Marcrist DDM1 Original Operating Instructions

WARNING – To reduce the risk of injury please read the

operating instructions.

DDM1 – Hammer drill operating instructions

Original operating instructions

BJ2012

1

Read these operating instructions thoroughly before using the hammer drill.

Wear ear protectors whenever you use the hammer drill.

Wear protective glasses when working with the hammer drill.

Within the EU, this symbol indicates that the product in question may not be disposed of

together with household waste. Used equipment contains valuable materials that should be

recycled to avoid environmental and personal health issues caused by uncontrolled garbage

disposal. Please therefore dispose of used equipment via suitable collection systems or return

the tool in question to the place where you bought it for safe disposal. This establishment will

then ensure that the device is recycled.

04/09/2012 14:34

ENG

2

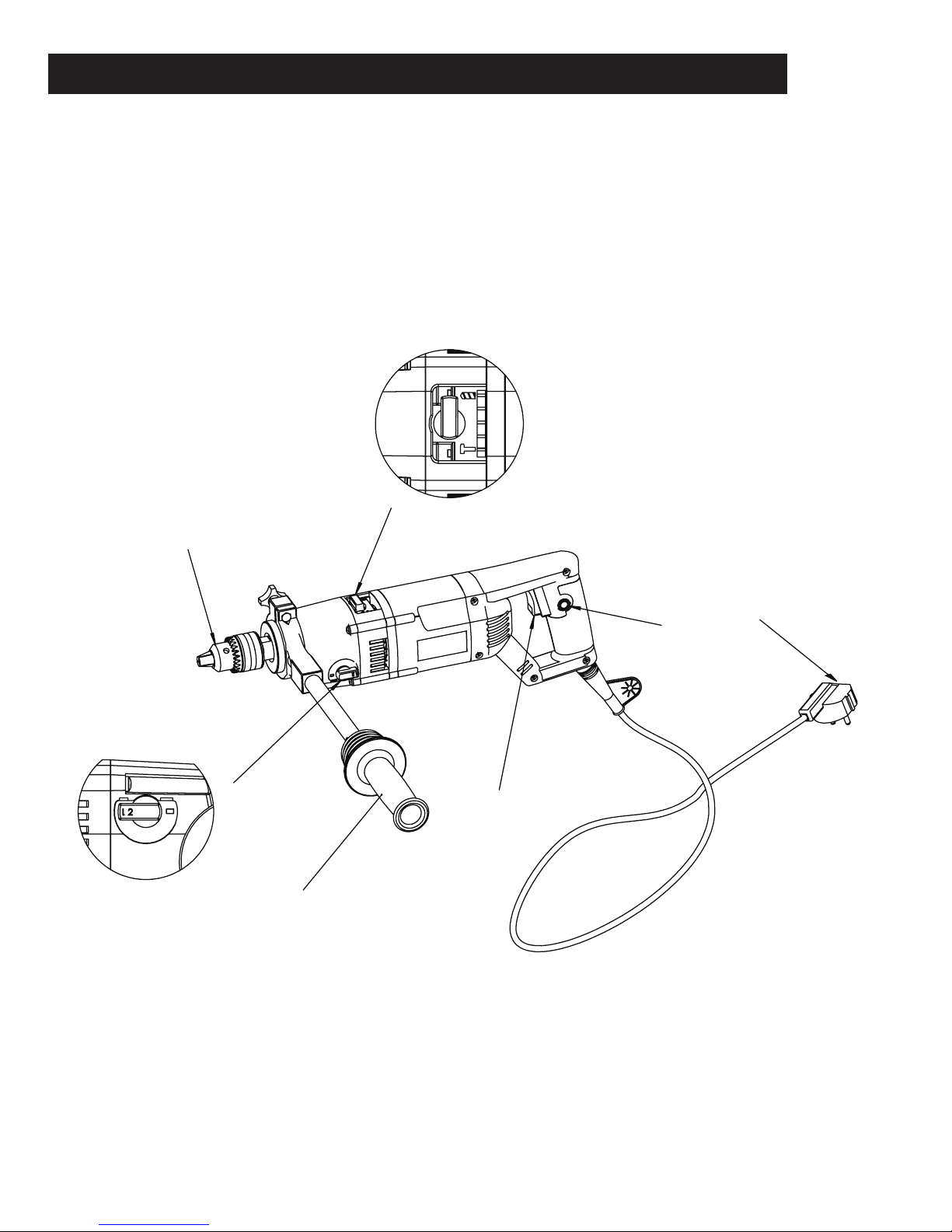

Product description

1 Drill chuck

2 Speed selector switch

3 On/off switch

4 Locking button

5 Regular drilling / Hammer drilling selector switch

6 Side handle

7 Plug

1

6

2

3

4

5

7

3

Intended use

This product is intended exclusively for drilling holes in wood, plastic, concrete, bricks and stone

Improper use

All applications of the drill that are not listed in the "Intended use" chapter are classed as improper

use.

The drill must not be used for the following purposes:

- To mix paint or building materials

- To polish, grind, sharpen or engrave with corresponding attachments

- To drive other devices

There is a risk of injury.

The user of the hammer drill is liable for any and all material and personal damage caused by

improper use.

Using other or non-original parts with the drill will void the manufacturer warranty.

Never use the hammer drill as a screwdriver.

Residual risks

Even when the drill is used properly, there is still a certain residual risk which cannot be ruled out.

Due to the nature and design of the drill, the following potential risks may occur:

- Contact with the rotating chuck (crushing type injuries)

- Reaching into the area of the rotating drill bit (cutting type injuries)

- Contact with the sharp edges of the holes drilled and drilling chips (cutting type injuries)

- Hearing loss if the stipulated ear protectors are not worn

- Inhalation of particles given off during drilling

- Electric shock when touching non-insulated electrical components.

If the operating instructions are not observed, other residual risks may occur due to

improper use.

4

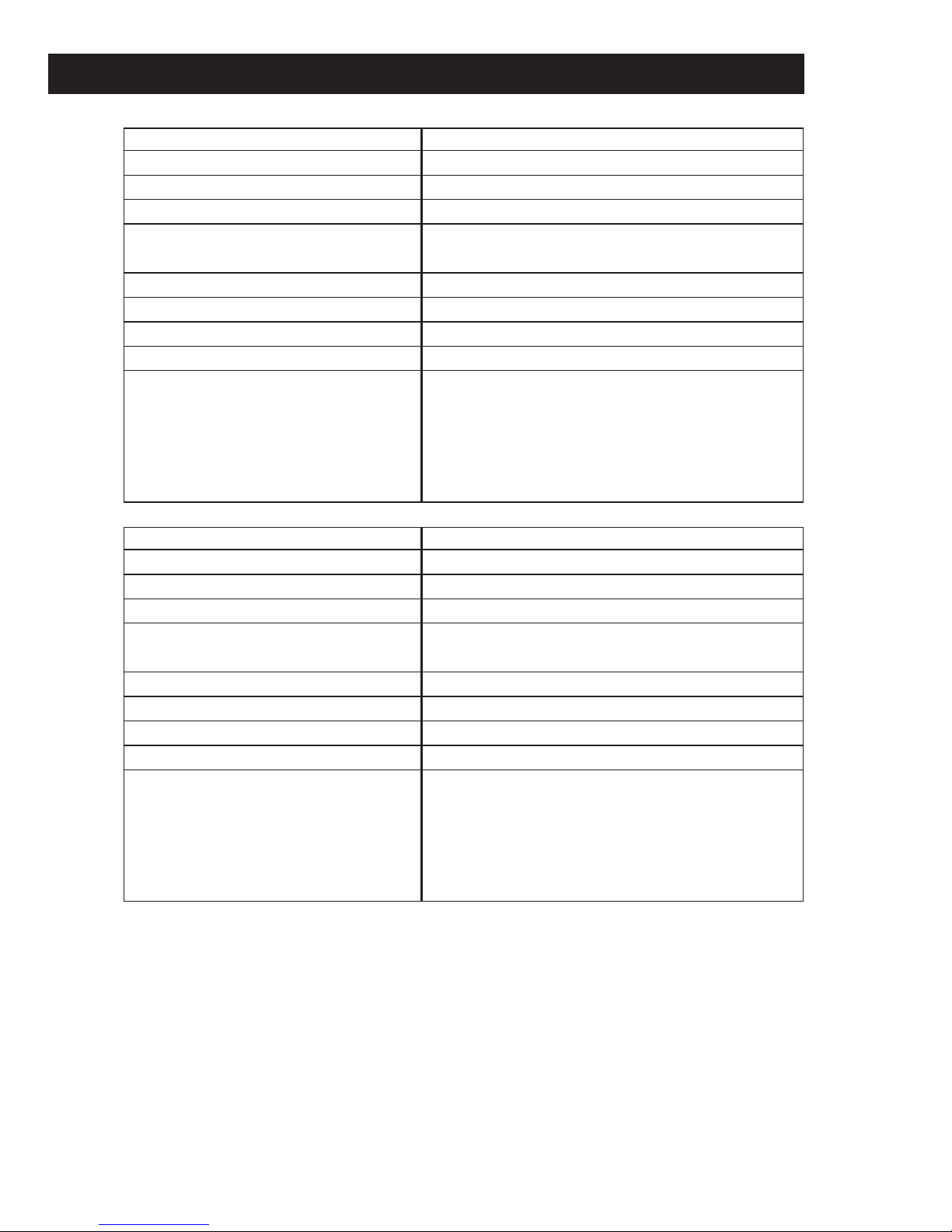

Specification

Model DDM1-230

Voltage 230-240V

Frequency 50Hz

Total input power 1200W

Idle speed Setting I: 0-1500 rpm

Setting 2: 0-3000 rpm

Drill chuck size Ø13mm

Weight 3.8Kg

Sound pressure level LpA 91 dB(A), KpA: 3 dB

Sound power level LwA 102 dB(A), KpA: 3 dB

Vibration emission values Holes in concrete

ah ID: 8,75 m/s

2

K ID: 1,5 m/s

2

Holes in metal

ah ID: 3,08 m/s

2

K ID: 1,5 m/s

2

Model DDM1-110

Voltage 110V

Frequency 50Hz

Total input power 1200W

Idle speed Setting I: 0-1500 rpm

Setting 2: 0-3000 rpm

Drill chuck size Ø13mm

Weight 3.9Kg

Sound pressure level LpA 90 dB(A), KpA: 3 dB

Sound power level LwA 101 dB(A), KpA: 3 dB

Vibration emission values Holes in concrete

ah ID: 8,36 m/s

2

K ID: 1,5 m/s

2

Holes in metal

ah ID: 3,30 m/s

2

K ID: 1,5 m/s

2

Measured values determined in line with EN60745-2-1 and EN60745-1

Loading...

Loading...