Mar Cor Purification M4-2200, M4-13200 Maintenance Manual

M4-SERIES

WATER PURIFICATION MACHINES

M4-2200 – M4-13200

Operation

and Maintenance Manual

1238160 Rev. D

2233MMaay

y11

This page intentionally left blank

1238160 Rev. D 23May11

OPERATION AND MAINTENANCE MANUAL

M4-SERIES WATER PURIFICATION MACHINES

M4-2200 – M4-13200

TABLE OF CONTENTS

Page

CHAPTER ONE: GENERAL INFORMATION 1-1

Section 1.1 General Information and Principles of

1-3

Operation

1.2 Machine Nomenclature 1-7

1.3 Machine Permeate Quality 1-7

1.4 Materials and Features 1-7

1.5 Specifications for M4-Series Machines 1-8

CHAPTER TWO: INSTALLATION 2-1

Section 2.1 Mounting 2-3

2.2 Plumbing 2-3

2.3 Electrical 2-4

CHAPTER THREE: PREPARATION AND START-UP 3-1

Section 3.1 Pretreatment for Water Purification 3-3

3.2 Start-Up 3-4

CHAPTER FOUR: OPERATION AND MAINTENANCE 4-1

Section 4.1

4.2

Daily Log Sheets

Prefilter

4-3

4-3

4.3 Flushing 4-4

4.4 Cleaning 4-4

4.5 Sepralator Replacement 4-7

1238160 Rev. D A 23May11

CHAPTER FIVE: OPTIONAL ACCESSORIES 5-1

Section 5.1 Level Controls 5-3

5.2 Conductivity Meter 5-3

5.3 Autoflush 5-3

5.4 Filters and Water Softeners 5-5

CHAPTER SIX: TROUBLESHOOTING 6-1

APPENDIX A: RETURN MATERIAL AUTHORIZATION (RMA)

PROCEDURE

1238160 Rev. D B 23May11

M-Series Water Purification Machines

M-Series Water Purification Machines

M4-2200 – M4-13200

CHAPTER ONE:

DESCRIPTION

1238160 Rev. D 1 - 1 Description

M-Series Water Purification Machines

This page intentionally left blank.

1238160 Rev. D 1 - 2 Description

M-Series Water Purification Machines

1.1 General Information and Principles of Operation

These instructions give operating and maintenance details vital to the sustained

performance of the machine.

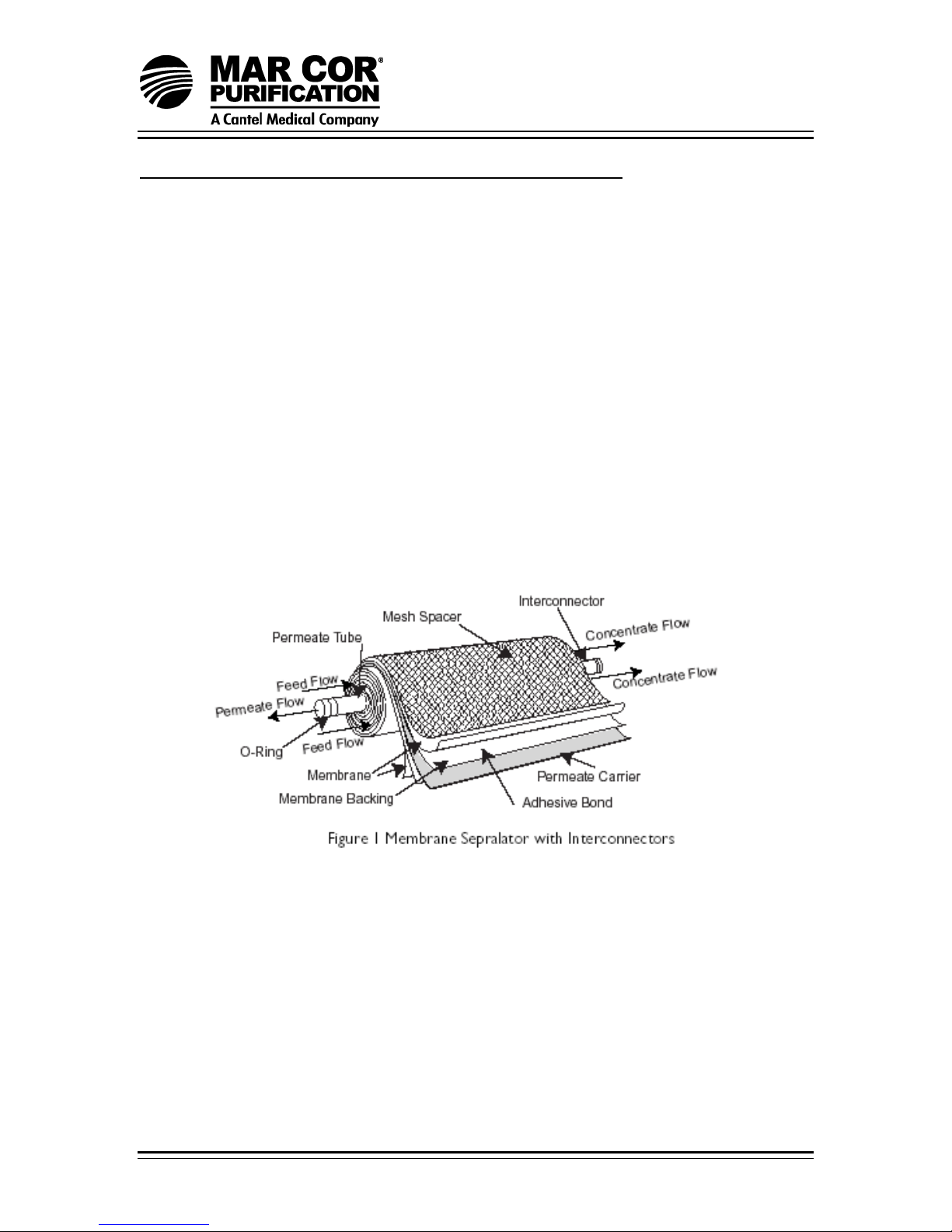

Reverse Osmosis (RO) is the removal of ionic, organic, and suspended

impurities from water by means of a membrane. Unlike a filter (“normal”

filtration), the feedwater or solution is separated into two streams by collecting

fluids from both sides of a pressurized membrane (“crossflow” filtration). A

semipermeable RO membrane, under sufficient pressure, allows passage of

purified water while rejecting and concentrating dissolved and suspended solids.

Mar Cor Purification manufactures a patented spiral-wound membrane package,

with a turbulent flow design. The membrane module (i.e. sepralator), also called

an element collects the purified water within a central tube (permeate tube), see

Figure 1.

Some operating definitions are provided to help you further understand your

machine:

PERMEATE RATE (PRODUCT WATER RATE) [QP]

This is the flow rate of purified water which has passed through the membrane

and out of the sepralator; expressed in gal/min (gpm) or gal/h (gph) [in metric,

liter/min (Lpm) or cubic meters/hour (m3/h). Specified permeate rates are

normally specified at 77°F (25°C).

1238160 Rev. D 1 - 3 Description

M-Series Water Purification Machines

CONCENTRATION

Concentration equals the Total Dissolved Solids (TDS) concentration of a

solution expressed as milligrams per liter (mg/L) or conductivity

(microSiemens/cm).

C

C

= Feed Concentration

f

Cp = Permeate Concentration

C

= Concentrate Concentration

c

= Average Concentration in machine

avg

SALT (IONIC) REJECTION:

This equals the percent of dissolved salt rejected by the membrane,

calculated from an average concentration over the membrane.

SALT (IONIC) PASSAGE:

This equals (100% - rejection) or the percent of dissolved salts passed

through the membrane.

CONCENTRATION RATE (WASTE WATER RATE) [Qc]:

This is the flow rate of water stream containing rejected solids to drain in

gpm or gph (pm or m3/h).

FEED RATE [Qf]:

This is the flow of incoming water in gpm or gph (Lp or m3/h). Feedwater

rate equals permeate rate plus concentrate rate.

An example of how to calculate salt rejection and recovery is given below:

1238160 Rev. D 1 - 4 Description

M-Series Water Purification Machines

Given the system case in Figure 2:

2

(C

Rejection = (C

(C

Passage = (C

(C

Recovery = (Q

(Q

Average Concentration (C

) = 123.5 mg/L TDS

avg

) 123.5 – (Cp) 6.2 x 100 = 95%

avg

) = 6.2 x 100% = 5.0%

p

) 123.5

avg

) 2 gpm x 100 = 33%

p

) 6 gpm

f

) = (Cf) 100 mg/L + (Cc) 146.9 mg/L

avg

) 123.5

avg

FLOW DESCRIPTION:

The feedwater passes through a replaceable 5-micron cartridge filter,

which removes bulk suspended solids. Filtered water then flows to the inlet

control valve. This solenoid-controlled diaphragm valve is wired to the

on/off switch and opens when the machine is turned on allowing water to

flow to the pump inlet. When the machine is turned off, the valve closes,

preventing non-turbulent flow through the sepralators, that would lead to

shortened membrane life.

The pump feeds water to the sepralator housings arranged in parallel and

serial combinations. An arrow on each element housing indicates the

direction of water flow. The water is sepralated by the membrane within

the elements and leaves the housings in two streams as permeate and

concentrate.

Permeate from each sepralator housing is collected in a common manifold.

A pressure relief valve is installed to alleviate excessive backpressure

build-up. The permeate then flows through a flow meter and to the outlet

point of the machine.

The concentrate leaves the last sepralator housing and flows to the flow

control center. At this point, the recycle valve channels a predetermined

amount of concentrate into the pump inlet. This achieves more efficient

water recovery while maintaining adequate crossflow through the

sepralators. The other two ports of the flow control center lead to the

concentrate valve and final pressure gauge. The concentrate valve has

three functions: It controls the amount of concentrate flowing to the drain; it

controls the pressure within the machine, and it helps control the system

recovery. An optional autoflush solenoid is added to the flow control center

with an additional tee. The concentrate then flows through a flow meter

and to the outlet point of the machine.

1238160 Rev. D 1 - 5 Description

M-Series Water Purification Machines

1238160 Rev. D 1 - 6 Description

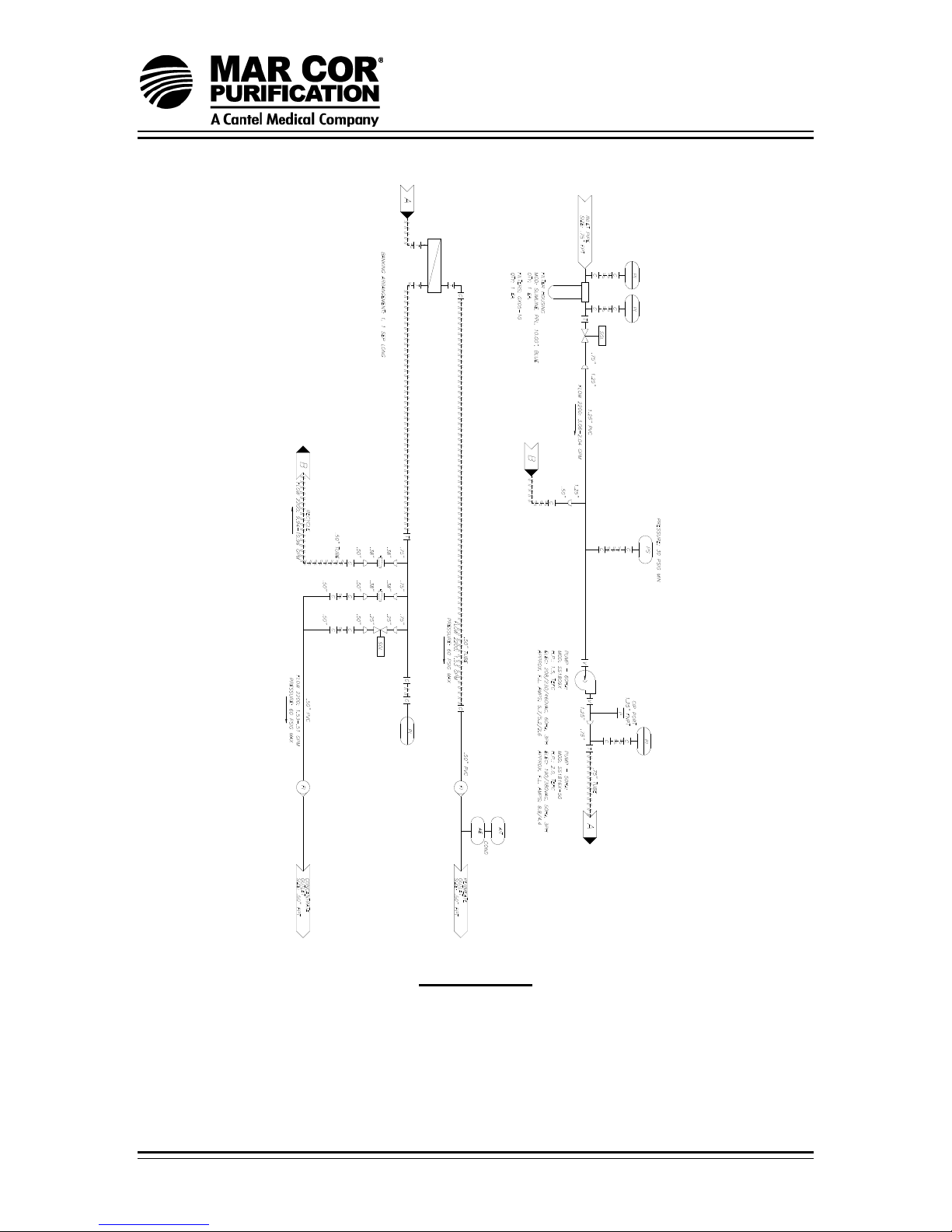

Typical P&ID

M-Series Water Purification Machines

1.2 Machine Nomenclature

M-Series water purification are numbered in such a way as to indicate the

permeate flow and quality you can expect from the machine.

Example: M4-6600, 208, 6, 50-75

• M4 indicates the machine series

• 6600 indicates the rated permeate flow in gallons per day

• 208 indicates motor voltage

• 6 indicates 60 Hz

• 50-75 indicates the % recovery capability of the RO

1.3 Machine Permeate Quality

The permeate rejection performances are as follows:

M-Series machines use high rejection FASTEKu S4040 membrane, providing the

ultimate in high purity water.

1.4 Materials and Features

M-Series water purification machines have all the features necessary for safe,

continuous production of high purity water. Also, the M-series RO contains an

array of useful features for monitoring and data collection to help prolong

membrane life. This assumes good quality feedwater, adequate pretreatment

and regular operator attention, each shift or daily, to the operation of the system.

• 50% or 75% recovery

• Multi-stage centrifugal pump, SB construction (nickel-plated cast iron

*

castings, Noryl

stages, remainder stainless steel) typically not

recommended for operation below pH 5.8

• Base model electrical package includes NEMA-4X enclosure with a 115

VAC, 60 Hz or 230 VAC, 50Hz single-phase control circuit.

• Automatic inlet shutoff valve

• Pre-filter, post-filter, primary, and final pressure gauges

• Concentrate and permeate flow meters

• Gauges, valves, and rigid plumbing of stainless steel, brass, or plastic

• Membrane element housings, all 304 stainless steel, with PVC end caps

• 316 stainless steel concentrate and recycle valves

• All components in contact with the purified water (permeate) are either

non-leachable acceptable plastic (nylon, Noryl, polypropylene, PVC) or

stainless steel materials

• All high pressure fittings are 304 stainless steel

1238160 Rev. D 1 - 7 Description

M-Series Water Purification Machines

• Autoflush System – programmable, automated high velocity membrane

flushing for the longest membrane life; set at the factory and adjustable in

the field, includes a digital panel-mount timer, complete with push button

Manual Flush

• An electrical package that includes alarm delay shutdown for low inlet

pressure condition to prevent pump damage should pressure fall below 15

psig (1 bar)

• Conductivity monitor, panel-mounted, for permeate quality monitoring

• NEMA-4X fiberglass electrical enclosure

1.5 Specifications for M-Series Machines

1.5.1 Feedwater

TEMPERATURE:

35-77° (22-25°C) [Not to exceed 85°F (29°C) unless specifically designed for

higher temperatures]

INLET PRESSURE:

Minimum: 30 psig (2.1 bar)

Maximum: 60psig (4.1bar)

CHLORINE (CONTINUOUS FEED):

For FASTEK TLC membranes 0 ppm

OPERATING pH:

Softwater [less than 1 grain per gallon 3.0-10.0 (gpg) or 17 mg/L hardness]

Unsoftened water (contact factory 5.5-6.0 with water analysis)

PRE-FILTER:

5-micron HYTREX cartridge (see machine label for part number)

INLET CONNECTIONS:

¾-inch FNPT (IPS)

1238160 Rev. D 1 - 8 Description

M-Series Water Purification Machines

1.5.2 Permeate (Product Water) Flow Rate

Stated on the RO test report form (assumes no permeate back pressure, 2000

mg/L TDS maximum feed concentration, and rated temperature).

To estimate permeate output with back pressure, use the formula below:

Permeate Flow on Label x Operating Pressure – (Permeate Back Pressure)

Operating Pressure

Permeate Back Pressure Maximum: 60 psig (5.5 bar)

Permeate Outlet 3/4-inch FNPT

1.5.3 Concentrate Flow Rate

Stated on the RO test report form

Concentrate Outlet 3/4-inch FNPT

1.5.4 Typical Pure Water

Recovery 50-75%

1.5.5 Operating Final Pressure

Minimum 100 psig

Maximum 140 psig

1238160 Rev. D 1 - 9 Description

M-Series Water Purification Machines

1.5.6 Pump

Multi-stage centrifugal, approximately primary operating pressure of 100 psig

excluding line pressure.

1.5.7 RO Membrane Rejection

FASTEK TLC

Typical Ionic Rejection (TDS) 95-98%

Average Molecular Weigh Cutoff* 150 MW

*The molecular weight cutoff is based on the pore size of the membranes and the

nature (shape/size) of the organic molecule.

1238160 Rev. D 1 - 10 Description

NOTES:

M-Series Water Purification Machines

1238160 Rev. D 1 - 11 Description

M-Series Water Purification Machines

This page intentionally left blank.

1238160 Rev. D 1 - 12 Description

M-Series Water Purification Machines

M-Series Water Purification Machines

M4-2200 – M4-13200

CHAPTER TWO:

INSTALLATION

1238160 Rev. D 2 - 1 Installation Guidelines and Instructions

M-Series Water Purification Machines

This page intentionally left blank.

1238160 Rev. D 2 - 2 Installation Guidelines and Instructions

Loading...

Loading...