Mar Cor Purification MILLENIUM HX Maintenance Manual

3030226 Rev. D ?

Mar Cor Purification

MILLENIUM HX® REVERSE OSMOSIS UNIT

Operation and Maintenance Manual

Trademarks

MILLENIUM HX® is a registered trademark of Mar Cor Purification

MINNCARE® HD is a registered trademark of Medivators Inc.

Viton® is a registered trademark of E.I. Du Pont De Nemours And Company

Liqui-Clean™ and Biosan™ are registered trademarks of GE Osmonics, Inc.

Memstor™ is a trademark of King Lee Technologies

This page intentionally left blank.

3030226 Rev. D A ?

TABLE OF CONTENTS

CHAPTER 1: GENERAL INFORMATION .................................................................... 1-1

1.1 The Manual ................................................................................................ 1-3

1.2 General Notes, Cautions and Warnings ........................................................ 1-3

1.3 Applications ............................................................................................... 1-7

1.4 Intended Use .............................................................................................. 1-7

1.5 Contraindications ....................................................................................... 1-7

1.6 Environmental Considerations ..................................................................... 1-8

1.6.1 Power ............................................................................................................ 1-8

1.6.2 Water ............................................................................................................ 1-8

1.6.3 Drain ............................................................................................................. 1-8

1.6.4 Water Purity ................................................................................................... 1-9

1.6.5 Temperature .................................................................................................. 1-9

CHAPTER 2: INSTALLATION AND INITIAL SYSTEM START-UP ................................... 2-1

2.1 Installation Considerations .......................................................................... 2-3

2.2 Installation Procedures ............................................................................... 2-3

2.3 Product Water AAMI Analysis Procedure ................................................... 2-13

CHAPTER 3: SYSTEM OPERATION .......................................................................... 3-1

3.1 Daily Start-Up ............................................................................................. 3-3

3.2 Shut-Down Procedure ................................................................................. 3-6

3.3 Disinfection Indications ............................................................................... 3-7

3.3.1 Heat Disinfection Procedure (Single Heat) ......................................................... 3-8

3.4 System Storage ......................................................................................... 3-11

3.4.1 Storage Heat Procedure ................................................................................. 3-12

CHAPTER 4: SCREEN OPERATION AND SPECIFICATIONS .......................................... 4-1

4.1 Theory of Operation ................................................................................... 4-3

3030226 Rev. D B ?

4.2 Fluid Components ....................................................................................... 4-3

4.2.1 Solenoid Valves............................................................................................... 4-4

4.2.2 Check Valves .................................................................................................. 4-4

4.2.3 High-Pressure Pump (HPP) ............................................................................... 4-5

4.2.4 Level Switches (L1, L2 and L3) ........................................................................... 4-5

4.2.5 RO Membrane Assembly (ROMA) ..................................................................... 4-5

4.2.6 Feed Port ....................................................................................................... 4-5

4.2.7 Product Port ................................................................................................... 4-5

4.2.8 Waste Port ..................................................................................................... 4-5

4.2.9 Product Return Port ........................................................................................ 4-5

4.2.10 RO Feed Water Conductivity Sensor (WP1) ...................................................... 4-6

4.2.11 Product Water Conductivity Sensor (WP2) ....................................................... 4-6

4.2.12 RO Feed Water Pressure Sensor (PT1) ............................................................. 4-6

4.2.13 Pump Outlet Pressure Sensor (PT2) ................................................................. 4-6

4.2.14 Product Water Pressure Sensor (PT3) .............................................................. 4-6

4.2.15 Pressure Regulator (PR) ................................................................................. 4-6

4.3 System Operation Controls .......................................................................... 4-7

4.4 Alarm Screens .......................................................................................... 4-20

4.5 Optional Equipment .................................................................................. 4-22

4.5.1 Pretreatment Cart ......................................................................................... 4-22

4.5.2 Carbon Filter Tanks ....................................................................................... 4-22

4.5.3 Carbon Block ................................................................................................ 4-22

4.5.4 Softeners ..................................................................................................... 4-23

4.5.5 Dealkalizers .................................................................................................. 4-23

4.6 Specifications ........................................................................................... 4-24

4.6.1 RO Feed Water Requirements ........................................................................ 4-24

4.6.2 Flow Rates ................................................................................................... 4-25

4.6.3 Electrical Requirements ................................................................................. 4-25

4.6.4 Dimensions .................................................................................................. 4-25

4.6.5 Membrane Performance Characteristics .......................................................... 4-25

4.6.6 Environmental Requirement .......................................................................... 4-26

4.6.7 Approvals ..................................................................................................... 4-26

4.7 Disposal ................................ ................................ ................................ ... 4-26

4.8 Electromagnetic Interference .................................................................... 4-27

4.9 Service Assistance ..................................................................................... 4-31

4.10 Return Materials Authorization (RMA) Procedure ..................................... 4-31

4.11 Symbols and Abbreviations ..................................................................... 4-32

3030226 Rev. D C ?

CHAPTER 5: ROUTINE MAINTENANCE ................................................................... 5-1

5.1 Routine Maintenance.................................................................................. 5-3

5.1.1 Per Treatment Day Maintenance ...................................................................... 5-4

5.1.2 Weekly Maintenance....................................................................................... 5-4

5.1.3 Monthly Maintenance ..................................................................................... 5-5

5.1.4 Quarterly Maintenance ................................................................................... 5-5

5.1.5 Annual Maintenance ....................................................................................... 5-6

5.1.6 As Required .................................................................................................... 5-6

5.2 Specific Maintenance Procedures and Instructions ....................................... 5-7

5.2.1 Leak Repair .................................................................................................... 5-7

5.2.2 Conductivity/Temperature Sensor Verification ................................................... 5-9

5.2.3 Membrane Replacement ............................................................................... 5-10

5.3 Cleaning Indications .................................................................................. 5-12

5.3.1 Cleaning Procedure ....................................................................................... 5-13

5.4 Chemical Sanitization Procedure ................................................................ 5-19

5.5 Product Water Microbiological Testing ...................................................... 5-25

5.5.1 Product Water Culture Procedure ................................................................... 5-25

5.5.2 Endotoxin Testing Procedure .......................................................................... 5-27

5.6 Chemical Storage Procedure ...................................................................... 5-28

5.7 Auto Run .................................................................................................. 5-30

CHAPTER 6: TROUBLESHOOTING ........................................................................... 6-1

6.1 RO Fails to Run ........................................................................................... 6-3

6.2 RO Feed Pressure Alarm .............................................................................. 6-3

6.3 Product Water Quality Alarm ...................................................................... 6-4

6.4 This Unit Must Stand Upright Alarm ............................................................. 6-4

6.5 Product Water High Temperature ................................................................ 6-5

6.6 RO Feed Water Quality Alarm ...................................................................... 6-5

6.7 Pump Pressure Alarm .................................................................................. 6-6

6.8 Product Pressure High Alarm ....................................................................... 6-6

6.9 Service Required Component Failure Detected ............................................. 6-7

6.10 Product Flow Too Low ............................................................................... 6-8

6.11 Product Flow Too High .............................................................................. 6-9

6.12 Leaks ........................................................................................................ 6-9

3030226 Rev. D D ?

6.13 Low Percent Rejection ............................................................................. 6-10

6.14 TDS/µS Value High .................................................................................. 6-11

CHAPTER 7: DRAWINGS ........................................................................................ 7-1

7.1 Component Identification ........................................................................... 7-3

7.1.1 Front View ..................................................................................................... 7-3

7.1.2 Rear View....................................................................................................... 7-4

7.1.3 Electrical Right Side View ................................................................................. 7-5

7.1.4 Electrical Left Side View ................................................................................... 7-6

7.1.5 Membrane Assembly....................................................................................... 7-7

7.1.6 Top Hydraulic View ......................................................................................... 7-8

7.1.7 Center Hydraulic View ..................................................................................... 7-9

7.1.8 Main Manifold .............................................................................................. 7-10

7.1.9 Lower Hydraulic View .................................................................................... 7-11

7.1.10 Tank View .................................................................................................. 7-12

7.2 Flow Schematics ....................................................................................... 7-13

7.2.1 Run Mode .................................................................................................... 7-13

7.2.2 Divert to Drain .............................................................................................. 7-14

7.2.3 Heat/Chemical Purge..................................................................................... 7-15

7.2.4 Heat/Chemical Recirculation .......................................................................... 7-16

7.3 Electrical Diagram ..................................................................................... 7-17

7.4 Maintenance Schedule .............................................................................. 7-18

CHAPTER 8: SPARE PARTS ................................................................ ..................... 8-1

8.1 Spare Parts List ........................................................................................... 8-3

Millenium HX RO System

3030226 Rev. D 1-1 General Information

Millenium HX RO System

CHAPTER 1:

GENERAL INFORMATION

Millenium HX RO System

3030226 Rev. D 1-2 General Information

This page intentionally left blank.

Millenium HX RO System

3030226 Rev. D 1-3 General Information

1.1 The Manual

This manual has been prepared to provide the operator with information and

instructions regarding the installation, use, maintenance and troubleshooting of the

Mar Cor Purification Millenium HX Reverse Osmosis System.

CAUTION:

When used as a medical device, Federal law restricts this device to sale by or on

the order of a physician. Per CFR 801.109 (b)(1).

The manual has been written in narrative form supplemented with schematics and

drawings for clarification. The operator can perform most procedures mentioned in

this manual. Any exceptions will be clearly identified by a qualifying statement.

1.2 General Notes, Cautions and Warnings

Words in BOLD CAPITAL letters are used to identify labels on the device and key safety

or qualifying statements. A list of all symbols and abbreviations is located at the end of

this chapter. This safety summary does not contain all of the safety statements in the

manual. Other safety statements are included within the manual text and are

enhanced and defined as follows:

NOTE:

Statements that provide further clarification.

CAUTION:

Statements identifying conditions or practices that could result in equipment or

other property damage.

WARNING:

Statements identifying conditions or practices that could result in personal injury

or loss of life.

WARNING:

Read this manual prior to operating or servicing this device. This manual must be

read and understood and no deviations from the procedures shall be made. Keep

this and other associated manuals for future reference and for new operators or

qualified service personnel. A note sheet is provided at the end of each chapter for

operators to make notations that may be valuable to other users.

Millenium HX RO System

3030226 Rev. D 1-4 General Information

WARNING:

Only chemicals listed in the manual may be used with the Millenium HX RO. Other

chemicals may not be compatible with the materials of construction. When using

chemical cleaners or sanitizers, ensure the system is properly rinsed prior to use for

dialysis.

WARNING:

The selection of water treatment equipment for dialysis is the responsibility of the

user and the product water should be tested periodically in accordance with AAMI

and CSA standards.

WARNING:

This device will reach temperatures up to 180°F (82°C). Only appropriate heat

resistant materials can be used for fluid pathways that are disinfected with hot

water.

WARNING:

After installation and subsequent use, if any device in the water treatment system is

changed or replaced, the user should conduct appropriate tests to ensure that the

revised system meets the initial design criteria.

WARNING:

The product water quality is proportional to the RO feed water quality. The product

water may not meet quality limits if RO feed water quality deteriorates significantly.

The user is responsible for monitoring the RO feed water quality.

WARNING:

Carbon cannot be regenerated and must be replaced with new beds when

exhausted or contaminated.

WARNING:

A suitable carbon filter should always be present as pretreatment for the RO in

order to prevent chlorine/chloramine damage to the thin film RO membrane and

harm to the patient. Mar Cor Purification strongly recommends the use of two

carbon devices, used in a series configuration.

WARNING:

This RO can only operate in the vertical position. This machine has been equipped

with a sensor that will prevent operation of the unit while lying horizontal. Damage

to equipment may result if operated in the horizontal position.

Millenium HX RO System

3030226 Rev. D 1-5 General Information

WARNING:

Some settings are user adjustable. Entering the SETTINGS screen and/or adjusting

any settings should only be done by properly trained personnel and according to

facility policies and procedures.

WARNING:

Do not attempt to tamper with or perform any unauthorized modifications to the

device including programming changes. Any unauthorized work on the device could

cause damage to the equipment or harm to personnel if any safety features are

circumvented.

WARNING:

While a water treatment system may produce water of sufficient quality to meet

the requirements of AAMI and CSA standards, distribution of the water may

degrade its quality to the point where it no longer meets the requirements of the

above mentioned standards if the distribution system is not maintained

appropriately.

WARNING:

DO NOT REMOVE COVERS OR PANELS: To avoid electrical shock hazard, do not

remove covers or panels when power is supplied to the device. Do not operate the

device when covers or panels are removed.

WARNING:

Connect this device to a proper ground connection in accordance with the National

Electrical Code. DO NOT under any circumstances remove the ground wire or

ground prong from any power plug. DO NOT use an extension cord with this

equipment. Keep the surface under the RO free of water.

WARNING:

During operation of the equipment, position the RO so there is access to the power

switch located on the back of the machine.

WARNING:

Do not, under any circumstances, remove any Caution, Warning or any other

descriptive labels from the devices until the conditions warranting the label are

eliminated.

WARNING:

To avoid fire or explosion, do not operate this device in an explosive environment or

near flammable products.

Millenium HX RO System

3030226 Rev. D 1-6 General Information

WARNING:

Do not remove the back panel of the RO during operation. System is under

pressure during operation. Only remove panel when RO is turned OFF.

WARNING:

To avoid physical and/or equipment harm, move the RO by using both handles at all

times.

CAUTION:

Do not cover or enclose the RO during operation to ensure the unit properly

dissipates heat.

CAUTION:

The input water quality to the RO must meet the National Primary Drinking Water

Standards of the United States Environmental Protection Agency (EPA) or Canadian

Federal and Provincial guidelines governing drinking water in Canada. If the input

water does not meet these standards, the RO may not produce water that meets

AAMI and CSA standards.

NOTE:

Use proper wiring and connection methods to satisfy hospital electrical codes.

NOTE:

Use proper water and drain connections to prevent contamination of the RO and

danger to the patient. The Product/Return Ports are male quick disconnect to

prevent mix up of connection ports.

NOTE:

The Millenium HX RO’s hot water disinfection process is effective in reducing at

least 99.9% of an introduced bacteria load of Pseudomonas aeruginosa under

normal operation conditions.

NOTE:

Clean the HMI display screen as necessary with an alcohol based fluid and a soft

towel as required to maintain the screen’s cleanliness.

NOTE:

This device does not supply hot water to disinfect hemodialysis machines.

Millenium HX RO System

3030226 Rev. D 1-7 General Information

1.3 Applications

The Millenium HX Reverse Osmosis (RO) System is designed to purify water by forcing

water through a semi-permeable RO membrane. Water purified by reverse osmosis has

had approximately 95% of the dissolved inorganic contaminants and approximately 99%

of all microorganisms, pyrogens, particulates and organics with a molecular weight

greater than 300 removed. The quality of the purified water, referred to as product

water or permeate, depends on the quality of the RO feed water and normally is equal

to or exceeds standards set forth by AAMI and CSA for water treatment equipment

hemodialysis applications. Refer to Technote 103 for AAMI and CSA Product Water

Quality Standards.

1.4 Intended Use

The Mar Cor Purification Millenium HX Portable Reverse Osmosis Water Purification

System is intended to be used as dialysis accessory to produce water through reverse

osmosis for use with hemodialysis equipment.

The Millenium HX can be connected to hemodialysis equipment used in hospitals,

clinics and in home environments, in conjunction with the appropriate pre and post

treatment units, as a part of a water treatment system designed to meet current AAMI

and Federal (US.) Standards.

1.5Contraindications

WARNING:

This system is not designed, sold, or intended for use in producing water for

injection.

Mar Cor Purification systems are not intended to be used outside of the device

specifications and limitations, as outlined in this manual and other related material. If

this equipment is used in a manner not specified by the operating instructions, the

protection provided by the equipment may be impaired.

Millenium HX RO System

3030226 Rev. D 1-8 General Information

1.6 Environmental Considerations

Prior to the installation of the Millenium HX RO, it will be necessary to provide utilities

and create an environment suitable for the trouble free operation of the RO and its

accessories.

WARNING:

Ordinary pipe dope must be avoided since it may leach objectionable and

potentially dangerous impurities into the water.

CAUTION:

It is necessary to keep the RO from freezing to prevent serious damage to the RO.

CAUTION:

The use of mobile telephones or communication equipment in the vicinity of the

Millenium HX could adversely influence the performance of the machine. See

specification in Section 4.8.

CAUTION:

Millenium HX needs special precautions regarding EMC and needs to be installed

and put into service according to the EMC information provided in the Operators

and Service Manuals.

1.6.1 Power

The RO operates on 115/230 VAC single-phase power. Histories of power failure,

power surges, and low line voltages should be noted and reported to the manufacturer

or their agent as they may create adverse conditions for the operation of equipment.

1.6.2 Water

Reverse osmosis systems require a reliable water source (rapid pressure fluctuation of

greater than 10 PSI should be avoided to prevent damage). The RO needs a minimum of

20 PSI pressure at a minimum flow of 1.5 gallons per minute. It is important that water

is flowing at the design flow rate when testing water pressure rather than reading static

pressure. Inlet water must contain less than 0.1 ppm free chlorine.

1.6.3 Drain

A drain outlet is required for the RO. The drain must have a minimum capacity of 2

gallons per RO per minute of continuous flow for as long as and as often as the RO is

operating.

Millenium HX RO System

3030226 Rev. D 1-9 General Information

1.6.4 Water Purity

Plumbing materials can significantly contribute to the contamination of the water.

Metallic pipes (with the exception of 316 stainless steel) must be eliminated once the

purification process has begun. Schedule 40 or 80 PVC pipes, polypropylene, PVDF, and

other FDA recommended materials are suitable for most grades of purified water. Care

must also be exercised in the choice of a thread sealant.

1.6.5 Temperature

The RO is normally connected to a cold water supply. The performance specifications of

the RO are based on 77°F (25°C) RO feed water temperature. The Millenium HX

contains a VFD motor that will increase the pump speed when operating on cold water

helping to increasing the amount of product water produced.

Millenium HX RO System

3030226 Rev. D 1-10 General Information

NOTES:

Millenium HX RO System

3030226 Rev. D 2-1 Installation And

Initial System Start-Up

Millenium HX RO System

CHAPTER 2:

INSTALLATION AND

INITIAL SYSTEM START-UP

Millenium HX RO System

3030226 Rev. D 2-2 Installation And

Initial System Start-Up

This page intentionally left blank.

Millenium HX RO System

3030226 Rev. D 2-3 Installation And

Initial System Start-Up

2.1 Installation Considerations

1. Select a location for the RO near the required utilities and dialysis equipment.

2. The RO requires 115 or 230 VAC for operation depending on model.

3. The RO requires nominally 1.5 GPM water at 20 PSI. Warmer RO feed water

(greater than 77°F (25°C)) will produce more permeate (product water), and will

consume more water. Inadequate RO feed water flow and pressure may cause

the RO to shut down due to low pressure. The water may also require some

pretreatment to ensure maximum performance and suitability. Mar Cor

Purification recommends that RO feed water be chlorine/chloramine free and

solids above 5 microns in size to be filtered out.

4. A free flowing drain with a minimum capacity of 2 GPM is required for the RO.

5. Back flow prevention may be required in accordance with local codes.

6. Special connections may be needed to connect to the facility water supply.

Connections vary with different facilities.

2.2 Installation Procedures

CAUTION:

If a carbon tank is present on the Millenium HX RO, the carbon tank must be

completely rinsed of all carbon fines and ash before connecting to the RO.

Otherwise, irreparable damage to the TF membrane and RO internals will result

(refer to Carbon Tank O&M Manual).

WARNING:

The Millenium HX RO is stored with Storage Solution from the factory. Follow all

Material Safety Data Sheet (MSDS) guidelines that are included with the RO.

CAUTION:

Supply water with a pH above 8.5 and containing chloramines will adversely affect

the operation of the RO membrane.

CAUTION:

Any pre-treatment device supplying water to the RO must be ready for use prior

to operating the RO.

Millenium HX RO System

3030226 Rev. D 2-4 Installation And

Initial System Start-Up

NOTE:

The Product Water and the Product Return connections on the RO are a male

quick disconnect fitting. All other quick disconnect fittings on the cabinet are

female disconnects to prevent cross connection. In addition, the RO fittings are

color coded. Green is RO feed water, red is RO waste water and the RO product

and return connectors are white.

1. Unpack the RO and inspect the contents for the following;

• Millenium HX RO

• Manual (this document)

• Hose Kit

• Y-Connector with adapter hose and sample port

• Power Cord

• Chemical Bottle

• AAMI analysis kit

2. Inspect the RO for damage. When removing the RO from the packaging, you

should use 2 people to lift out of the box.

NOTE:

If using pre-treatment equipment, refer to the specific O&M manual for proper

placement and hose connections.

3. Connect the RO feed inlet hose connector to the water supply, and the QD end

to the “Feed” connection on the RO. This is a green quick disconnect fitting on

the RO.

4. Connect the waste water line to the red “Waste” QD fitting on the back of the

RO and route to drain in accordance with the local plumbing code.

5. Assemble the product line. Take the two ¼” silicone lines from the hose kit.

Place hose clamps over the tubing and install the Y connection. Secure the hose

clamps to secure the line on the Y connection. On the product side of the line,

cut the silicone tubing a few inches back from the Y connector. Place the hose

clamps on the tubing ends. Install the sample port and secure the hose clamps.

Connect the product line between the Product and the Return connector on the

back of the RO. The Y connector will be connected to the mating item on the

dialysis machine. Do not connect the Y connector to the hemodialysis machine

until the completion of this installation procedure.

Millenium HX RO System

3030226 Rev. D 2-5 Installation And

Initial System Start-Up

6. Plug the power cord into a 115 VAC (230 VAC) grounded outlet and reset the

GFCI if necessary (60 Hz RO only). Do not use an extension cord or an

ungrounded adapter.

7. Turn the water supply to the RO ON.

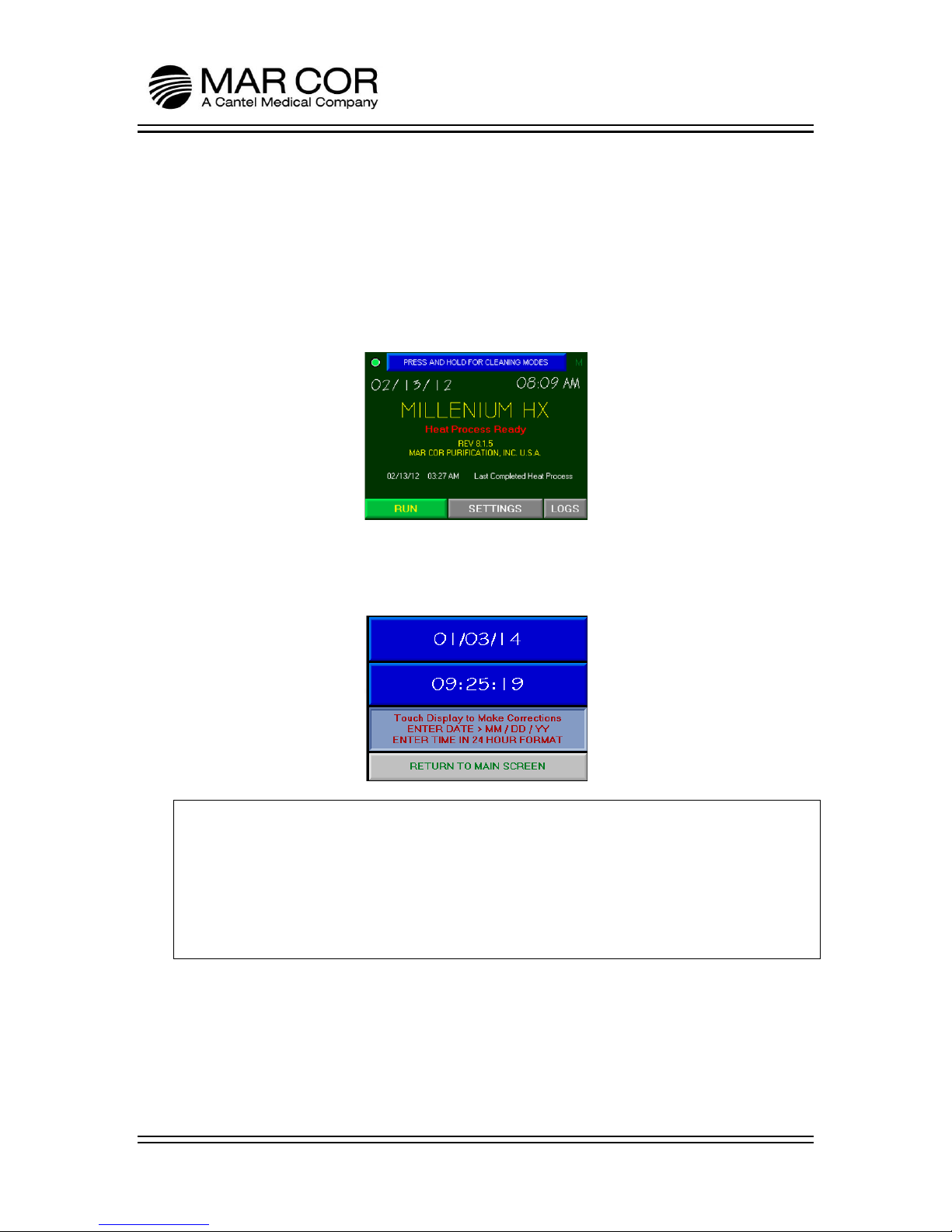

8. Turn ON the power module switch located on the rear of the RO. The touch

screen will illuminate and read PLEASE WAIT as the RO starts up. Once the

startup is complete, navigate to the MAIN Screen by pressing EXIT if necessary.

9. Verify the time and date on the RO. If they need to be adjusted, touch in the

area of the time and date and follow the on screen instructions to adjust. The

time does not automatically adjust for day light savings.

NOTE:

The RO is ready for initial startup.

NOTE:

The RO SETTINGS have been set at the factory. It may be necessary to adjust the

Product Quality Alarm set point and the Membrane Performance Monitor Setting

to allow the RO to operate without interruption.

Millenium HX RO System

3030226 Rev. D 2-6 Installation And

Initial System Start-Up

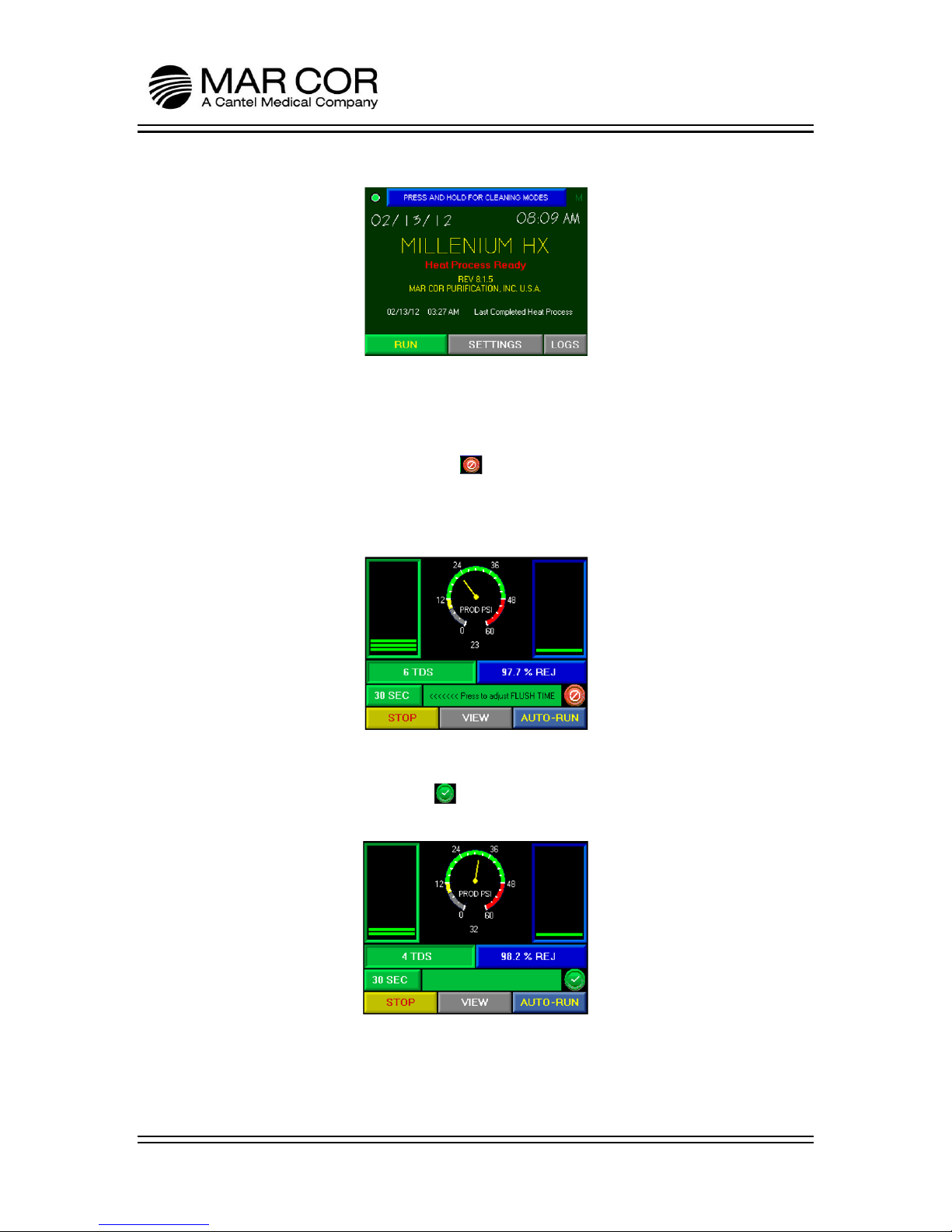

10. Press the RUN button.

11. The RO will start in a flush and divert mode where the product water is diverted

to the internal tank. The machine will operate in this flush mode for a user

specific time (adjustable from 30-300 seconds) indicated on the run screen. The

RO will not come out of divert mode until the flush is complete and the TDS/µS

is below the alarm set point. The symbol in the lower right hand side of the

display indicates the machine is in divert mode. If water quality does not

improve as the RO is operating, the RO may shutdown because of product water

quality. If this occurs, clear the alarm screen and press RUN again.

12. After the RO startup flush is complete and the product water is below the alarm

set point, the divert valve will open and start supplying product water through

the product water line. The symbol in the lower right hand side of the

display indicates the machine is supplying water to the product water line.

13. Let the RO run for 15 minutes or until the percent rejection and TDS/µS values

have stabilized.

Millenium HX RO System

3030226 Rev. D 2-7 Installation And

Initial System Start-Up

WARNING:

Ensure that TDS/µS and membrane performance (% rejection) are normal for the

regions water quality. Consult your facility physician. An appropriate AAMI

analysis and bacteria/Endotoxin test meeting AAMI or CSA requirements of the

product water must be obtained and interpreted before using the RO unit for

hemodialysis treatment, refer to Section 2.3 “Product Water AAMI Analysis

Procedure” and Section 5.5.1 “Product Water Culture Procedure”.

14. Once the RO has achieved a steady state, note the percent rejection, and

product TDS/µS (Run Screen), and the Combined Pump Feed Water Condition

TDS/µS (V-1 screen). You will need these values when setting the operating

parameters in the SETTINGS screen.

15. After a minimum of 30 minutes of run time, perform a Single Heat disinfection

of the RO (steps 17 through 25).

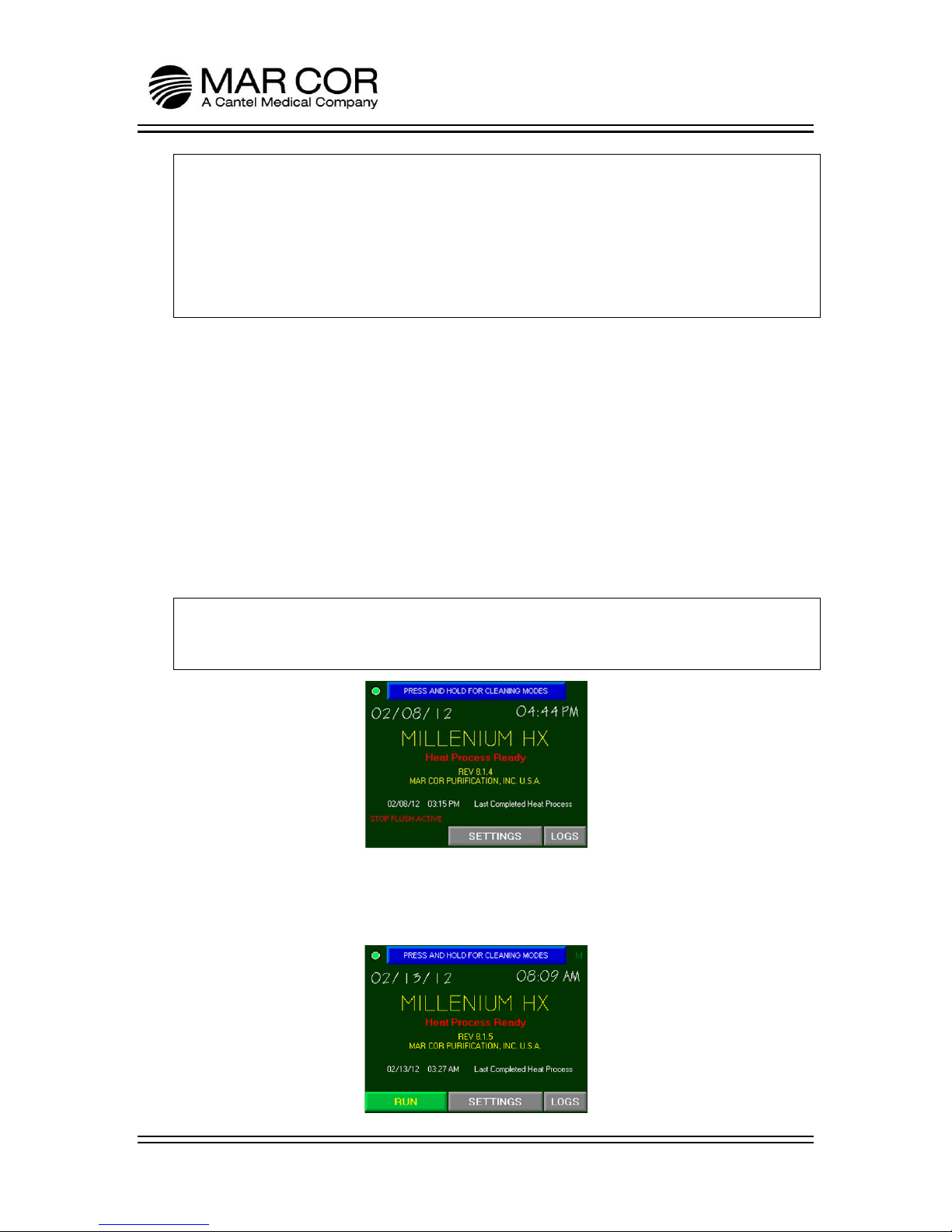

16. From the RUN screen, press and hold the STOP button for 2 seconds. The RO

will continue to operate for 60 seconds in a flush mode. When in flush, the RO

RUN button is not visible until the process is complete.

NOTE:

When in stop flush, the message STOP FLUSH ACTIVE is visible on the screen

indicating that the RO is flushing the membrane with low TDS/µS water.

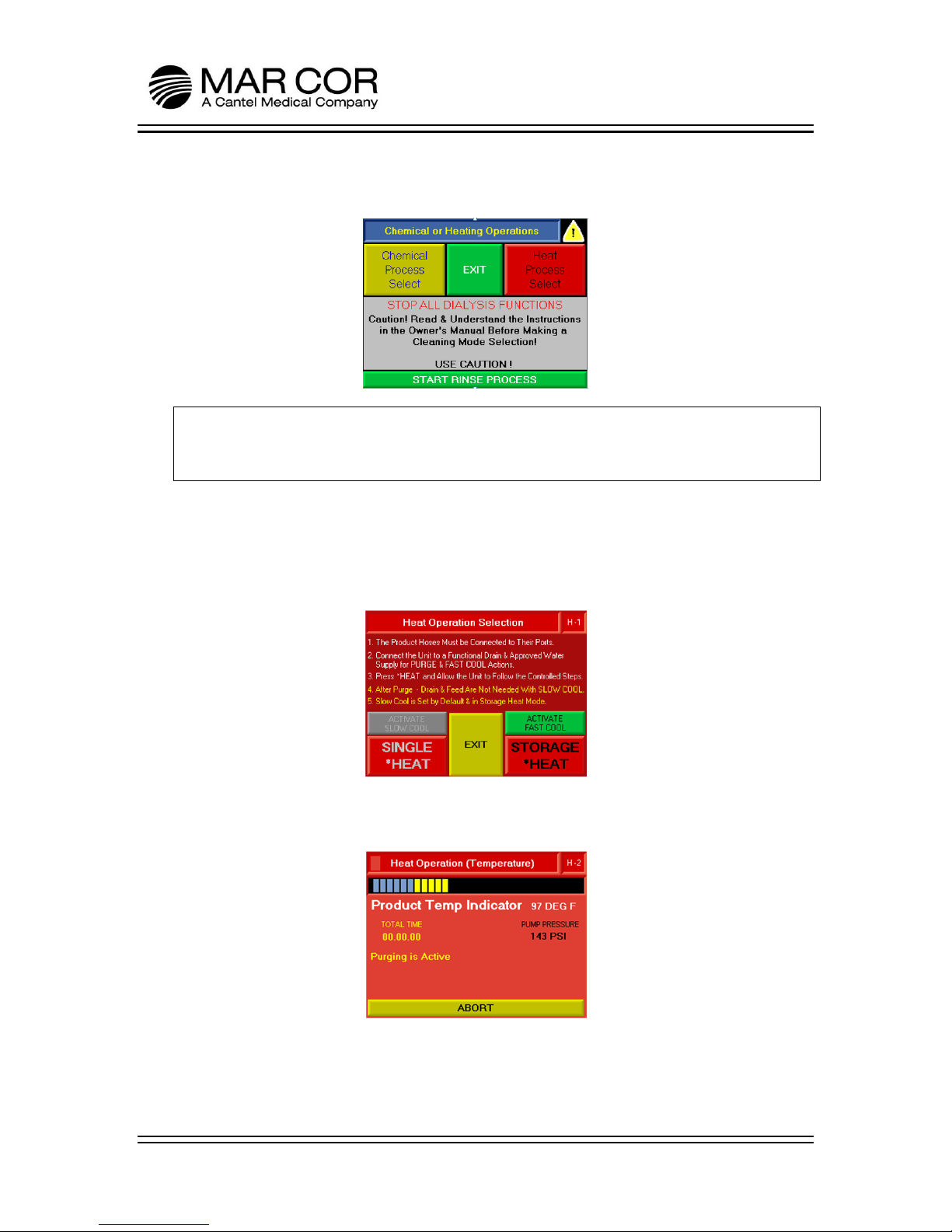

17. Press and hold the blue banner at the top of the screen that states PRESS AND

HOLD FOR CLEANING MODES to enter the Chemical or Heating Operations

selection screen.

Millenium HX RO System

3030226 Rev. D 2-8 Installation And

Initial System Start-Up

18. Review the instructions on the screen and press and hold the HEAT PROCESS

SELECT button.

WARNING:

During heat disinfection, the RO heats the internal water to approximately 176F

(80C). To avoid injury, do not touch the RO connections during the heat cycle.

19. Press the ACTIVATE FAST COOL cooling method. Default cooling method is Slow

Cool. Review the instruction on the display. Verify all instructions have been

completed. Once verified, press and hold the SINGLE HEAT button.

20. The machine starts to purge, filling the internal tank to the proper level with

product quality water.

21. Once the purge process is complete, the RO’s internal water is circulated and

heated to a target temperature of 176F (80C).

Millenium HX RO System

3030226 Rev. D 2-9 Installation And

Initial System Start-Up

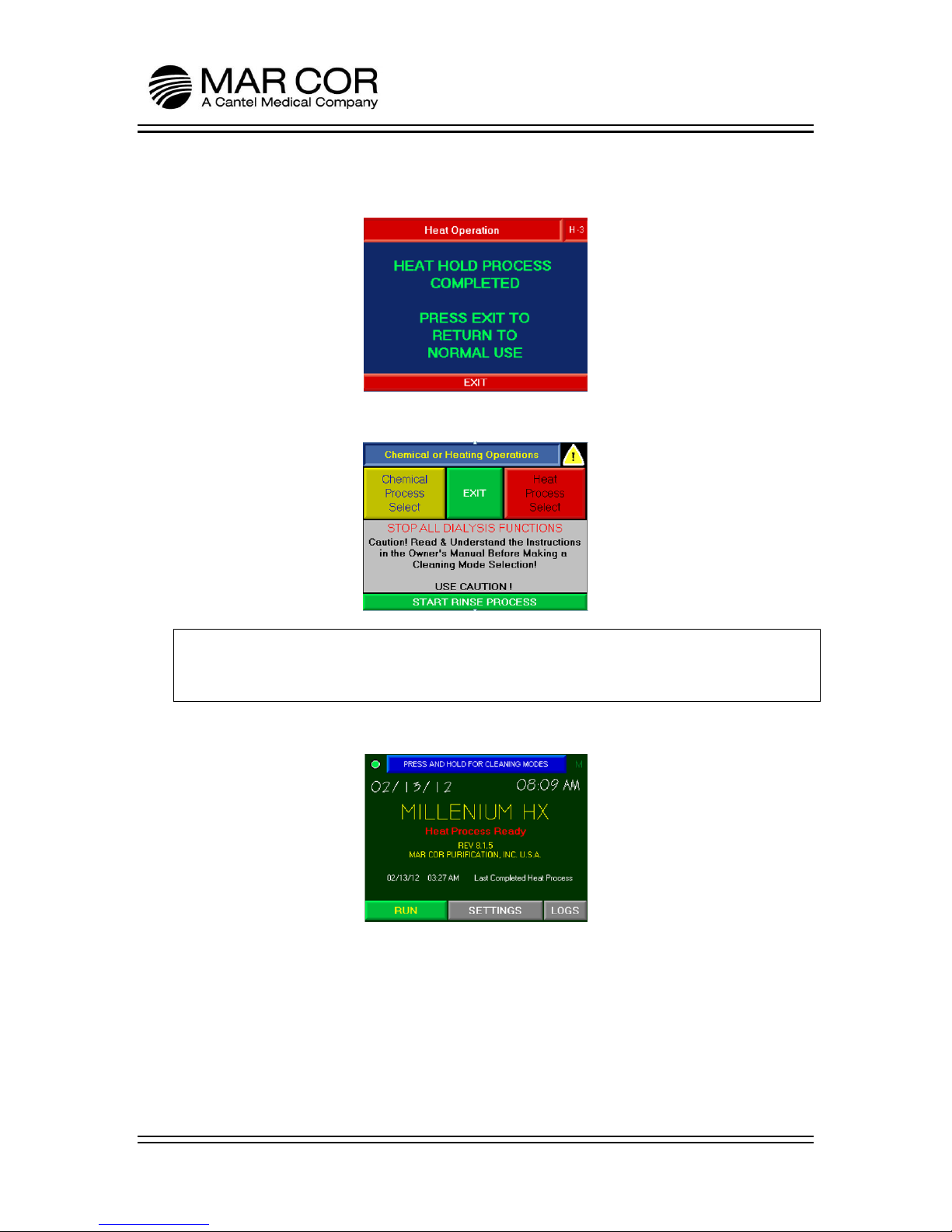

22. Once the target temperature is achieved, the system will maintain the

temperature for 30 minutes by automatically cycling the heater modules

ON/OFF.

23. After the system is held at the target temperature for 30 minutes, the RO enters

cool down. With ACTIVATE FAST COOL selected, the inlet solenoid cycles to

introduce small amounts of RO feed water to slowly reduce the RO’s

temperature.

24. After the RO reaches 120°F (49°C), the RO will enter a POST HEAT RINSE. This

will further cool and rinse the RO for a minimum of 5 additional minutes.

Millenium HX RO System

3030226 Rev. D 2-10 Installation And

Initial System Start-Up

25. After the POST HEAT RINSE is complete, the RO is ready for normal use. Press

the EXIT button to return to the CHEMICAL OR HEATING OPERATIONS screen.

26. Press EXIT to return to the Main Screen.

NOTE:

Entering the SETTINGS screen and adjusting any setting should only be done by

properly trained personnel and according to facility policies and procedures.

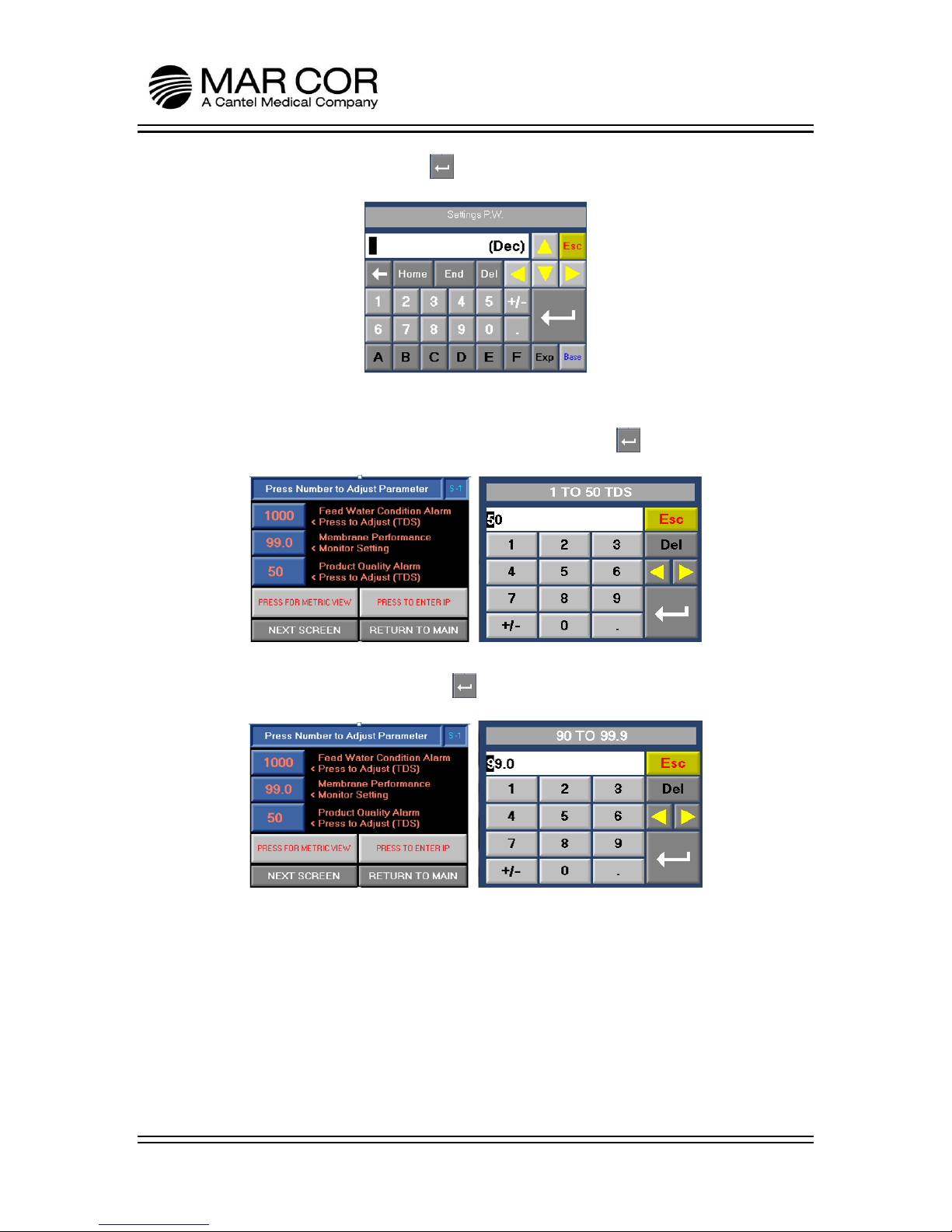

27. From the Main Screen, press SETTINGS.

Millenium HX RO System

3030226 Rev. D 2-11 Installation And

Initial System Start-Up

28. Enter a value of 999 and press to access the alarm set point screens.

29. Press the PRODUCT QUALITY ALARM. Once in the set point screen, set the

alarm set point per facility protocol or if no protocol exists, set at two times the

steady state operating TDS (µS). Once complete, press .

30. Press MEMBRANE PERFORMANCE and input the operational % Rejection noted

in step 14. Once complete, press .

Millenium HX RO System

3030226 Rev. D 2-12 Installation And

Initial System Start-Up

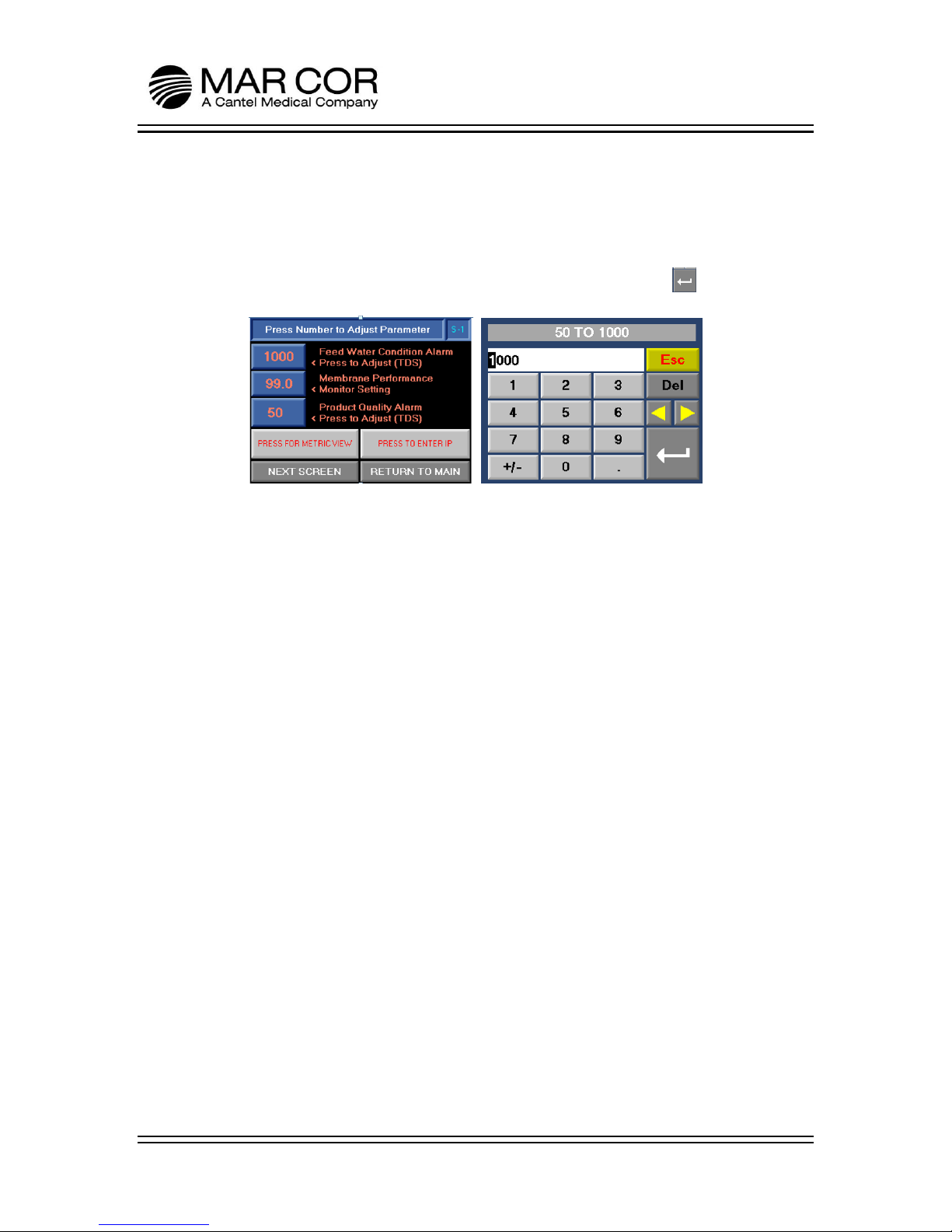

31. Press the Feed Water Condition Alarm. Set the RO feed water quality alarm 50

TDS/100 µS above the steady state Combined Pump Feed Water Condition

noted in step 14. If the Combined Pump Feed Water Condition is greater than

or within 50 TDS/100 µS of the alarm limits of 1000 TDS/2000 µS, disable the

alarm to prevent nuisance alarms. To disable the alarm, set the TDS setting to

1001 or conductivity setting to 2001 µS. Once complete, press .

32. Press RETURN TO MAIN.

33. The RO product may be used in conjunction with hemodialysis treatment

equipment only after obtaining test results, which validate compliance with

accepted standards.

• AAMI or CSA Product Water Panel

• Microbiological Culture (colony count) results

• Endotoxin (pyrogen) level testing

34. The Millenium HX RO is now ready for use.

Loading...

Loading...