that is

produced during the combustion process. With this method the heat from the combustion chamber

is taken to remote and hard to reach for a normal heat exchange premises in order to maintain an

even temperature and warmth comfort.

1. Ensure that every branch and element of the installation is airtight at every single moment

of its exploitation.

2. All elements of the installation must be protected from freezing, especially if the enlarging

pot or other parts are situated in non-heated premises.

3. The circulation pump can be chosen by the capacity required by using the following

formula:

G=0,043. P, (m³/h), in which:

P, kW is the heat output of the water jacket. The circulation pump can be turned on and off

by the means of a thermostat in combination with an electric switch

5. The first service cleaning of the pump’s filter must be done immediately after testing the

installation.

6. If an old installation is going to be used it must be washed several times to ensure the

removal of any accumulated dirt on the surfaces of the water jacket.

7. Do not drain the circulating water of the installation during the non-heated season.

8. Chemical treatment of the circulating water is not recommended.

6

Chart 1 is a basic combined chart for heating with solid fuel stove, electrical boiler equipped

with water serpentine and a solar panel. For economy and efficiency of the system and a constant

availability of cheap hot water a qualified assembly of the automatic shifter controlling the

thermal flows to and out of the solar panel and the boiler is required.

Chart 2 shows a one storey heating with a compulsory circulation. The advantage of this

chart is that the water-conducting elements can be hidden.

The enlarging pot must have a direct atmosphere connection which means that it must be

placed on the highest spot in the system. Its capacity can be determined as 0,1 part of the total

capacity of the system.

The filling or unloading of the system is done via a hose through a faucet mounted in the

lowest area. Mounting a membrane enlarging pot is permitted when constructing a closed type

system.

During the initial 3-4 startups a condensation on the surfaces of the water jacket may occur

which depending on the fuel’s humidity and the temperature of the incoming water may reach 0,3

litr on a single startup. The accumulating char reduces the temperature difference and the

condensation.

- “Mareli Systems” provides a warranty and out of warranty service and replacement

of the water jackets.

- The warranty is not valid in case of a stove with a swollen water jacket which is a

result of pressure increase in the system and improper connecting.

- The water jackets are tested under pressure of 400 kPa (4 bar).

It is recommended that the assembly is performed by an authorized specialist.

Chart 1

3.3 Assembly of the duct and duct components.

Duct components and pipes

For the assembly of the duct pipes the use of non-flammable materials, resistant to the

flammable products and condensation is obligatory. The assembly must be performed in such a

manner so it guarantees the airtight sealing and prevents condensation. If possible, avoid adding

horizontal sections. Direction shift is done by using knee joints with a max angle of 45˚.

For heating devices equipped with a smoke ventilator, i.e all of the “MARELI” stoves, the

following instructions must be observed:

Horizontal sections must have a minimum incline of 3° upwards;

7

The length of the horizontal sections must be as short as possible, but without exceeding 3 m;

More than four direction shifts are forbidden, including the cases where a T-shaped element is

used;

The duct components must be airtight and to be insulated if extending outside the premises in

which the fireplace is installed;

The duct components must allow a soot cleaning;

The duct components must have a constant section. A section change is allowed only in the

chimney joint;

Chimney

The chimney or the duct component must conform with the following requirements: to be

airtight, waterproof and properly insulated, to be constructed with materials resistant to the normal

mechanical wear and to the heat coming from the combustion products and condensation.

To be kept away from flammable materials.

The recommended chimney draft at work - from 12-20 Pa.

Attention!!!

In case of a fire hazard turn off the product from the display. This will stop the

oxygen flow to the product.

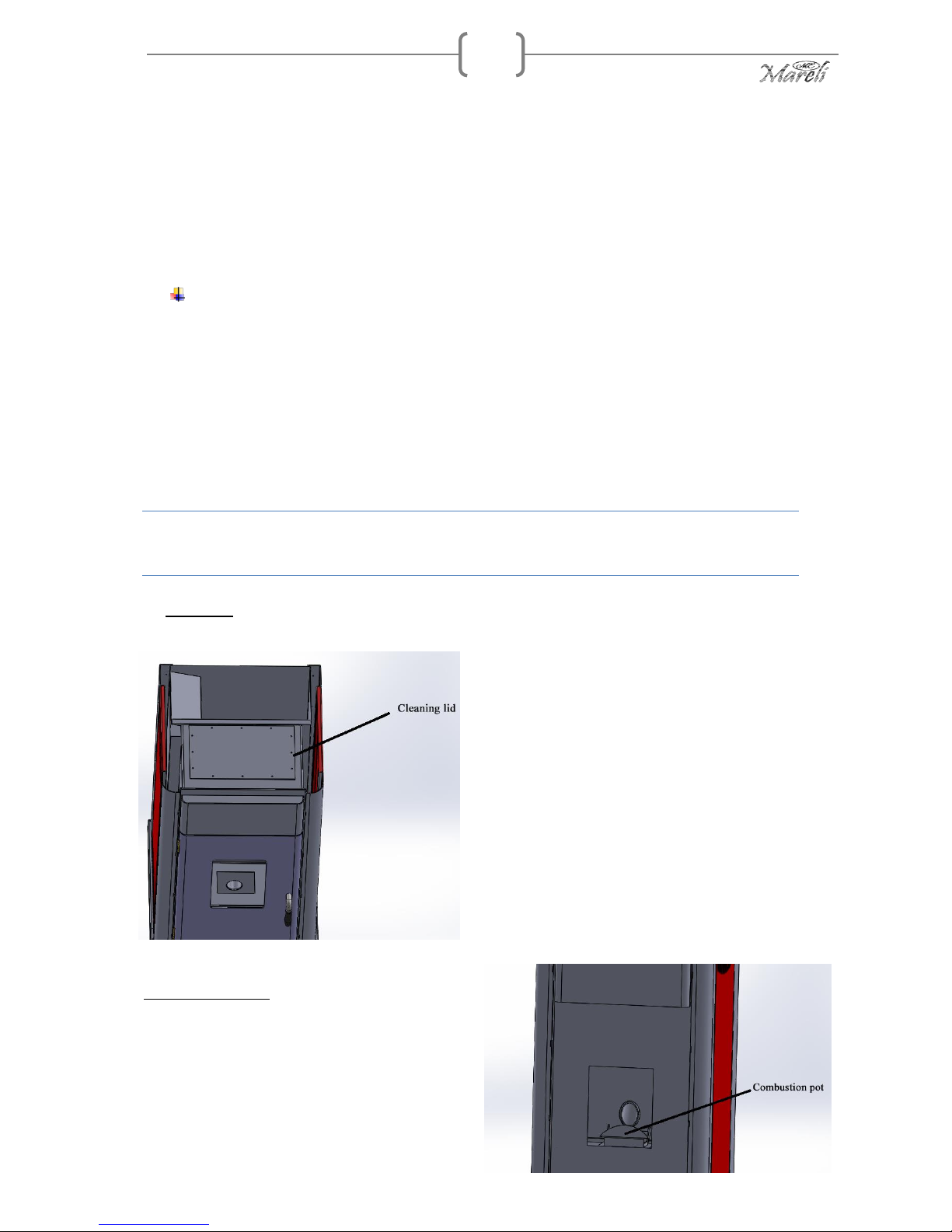

4. Cleaning

Cleaning the fireplace should be done only when

cold. The cleaning of the combustion chamber must

be carried out daily. For this purpose, make sure the

fireplace has ceased operation and is completely

cold. Pull up the combustion pot and remove it

from the stove and then clean it from soot. When

removed fuel pot at the bottom of the combustion

chamber opens a hole designed for the accumulated

ash. Collect ashes in the ashtray and return fuel pot

in place and then close the door. The fireplace is

ready for operation.

Cleaning of flues and chimneys are conducted once

every 1.5 tons of fuel used.

Cleaning of flues:

1. Open the top cover of the fireplace by

pulling it up;

2. Loosen the screws on the lid for cleaning

(key number 10);

3. Remove decorative shutters;

Loading...

Loading...