Mar Cor Purification WRO 300, WRO 300 H Service Manual

Mar Cor Purification

WRO 300/300 H

Service Manual

Important User Information

Copyright © 2012 by Mar Cor Purification, Inc.

All rights reserved. No part of the contents of this manual may

be reproduced, copied, or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or

photocopying, recording, or information storage and retrieval

systems without the written permission of the publisher, unless

it is for the purchaser's personal use.

The information in this manual is subject to change without

notice and does not represent a commitment on the part of Mar

Cor Purification (MCP). MCP does not assume any responsibility for any errors that may appear in this manual. In no event

will MCP be liable for technical or editorial omissions made

herein, nor for direct, indirect, special, incidental, or consequential damages resulting from the use or defect of this manual.

The information in this document is not intended to cover all

possible conditions and situations that might occur. The end

user must exercise caution and common sense when installing, using, or maintaining MCP products. If any questions or

problems arise, call MCP Technical Services at 1-800-633-

3080.

Intended Use

MCP products are intended to be installed and used as

described in this manual and other related MCP literature.

WRO 300/300 H

Table of Contents

Table of Contents

Important User Information. . . . . . . . . . . . . . . . . . . . . . . 2

Intended Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table of Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Related Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Message Definitions . . . . . . . . . . . . . . . . . . . . . . 7

Safety Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

List of Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Certification Marks . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

IPR - Intellectual Property Rights . . . . . . . . . . . . . . . . . 10

Copyright. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Intended Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Reverse Osmosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Water Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pretreatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Microbiology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Check Water Quality . . . . . . . . . . . . . . . . . . . . . . . . 12

Technical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

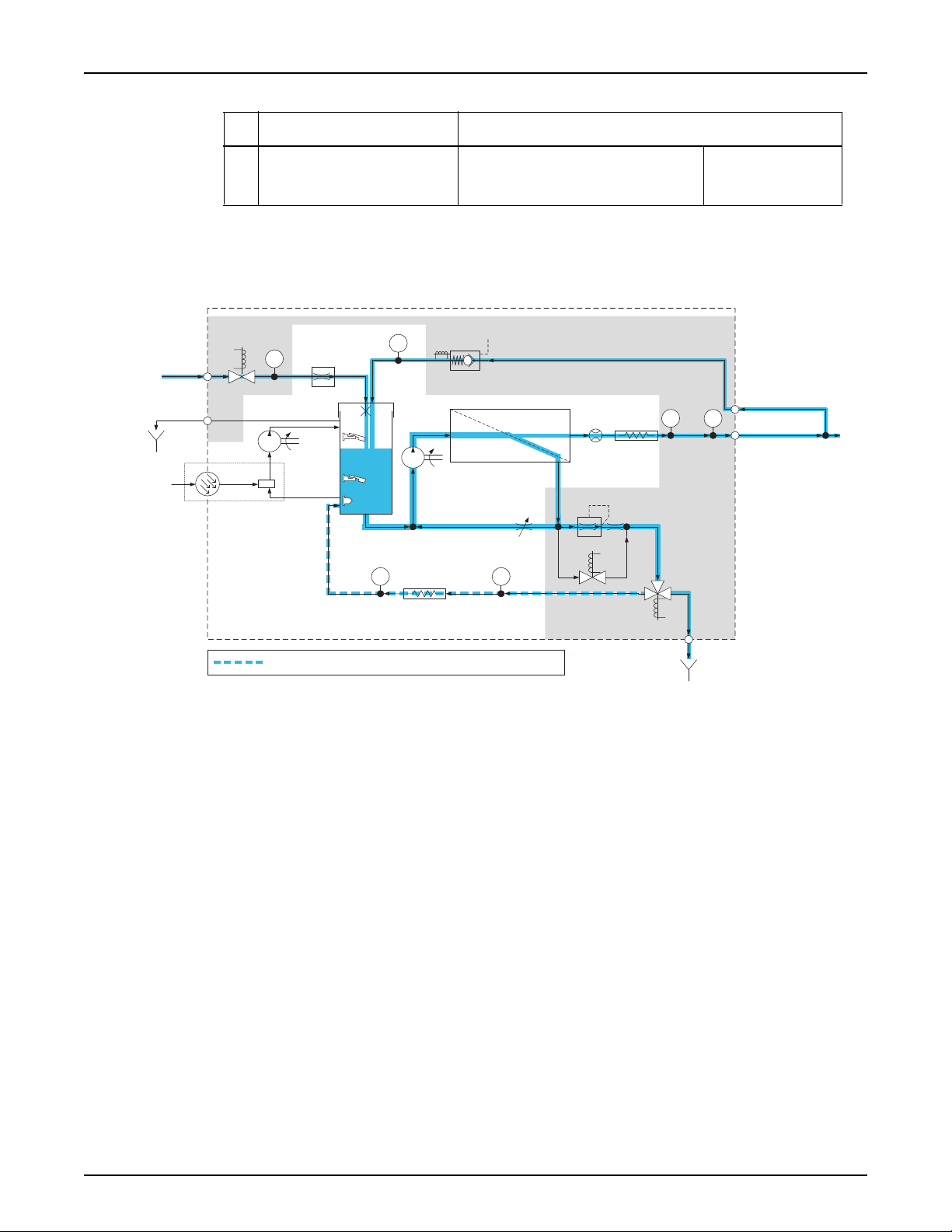

Flow Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Components in Flow Diagram. . . . . . . . . . . . . . . . . . . . 16

Flow Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chemical Disinfection and Cleaning . . . . . . . . . . . . 19

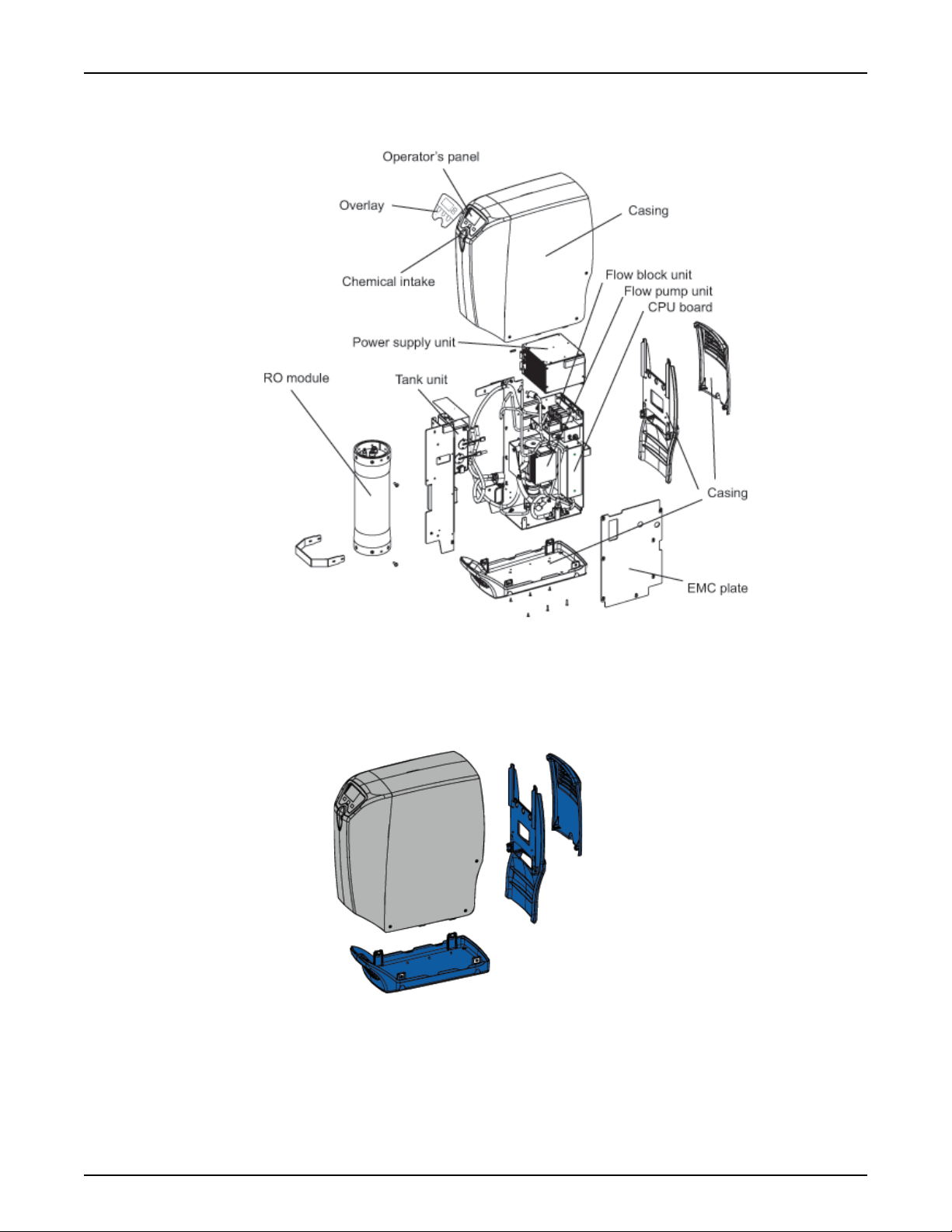

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

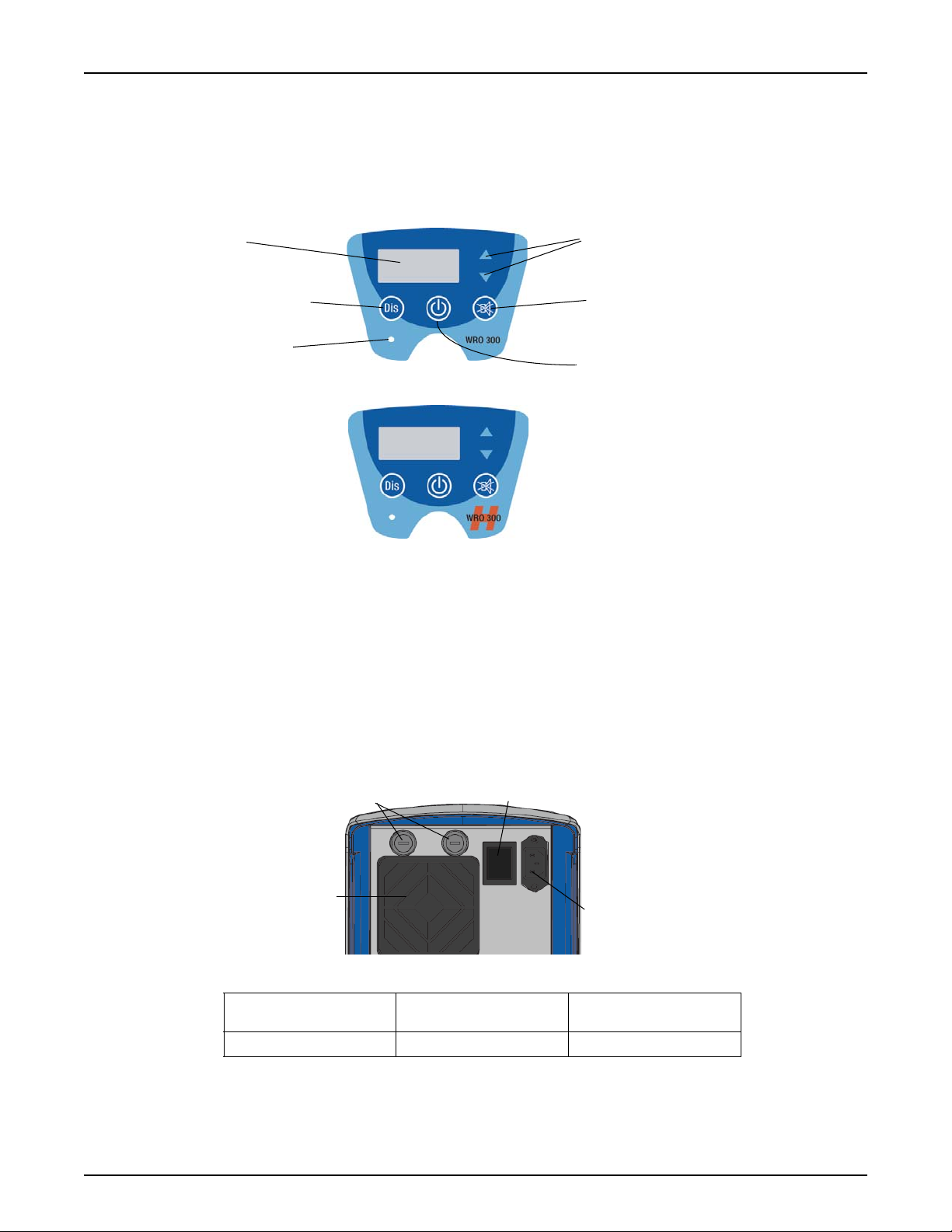

Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Power Supply Unit. . . . . . . . . . . . . . . . . . . . . . . . . . 22

Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Y Coupling and Product Water Loop. . . . . . . . . . . . 23

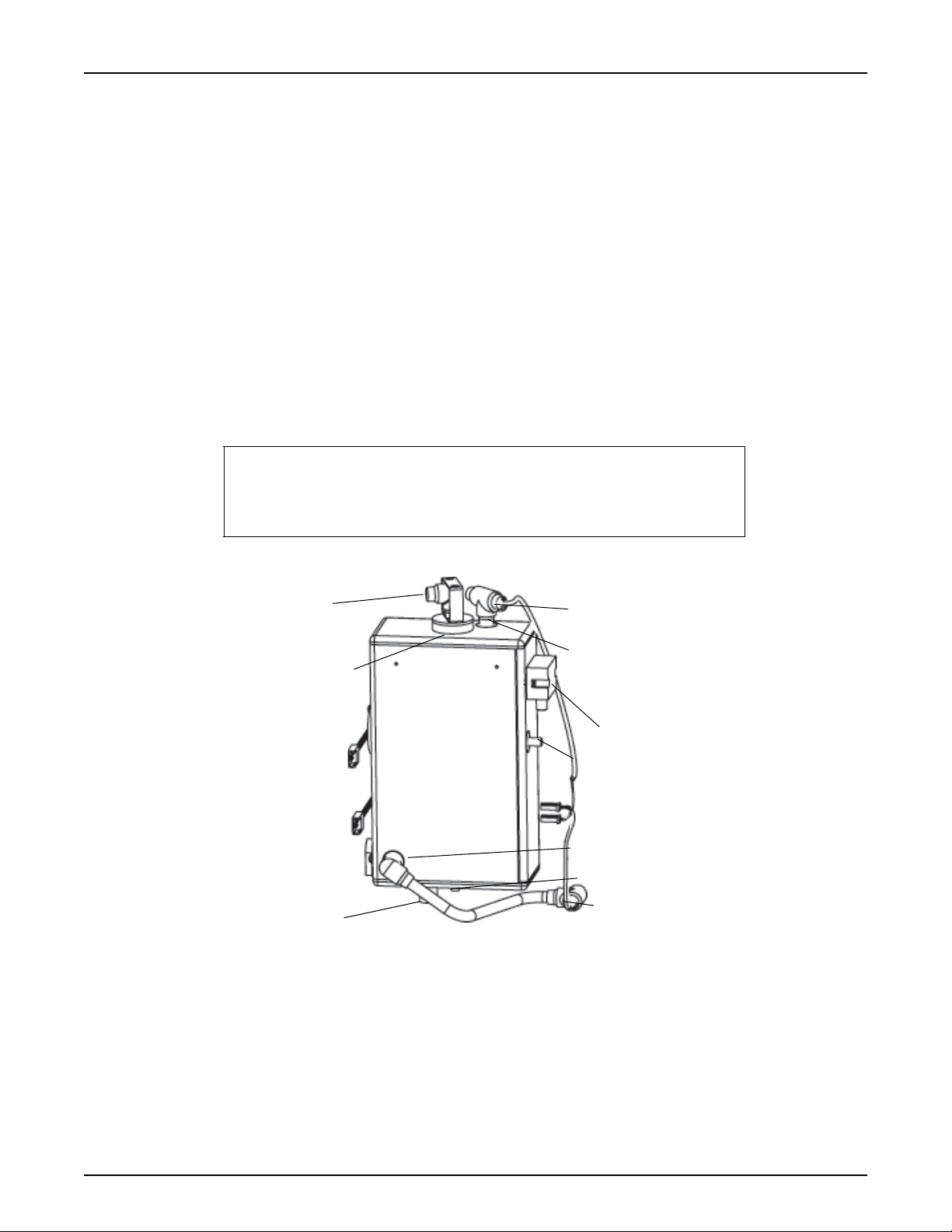

Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

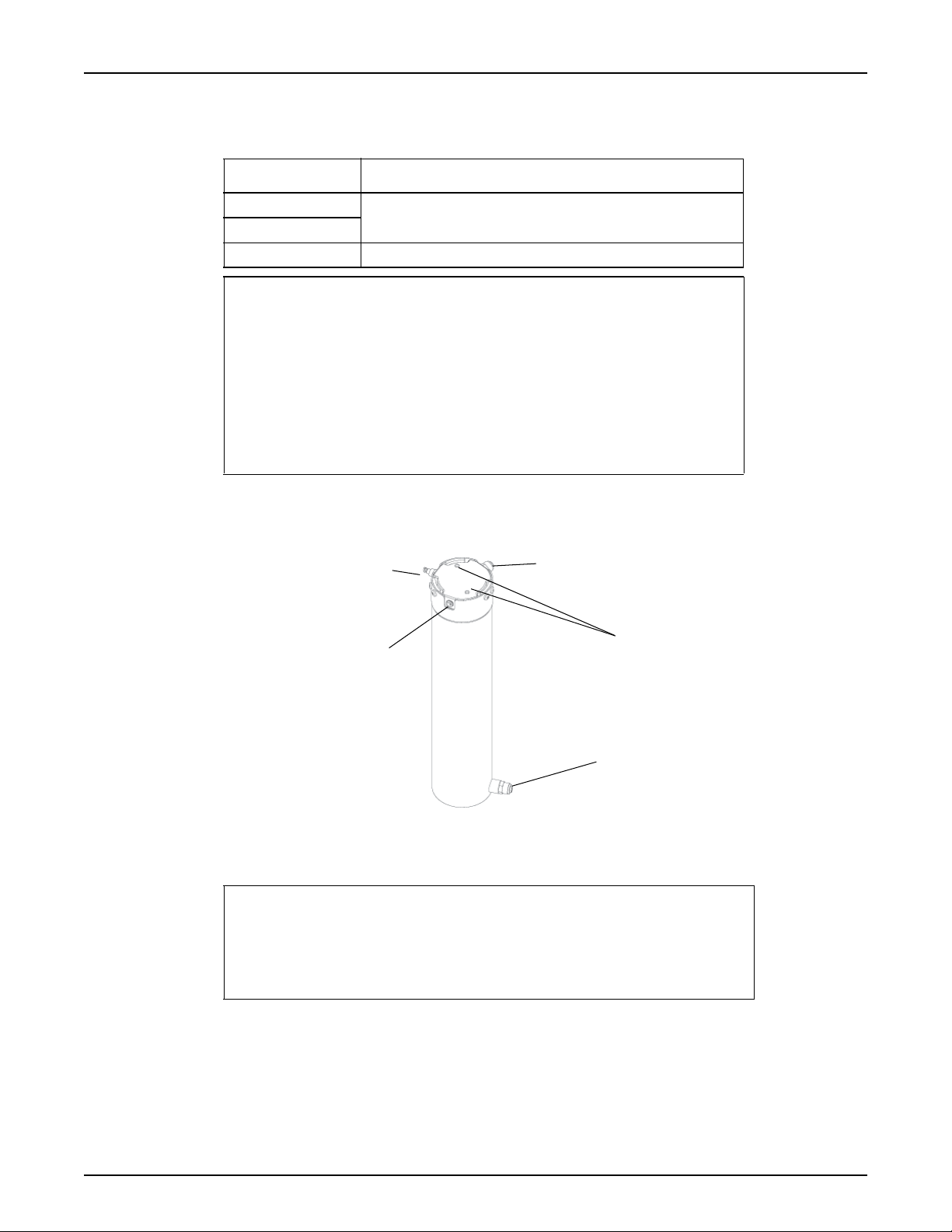

RO Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Motor and RO Pump Unit . . . . . . . . . . . . . . . . . . . . 25

Cooling Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Flow Block Complete. . . . . . . . . . . . . . . . . . . . . . . . 26

Needle Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chemical Intake Unit . . . . . . . . . . . . . . . . . . . . . . . . 27

P/N 3027437 Rev. B

3

Table of Contents

WRO 300/300 H

CPU Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

AC Relay Board (only WRO 300 H) . . . . . . . . . . . . 28

External Communication Connections . . . . . . . . . . 28

Heaters (only WRO 300 H) . . . . . . . . . . . . . . . . . . . 28

Mains Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . 29

Description of Indications . . . . . . . . . . . . . . . . . . . . . . . 29

Light Indications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Buzzer Sounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Operation Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Auto Flush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Changing from Run to Standby Mode. . . . . . . . . . . . . . 35

Start After Power Loss. . . . . . . . . . . . . . . . . . . . . . . 35

Hygiene Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Manual Flush. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Chemical Disinfection and Cleaning . . . . . . . . . . . . 37

Dwell and Rinse. . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Preservation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Heat Disinfection (only WRO 300 H). . . . . . . . . . . . 48

Features — Extra Functions. . . . . . . . . . . . . . . . . . . . . 53

Water Save Function. . . . . . . . . . . . . . . . . . . . . . . . 53

Reminders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Time Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Replacements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Replacement Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Internal Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Changing Configuration Parameters. . . . . . . . . . . . . . . 59

Internal Service Mode. . . . . . . . . . . . . . . . . . . . . . . . . . 59

Enter Internal Service Mode . . . . . . . . . . . . . . . . . . 59

Internal Service Loop. . . . . . . . . . . . . . . . . . . . . . . . 60

PC Support Software . . . . . . . . . . . . . . . . . . . . . . . . . . 71

USB Serial Driver Installation . . . . . . . . . . . . . . . . . 71

GXL — Logging. . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

GXP — Preset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Checksum Status . . . . . . . . . . . . . . . . . . . . . . . . . . 75

GWD - Download. . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Start the GWD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Presets and Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Change Presets for WRO 300 H. . . . . . . . . . . . . . . 82

RO Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Tank Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Water Save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Conductivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

User Interface Panel (LCD). . . . . . . . . . . . . . . . . . . 87

4

P/N 3027437 Rev. B

WRO 300/300 H

Table of Contents

Heat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Disinfection Protocol Manager. . . . . . . . . . . . . . . . . 90

Chemical Disinfection . . . . . . . . . . . . . . . . . . . . . . . 95

Time Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Time Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Reminders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Remote . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

External relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

WRO 300 H. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

WRO 300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Water Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Total Chlorine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Residual Hardness . . . . . . . . . . . . . . . . . . . . . . . . 105

Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . 105

Changing Prefilter Cartridges . . . . . . . . . . . . . . . . . . . 105

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Replacing Carbon Block Filters. . . . . . . . . . . . . . . 106

Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Air Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Protective Earth (PE). . . . . . . . . . . . . . . . . . . . . . . 106

Adjusting Product Water Flow. . . . . . . . . . . . . . . . . . . 106

Using Adjustment Tool 3027493 . . . . . . . . . . . . . . 106

Using Adjustment Tool WT100TEST. . . . . . . . . . . 108

Conductivity Adjustment . . . . . . . . . . . . . . . . . . . . . . . 109

Adjustment Procedure. . . . . . . . . . . . . . . . . . . . . . 109

Checking Operator Panel . . . . . . . . . . . . . . . . . . . . . . 110

Checking Chemical Intake O-rings . . . . . . . . . . . . . . . 111

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 111

WRO 300/300 H Battery . . . . . . . . . . . . . . . . . . . . 111

Battery and Electronic Waste Handling. . . . . . . . . 111

Waste Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . 112

P/N 3027437 Rev. B

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Protective Earth Test . . . . . . . . . . . . . . . . . . . . . . . . . 113

Test Equipment for PET Test.. . . . . . . . . . . . . . . . 113

PET for WRO 300 . . . . . . . . . . . . . . . . . . . . . . . . . 113

PET for WRO 300 H . . . . . . . . . . . . . . . . . . . . . . . 113

Electrical Leakage Test (ELT). . . . . . . . . . . . . . . . . . . 113

ELT Test Equipment . . . . . . . . . . . . . . . . . . . . . . . 113

ELT General Conditions . . . . . . . . . . . . . . . . . . . . 113

ELT WRO 300. . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

ELT WRO 300 H . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Earth Current Limits. . . . . . . . . . . . . . . . . . . . . . . . 114

5

Table of Contents

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

WRO 300/300 H

Performance and Specification. . . . . . . . . . . . . . . . . . 115

Chemical Disinfection . . . . . . . . . . . . . . . . . . . . . . . . . 119

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Materials Contacting Product Water. . . . . . . . . . . . . . 120

Environmental Data . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Electromagnetic Environment. . . . . . . . . . . . . . . . . . . 121

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Internal Error (103:N). . . . . . . . . . . . . . . . . . . . . . . 127

Internal Error (104) . . . . . . . . . . . . . . . . . . . . . . . . 131

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Heat (only WRO 300 H). . . . . . . . . . . . . . . . . . . . . 138

Chem/Rinse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Boot Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

6

P/N 3027437 Rev. B

WRO 300/300 H

Preface

Related Manuals

This manual provides the information needed to carry out maintenance

and to identify and remedy any fault that may occur on the WRO 300

water purification unit and the WRO 300 H water purification unit.

The complete model name WRO 300 unit or WRO 300 H unit is used

only when the information is specific and only valid for one of the models. The WRO unit refers to information valid for both models.

The list below shows manuals related to this Service Manual. Always

specify the revision level when ordering the manual for your water purification machine.

Installation Guide, WRO 300/300 H 3027502

Operator’s Manual WRO 300 3027435

Operator’s Manual WRO 300

H

3027436

Preface

Safety Message Definitions

WARNING

Is used to alert the user/operator not to take a certain action,

which if taken can cause a potential hazard and result in a

serious adverse reaction, injury or death. A warning may also

be used to alert the user/operator to take a certain action to

avoid the potential hazard as above.

CAUTION

Is used to alert the user/operator to take a certain action to

protect against a potential hazard which, if ignored, could have

an adverse effect on the patient or the device. A caution may

also be used to alert the user/operator not to take a certain

action to avoid the potential hazard as above.

NOTE

A reminder to the user/operator on normal treatment activity and on

what is a suitable action in a particular situation.

Safety Considerations

WARNING

Unauthorized installation, modifications, alterations or repair of

the WRO unit may result in malfunctioning or have other serious

consequences for the safe operation of the equipment.

P/N 3027437 Rev. B

7

Preface

WRO 300/300 H

CAUTION

• Dialysis machines that are supplied with water from the WRO

unit, must comply with IEC 60601-2-16.

• The WRO unit should only be operated by persons trained in

the use of this equipment and who have studied the instructions in the Operator’s Manual. If the WRO unit does not perform as described in the Operator’s Manual, it should not be

used until the condition is rectified.

• The operator should pay attention to alarms and follow the

instructions, warnings, cautions and notes given in the manual.

• The use of mobile telephones or communication equipment

in the vicinity of the WRO unit could adversely influence the

performance of the machine.

• The WRO unit needs special precautions regarding EMC and

needs to be installed and put into service according to the

EMC information provided in the Operator’s and Service

Manual (refer to Technical Data on page 115).

• The WRO unit is not suitable for use in the presence of a flammable anesthetic mixture with air or with oxygen or nitrous

oxide.

• The WRO unit will perform as designed only if it is used and

maintained in accordance with MCP’s instructions. Any warranties made by MCP with respect to the WRO unit, are void

if the equipment is not used in accordance with the instructions provided. MCP will not accept responsibility for any

damage or injury resulting from improper use or maintenance

or unauthorized repair.

• The user must verify the quality of the protective earth in the

installation.

• U.S. Federal law restricts this device to sale by, or on the

order of, a physician.

NOTE

• On delivery the WRO unit is filled with preservation and antifreeze solution. This solution must be rinsed out before the WRO

unit is put into operation.

• During transportation and storage the equipment must be kept in

its original packing. If transportation or storage time is more than

15 weeks the environmental data relating to the operation must

be fulfilled (refer to Technical Data on page 115).

• The WRO unit is intended for continuous operation.

8

P/N 3027437 Rev. B

WRO 300/300 H

CB

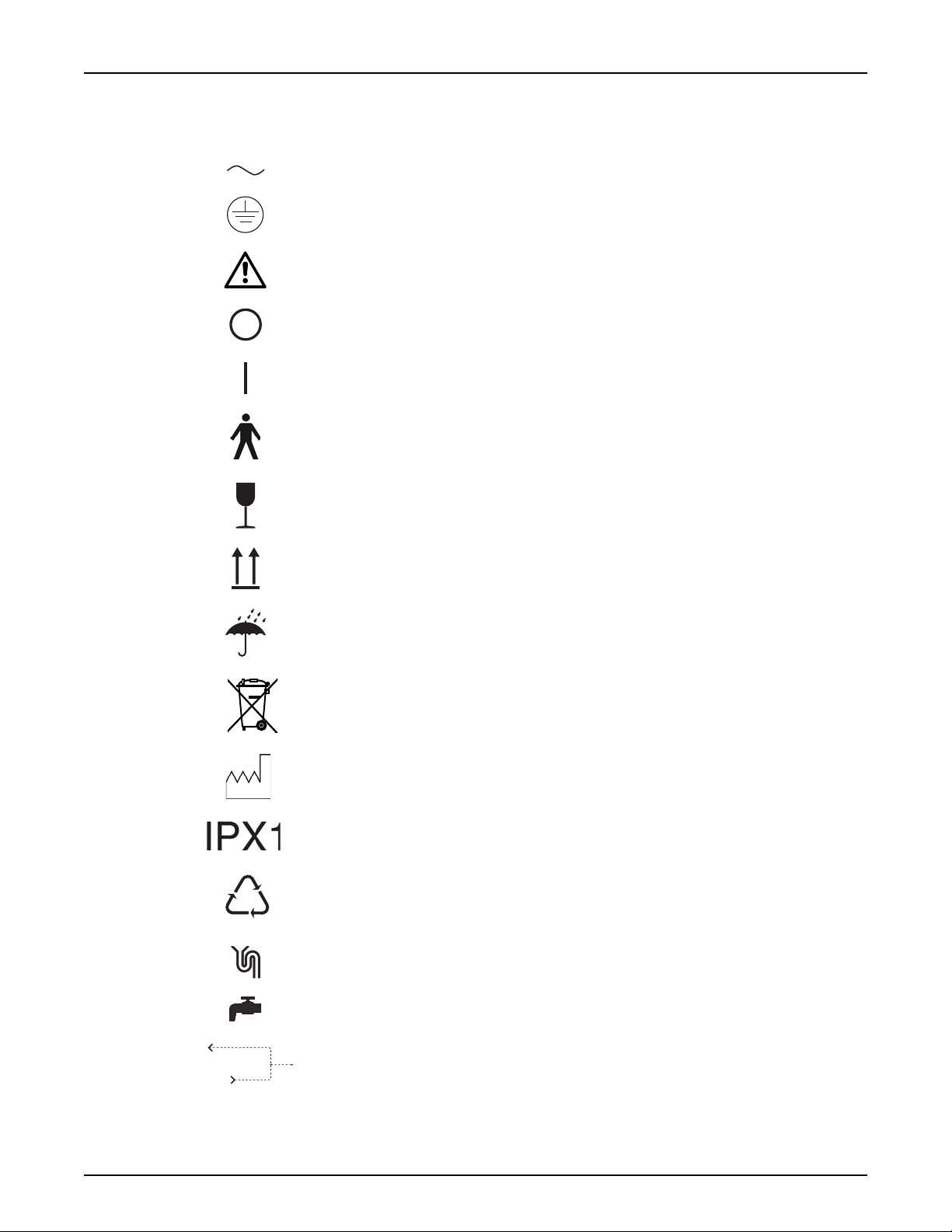

List of Symbols

Preface

Alternating current

Protective earth (ground)

Warning, consult accompanying documents

Off (power, disconnection from the mains)

On (power, connection to the mains)

Type B, applied part

Handle with care

This way up

Keep dry

Separate collection for electrical and electronic

equipment

Year of manufacturing

The WRO 300/300 H is protected against dripping

water

Recycling symbol -General

Reject water connection

Feed water inlet connection

P/N 3027437 Rev. B

Loop connections (Product water outlet and return)

9

Preface

WRO 300/300 H

ME equipment and ME systems that include RF

transmitters or that intentionally apply RF electromagnetic energy for diagnosis or treatment shall be

labeled with this symbol.

Certification Marks

The CSA(C-US) mark indicates that the WRO 300/

300 H water purification units conform to the requirements related to safety of medical devices for the US

and Canada. The C and the US adjacent to the CSA

mark indicates that the WRO 300/300 H water purification units have been evaluated to the applicable

ANSI/UL and CSA standards for use in the US and

Canada.

IPR - Intellectual Property Rights

Copyright

© 2012 Mar Cor Purification, Inc.

Trademarks

DIALOX® is a trademark registered in several countries, including Sweden, United

Kingdom and Japan by their respective owners.

MINNCARE® is a trademark of Minntech registered in several countries including

United States and United Kingdom.

MINNCLEAN® is a trademark of Minntech registered in several countries including

the United States.

SteriChek® is a trademark registered in several countries including the United

States and Japan by their respective owners.

ULTRASIL® is a trademark of Ecolab registered in several countries including Australia and Canada.

Manufacturer

Mar Cor Purification, Inc.

14550 28th Avenue North

Plymouth, MN 55447

USA

Phone: 1-800-633-3080

Fax (Customer Service): 1-763-210-3868

www.mcpur.com

10

P/N 3027437 Rev. B

WRO 300/300 H

product water

Pressure

membrane

feed water

reject water

1 Introduction

1.1 Intended Use

Introduction

The MCP WRO 300/300 H Water Purification Unit is intended to be

used as a dialysis accessory to produce water through reverse osmosis for one hemodialysis equipment.

The WRO 300/300 H can be connected to hemodialysis equipment

used both in hospitals and in home environments, in conjunction with

appropriate pre and post treatment units, as a part of a water treatment

system designed to meet applicable regulations or standards for water

for dialysis, for example current AAMI and Federal (U.S.) standards.

CAUTION

The water produced by the WRO unit should be analyzed at

installation and on a regular basis to verify that it conforms to

applicable regulations or standards for water for dialysis.

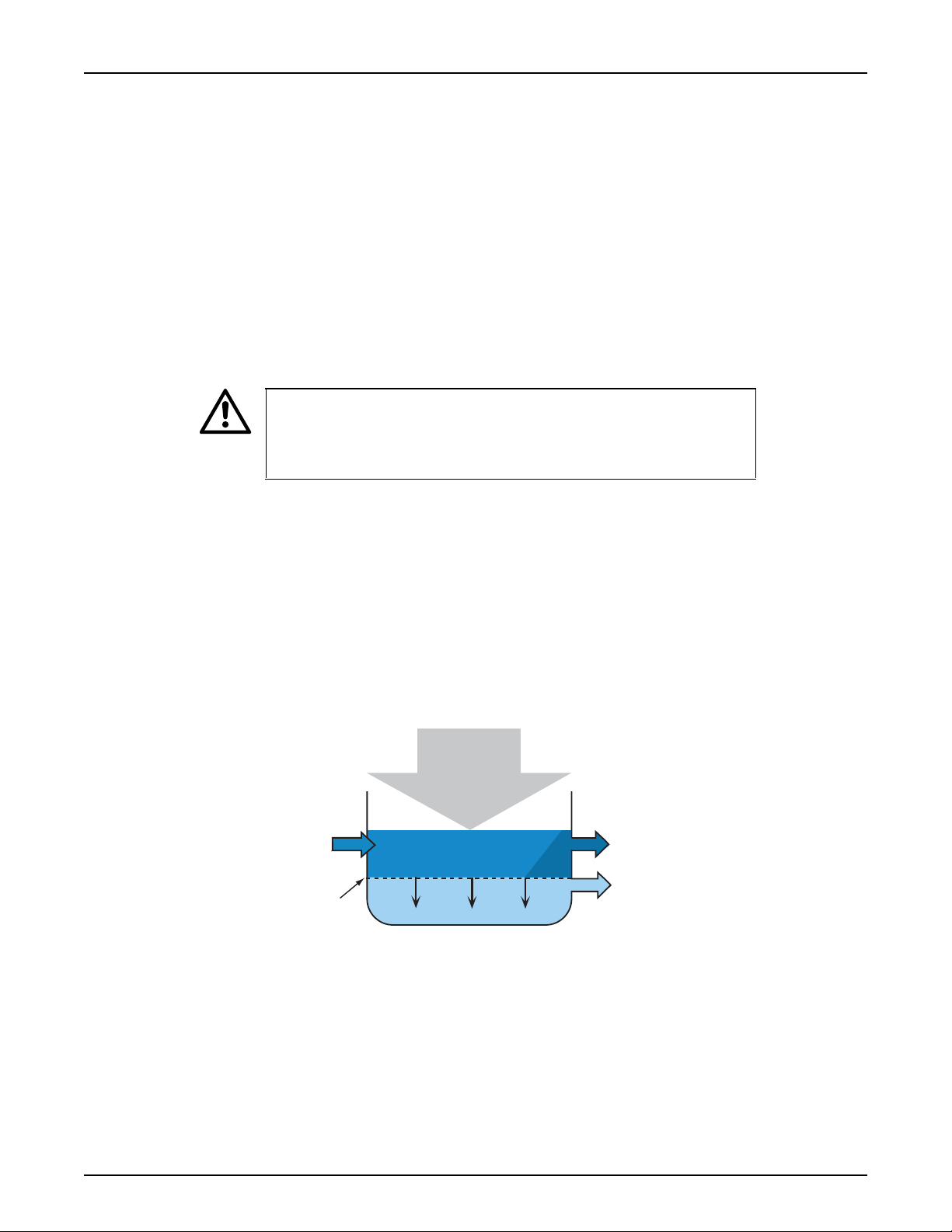

1.2 Reverse Osmosis

Reverse osmosis (RO) is a membrane process that is the most widely

used technique for purification of water for dialysis. When the feed

water is in contact with the semipermeable membrane (the most vital

part of the system) and a high pressure is applied, water will flow

through the membrane to the product water side. Most of the other

constituents (dissolved salts, particles, bacteria and pyrogens) will

remain on the feed water side of the membrane and be flushed to drain

as reject water.

Fig.1.1 — Principal of reverse osmosis

P/N 3027437 Rev. B

1.3 General Function

A high-pressure pump feeds water (usually pretreated water) into the

RO module, containing the membrane. The product water leaves the

RO module through the product water outlet into the product water

loop, to which the dialysis machine is connected. The reject water

leaves the WRO unit via the drain outlet.

11

Introduction

WRO 300/300 H

1.4 Water Quality

1.4.1 Pretreatment

The quality of the incoming water varies from one place to another. Different pretreatment equipment may be required depending on the local

water quality and regulations. An acceptable quality of the feed water

is required, that is in accordance to Technical Data on page 115. As a

minimum, 5 micron prefiltration must be applied. Additional pretreatment, such as carbon filters and softener, may be required depending

on the feed water quality.

WARNING

This device does not remove chlorine and chloramines from the

water. Carbon filtration to remove these substances is therefore

required if the total chlorine concentration might exceed 0.1 mg/l

(ppm). Severe patient injury may otherwise occur. Ensure by testing or by other means that the total chlorine concentration is

below 0.1 mg/l (ppm) prior to initiating dialysis treatment.

1.4.2 Microbiology

The water quality is a very important factor in achieving and maintaining an adequate quality of the dialysis fluid. The microbiological quality

of the product water depends not only on technical parameters such as

retention rates of membranes, but also to a large extent on other factors:

• Feed water shall comply to relevant standards for drinking water.

• Handle taps and connectors in such a manner to avoid microbiological contamination (any pretreatment device, the WRO unit and

the dialysis machine).

• Provide for regular and pro-active disinfection of the WRO unit.

• Set up air gap between the drain outlet and the drain to avoid

microbiological contamination from the drainage system. Refer to

the Installation Guide for the WRO unit.

1.4.3 Check Water Quality

The ions in the water effect the conductivity; the ability to conduct an

electric current. To get an indication of the water quality from a chemical perspective, the WRO unit measures the conductivity of the feed

water and the product water. The conductivity values (µS/cm) indicate

the performance of the WRO unit. Further water tests are, however,

necessary. Refer to Water Testing on page 105.

12

P/N 3027437 Rev. B

WRO 300/300 H

Introduction

CAUTION

The conductivity value does not always indicate the suitability of

the water for dialysis. For example, aluminium may be present in

concentrations well exceeding recommended standards without

affecting the conductivity. Therefore the quality of the product

water, used for dialysis, should be verified by regular analysis of

the water.

P/N 3027437 Rev. B

13

Introduction

WRO 300/300 H

This page is blank.

14

P/N 3027437 Rev. B

WRO 300/300 H

C2T1

RO module

Tank

Needle

valve

Constant flow valve

Feed

water

Chemical

Connector

Drain

Tank air vent

INVA

Chemical

intake

pump

RO pump

L.H.

L.L.

L.E.

Chemical

Intake

OFVA

BYVA

REVA

Drain

Drain

outlet

Product

water

Loop

Constant

flow valve

Spray nozzle

FT2

Heater A

Heater B

Flow meter

T3

C1

Flow block

12 3

4

5

8

6

9

10

7

11

12 13 14

16

15

17

18

19

20

21

22

23

25

24

26

28

27

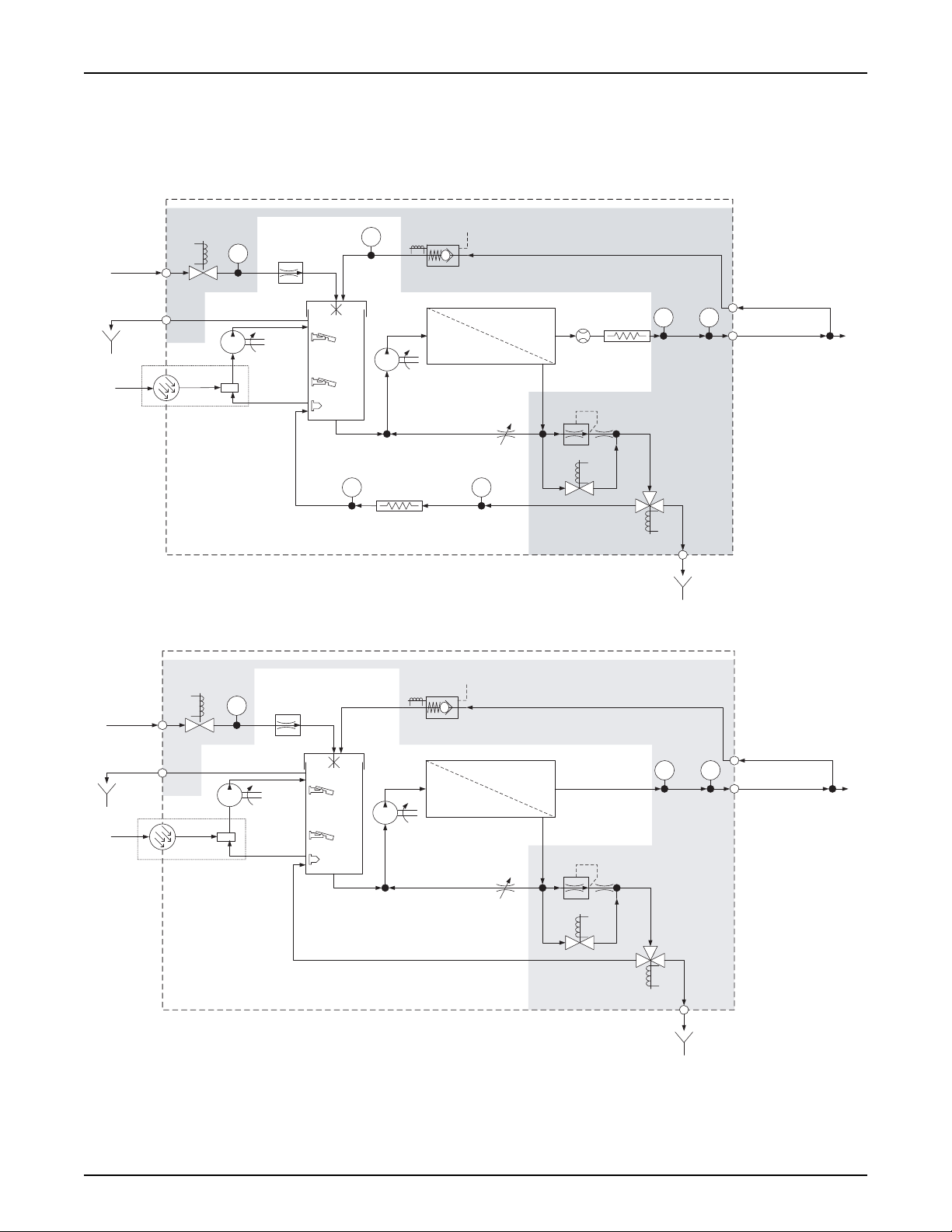

Fig.2.1 — Flow diagram for the WRO 300 H unit

C2T1

RO module

Tank

Needle

valve

Constant flow valve

Feed

water

Chemical

Connector

Drain

Tank air vent

INVA

RO pump

L.H.

L.L.

L.E.

Chemical

Intake

OFVA

BYVA

REVA

Drain

Drain

outlet

Product

water

Loop

Constant

flow valve

Spray nozzle

C1

Flow block

12 3

4

5

8

6

9

7

12 13 14

15

17

18

19

20

25

24

26

28

27

Chemical

intake

pump

Fig.2.2 — Flow diagram for the WRO 300 unit

2 Technical Description

2.1 Flow Diagrams

Technical Description

P/N 3027437 Rev. B

Components in the grey area in the illustrations above are mounted on

the flow block.

15

Technical Description

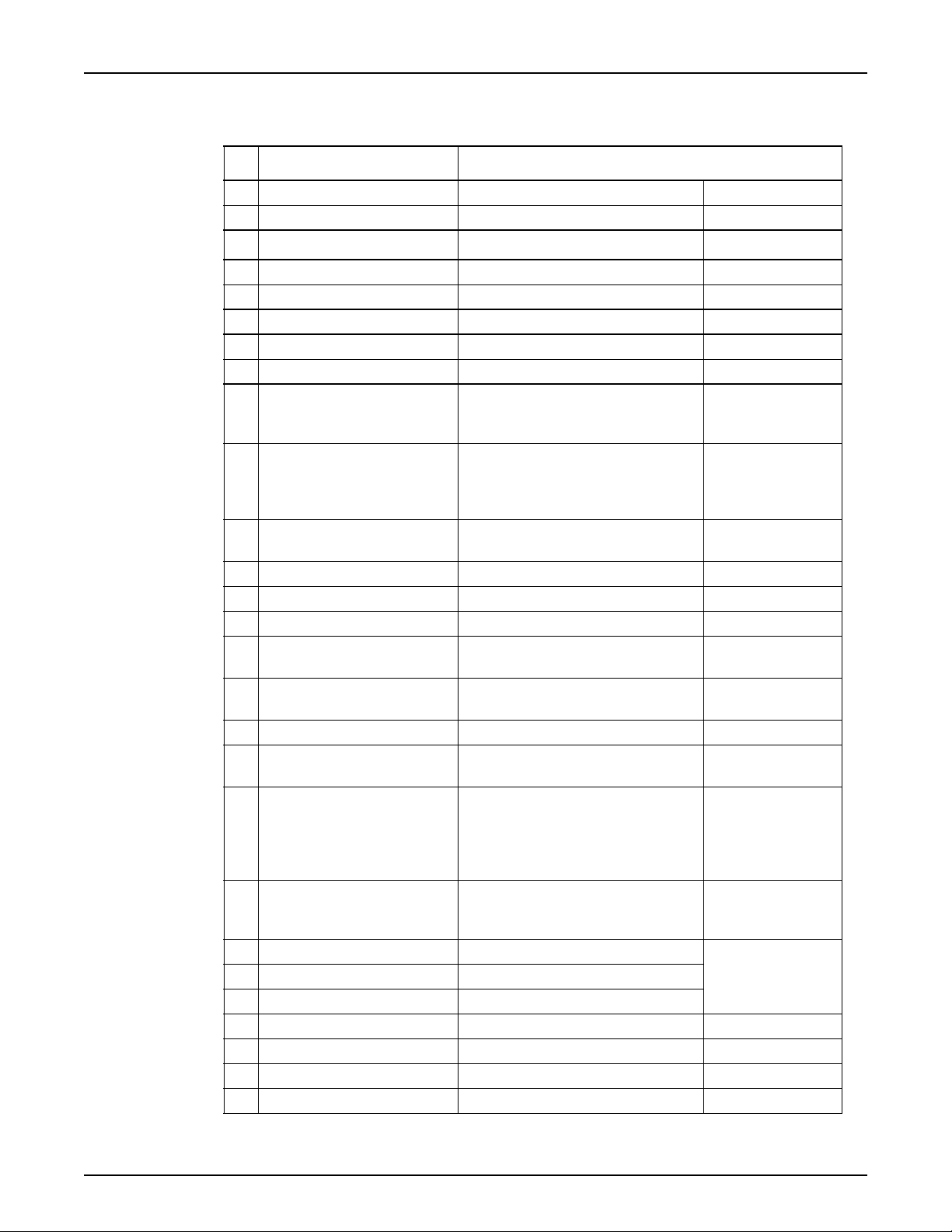

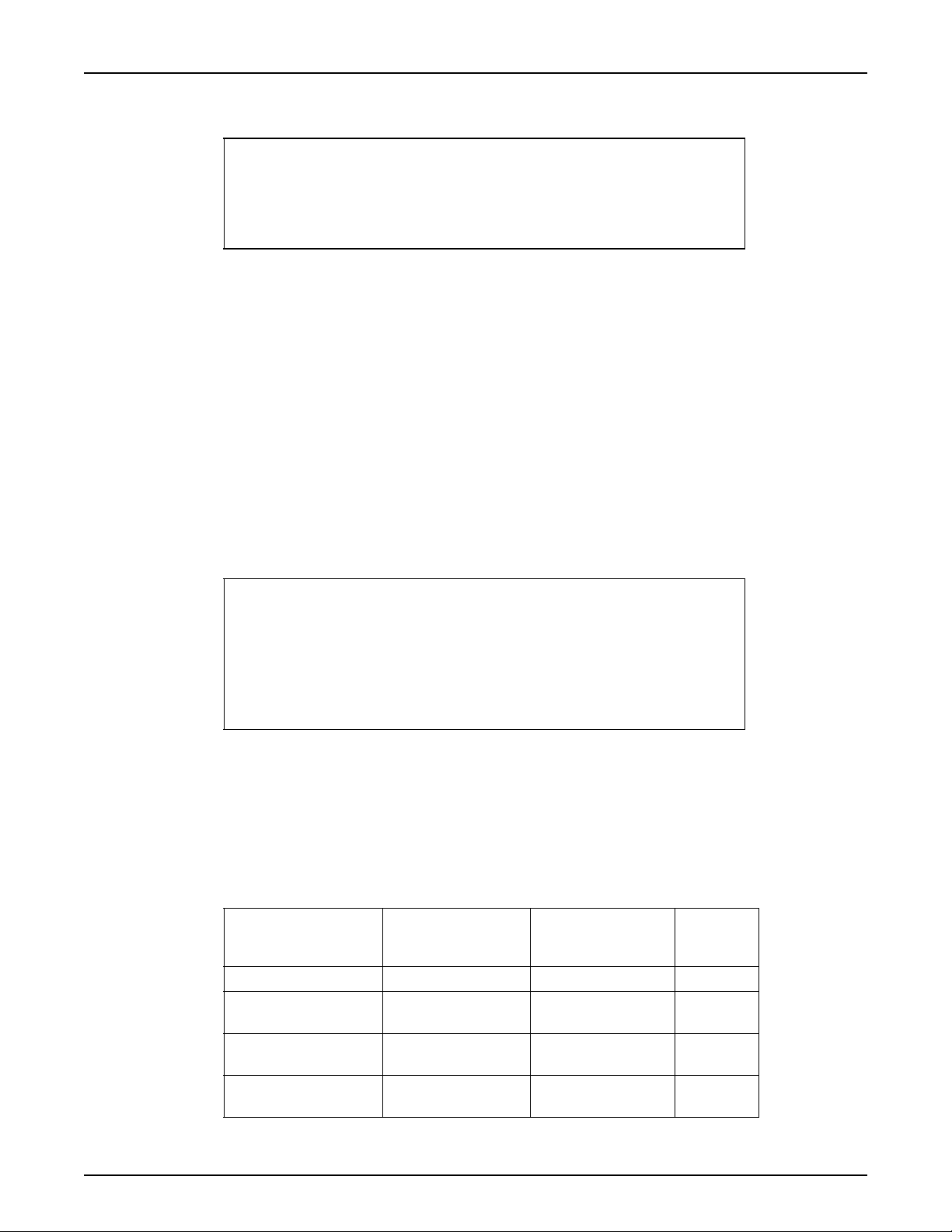

2.2 Components in Flow Diagram

Components Additional Information

1 Inlet valve (INVA) Two-way solenoid valve

2 Conductivity cell (C1) Monitor feed water conductivity

3 Constant flow valve

4 Tank Providing air gap

5 High level sensor (LH) Float level switch

6 Low level sensor (LL) Float level switch

7 Empty level sensor (LE) Optical sensor

8RO pump

9 RO module The WRO 300 unit and the WRO 300

10 Flow meter In product water line

11 Heater B In product water line only in the

12 Temperature sensor (T1) For product water

13 Conductivity cell (C2) Monitor product water conductivity

14 Product water loop To and from the dialysis machine

15 Overflow valve (OFVA) Two-way solenoid valve

16 Temperature sensor (T3)

product water return

17 Needle valve For reject recirculation

18 Constant flow valve 1200 ml / minute when BYVA (19) is

19 Reject bypass valve (BYVA) The two-way solenoid valve,

20 Reject valve (REVA) Three-way solenoid valve

21 Flow indicator Recirculated reject water only in the

22 Heater A Recirculated reject water

23 Temperature sensor (T2) Recirculated reject water

24 Chemical intake

25 Three-way valve Manual operation

26 Optical sensor Detects the wand

27 Chemical intake pump

Approximately

H unit have different membranes and

different pressure vessels.

(Can also be installed in the WRO 300

unit, refer to separate Spare Part

Instruction).

for product water return

closed.

when active (open), most of the reject

water bypasses the constant flow

valve (18) and the pressure in the

WRO unit is minimized.

diverts reject water either to tank or to

drain.

4000 ml / minute

WRO 300/300 H

only in the

WRO 300 H unit

WRO 300 H unit

only in the

WRO 300 H unit

WRO 300 H unit

16

P/N 3027437 Rev. B

WRO 300/300 H

C2T1

RO module

Tank

Needle

valve

Constant flow valve

Feed

water

Chemical

Connector

Drain

Tank air vent

INVA

Chemical

intake

pump

RO pump

L.H.

L.L.

L.E.

Chemical

Intake

OFVA

BYVA

REVA

Drain

Drain

outlet

Product

water

Loop

Constant

flow valve

Spray nozzle

FT2

Heater A

Heater B

Flow meter

T3

C1

Flow block

= only during Water Save phases if the function is enabled

2.3 Flow Description

2.3.1 Run

Technical Description

Components Additional Information

28 Tank air vent Connects the tank to the atmosphere

and is also used as overflow connection.

Fig.2.3 — Flow description

The feed water enters the WRO unit through the inlet solenoid valve

INVA. The conductivity cell C1 monitors the feed water conductivity.

The feed water passes the constant flow valve which regulates a

steady flow of water into the tank, approximately 4 l/min, if the feed

water pressure is above minimum pressure.

The low and high level sensors in the tank (LL and LH) detect the

water level and the program controls the opening and closing of the

inlet solenoid valve INVA. INVA is open during filling, and closes when

the water level reaches LH. INVA opens again when the water level is

below LL. If the water level in the tank gets too high, excess water is

drained through the tank air vent (overflow connection). The RO pump

stops when the empty level sensor LE detects air.

The RO-pump creates the feed water flow required for the reverse

osmosis process. The pump speed ramps up during the initial two to

three seconds. Higher pressure forces more water through the membrane. (The manually adjusted needle valve effects the water pressure

in the RO module.).

P/N 3027437 Rev. B

17

Technical Description

NOTE

High flow velocity over the RO membrane is important for proper

function of the WRO unit. Part of the reject water is recirculated

through the needle valve, while still maintaining low water consumption. Also, excess product water is recirculated to save water.

When the product water leaves the RO module in a WRO 300 H unit, it

flows by the flow meter, the heater B, and the temperature sensor T1,

(in a WRO 300 unit only T1). The conductivity cell C2 monitors the

product water conductivity.

The product water leaves the WRO unit through the product water outlet and flows to the dialysis machine through the product water loop.

Excess product water, not used by the dialysis machine, returns to the

tank through the overflow solenoid valve OFVA (for functionality of the

OFVA, refer to page 26). In a WRO 300 H unit, the water flows across

the temperature sensor T3 before entering the tank.

The reject water leaves the RO module and flows through the constant

flow valve which regulates a steady flow of reject water to the threeway solenoid valve REVA. The rest of the reject water goes back to the

RO pump through the needle valve.

WRO 300/300 H

NOTE

As the needle valve is closed, it creates higher pressure in the RO

module and lower recirculation flow. Do not close the valve more

than necessary to obtain the required product water flow and pressure. Otherwise, ions build up at the membrane surface and cause

increased product water conductivity which may shorten the lifetime

of the membrane.

REVA diverts the reject water either to the drain or back to the tank

(if the water save function is enabled). In a WRO 300 H unit the water

also passes the flow indicator F, the heater A and the temperature sensor T2 when recirculating to tank.

The tables below illustrate an example of the relationship of the water

flow in the WRO unit during run, when the total amount of water flow

is 5.0 liters/minute.

1

Flow

From To Type of water

RO module product water loop total product water 1.1

RO module needle valve and

constant flow valve

constant flow valve drain outlet reject water,

needle valve RO pump reject water,

total reject water 3.9

to drain

recirculated

liter/min

1.2

2.6

18

P/N 3027437 Rev. B

WRO 300/300 H

From To Type of water

Technical Description

1

Flow

liter/min

product water loop tank product water,

recirculated

tap tank feed water 1.7

product water loop dialysis machine product water 0.5

1. In this example:

0.7

Flow

Sum of Flows to and from the RO module, (according

to example above)

feed water to the WRO unit +

product water (recirculated) +

reject water (recirculation part)

= total volume to RO module

total product water +

total reject water

= total volume from RO module

liter/

minute

1.7+

0.7+

2.6

= 5.0

1.1+

3.9

= 5.0

2.3.2 Chemical Disinfection and Cleaning

When the disinfection wand is connected to the chemical intake at the

front of the WRO unit, the three-way valve in the chemical intake unit

opens towards the chemical intake pump and the tank. The other end

of the wand is inserted into an external container with cleaning or disinfection solution. The chemical intake pump feeds the solution through

the wand into the tank. The optical sensor detects if the wand is connected or disconnected. When removed, the chemical intake pump

stops and the three-way valve closes towards the chemical connector

and instead allows for recirculation from tank through the chemical

intake unit, back to the tank, (during chemical disinfection, cleaning or

rinse). REVA also recirculates to the tank during some phases of

chemical disinfection, cleaning or rinse.

P/N 3027437 Rev. B

CAUTION

The chemical container must be located below the chemical

intake.

CAUTION

When requested by the WRO unit, remove the disinfection wand

from the chemical intake. Failure to remove the disinfection

wand can cause siphoning of the chemical solution from the bottle resulting in the tank overflowing chemical solution through the

back of the machine.

19

Technical Description

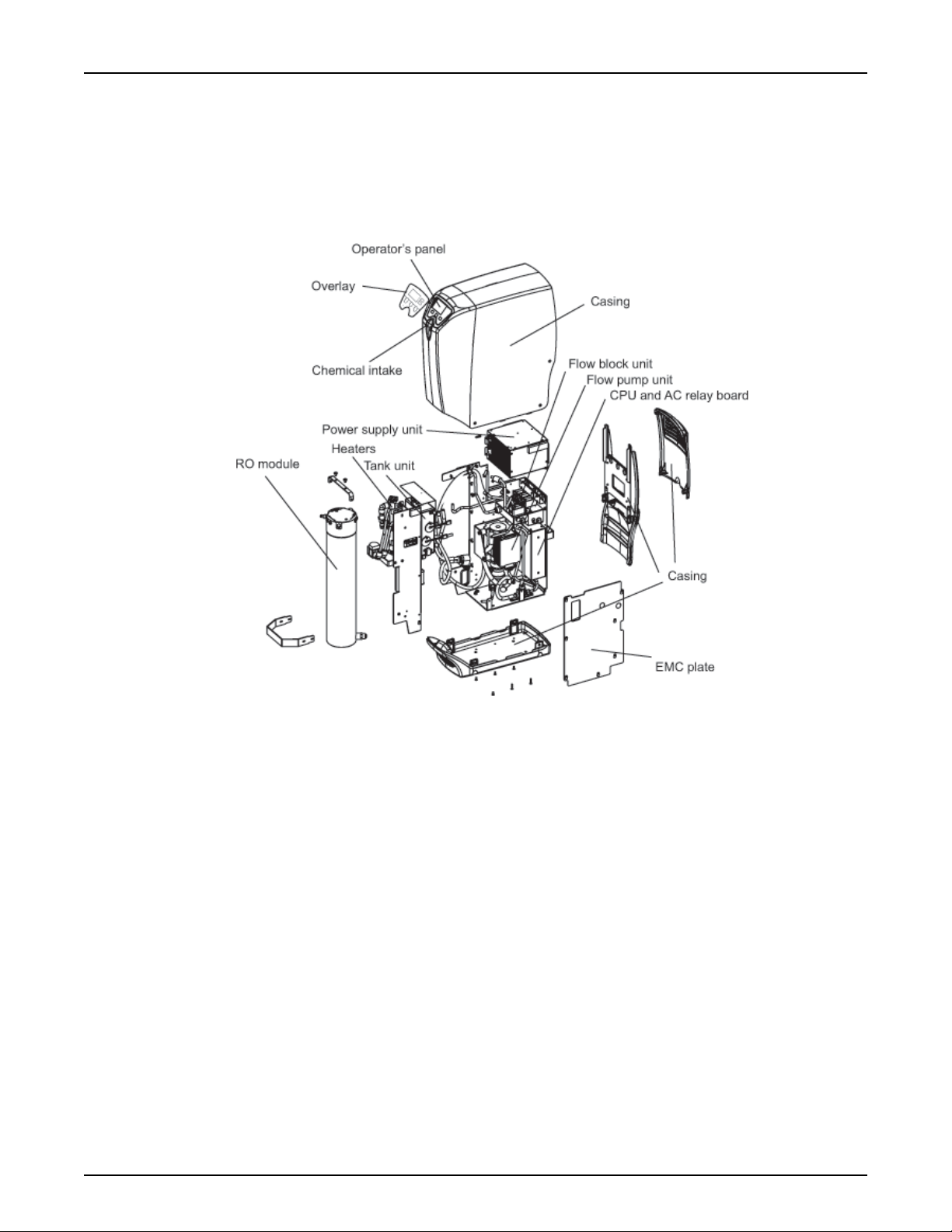

2.4 Components

2.4.1 Overview

WRO 300/300 H

20

Fig.2.4 — The WRO 300 H unit overview

P/N 3027437 Rev. B

WRO 300/300 H

Detachable cover

Casing back

Casing top

Tray

Technical Description

Fig.2.5 — The WRO 300 unit overview

2.4.2 Casing

The casing consists of four pieces as shown in the figure below.

Fig.2.6 — Casing

P/N 3027437 Rev. B

21

Technical Description

LCD

Arrow buttons

Mute button

Disinfection button

Run /Standby button

Lamp indication

Power ON

Power inlet

Mains power switch

Fan

Fuses

(only used in the WRO 300 H unit)

2.4.3 Operator Panel

The circuit board with the display, buttons, buzzer and LCD screen is

covered with an overlay. Overlay depends on model; WRO 300 unit or

WRO 300 H unit.

WRO 300/300 H

2.4.4 Power Supply Unit

The power supply unit adjusts automatically to the supplied voltage

(100, 115 or 220 to 240 VAC with 50 or 60 Hz). The internal voltage

supply is 24 VDC except for the heaters that are supplied with mains

power voltage, refer to Heat on page 87.

2.4.5 Fan

The fan cools the power supply unit.

Fuses for the WRO 300 H unit

1

1. Preset S32 must be changed, from GXP, to select the correct mains voltage.

Voltage

100 - 115 VAC 15 A SLO BLO ME20165

Fig.2.7 — Operator Panel

Fuse size MCP Order Number

22

P/N 3027437 Rev. B

WRO 300/300 H

Level sensor 1 (High)

Level sensor 2 (Low)

Level sensor 3 (Empty)

Tank air vent

Feed water inlet

Reject water

Product water return

From chemical intake pump

To chemical intake

To RO pump (RO module)

Spray nozzle

Temperature sensor (T3)

Temperature sensor (T2)

(only WRO 300 H)

(only WRO 300 H)

2.4.6 Y Coupling and Product Water Loop

2.4.7 Tank

2.4.7.1 Tank Air Vent

Technical Description

The product water loop consists of two hoses from the WRO unit connected to the parallel connections at the Y coupling. The hose from the

third connection at the Y coupling is connected to the dialysis machine.

The tank is supplied with feed water from the feed water inlet and product return water and, if the water saving function is in use, also reject

water from the reject valve (REVA). The water is distributed to the RO

module or to the chemical intake pump (during disinfection).

The tank air vent connects the tank to the atmosphere. If the water

level reaches the tank air vent the excess water leaves the tank. To

avoid back contamination of the feed water supply there is an air gap

between the feed water at the top of the tank, above the tank air vent.

NOTE

The tank air vent outlet must be connected with an air gap to drain.

If a hose is connected to the tank air vent the hose should have a

constant slope.

P/N 3027437 Rev. B

Fig.2.8 — Tank

2.4.7.2 Spray Nozzle

The feed water enters the tank unit through a spray nozzle to spray the

walls of the tank.

23

Technical Description

Feed water inlet

Product water outlet

Reject water outlet

Quick connector for

pressure gauge

2 holes, used to

remove the end plug

with withdrawing tool

2.4.7.3 Level Sensors

There are three level sensors in the tank to monitor the water level.

Level sensor Description

Low The high level sensor (LH) and the low level sensor (LL) are

High

Empty The empty level sensor (EL) is an optical sensor.

NOTE

• Avoid touching the optical sensors detection area with fingers and

do not expose it to dust. Optical sensors may be cleaned with a

gentle detergent or soap. Substances containing alcohol must not

be used.

• The float level switch can be permanently damaged if it is

dropped on a hard surface.

• To be able to use float level switches the program version must

be 4.0 or higher.

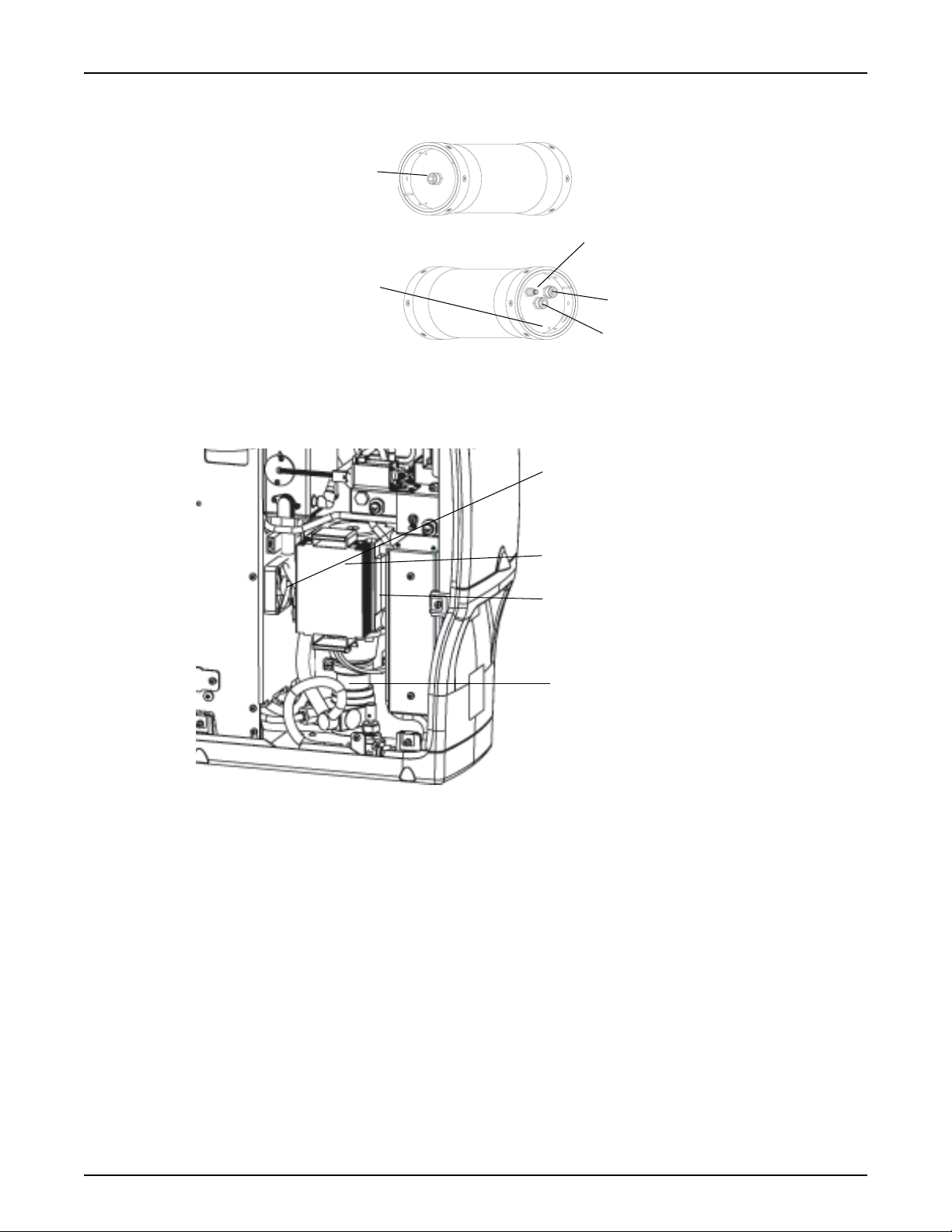

2.4.8 RO Modules

WRO 300/300 H

float level switches.

24

Fig.2.9 — RO module for the WRO 300 H unit

.

NOTE

• In a WRO 300 H unit, a new membrane element must be exposed

to at least one heat cycle before the rejection rate is acceptable.

• The membrane element must not be exposed to a pressure

exceeding 3 bar at temperatures above 45 °C.

P/N 3027437 Rev. B

WRO 300/300 H

Feed water inlet

Product water outlet

Reject water outlet

Quick connector for

pressure gauge

There are 4 holes,

used to remove

the end plug

with withdrawing tool

Motor controller unit

Pump motor

Cooling fan

RO pump

2.4.9 Motor and RO Pump Unit

Technical Description

Fig.2.10 — RO module for the WRO 300 unit.

P/N 3027437 Rev. B

Fig.2.11 — RO pump

The RO pump creates the required pressure and flow for the reverse

osmosis process and circulates the water in the WRO unit. It is driven

by a 24 VDC brushless motor with a controller unit.

2.4.10 Cooling Fan

The pump motor and the motor controller unit are cooled by a separate, internal cooling fan.

25

Technical Description

Reject valve

Inlet valve

Bypass valve

Return overflow

Conductivity sensor (C2)

Temperature sensor (T1)

Conductivity sensor (C1)

valve (OFVA)

(BYVA)

(REVA)

(INVA)

From tank air vent

To needle valve

To product water outlet

From reject outlet on the RO module

Return overflow line to tank

Feed water to tank

Reject water line

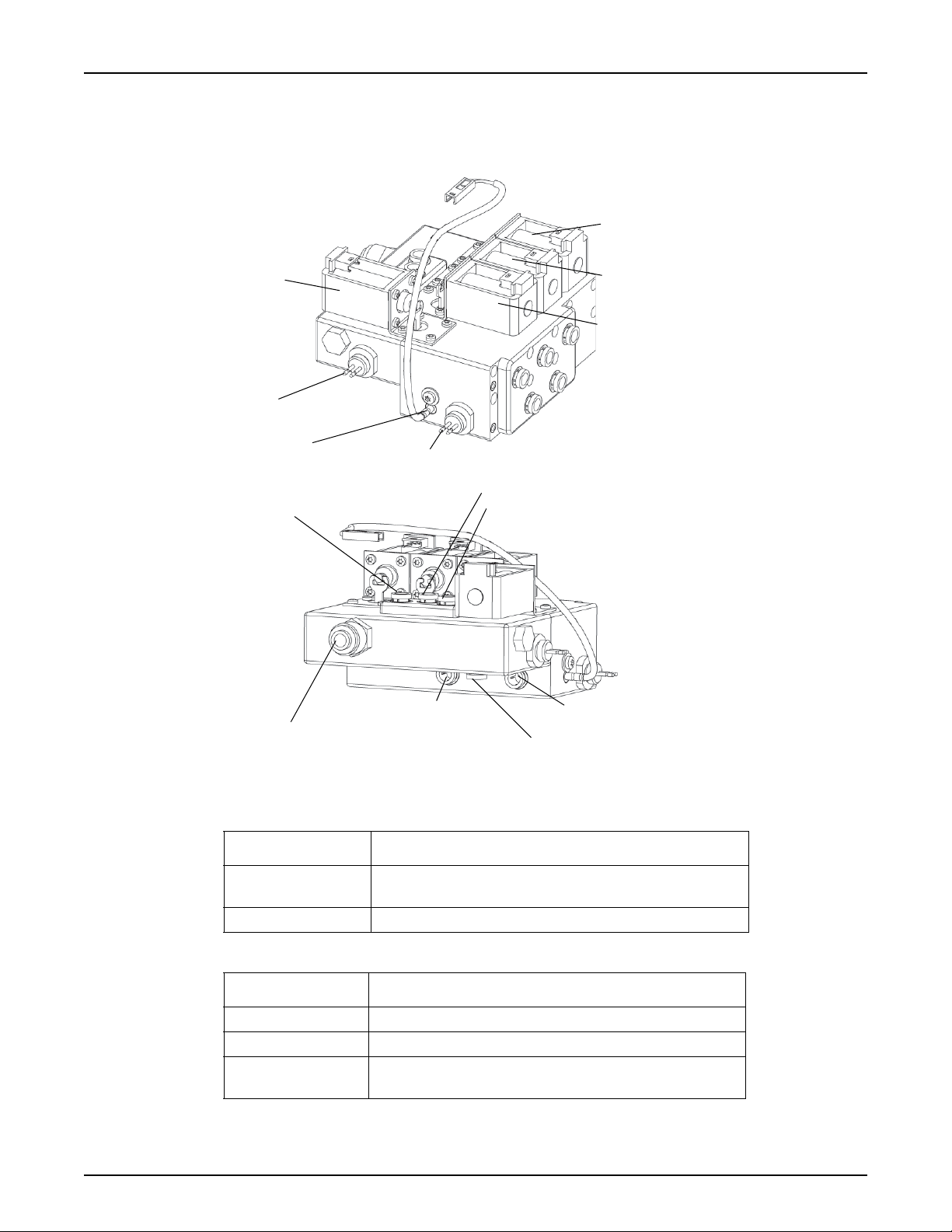

2.4.11 Flow Block Complete

A number of the components required for the operation of the WRO

unit are located in the flow block.

WRO 300/300 H

26

Fig.2.12 — Flow block

Sensors Description

Conductivity sensors C1 in the feed water line and C2 in the product water line

measure the conductivity of the water.

Temperature sensor T1 measures the temperature in the product water line.

Valves Description

Reject valve (REVA) Three way solenoid valve, either diverts to drain or tank.

Inlet valve (INVA) Two way solenoid valve, opens and closes for feed water.

Bypass valve (BYVA) Two way solenoid valve, when open (active) the flow

bypasses the constant flow valve.

P/N 3027437 Rev. B

WRO 300/300 H

S

Product water loop

(Pressure)

Needle valve

Chemical intake

Chemical intake unit

Optical sensor

Disinfection wand

and connector

Technical Description

Valves Description

Return overflow valve

(OFVA)

Constant Flow valve This valve gives a steady flow of 1.2 ±0.1 l/min.

The spring-assisted solenoid valve (OFVA) has two functions:

• To maintain pressure in the loop. When deactivated

(run), the valve remains closed (= no flow) at pressures

below 0.25 MPa (2.5 bar). When the pressure increases

further, it gradually opens and lets water through.

• To relieve the pressure in the loop during certain

modes of operation. When activated, the valve opens

to the inlet water tank. This will minimize the flow from

the product water loop into the dialysis machine.

2.4.12 Needle Valve

Fig.2.13 — Needle valve

The needle valve controls the desired product water consumption (1.1

l/min) at a loop pressure of 1.5 bar.

NOTE

The setting of the needle valve affects the reject recirculation flow.

Turning the needle valve clockwise towards closed position will

reduce recirculation and increase module pressure.

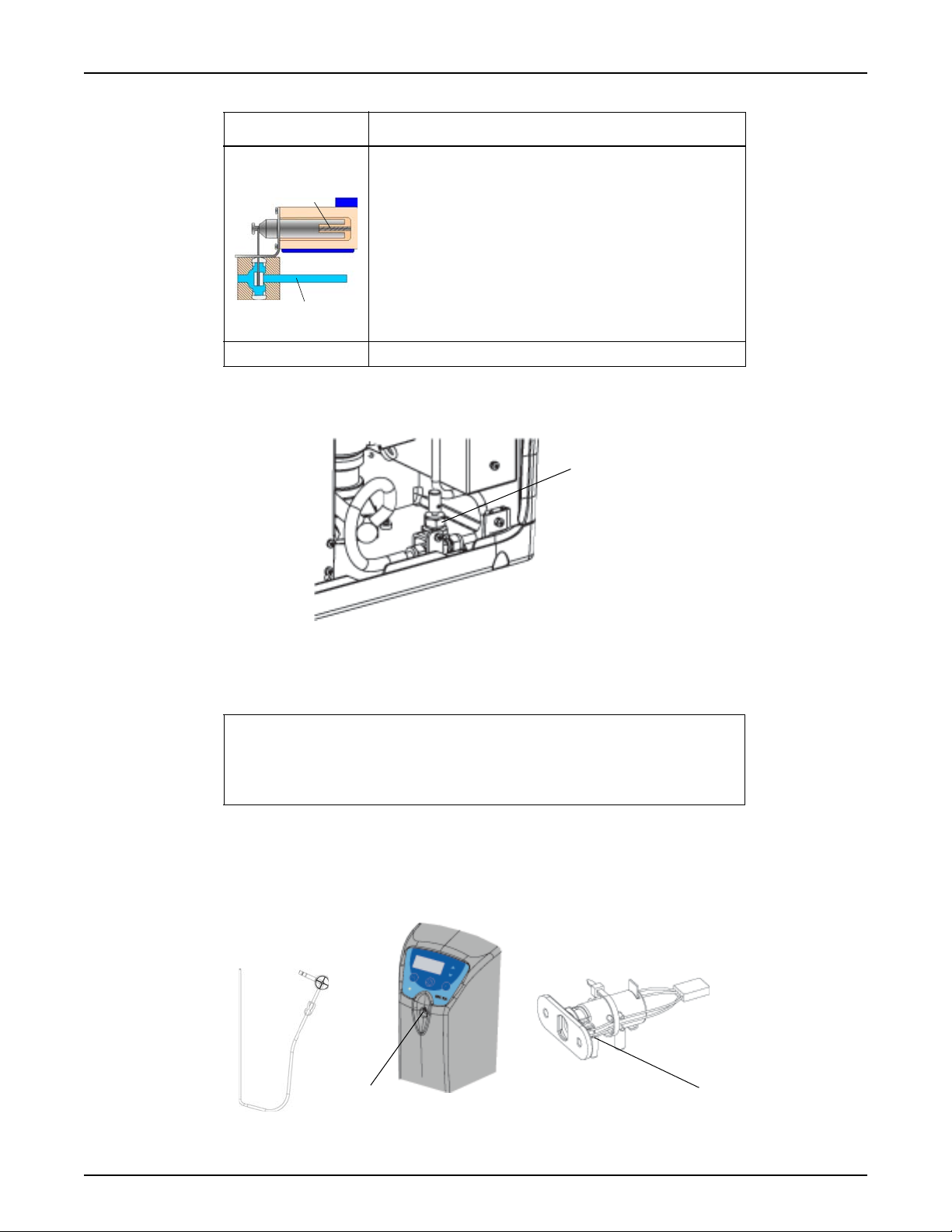

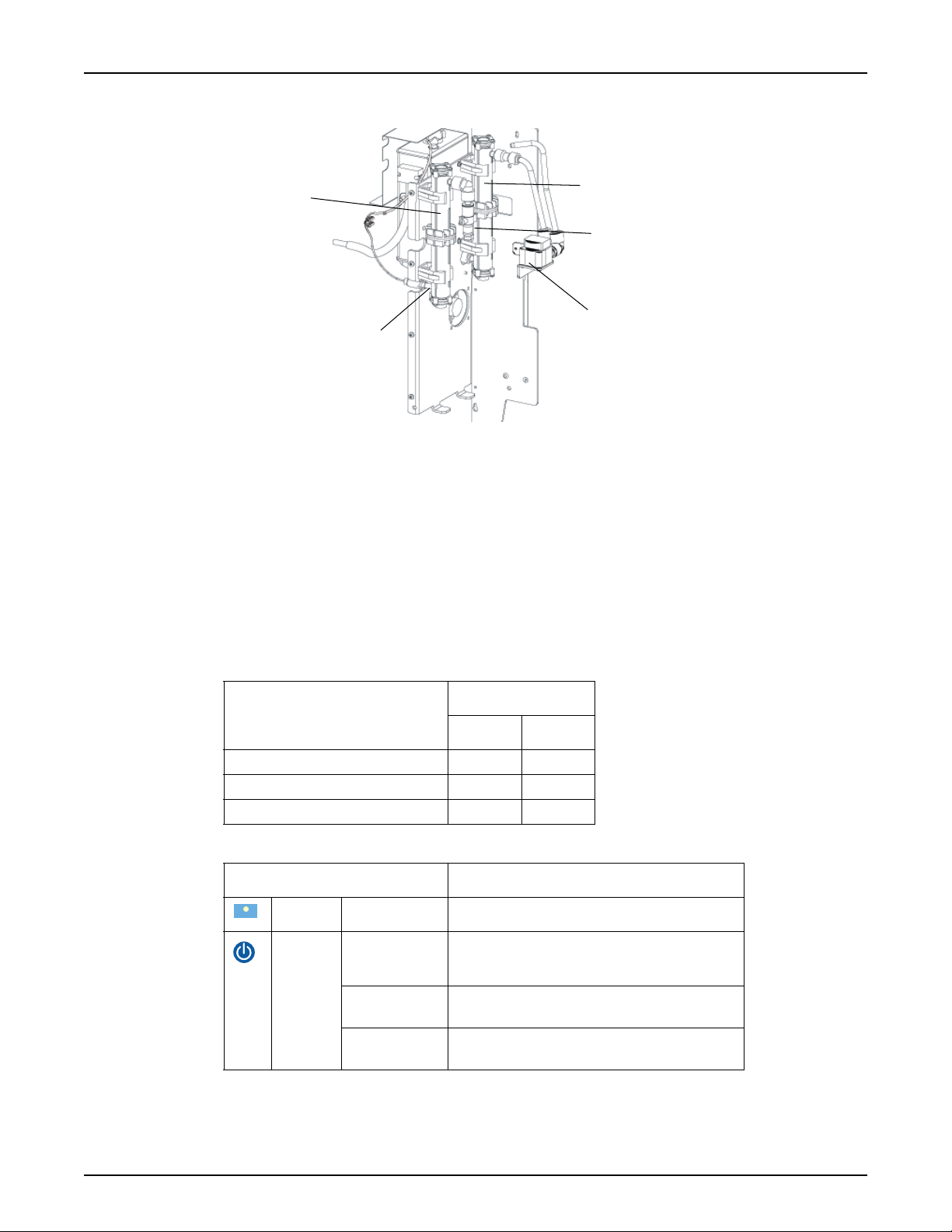

2.4.13 Chemical Intake Unit

The chemical intake unit supplies the WRO unit with chemicals for disinfection or cleaning. The optical sensor detects if the disinfection

wand connector is inserted in the chemical intake.

P/N 3027437 Rev. B

Fig.2.14 — Chemical intake

27

Technical Description

2.4.14 CPU Board

The CPU board contains most of the electronics that control the function of the WRO unit.

2.4.15 AC Relay Board (only WRO 300 H)

The AC relay board contains the electronics that control the heater

rods.

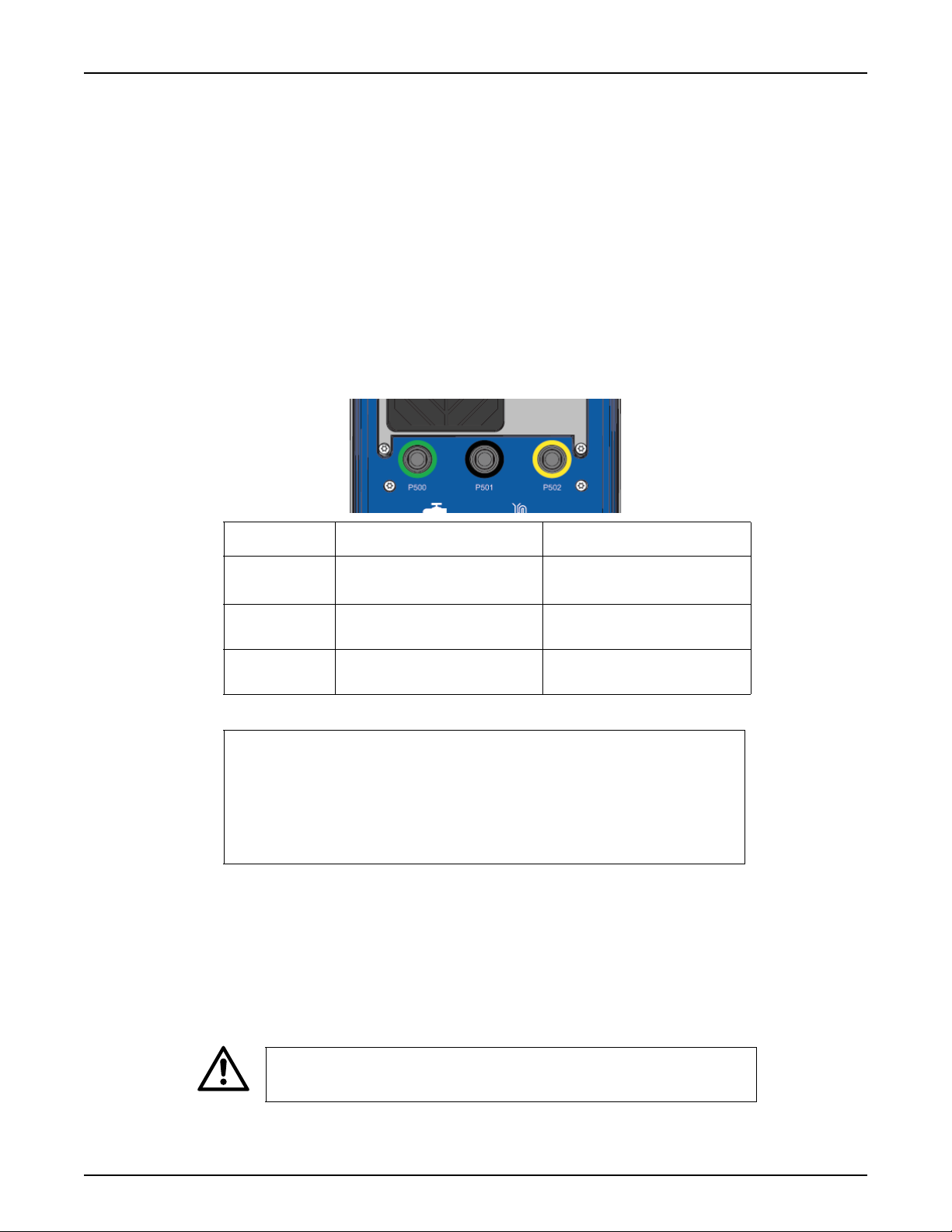

2.4.16 External Communication Connections

At the rear side of the WRO unit there are three external communication connections. These are used for external communication, logging

of data to a PC, and downloading upgraded software from a PC. The

required cables are optional and may be ordered from MCP.

WRO 300/300 H

Connection Function Description

P500

1

Green

P501

Black

P502

Yellow

1. Blue in older version of WRO unit.

External communication Currently not used.

Software communication Connection to PC.

External Signal/Remote Start Currently not used.

NOTE

• Only cables specified by MCP must be used when connecting the

WRO unit to external equipment.

• Be sure to use the correct cable type to the yellow connector

when an external alarm is connected, refer to Connection of

External Equipment on page 118.

2.4.17 Heaters (only WRO 300 H)

The WRO 300 H unit is equipped with two heaters with different properties. The electrical connections are therefore different and marked

REJECT and PRODUCT on the AC relay board. Mount the reject

water heater to the left and the product water heater to the right as

seen in the figure below — if mounted incorrectly steam may come out

from the tank air vent.

28

CAUTION

Ensure that the heaters are mounted in the correct position.

P/N 3027437 Rev. B

WRO 300/300 H

Temperature sensor (T2)

Flow meter

Flow indicator

Heater REJECT

Heater PRODUCT

2.4.18 Mains Power Cable

Technical Description

Fig.2.15 — Heaters

Mains power cable is supplied with the RO and is a hospital grade, 15

Ampere rated capacity, detachable type cord.

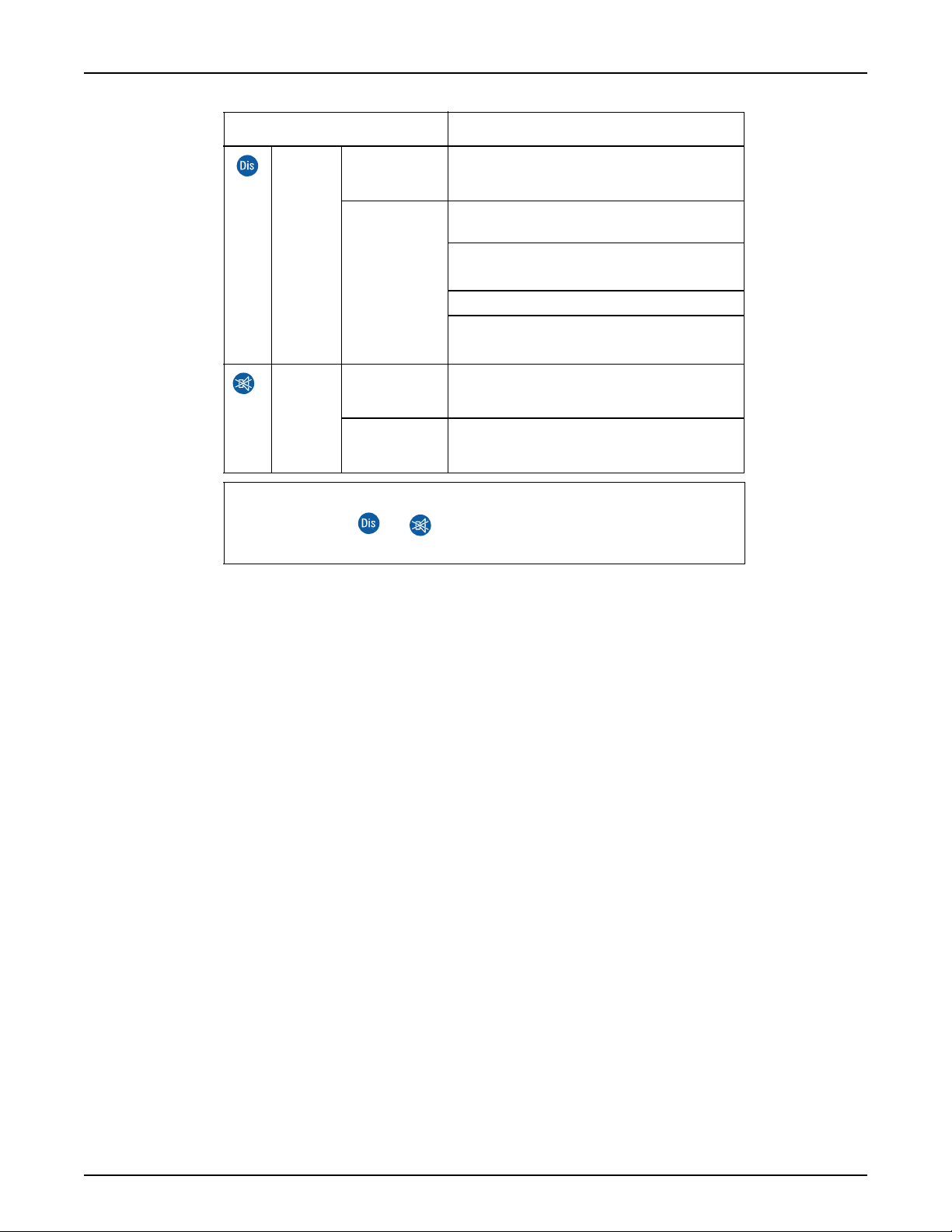

2.5 Description of Indications

2.5.1 Light Indications

The light indications of the operator’s panel are described in the tables

below.

Time

Flash Indication

Slow flash 0.4 sec 2.0 sec

Medium flash 0.4 sec 0.4 sec

Fast flash 0.2 sec 0.2 sec

Indications Description

Green General

Green Steady

light

Slow flash

Fast flash

On Off

Indicates that the WRO 300 is energized.

Run mode, auto flush or manual flush in

progress.

The auto flush function is activated (only in

standby mode).

Insufficient feed water supply (only in run

mode).

P/N 3027437 Rev. B

29

Technical Description

Indications Description

WRO 300/300 H

Yellow Steady

light

Medium

flash

Chemical disinfection or cleaning is in

progress.

The disinfection wand connector is inserted

into the chemical intake.

During selection of procedure in

SELECT or

CHEM SELECT.

The chemical intake phase is paused.

404 RINSE

Red Medium

flash

Steady

light

Forced rinse is required (

REQUIRED

Unconfirmed notification, info, alarm or stop

conditions are present.

Notification, info, alarm or stop condition has

been confirmed.

).

NOTE

Medium flash of or alerts the user to push the flashing button.

30

P/N 3027437 Rev. B

Loading...

Loading...