V12-CE SETUP MANUAL

V12-CE

SETUP

MANUAL

V12-CE SETUP MANUAL

INTRODUCTION

This document is not meant to act

as a complete instruction manual

– it has been written to support the

build instructions that come in the

kit, as well as suggest a variety of

tips that can improve the way the

car drives. It is aimed mainly at

The V12 ‘CE’ kit shares many of

the same parts as the older V12

kits. However, both the main chassis plate and new front suspension

plate are now made from either

GRP or Carbon composite material,

and these need careful preparation.

Round the edges with a light rub

down with 400 wet/dry paper (a

V12 runs close to the ground and

smoothing these edges prevents

the chassis from grabbing at the

carpet during a race). Then carefully seal the edges with a thin

layer of Super Glue to help prevent de-lamination during impacts.

Club racers at WSMCC, but does

make reference to the changes

required for racing at other clubs

which have different track sizes

and layouts, and for racing at

National level (to current BRCA

rules) too.

It is also assumed that the driver

has bought the additional differential rear axle to use on the car.

Buying one is not 100% essential, but most drivers agree that

you will get a better driving car if

you install one.

1. PARTS PREPARATION

On the CE chassis, the wishbones

mount directly on the front suspension plate. They must be mounted

at on the front plate and the other

way up from the standard V12 kit.

Mount them with the lugs facing

‘upwards’. Do not add shims or

washers under the front end of the

wishbones to give you castor like

you used to on an old V12 chassis.

You’ll add shims, but you’ll do this

under both ends of the wishbone to

alter the ride height once the rest

of the car is built up; castor is best

changed by angling the plate itself.

It is best to get castor through

angling the whole plate, not by

angling the wishbones on the

plate. We have found that forcing

a twist in the wishbones by adding

spacers under their front end is

good to start with, but the plastic

the wishbones is made from has a

tendency to ‘creep’ and will try to

re-mould itself back it its original

shape over time. The problem

is that your left and right hand

wishbones won’t always creep at

the same rate, and after a week or

two you’ll have different castor on

each side – not good for consistent handling!

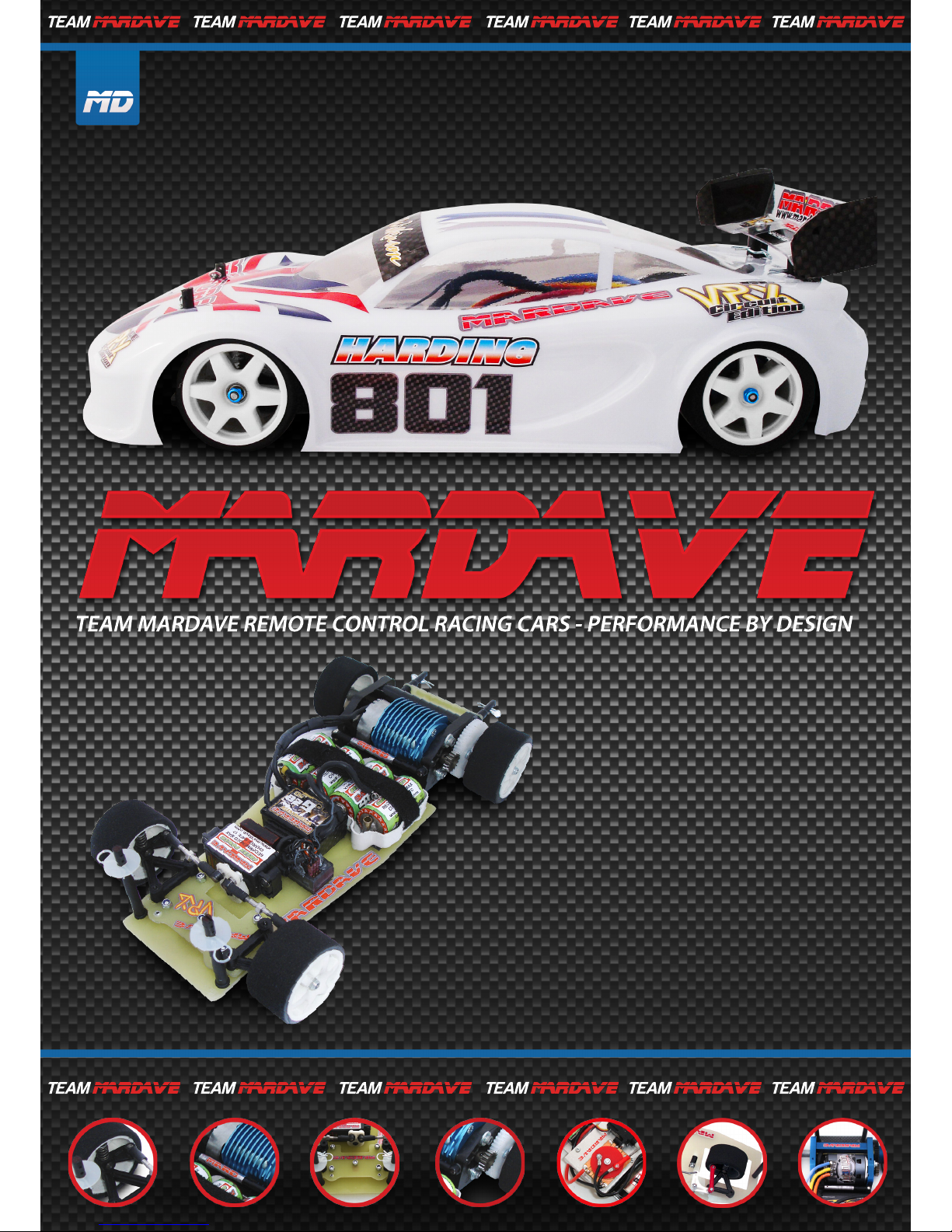

2. FRONT END

Wishbones lug side up.

Mounted at on the front plate.

No shims under here!

NEED UPGRADES & PARTS? WWW.MARDAVE.COM

V12-CE SETUP MANUAL

The holes you use to bolt the wishbones to the front plate depend

on the type of track you run on

and how you like the car to han-

dle. Wide wishbone spacing helps

prevent grip roll in the fast sections

but reduces steering a bit through

slow, tight sections of tracks; a

long wheelbase promotes stability at high speed while a shorter

wheelbase allows faster changes of

direction. At this point many drivers ditch the self-tapping screws

that come in the kit and use slightly

longer (12mm) button head M3

machine screws to give a stronger

mount when xing the wishbones

to the plate. Since the 4 holes for

each screw are quite close together you should also use a relatively

large diameter M3 washer under

the each of the screws’ heads to

help spread any loads. For the

time being, screw them all down

tight.

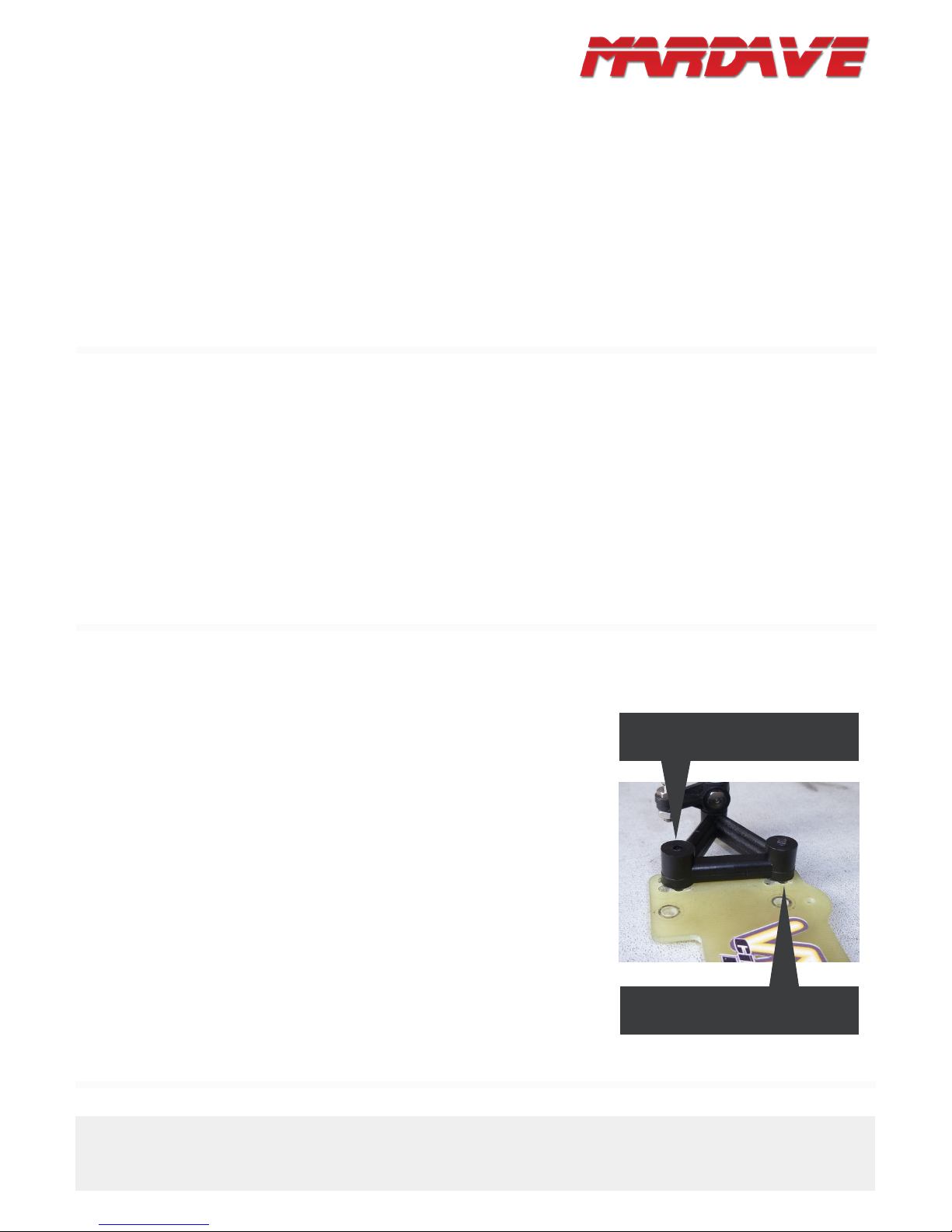

2.A. FRONT END

In this case, wishbones set to

“long and wide”.

M3 washer between screw

head and plate.

NOTE: do not use less than 2mm

spacing on the rear two screws

– doing so will allow the head

of the rear screw holding the

wishbone to the front plate to hit

the chassis and tweak the front

plate.

Now, add the central screw, but do

not add anything between the front

plate and chassis - we have found

that having a bit of ex in the plate

gives better front bite mid-corner

and more even tyre wear. Tighten

the screw’s top nut so that it compresses the plate to give about 1.5’

camber.

2.B. FRONT END

1mm thick washer under front bolts.

No washer under rear bolts.

Standard Nut

M3 “Low-Prole” nut is about 1mm

thinner than a standard nut.

V12-CE SETUP MANUAL

The steering system is easier - assemble all the parts and make sure

they all move freely. Add a 2mm

shim under the balls on the steering

arm (and use the bottom holes in

the servo saver) to get the steering

track rods as horizontal as possible

and minimize bump steer.

Lastly, make sure that the wishbones are seated level. Sometimes they can sit unevenly (this

can happen if any mould ashing

is not trimmed off the wishbone

mounts or steering blocks during

the build, or from racing impacts).

To check the wishbones, put the

chassis on a at surface, centre

the steering and measure the

clearance of the stub axels off the

ground. Left and right sides must

be identical. If they are not, check

for mould ashing and trim it, check

that kingpins and stub axels are

straight and replace any defective

parts.

2.C. FRONT END

“Ride Height” of left and right stub

axels must be identical.

Approx 2mm of spacers under the

pivot ball to eliminate bump steer.

This is almost identical to all other

V12 kits, the only difference is the

damper tube. Assemble the pod

and add the damper tube’s ball

stud, axel bearings and diff. Some-

times the rear pod’s pivot ball can

be stiff when tted in its hole in the

pod base plate. This is not good.

It is wise to give the ball a light rub

down by spinning it up in a drill and

polishing it with 400 wet/dry – this

will give a smoother movement, but

be careful not to make it so small

that you get any slop!

3. REAR END

If the rear pivot ball is tight in the cup, remove

it and sand it smooth with wet and dry paper.

This pivot ball has had a rear guide pin added to it via a grub screw.

The ball can rotate freely in the cup with just the weight of the pin.

V12-CE SETUP MANUAL

Next, add the rear spring screws

and nuts to the back of the chassis.

Add a washer between the rear

guide pin and the chassis – this

will stop the pin digging into the

chassis and reduces the risk of it

shaking loose or pulling through

the chassis in a big impact (new

part V9BT does this for you!). At

this point, check that the rear pod is

moves freely, sometimes the hole

in the pod’s base plate where the

pivot pin goes through needs to be

reamed out.

NOTE: this is just the hole in the

base plate itself, NOT the o-ring

and not the hole in the o-ring

holder!

3.A. REAR END

M3 washer under the rear pin – this

will help stop chassis denting.

If you are using large diameter rear

tyres (50-52mm diameter) then a

1.0 - 1.5mm thick washer under the

front pivot ball can be a good idea.

With tyres this size you’ll have to

loosen the rear springs right off to

get 3.5mm ride height. This will

give you a nice wide gap between

the bottom of the rear pod and the

top of the chassis but can, in fact,

bring the bottom of the rear pod

close to horizontal when the car

is sat at ride height. Horizontal is

not good for handling when you

accelerate – run the front of the

pod angled up to be at least 2mm

higher than the rear. For smaller

diameter rears you can remove

washers from under the pod’s ball

joint, or use none at all.

3.B. REAR END

Approx 1.5mm clearance be-

tween pod and chassis when the

car is resting on its wheels.

FOLLOW US! WWW.FACEBOOK.COM/TEAMMARDAVE

V12-CE SETUP MANUAL

The new, adjustable rear pod is different – ride height is changing by

swapping the axle bearing cams;

rear spring tension is only used to

get the required chassis droop and

is then left alone. The means no

washers are needed under the front

pivot ball, even if larger tyres are

used, resulting in your whole pod

(and CoG) being up to 2mm lower.

Just remember that when you

change the cams your gear mesh

will also need changing.

3.C. REAR END

Use a “Low” cam as your rear

wheels wear down.

Use a “High” cam when your

rear wheels are new and up to

51mm diameter.

This is a new part for this kit and

has a big impact on car handling.

The short story is that it affects

how the rear of the car behaves

as you go through corners. The

longer story is that oil thickness

changes the speed of the piston,

which changes how far/fast the

chassis can roll as you corner

which, in turn, affects how weight

is transferred and the outside tyre

is loaded up. Rear spring stiffness

/ diff tightness also come into play

and you risk some really poor handling if any of the settings are out!

Getting it right is a careful balance

of oil thickness, diff tightness and

spring rate.

Always keep the damper tube

topped up with oil. NOTE: There

is a difference between the units

used to measure oil thickness.

WT is not the same as CST so

30,000wt oil will be different to

30,000cst oil.

30,000wt oil is good on larger,

faster tracks and down to

12,000wt is good if you need

faster weight transfer and quicker

steering response on tight tracks.

Re-ll the tube every 3-6 runs,

whether it feels like it needs it or

not - wipe excess off the rod and

clean the inside of the tube with

motor spray. Pour a small amount

of oil into the tube and smother

the rod’s grooves in the stuff.

Slowly slide the rod into the tube

and give it a bit of a bounce and

twist as you push it in so that the

oil is evenly distributed. Expect

to get some oil squeezing out of

the breathing holes and some left

on the rod once it is fully in – this

way you know it is completely full

each time re-ll it.

As for handling:

1. Rear end ‘hops’ on accelerate out of corners - softer rear

springs, lighter damper oil or

loosen the diff.

2. Inside wheel front wheel lifts

(or car grip rolls) in corners harder rear spring and damper

oil use smaller diameter, harder

tyres.

3. On-power understeer out of

corners - loosen the diff; tighten it

for oversteer.

4. DAMPER TUBE

NEED UPGRADES & PARTS? WWW.MARDAVE.COM

V12-CE SETUP MANUAL

Recent BRCA ruling now recognises three forms of power for

running a Mardave / GT12 car –

4cell/G2, 1s LiPo/13.5t brushless

or 2s LiPo/21.5t brushless.

4-CELL/G2:

This is a very easy system for a

beginner to use - components are

cheap and reliable and there is a

wide variety available. However, it

is not so suitable for top end competition because getting the very

best out of a motor and cell is extremely time consuming, expensive

and difcult.

For this system, only the Mardave

G2 motor is eligible, speedos

must retail for under £65 and have

reverse but there is free choice of

cells. The CE kits come with a battery tray that is perfect for the 4-cell

packs.

1S LIPO / 13.5T

BRUSHLESS:

Slightly more powerful than the

4-cell/G2 system, zero maintenance and the most popular system for top end club and National

racing. However, the low voltages

of the 1s LiPo packs mean that

speedo choice is tricky – only a few

(expensive) speedos work properly,

and cheaper ones will need an additional voltage booster installed.

Speedos do not need reverse.

The most popular speedos are:

1. HobbyWing 1s: install the

508 version of the software for

full ‘blinky’ mode. This speedo is

slightly larger than the other speedos below, but it is the cheapest at

about £110 in the UK (or £70 from

Hong Kong).

2. LRP SXX Stock Spec: probably the most expensive of the

three (around £175 UK price)

but comes with the best warranty

and manufacturer backup too. If

possible, get the Version 2 unit

as some software versions on the

Version 1 units can be less reliable than others.

3. Nosram Pearl Version 2: essentially the same as the SXX V2,

but in a red box rather than a blue

one. Don’t get the V1 units as

these don’t have 1s LiPo capabil-

ity. New cost is usually around

£150.

4. Fusion Exceed: comes with a

perfectly good motor for £95 but

will need a voltage booster tted.

Not eligible for National racing as

it has no ‘blinky’ mode.

Motors can be any 13.5t from the

BRCA EB list (there is no restric-

tion of price any more). Popular

choices are the HPI Flux, Fusion

Exceed, Team Powers Plutonium.

The lexan battery tray that comes

in the kit will take most varieties of

1s LiPo cell and offers a degree of

extra protection too. Mounting the

cells in the designated place will

give a reasonable balance and

setup for medium to high speed

tracks.

Another option is to use ‘Cobra’

battery boxes to hold LiPo cells

and to mount them lengthways

(slightly to the left) down the chassis rather than across it. This will

get the weight closer to the centre

line of the chassis and is generally

better for faster changes of direc-

tion and faster, atter cornering. If

you choose to do this you should

position the cell, speedo, servo

and receiver very carefully to help

counterbalance the off-set weight

of the motor.

2S / 21.5T

BRUSHLESS

A new idea but extensive testing

has proved it to be very close to

the 13.5t / 1s setup, with none of

the low voltage problems. The

BRCA support this setup for club

racing but is not recognized at

National level.

For cells there are 3 main

choices:

1. Hard-cased, mini LiPo packs

used in the micro off-road buggy

classes. Small, very light but

still enough punch and capacity

to last an 8 min race. There are

battery trays available from Mardave that house these perfectly.

2. New 1s/2s packs for GT10

cars (Intellect CC2S3200V7 or

Yokomo YB-P228BE). Same

physical size as a standard 1s

pack (so t the standard cell

holders) but are internally wired

to give 7.4v.

3. “Shorty” packs used for

1/10 buggies. Taller than the

1s/2s packs (25mm compared

to 18mm) and are signicantly

heavier too. However, they offer

faster re-charge times between

races

For speedos and motors try

a HobbyWing “Just Stock” or

SpeedPassion Citrix or Reventon

“S” speedo and any 21.5t motor

that has a xed endbell (HobbyWing Stock, SpeedPassion V2 or

V3 Ultra Sportsman etc).

5. POWER: CELLS, SPEEDOS AND MOTORS

V12-CE SETUP MANUAL

The chassis is drilled for a standard

size (Touring Car size) steering servo to be mounted on the right hand

side of the chassis. This is ne for

oval Hot Rod racing but does not

give an ideal weight distribution for

circuit racing.

You’ll get a better balance if you

mount the servo on the left hand

side of the chassis. It is also a

good idea to invest in a ‘low-prole’

type servo (eg Savox 1251MG or

Futaba s9550 for example) since

these are short front to back, and

using these will free up some more

room for cells and electrics in the

chassis. Choosing a servo with

fast movement (<0.10 sec to 60’ at

6V) and reasonable torque (>4Kg/

cm) is also wise. Dedicated 1/12

scale servos can be good as they

are light in weight, just as fast and

usually have lower current draws,

but they are often longer in the

body (so take up more room) and,

as they are so slim, they need to

be raised off the chassis so there

is clearance for the servo saver to

move freely. It is a close call between the two types and really depends on budget and how/where

you plan to mount your cells.

NOTE: the holes that come predrilled in the chassis are designed to accept Futaba makes

of servo. The holes are spaced

so that the central output spline

on most Futaba servos is dead

centre on the chassis. Savox servos do not have the

same position for their output splines and, although the

1251MG model will t the holes

as they come, it will not be

dead centre.

If you choose to re-drill your

servo holes, mark them extremely carefully. Get your steering

assembled, mount the track

rods onto the servo saver and

then mount that onto the servo

itself. Position the servo so that

the track rods are perpendicular

to the centre line of the chassis

and this will give you reasonable

Ackerman change.

6. SERVO

Lexan shells are lighter, ABS ones

can be a little tougher. Some good,

and popular choices are :

Lotus GT1: most front end downforce of the common shells. Good

on slower, twisty tracks, but you’ll

need to add a bigger rear wing

and probably use small diameter,

harder compound front tires to stabilize it on faster tracks.

Mazda Speed 6: good aerodynamic balance makes this the safest,

most forgiving shell to drive.

Ascari GT3: half way between

the Lotus and Mazda for handling.

Common favorite for many drivers.

GT2 ‘Wedge’: can look nice,

but can also look like a piece of

cheese! Aside from looks, be very

careful when mounting it on your

chassis as the front/rear position

has a massive effect on aerodynamic balance – 2mm forwards

gives oversteer, 2mm backwards

gives understeer. Front and rear

wheel mould lines are not an ideal

shape.

Calibra: another good looking

shell but complex molding splits

easily and a high roof line and

high rear wing positions make

it unstable / prone to grip roll

through high speed corners.

Porsche 911: Soon to be released.

All the above are ne for club

meetings. Only the Ascari, Lo-

tus, and GT2 shells are permitted

for Nationals.

A nal word on bodies – many

drivers suggest investing in a set

of vertical rear posts or a V10M

‘Banger Mount’ and have these

mounted to come through your

shell under the rear wing. If you

turn them so the body pin holes

face front to rear the pins are

then easy enough to get in and

out.

7. BODY SHELL

VISIT OUR FORUM! WWW.MARDAVE-FORUM.CO.UK

V12-CE SETUP MANUAL

Ofcial Mardave bumper plates will

be released soon. Until they are,

cut a 45mm x 125mm rectangle

of 3mm nylon sheet, round off the

front corners and mount it to the

chassis using the two holes usually

used for the front body posts. Drill

another pair of holes in the bumper

plate, just in front of the edge of

the chassis, and mount the body

posts through these. This gives the

option to position the posts further

forward for better support of the

front of the shell, and body posts

could spaced from side to side to

avoid any awkward moldings in the

shell. Lastly, cut and shape some

15mm deep foam, punched holes

in this to go over the body posts,

and it is job done.

8. FRONT BUMPER

It can be worthwhile to have differ-

ent bumpers to t different shells.

Bumper plate bolted to chassis and

body posts bolted to the plate.

9. GENERAL SETUP

Any small, light, rear wheel drive

car is very delicate to set up right

- small changes have a big effect

on the way the car drives. Below

are some tips that should keep you

pointing (mostly) in the right direction.

TRYRES:

The most important setup tool are

your tyres, being on the right tyre

at the right time is 90% of getting

your car running well. UFRA pink

‘Medium’ (part number V54P) is

extremely popular as the rear tyre,

but front tyre compounds can vary

widely depending on track layout,

grip level and driver preference.

The JAP range are good - ‘shore’

ratings are a good indication of grip

with low shores (38’ for example)

giving more grip than the harder

52’ shore. JAP ‘Medium’ fronts are

actually the softest and offer most

grip. Start with a pair of 44’ or 46’

fronts, and get a pair of hard JAP

50s and some softer JAP Medi-

ums so you can test what works

best for you.

ADDITIVE:

Be careful. UFRA Pinks can take

additive twice a day (maximum)

with no ill effects, but JAP fronts

can get over-softened easily.

Most front tyre compounds pick

up most of the additive they need

straight off the track, but some

can be applied on the inside 1/3

of each tyre if you need extra

bite. Using additive more than

3 times a week on any tyre will

over-soften it – the structure of

the rubber changes and the tyres

just fall apart. A good strategy is

to buy multiple sets of the same

compound and run each tyre just

twice each meeting. Sure, this

means an increase in expense to

begin with but they last longer in

the long run.

Contact have recently released

a range of tyres for the Mardave

cars. Initial testing indicates

that grip is good, compounds

take additives well and wear is

not excessive. They are more

expensive at £6 (rears) or £7

(fronts) but they do come ‘trued

and glued’ which saves a lot of

mess. Their 32’ shore rears and

either 42’ or 45’ shore fronts are

popular, but true them down to

47mm (front) and 50mm (rear_

for best results. Their drawback

is that the wheel rims have no

lip on the outer edge – the tire

is much more prone to chunking

when you hit something. >>

V12-CE SETUP MANUAL

Once you have run any set of tyres,

store them in an airtight container

or bag. This increases their life

by not allowing them to ‘dry out’

between meetings. It is also a

good strategy if you ever run your

car at a club that does not allow

the use of additive – there is usually enough left in your tyres from

the last meeting when you did use

additive to see you through the

rst couple of rounds at the non-

additive club when grip is likely to

be lower.

After every race, check that your

tyres have not started to come

unstuck from the rims. Even the

smallest unstuck area will encour-

age grip roll. Use either EvoStick

or Super Glue to re-attach the tyre

to the rim.

Lastly, it is vital to round off the inside and outside edges of all tyres.

This will help prevent the outer

edge ‘rolling under’ during heavy

cornering. Grip roll is likely if this

ever happens.

FRONT SUSPENSION:

Since this is such a simple system

it requires very little work done on

it. However, since the steering

system is so direct, the work you do

need to do is extremely important.

Make sure each part moves completely freely and there is no stick-

ing or binding. If anything feels

stiff, disassemble, clean and

re-assemble. Check that kingpins

are not bent, that track rods have

not been knocked out of alignment, that ball cups have not got

grit in them or have too much play

and that bearings rotate freely.

REAR SUSPENSION:

Again, very simple, but very important too. The front ball joint can

gather dust and get stiff. Remove

the ball from time to time and

clean. Taking the ball in and out

too many times though causes the

cup to wear and the ball can then

be easily knocked out during a

race. If this happens, replace the

pod plate straight away. Use the

rear spring nuts to adjust your ride

height and chassis tweak (more

on that in a moment).

As the rear tyres wear down you

will have to change the spring

tension again (or change the axel

bearing cams if you have the ad-

justable alloy pod). Always leave

at least 1.2mm clearance between

the bottom of the rear pod and the

top of the chassis when the car

is resting at its given ride height.

Less than this and the pod will hit

the chassis as the rear suspension compresses in the corners,

leading to poor handling.

DIFF:

This must run smoothly. Do not

over tighten the diff side wheel

nut as this will cause the diff to

bind, back it off about ½ a turn

and this should be about right. It

is also wise to run a 5mm drill bit

through the rear wheel axel holes

so that the diff axle can rotate

freely in it. If the diff feels gritty,

take it all apart and clean everything (except the thrust race) in

motor cleaner, paying particular

attention to the insides of the ball

holes in the spur gear. Diff plates

can be lightly sanded to remove

the ball-ring and to scuff the surface slightly. Re-assemble with

just the lightest possible smear

of silicone diff grease on the balls

(but none on the diff plates).

Tighten the adjustor nut extremely gently and by very, very small

increments.

The best way to check the diff

tension is to get the car on the

track (with rear tyres fully additived but dry) and accelerate

HARD from a standstill. If the

diff slips, tighten it. If it does not

slip, back the nut off until it does,

and then tighten it a bit. Once

set, the diffs can run for weeks,

or even months, without the need

for adjustment.

RIDE HEIGHT:

Mardaves run at their best when

about 3.0 - 3.5mm off the deck.

You will need to keep on top of this

as tyres wear down, so be prepared to add/remove shims from

under the wishbones to change the

front ride height and change the

rear spring tensions (or rear axle

cams) to set the rear ride height.

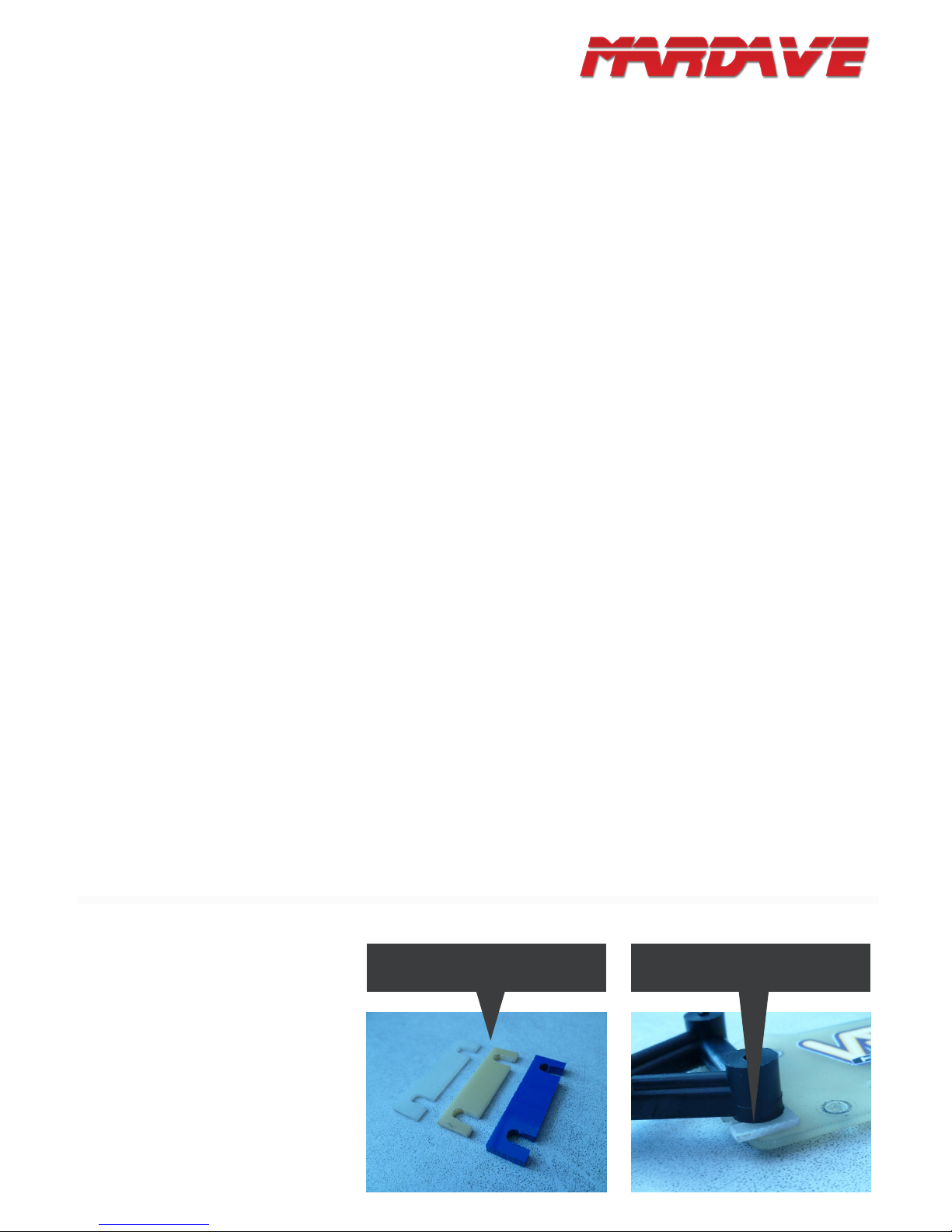

1.0mm spacer tted under

whish bones

Ride Height Spacers – 0.5, 1.0

and 1.5mm.

V12-CE SETUP MANUAL

CHASSIS BALANCE:

The V12 chassis was rst designed

to go around an oval rather than

a circuit, so it will turn right better

than it turns left. To counteract this,

mount your motor on the right hand

side of the pod (but space it away

from the pod by 3-4mm by adding

washers between the motor and

the pod), locate your cells slightly

offset to the left of the chassis and

mount your servo on the left of the

chassis too. Check for left/right

balance by placing the fully built up

chassis on drawing pins and seeing

if it falls off to one side. Add lead

weights as needed.

For front/rear balance, a 40/60

front/rear weight split is good (the

chassis should balance at a point

roughly 81mm forward of the rear

axle line, but this point may change

in position depending on hardness

of the tyres, width of tyres and how

much additive you are using etc).

Finding the ‘Grip Balance Point’

instead can me more useful.

To nd this, put the car on a

smooth, at surface (like a setup

board) with tyres that have just

been used in a race. Use a

screwdriver blade on the edge

of the chassis plate to push the

chassis sideways. If the front end

slides sideways before the back

slides you are pushing at a point

on the chassis that is too far forwards; if the rear slides sideways

rst you are pushing too far backwards. Change your push point

until both front and rear slide at

the same time – this is your ‘Grip

Balance Point’. Once you have

this point, mark it on the chassis

and then measure from here to

the rear wheel axle line. Move

any ballast weight about to get the

46/60 split.

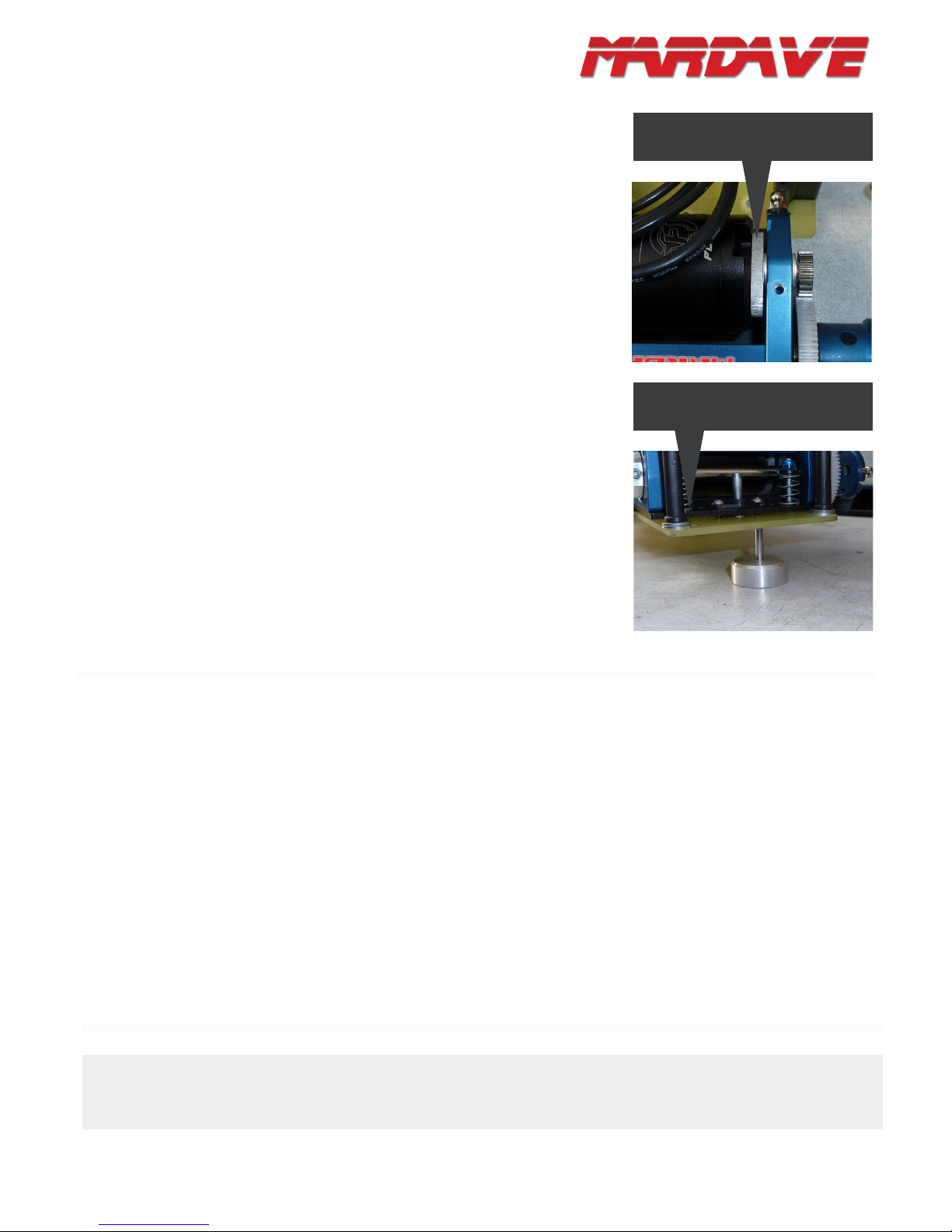

Motor is spaced away from the rear

pod – in this case, about 4mm

Use the 1.5mm holes in the front &

rear of chassis to test for balance.

MOTOR GEARING:

Brushless motors are more complex to gear then brushed ones.

The temptation is to gear up because they have a wider torque

band than the G2 motors. However, while this might give a good top

speed, you’ll start to lose acceleration out of the corners. The best

gearing will give you top speed just

before the end of the straight, but

only just. Next, after each race,

check your motor temperature, ide-

ally it should be less than 60’C. If

it is, advance the motor’s timing a

bit (and gear down a tooth on the

pinion at the same time); if your

motor is nishing the race with a

temperature in the high 50s then

stick where you are.

Unfortunately, as rear tires wear,

our overall gearing changes.

Hence why we cannot say that a

23t pinion on a 70t spur is perfect

for a given track– it will also depend on tire size. The best way to

compare gearing is to calculate

your ‘mm/rev’ gure (how far the

car travels for each single revolution of the motor):

mm/rev = (3.142 x pinion x tire

diameter) / spur

A gure around 56-58mm/rev is

a good starter for a 12x20m track

with a HPI Flux motor on its full

timing advance. Go up to 63mm/

rev on 20x30m tracks.

FOLLOW US! WWW.FACEBOOK.COM/TEAMMARDAVE

V12-CE SETUP MANUAL

FRONT:

• JAP Medium, Jap 38, Contact 32’ or 35’ shore tires trued to 47mm diameter (inside and outside edges

well rounded off), 6mm wide inside edge additive.

• Silver ‘Medium’ spring

• Zero degrees toe in/out

• 3.2mm ride height

• 5th, central plate screw done up with only very light tension (approx 1.5’ camber)

• 1.0mm castor shims added under front end of wishbone plate.

QUICK SETUP

FRONT:

• UFRA Pink Medium or Contact 32 shore tires trued to around 49mm diameter (edges well rounded again)

and full width additive

• Silver ‘Medium’ springs

• 20,000 – 30,000wt damper oil

• Diff set to medium

• Motor spaced 4mm away from motor pod

• 3.2mm ride height

• Gearing on 1s LiPo / 13.5t motor (HPI Flux) – 54-56mm/rev

THANKS GOES OUT TO JAMES GARRETT, JOHN PARKER & OTHERS. HAPPY RACING!

© 2012 MARDAVE. ALL RIGHTS RESERVED.

CALL MARDAVE: 01953 861134

MARDAVE, TURNPIKE HOUSE, THE TURNPIKE,

CARLETON RODE, NORWICH, NR16 1NL,

UNITED KINGDOM

Loading...

Loading...